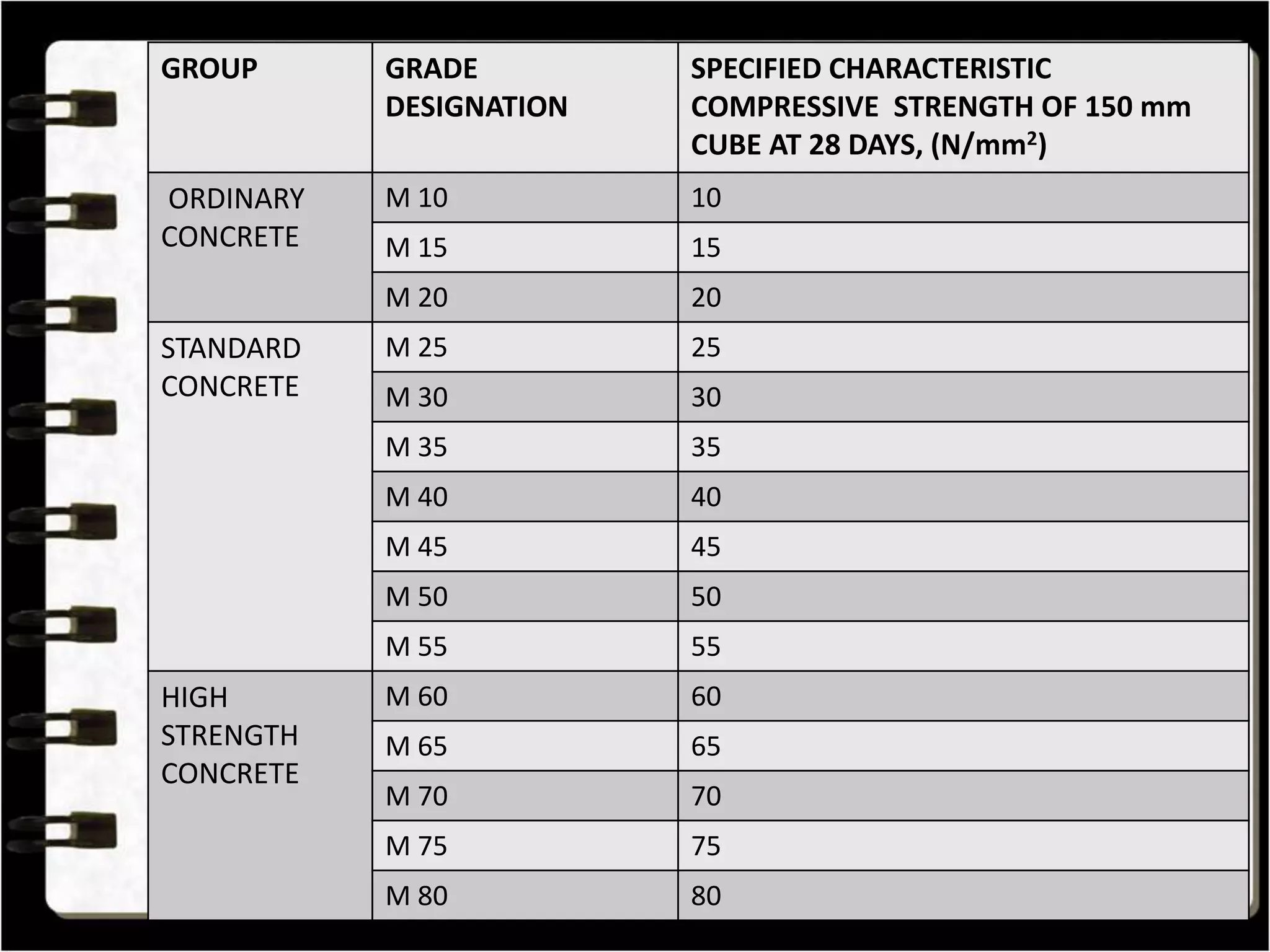

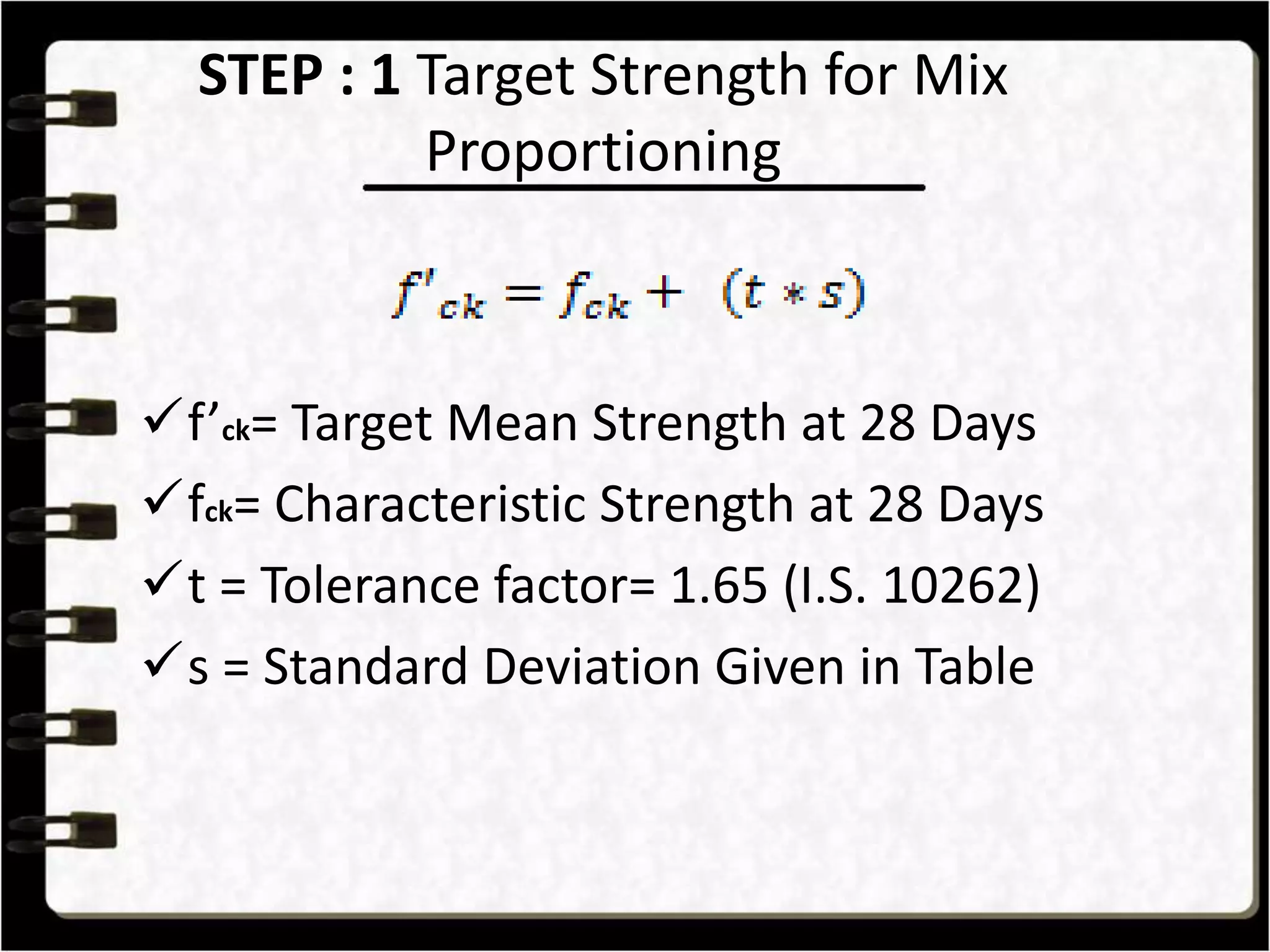

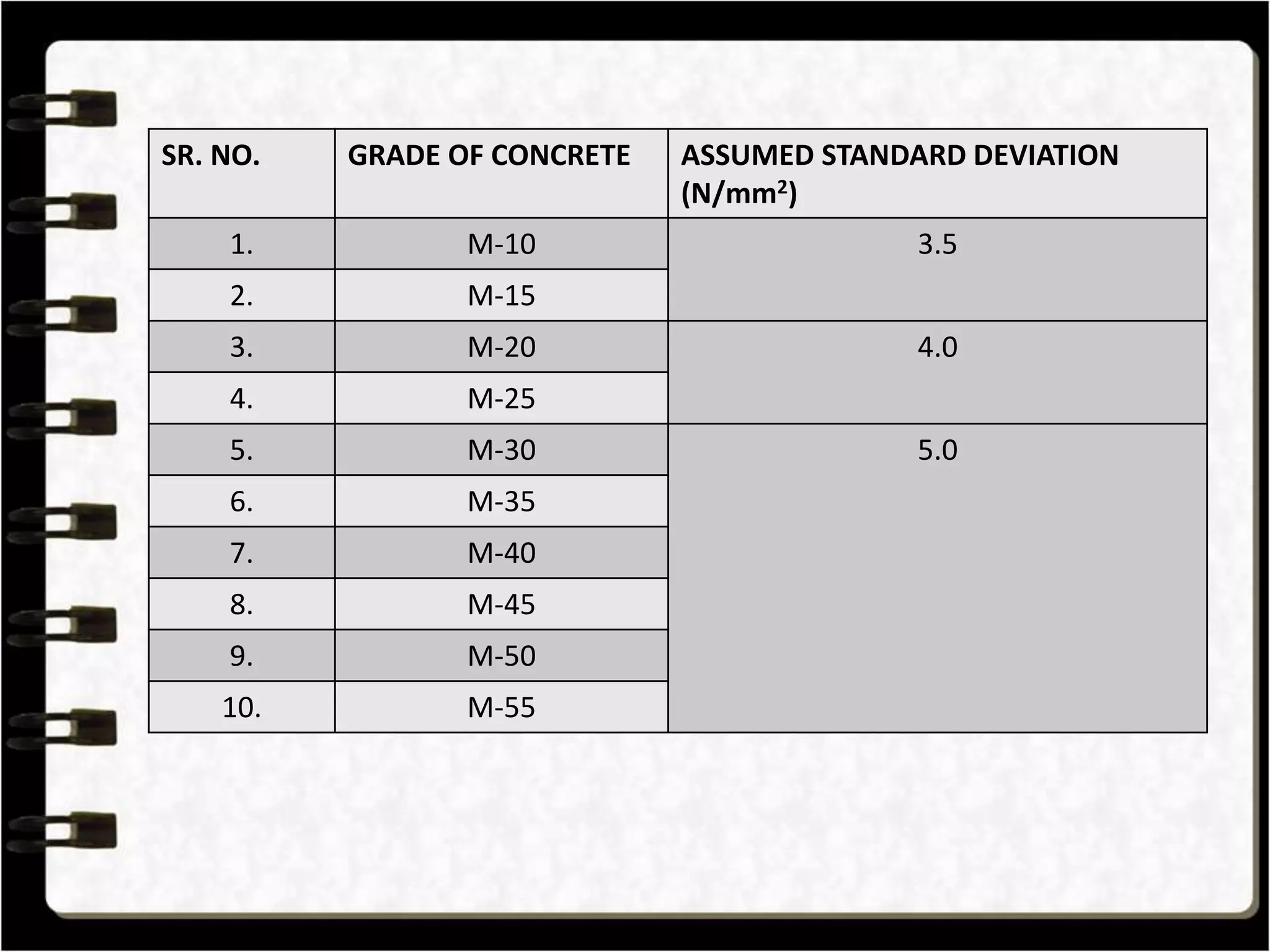

