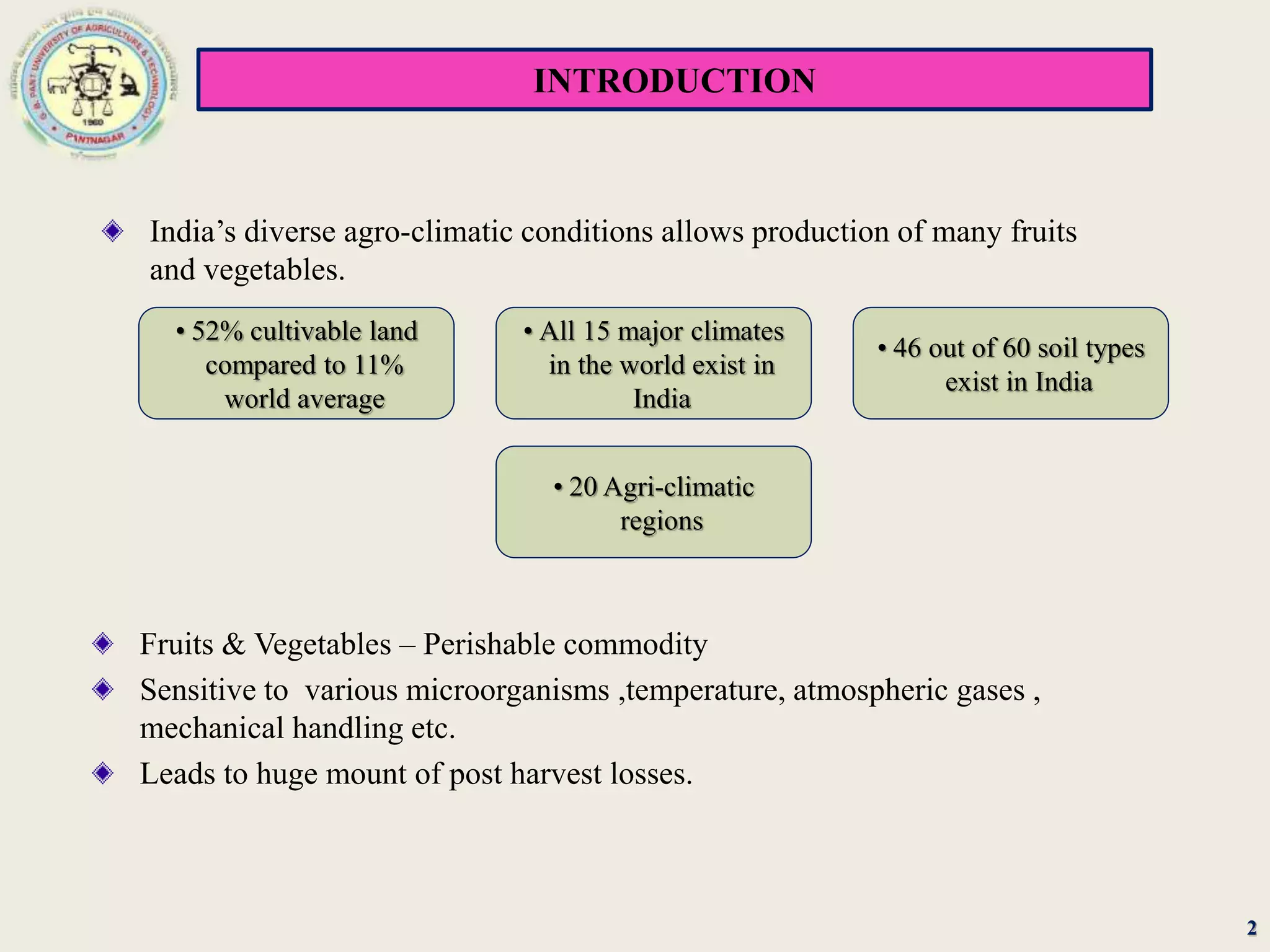

