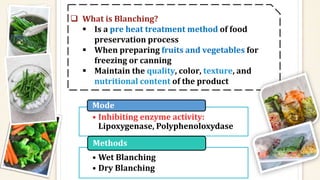

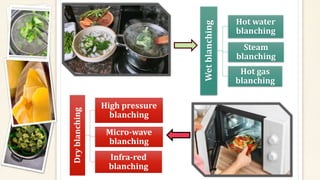

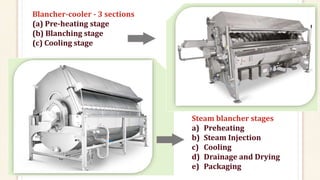

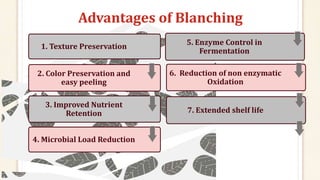

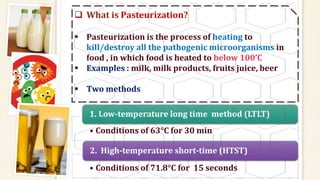

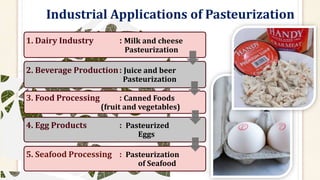

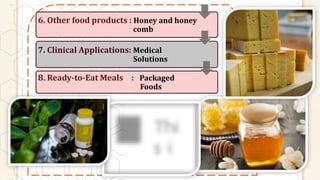

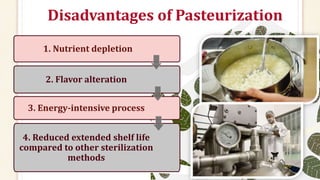

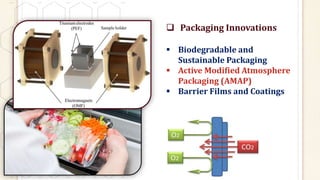

Blanching is a pre-heat treatment for food preservation that enhances color, texture, and nutrient retention while inhibiting enzyme activity, with various industrial applications including frozen foods and canned goods. Advantages include improved shelf life and nutrient retention, but it can also lead to nutrient loss and tissue damage. Modern trends focus on hybrid technologies for efficiency and sustainability, alongside pasteurization methods aimed at eliminating pathogens in food products.