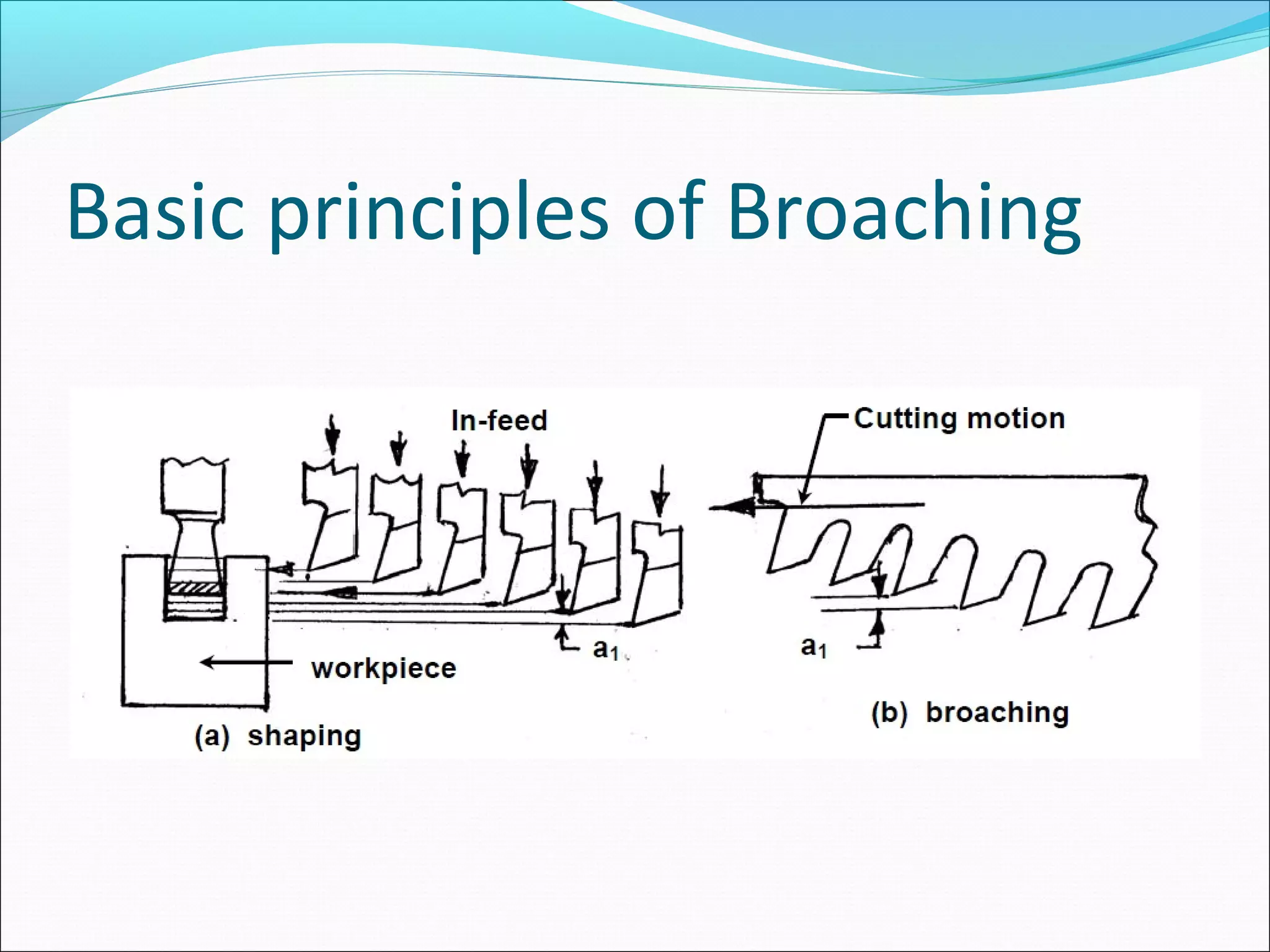

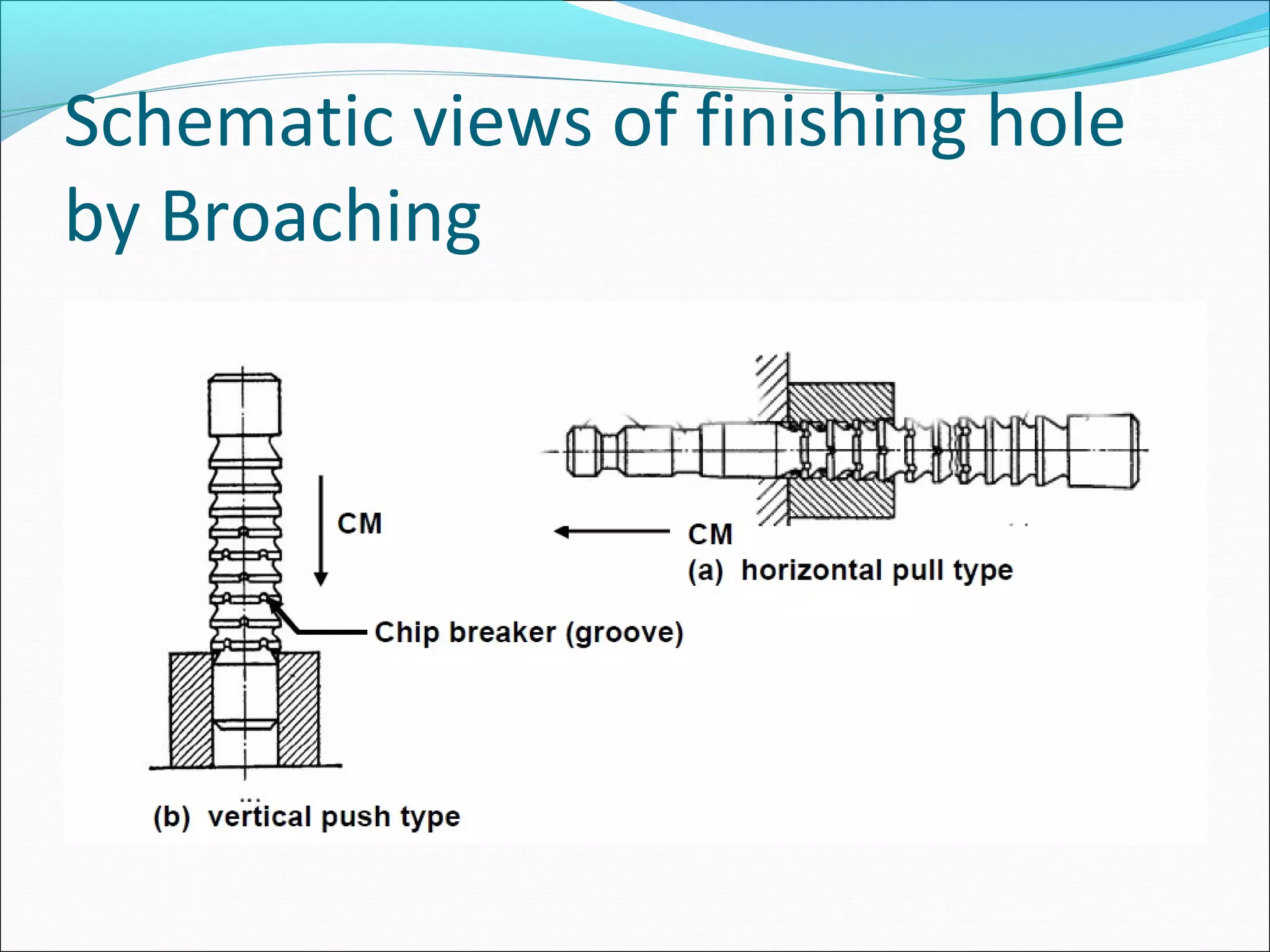

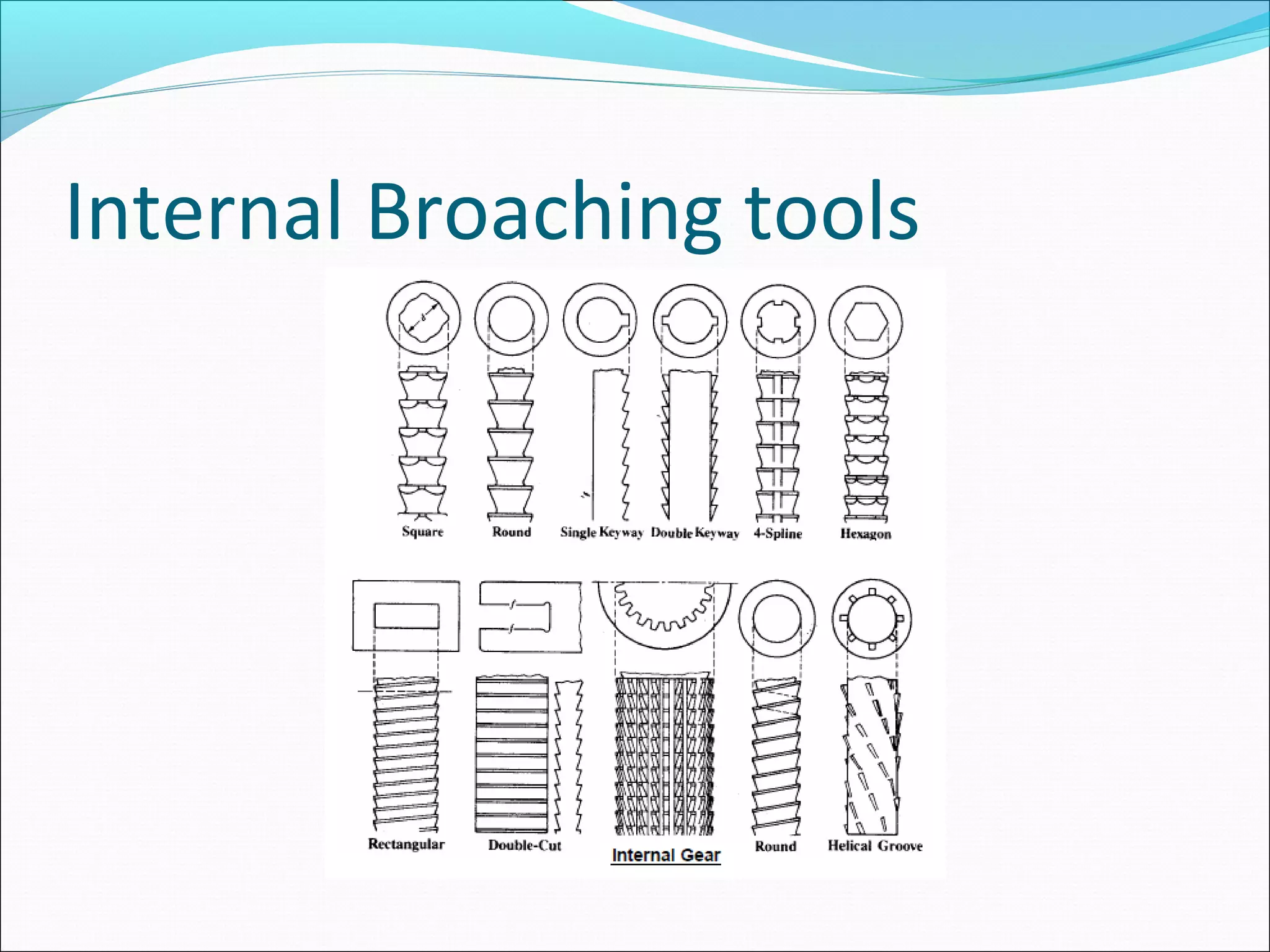