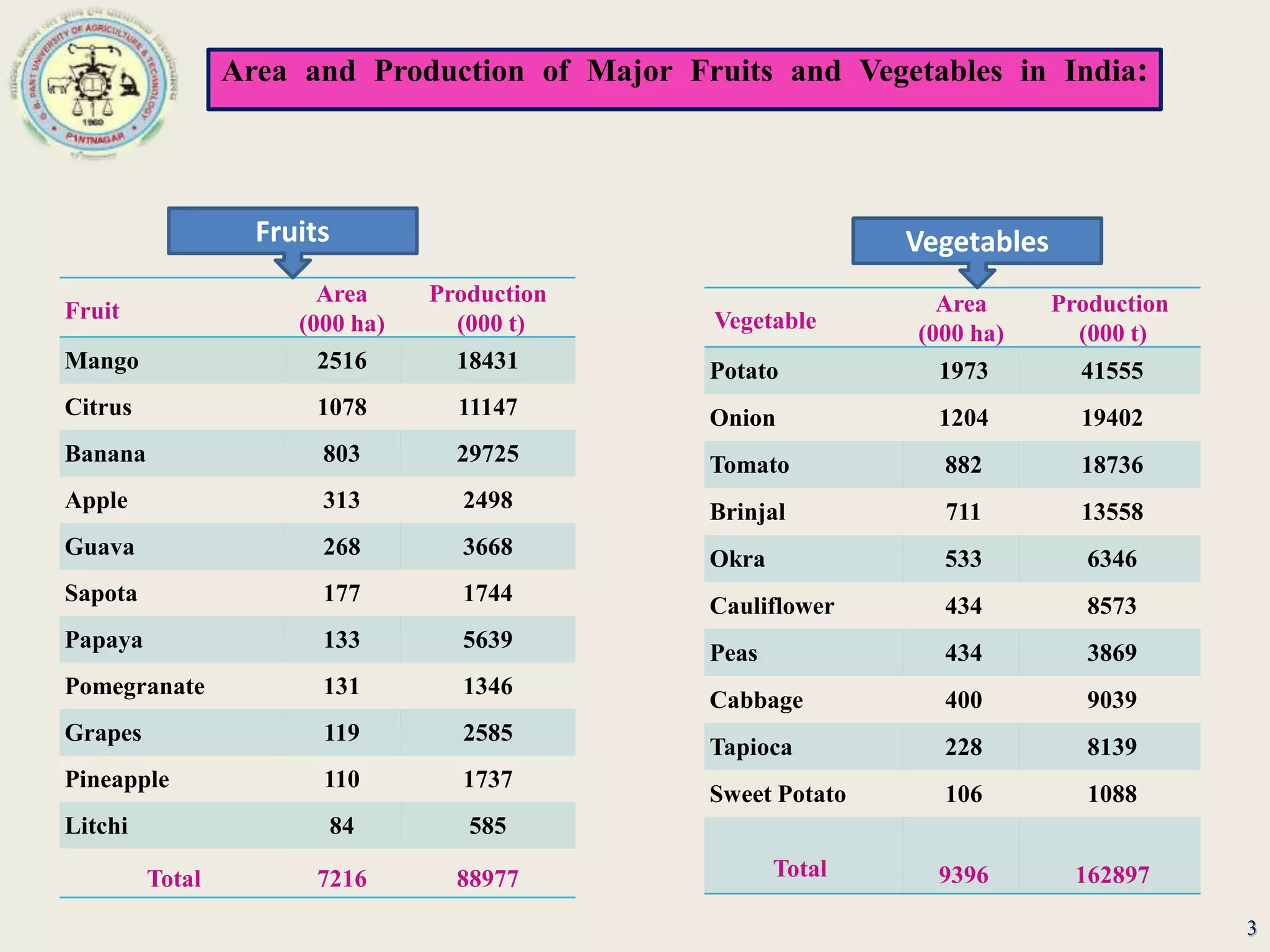

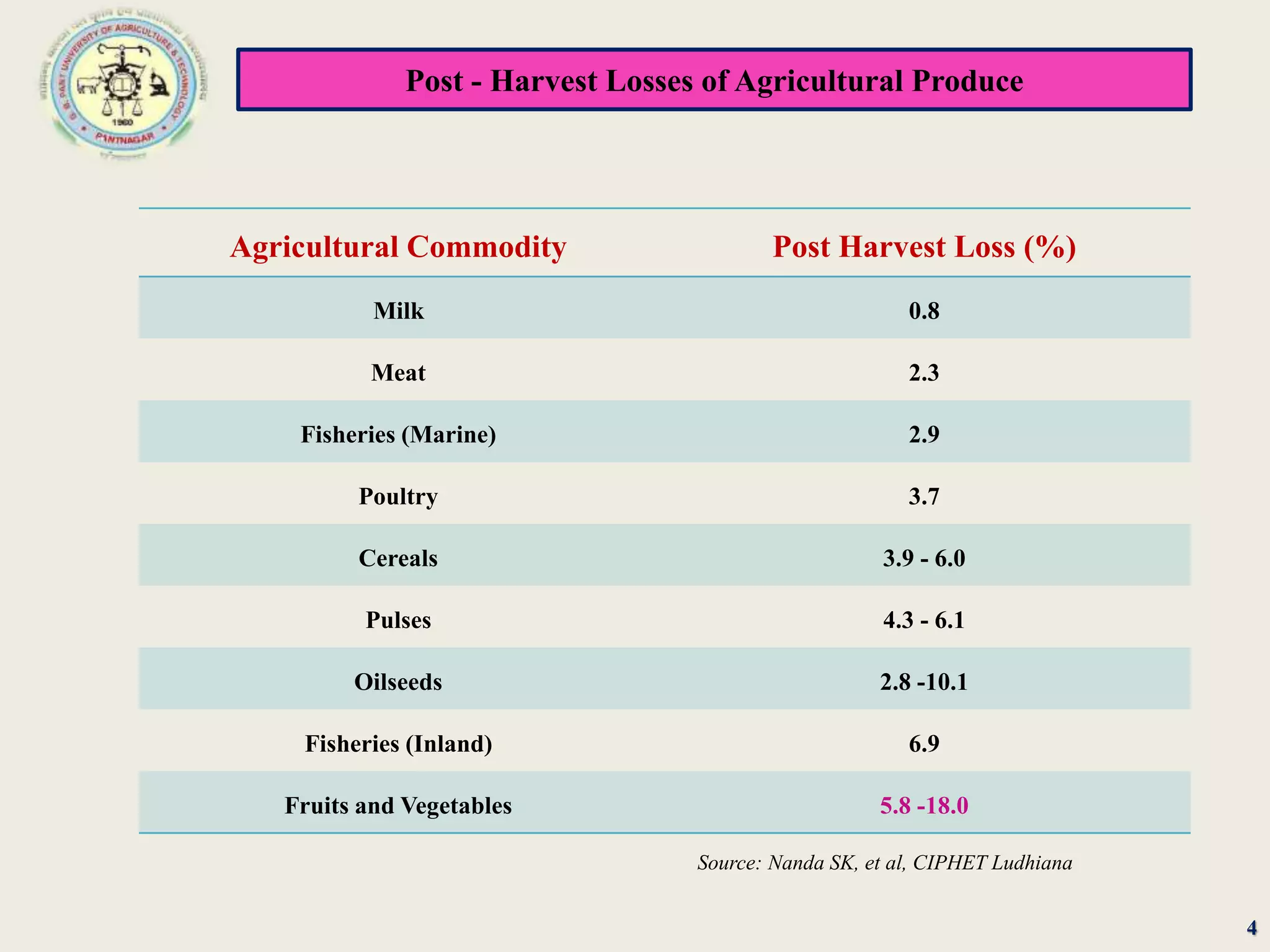