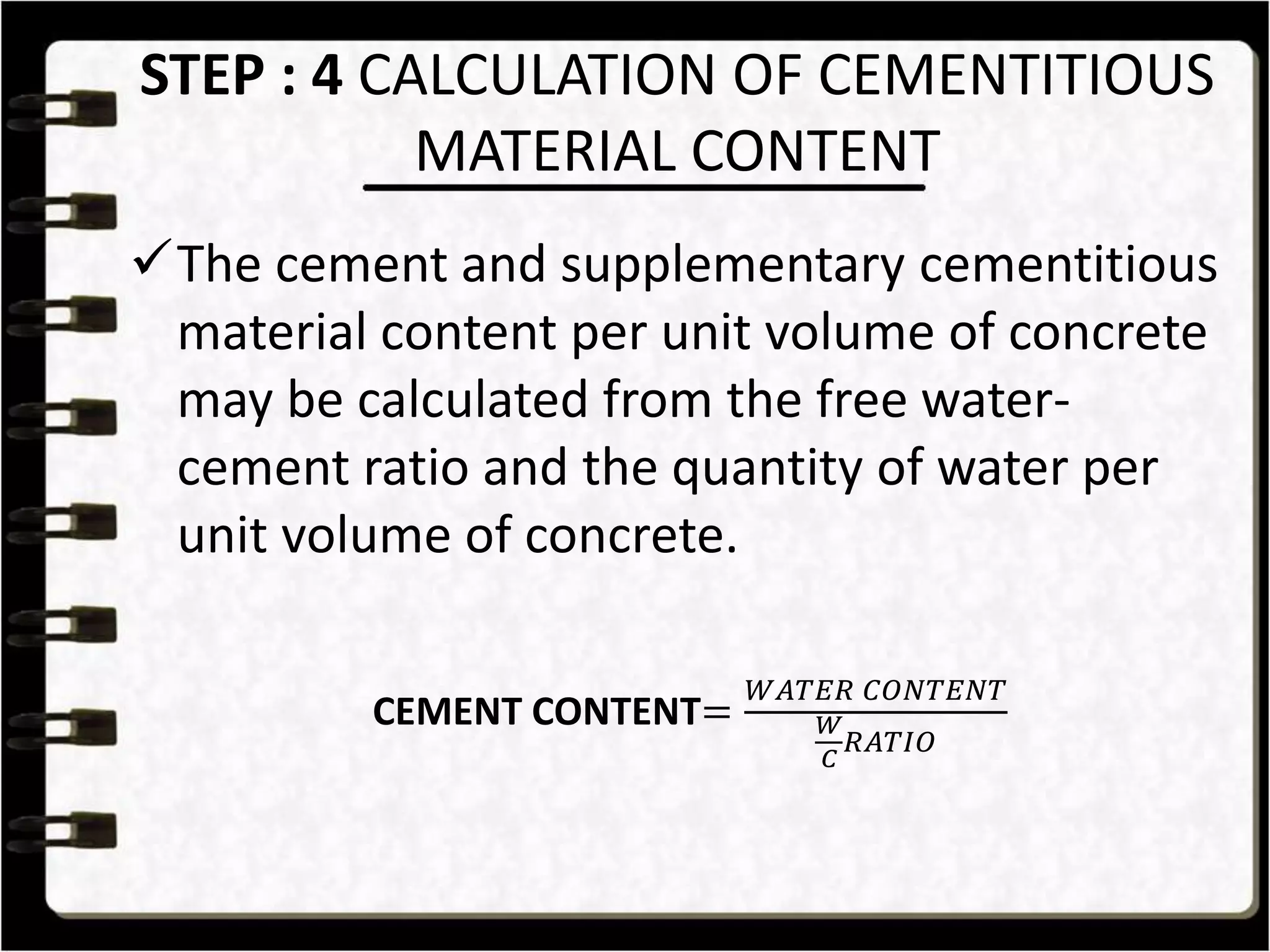

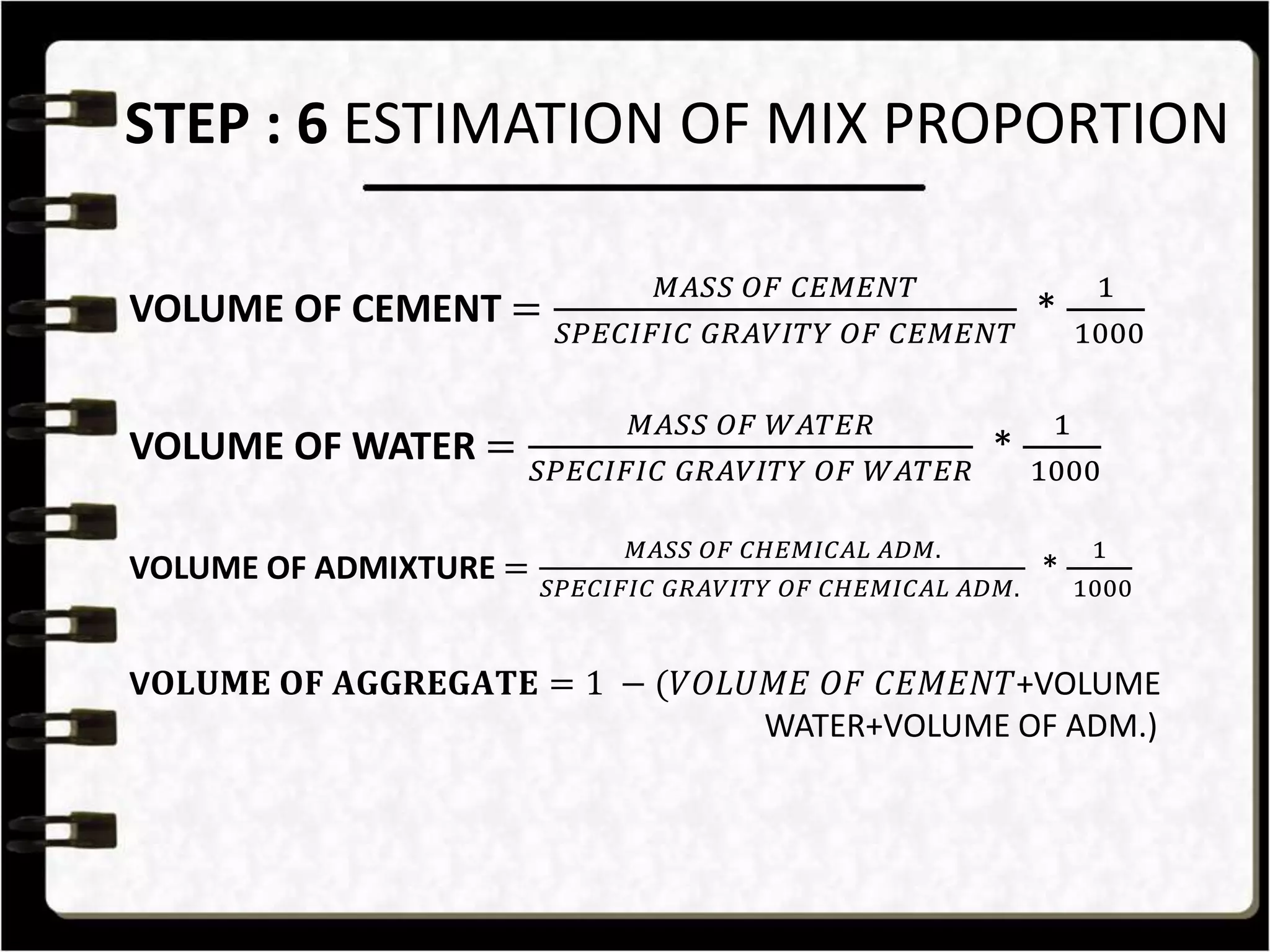

The document outlines the concept of concrete mix design, emphasizing the importance of selecting appropriate ingredients and their proportions to achieve desired strength, durability, and workability. It discusses the classification of concrete grades, the factors influencing mix design, and several methodologies for mix design, primarily focusing on the IS method. Additionally, it provides detailed steps for calculating various mix components based on target strengths and water-cement ratios.