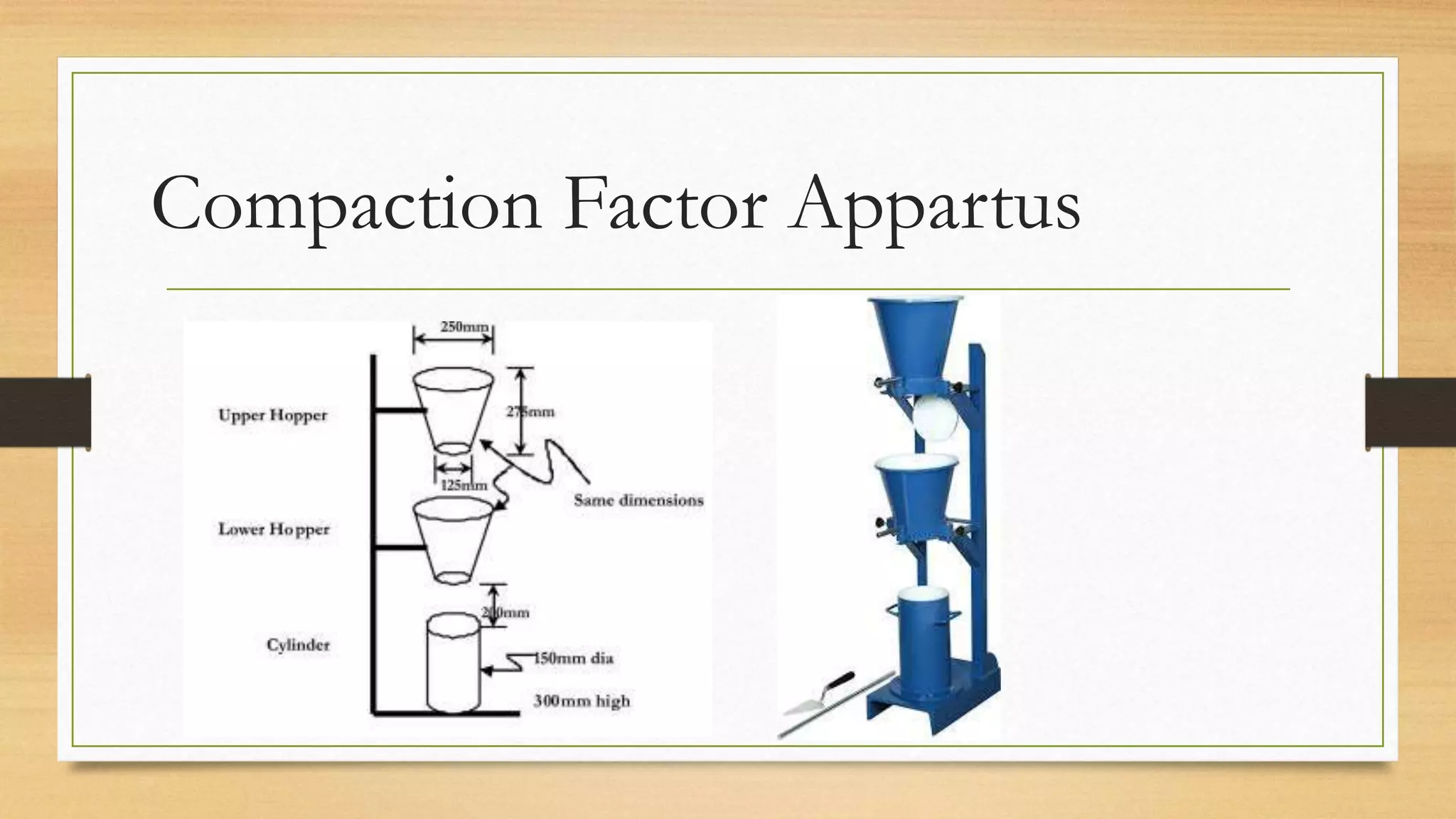

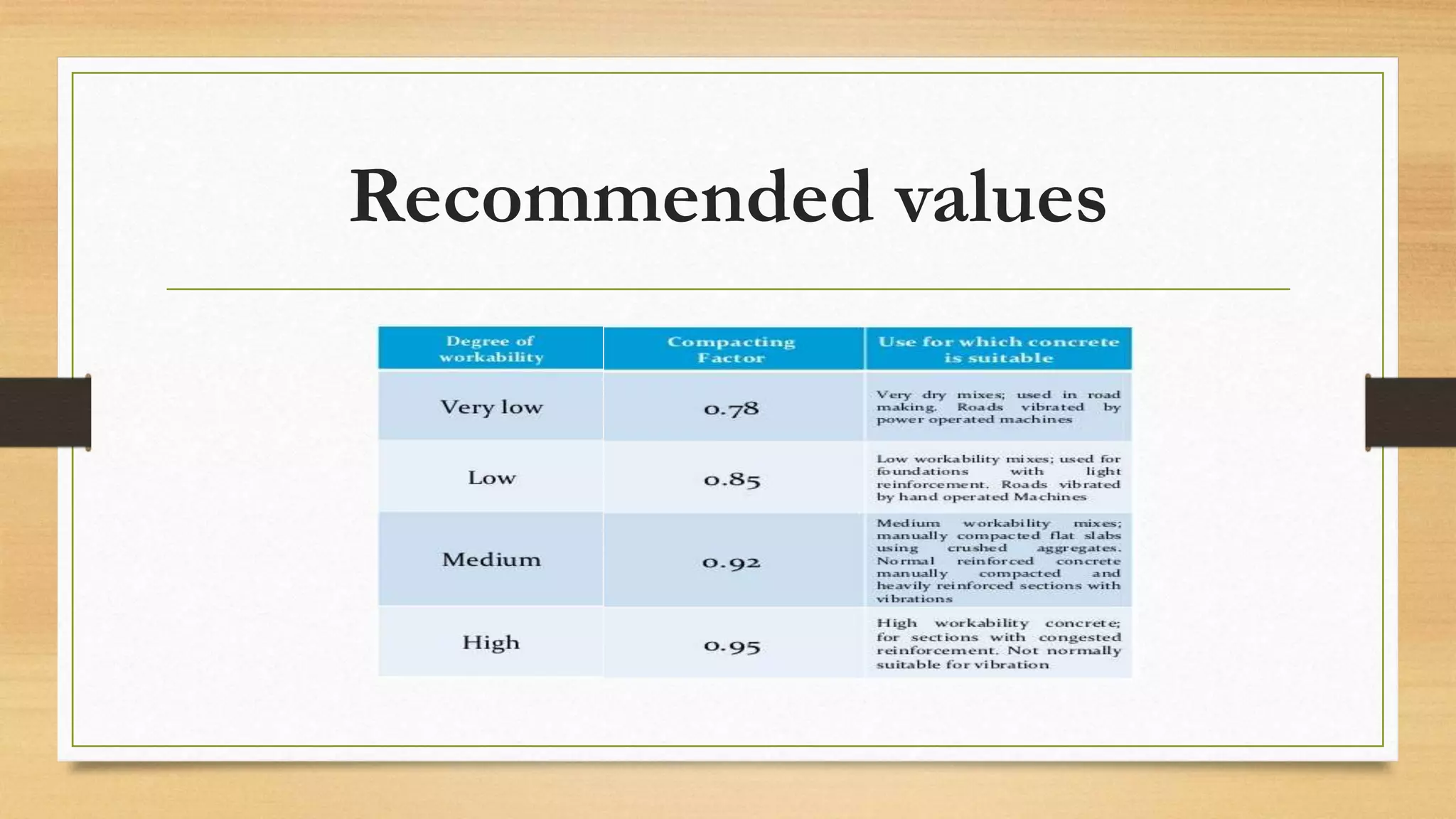

The document discusses the compaction factor test for measuring the workability of concrete. The compaction factor test determines workability by measuring the compaction achieved when concrete falls freely from a hopper into a cylinder. A compaction factor of 0.75 to 0.8 is recommended, according to IS 456-2000 standards. The test involves partially filling a cylinder by simply allowing the concrete to fall in, then fully compacting it with a rod and calculating the ratio of the weights.