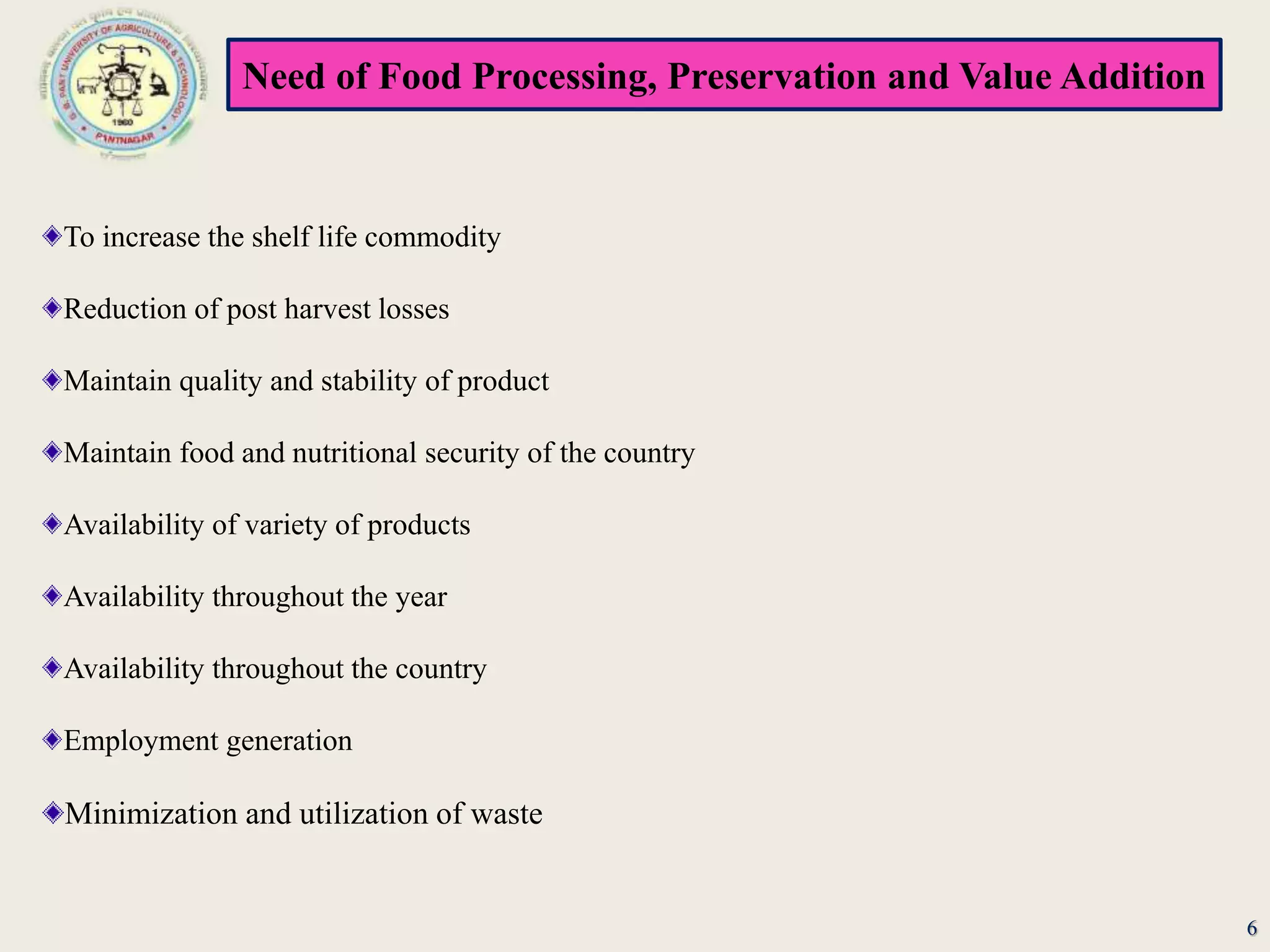

