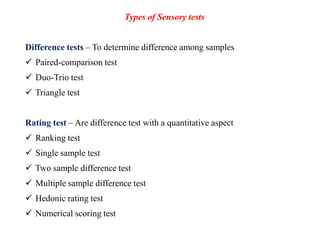

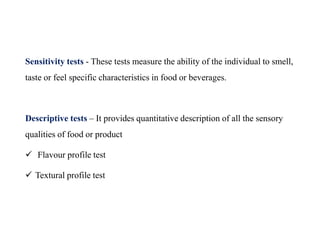

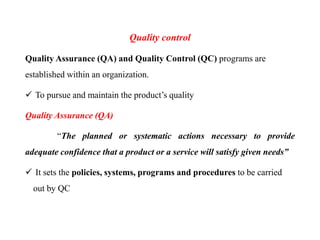

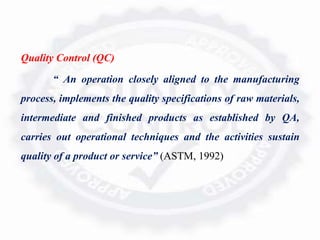

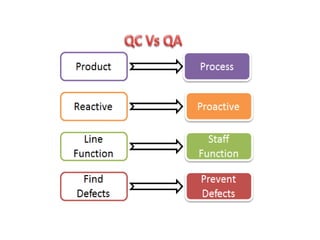

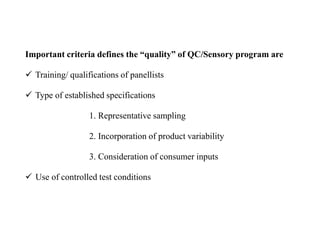

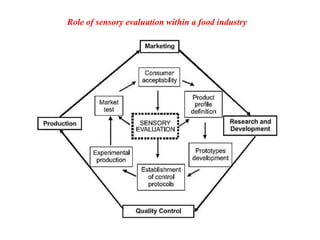

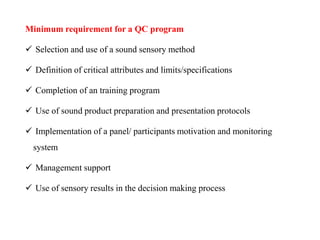

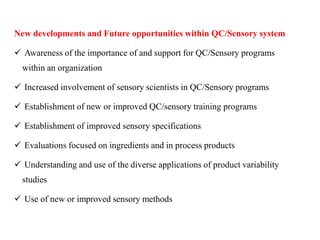

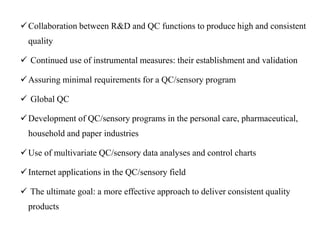

The document discusses sensory evaluation as a scientific discipline essential for food quality control, involving the use of human senses to judge food characteristics. It outlines various sensory tests and quality control processes, emphasizing the importance of having well-defined quality assurance and control programs. The document also highlights the future opportunities in sensory evaluation, indicating the demand for improved methods and collaboration within the food industry.