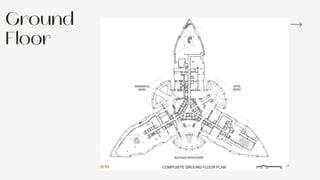

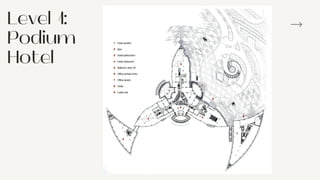

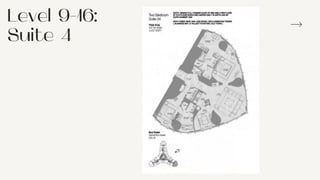

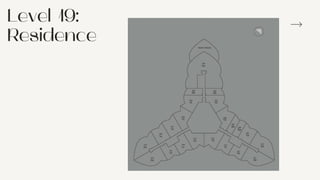

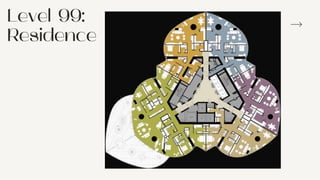

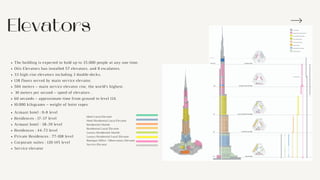

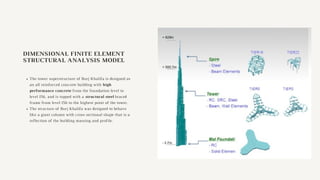

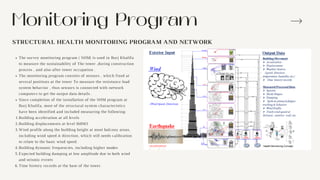

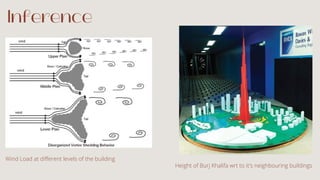

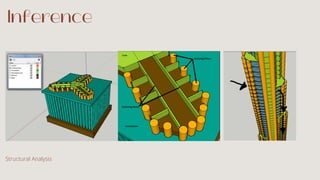

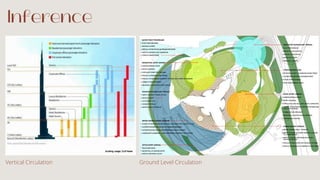

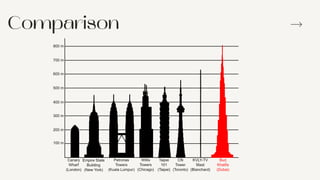

The document provides details about Burj Khalifa, the tallest building in the world located in Dubai. It discusses the building's design, construction, and various systems. Key points include that Burj Khalifa has 163 floors, a height of 828 meters, a Y-shaped floor plan for optimal views, a buttressed core structural system, over 26,000 glass panels in its stainless steel cladding, and 57 elevators.

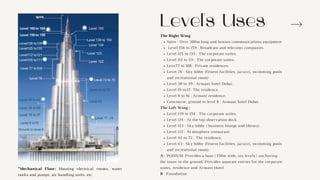

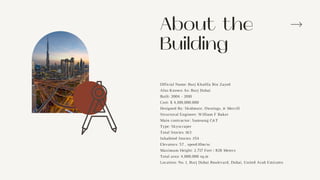

![Construction Type: Skyscraper Current

Status: Existing [Completed]

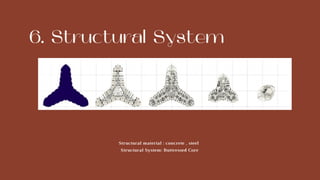

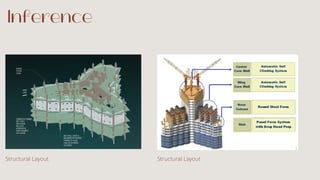

Structural System: Buttressed

Core Structural Material: Concrete, Steel

Façade Material: Stainless Steel

Façade System: Curtain Wall

Architectural Style: Modernism

Floor Plan: 517,240m2

Order Year: 2003

Construction Start: 2004

Project Type: Mall, Residential And Retail Facilities And World's

Tallest Skyscraper

Estimated Investment: Aed800m (Mall, Residential And Retail

Facilities); Aed3.9bn (Tower); Overall Development $8bn

Completion: 2008 (Mall); 2008 (Tower), Mall Opening On 31st

August 2008, Tower Officially Opened 4 January 2010

Retail Space: 9 Million Square Feet 7

About the

Structure](https://image.slidesharecdn.com/burjkhalifa-210421121853/85/Burj-khalifa-6-320.jpg)