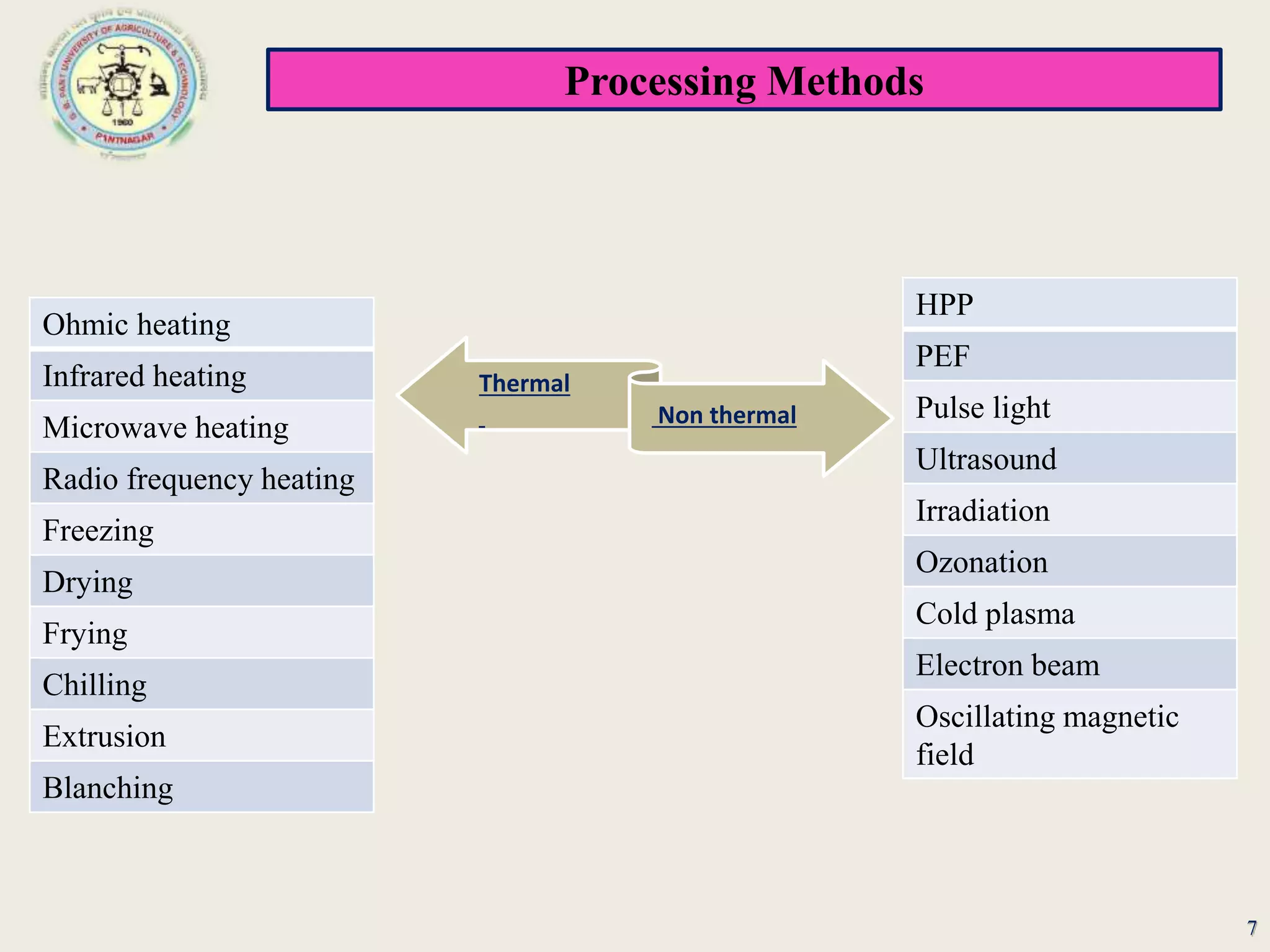