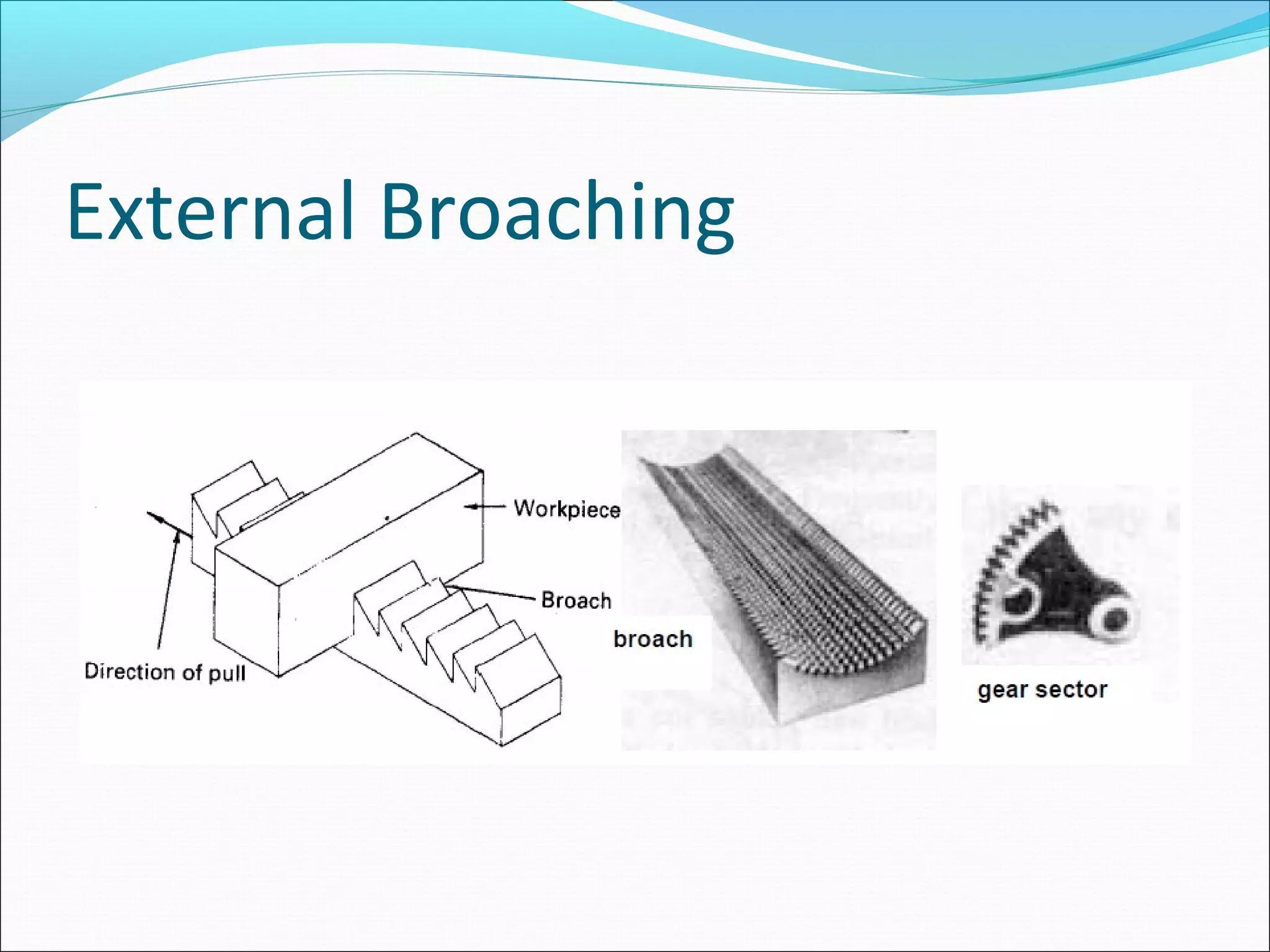

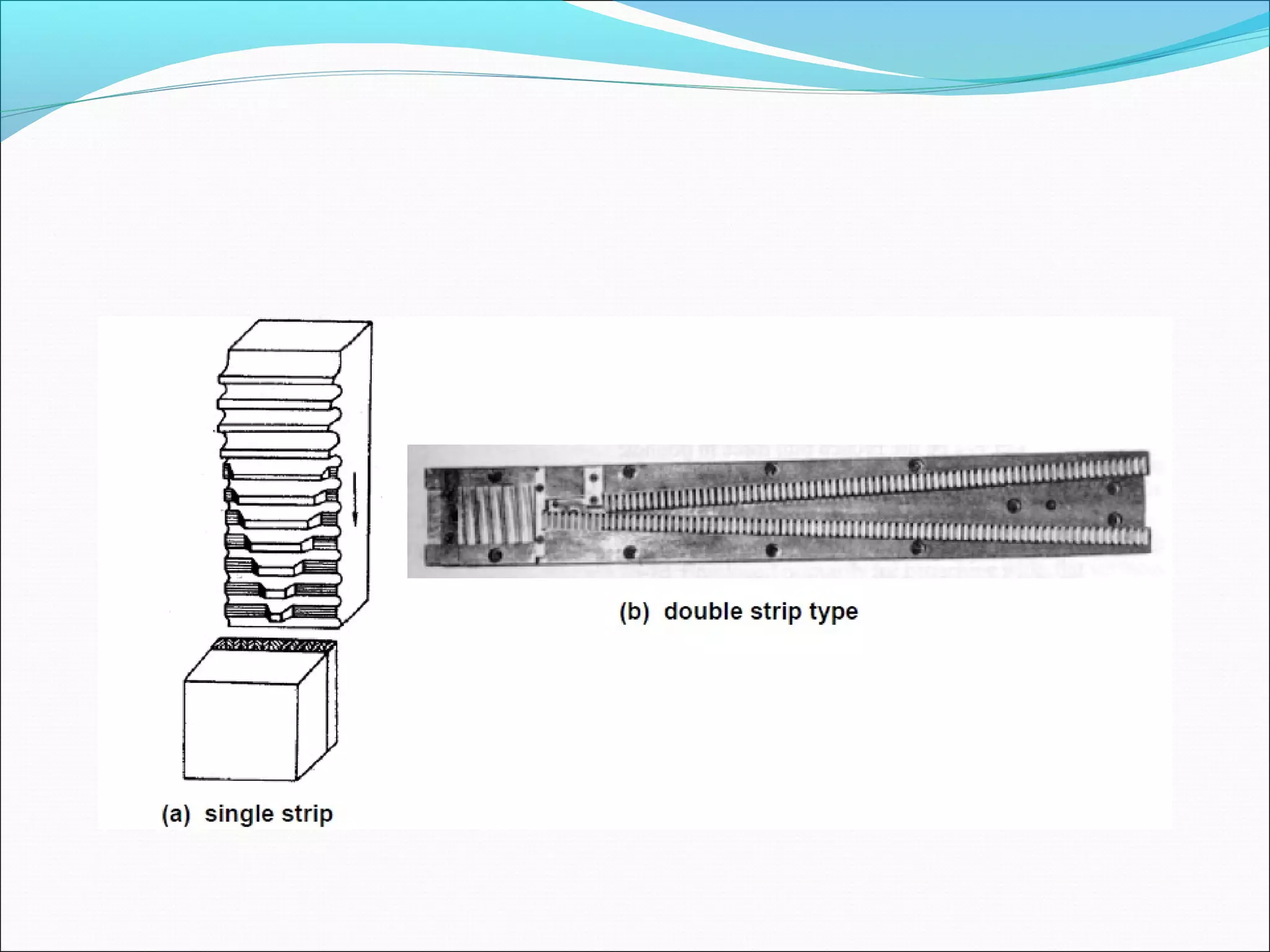

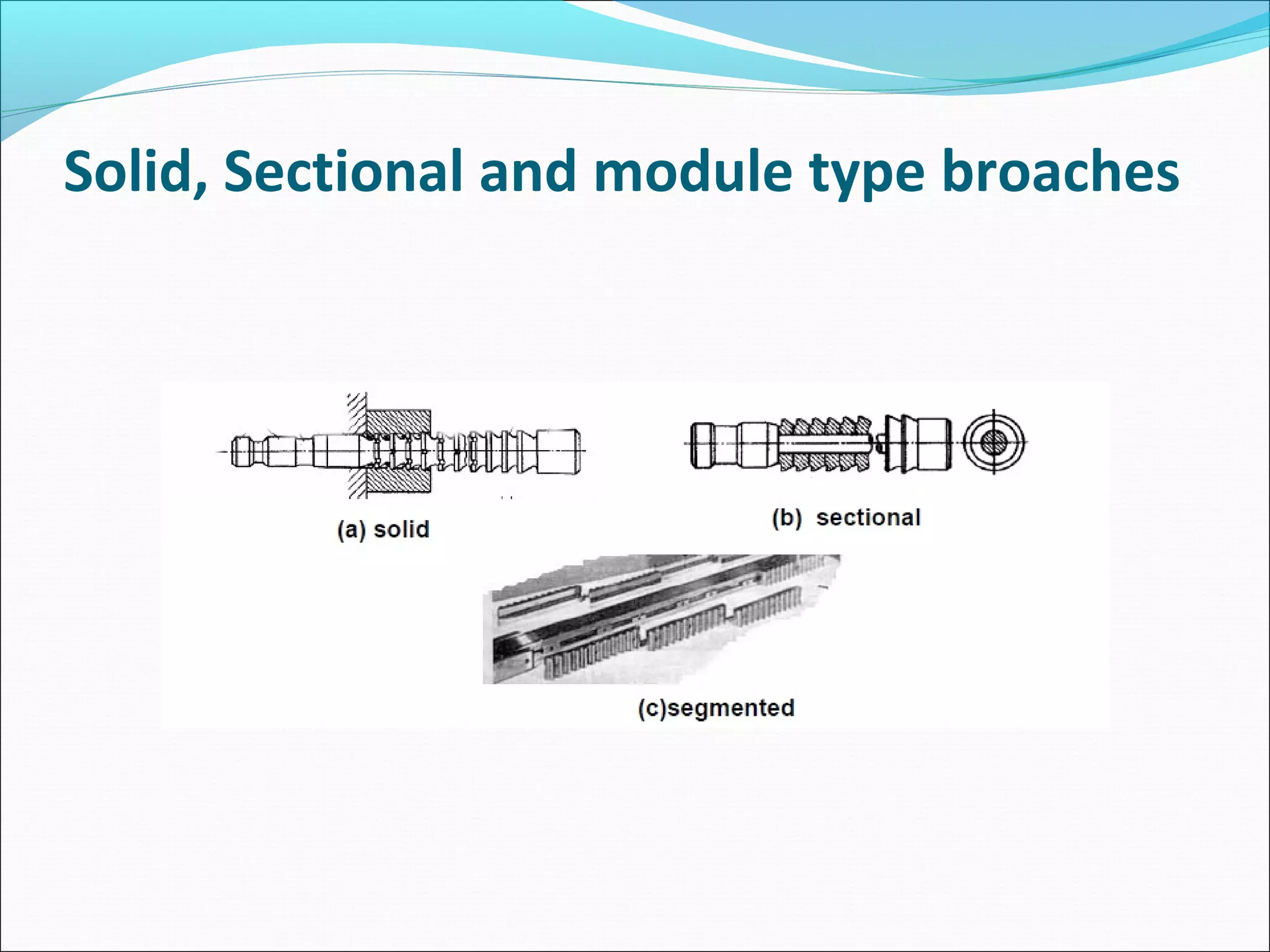

Broaching is a machining process that removes material in a single stroke using a broach tool with gradually rising teeth. It can machine internal and external surfaces and is well-suited for mass production. The appropriate broach type and broaching machine must be selected based on the workpiece material, size, and desired machining operation. Broaching provides high production rates, accuracy, and surface finish compared to other machining methods.