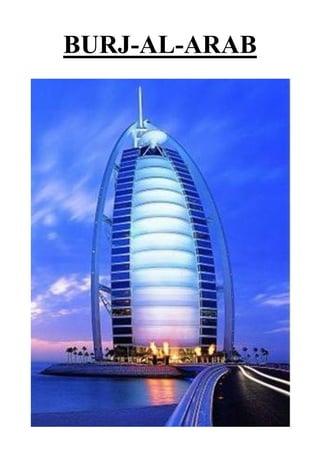

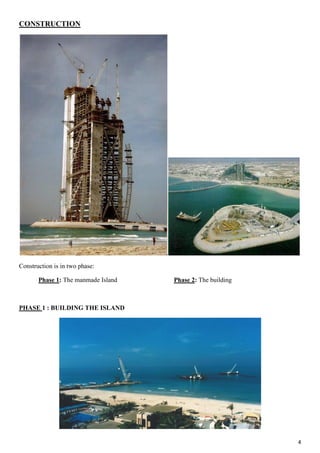

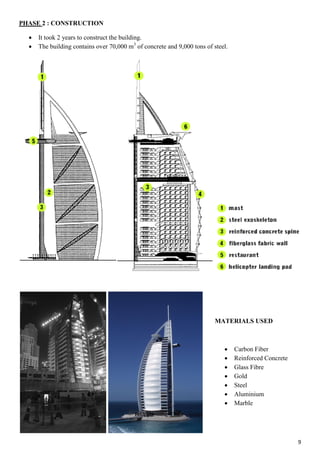

Burj Al Arab is a luxury hotel located on an artificial island in Dubai. It is 321 meters tall and has 202 rooms. The hotel took over 6 years to construct at a cost of $650 million. Some key facts about its design and engineering include:

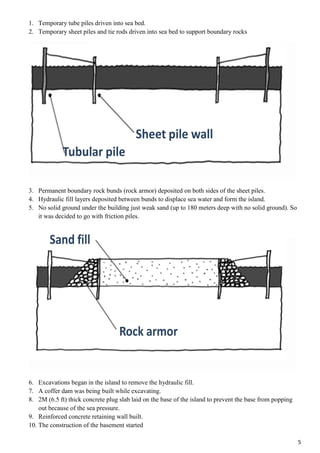

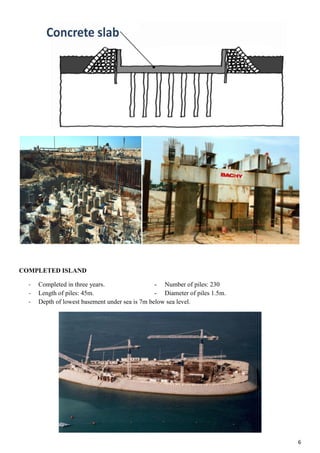

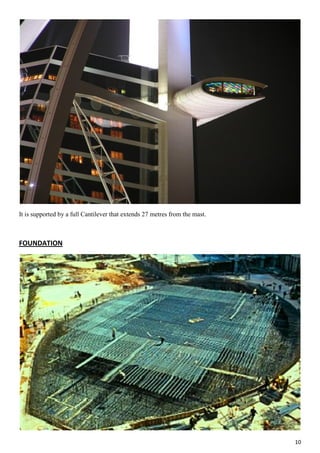

- It is supported by 230 concrete piles that are 40 meters long driven into the sandy soil below.

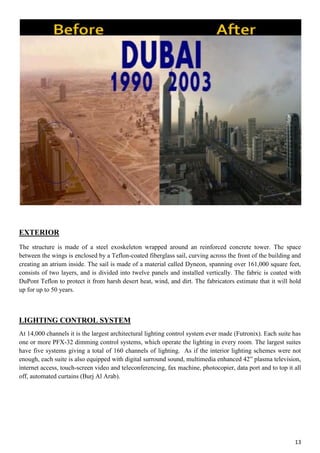

- The exterior is clad in glass and aluminum and is designed to resemble the sail of a dhow ship.

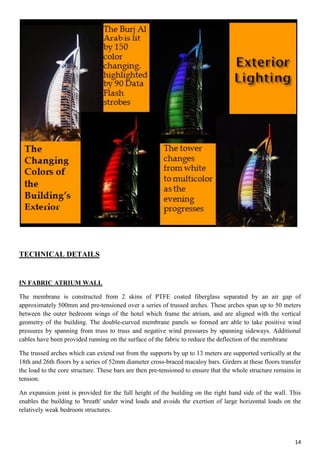

- The large atrium is spanned by trusses and enclosed by a lightweight fabric sail that is 161,000 square feet in area.

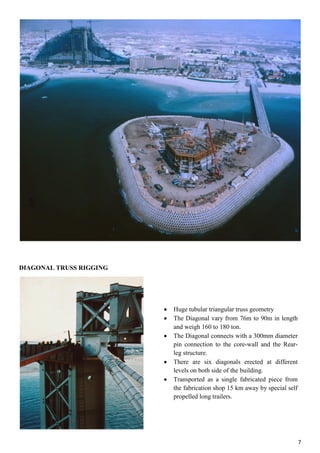

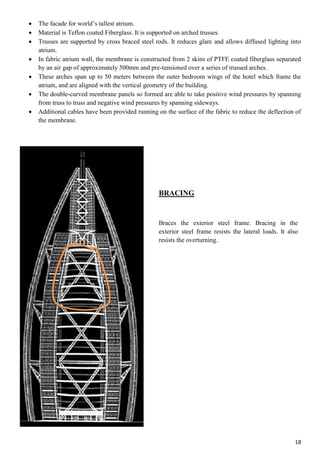

- Structurally, it relies on steel trusses and cross-bracing