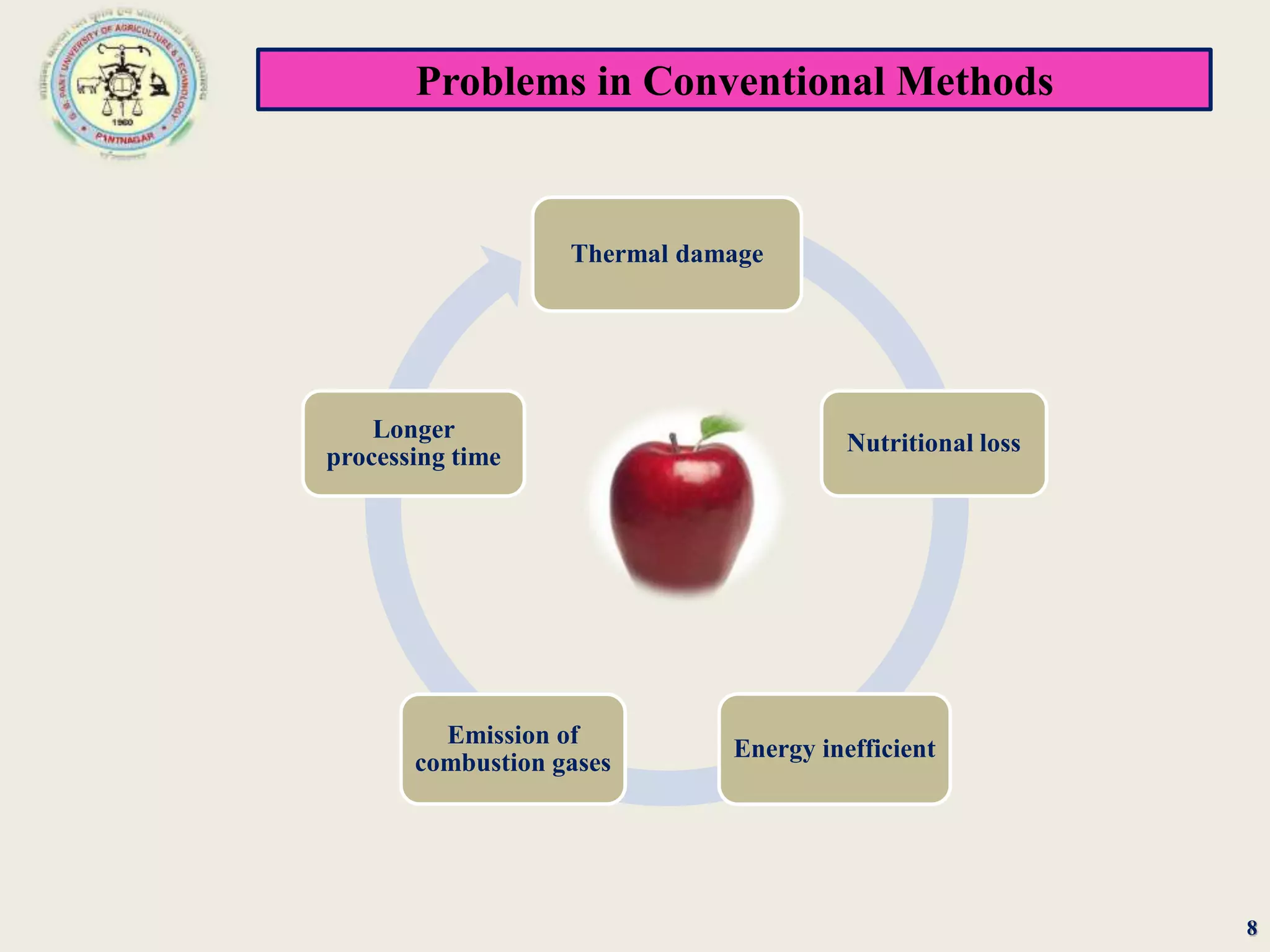

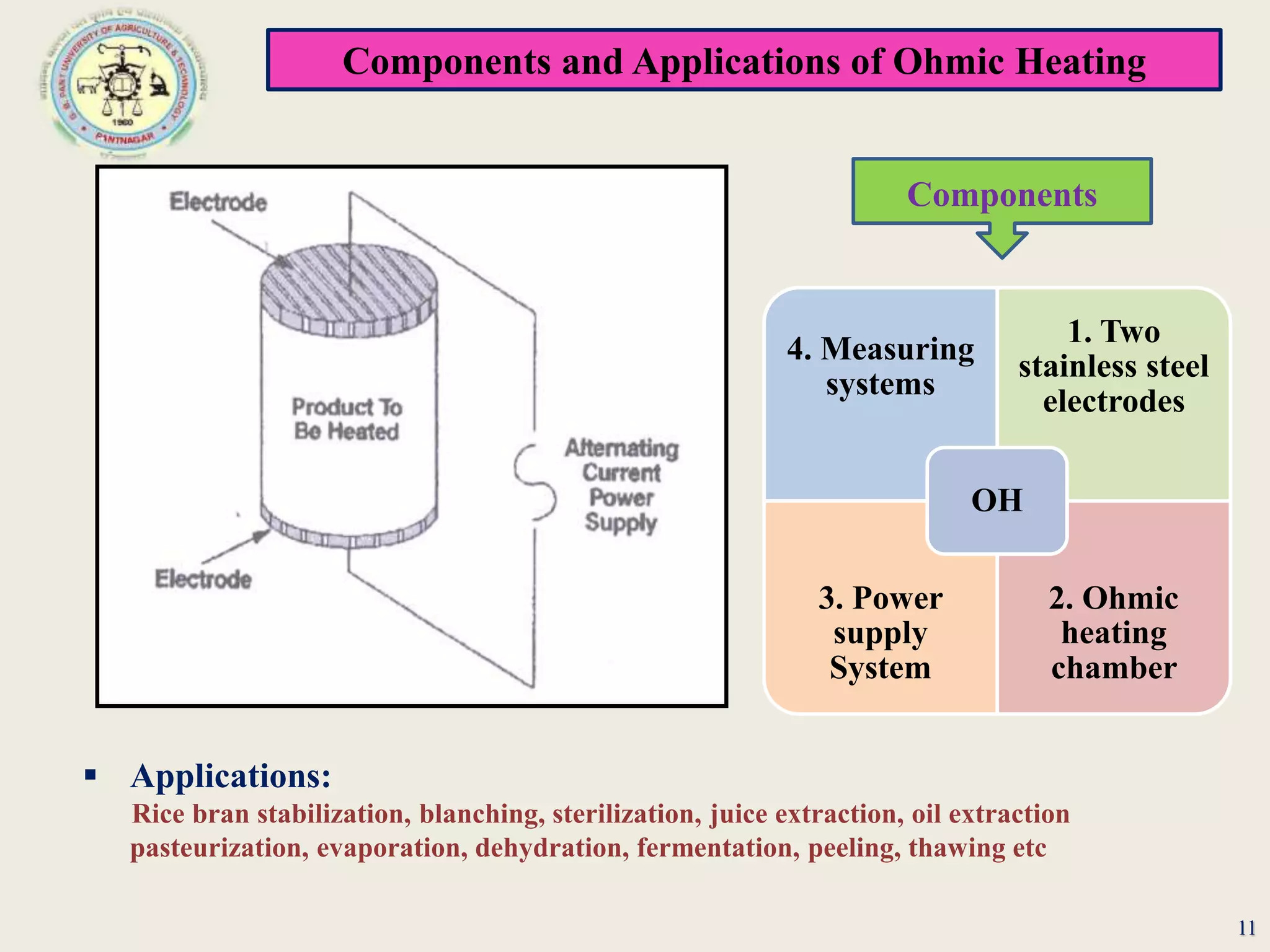

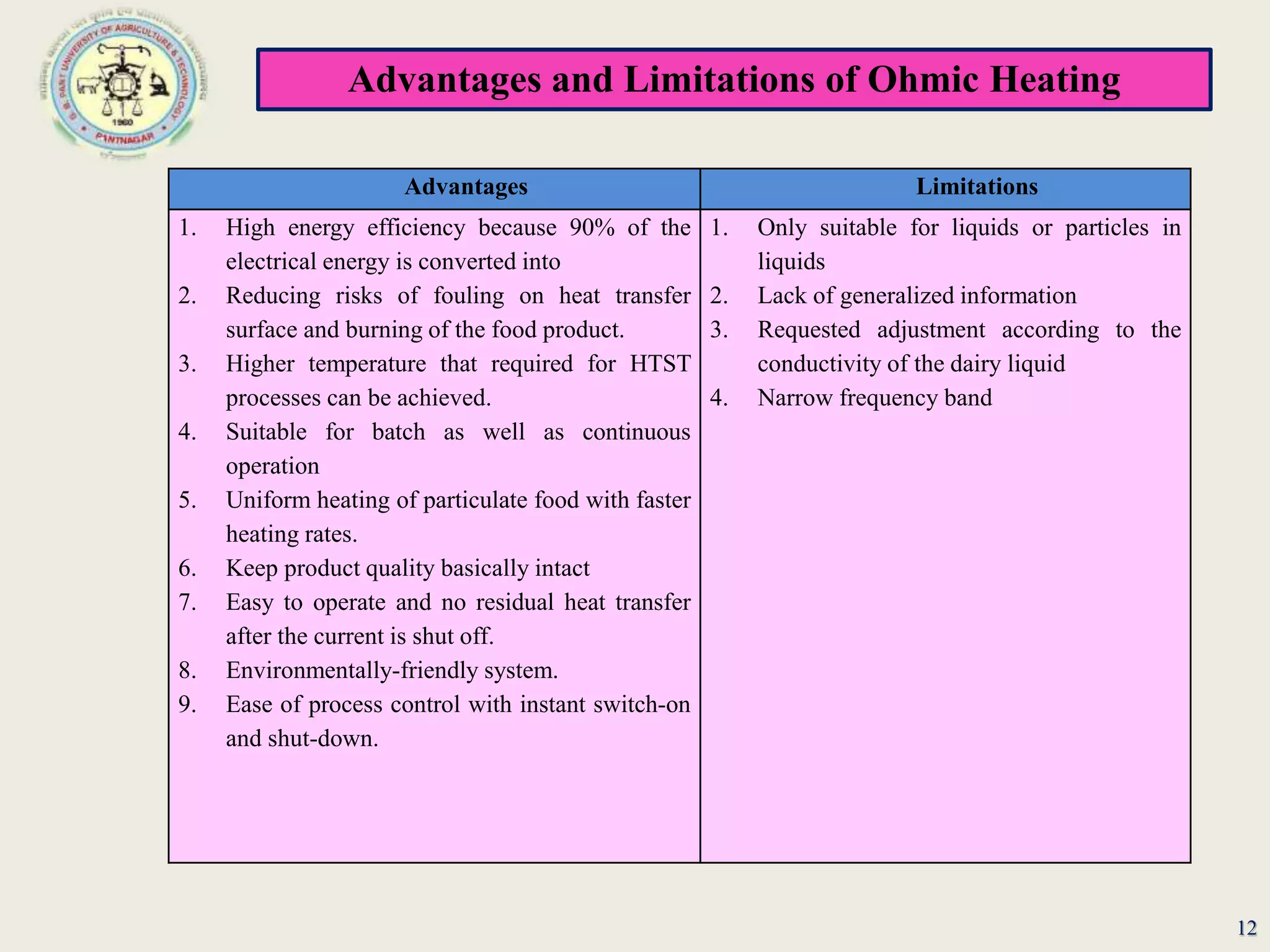

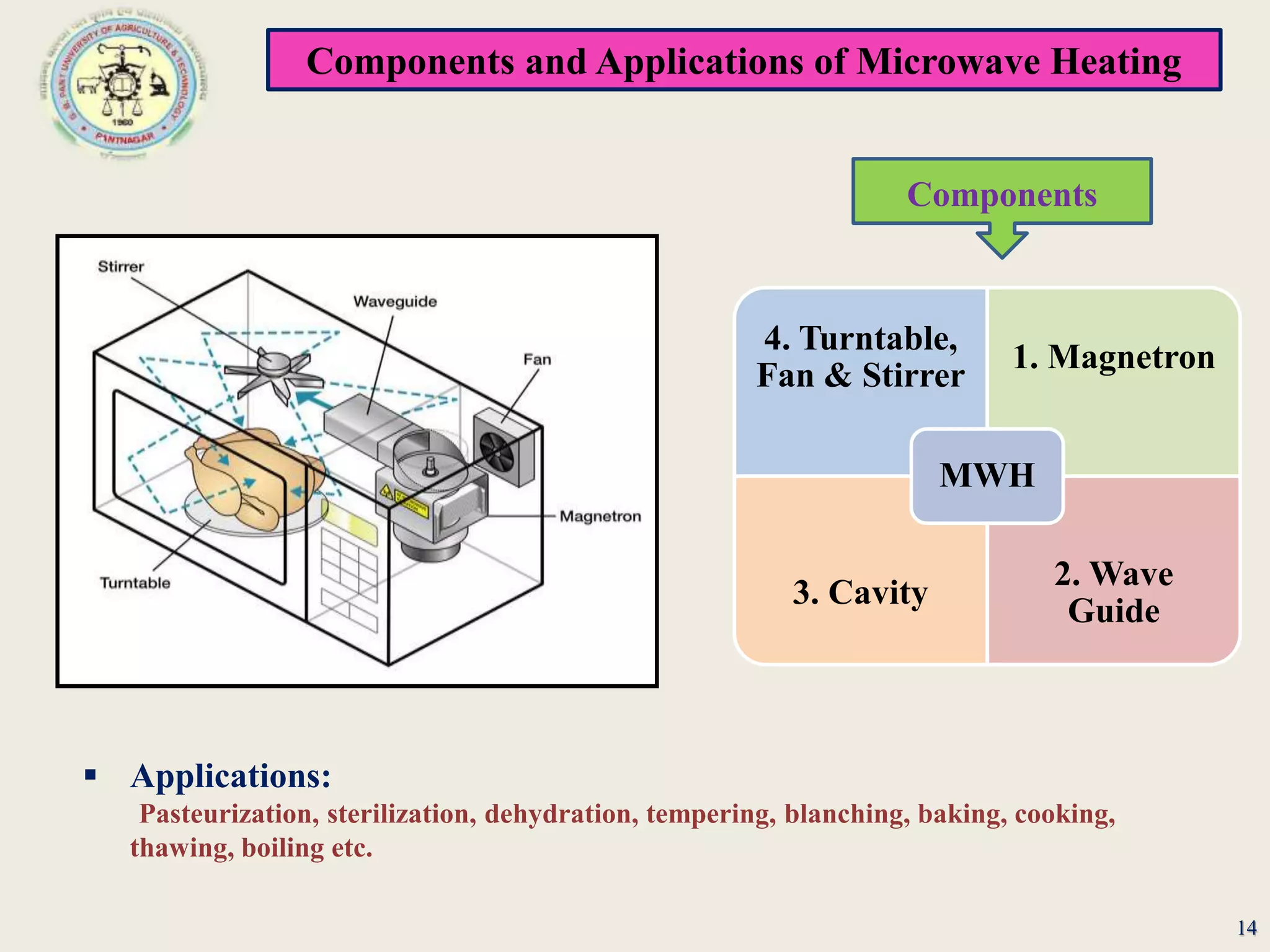

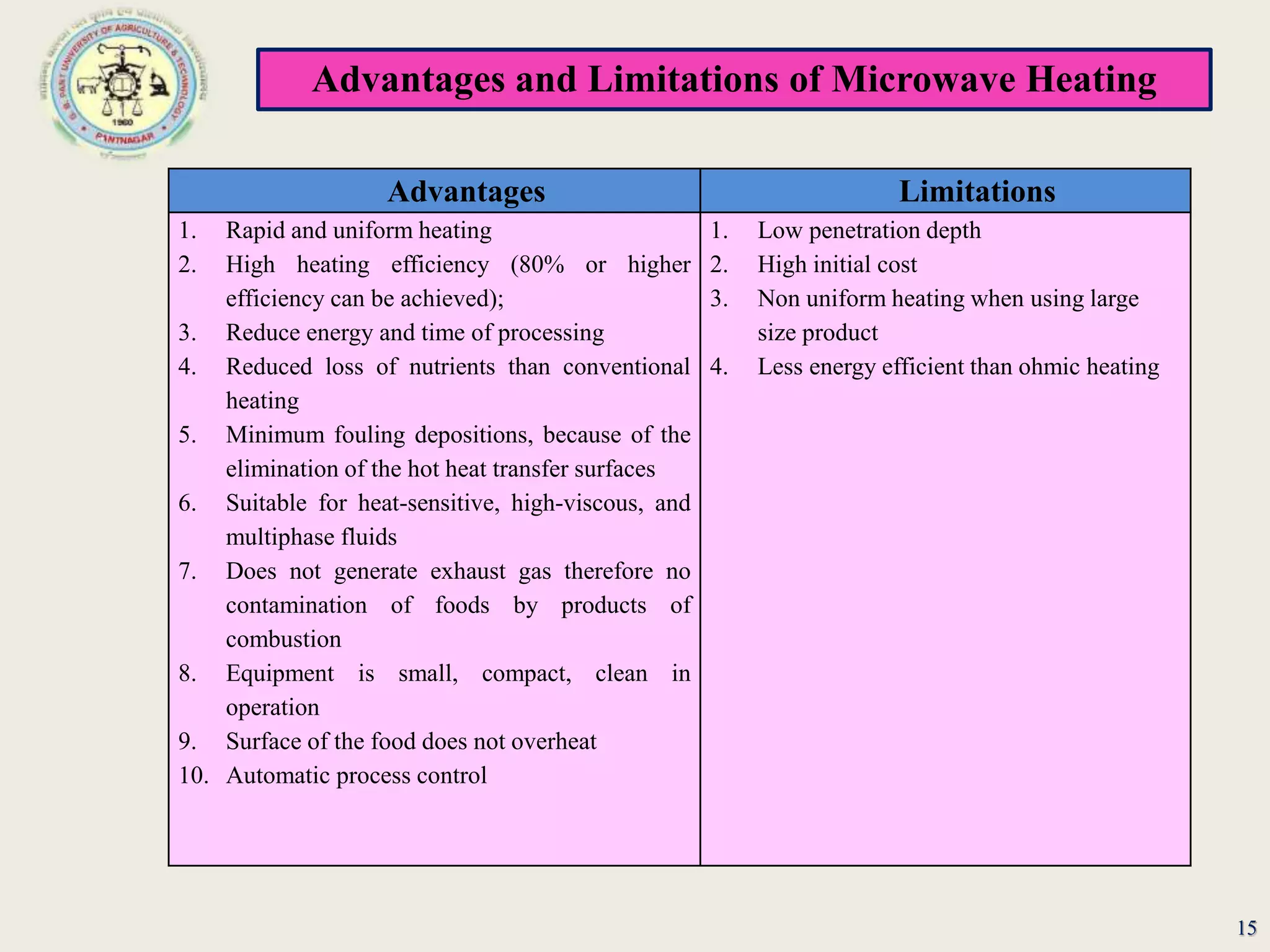

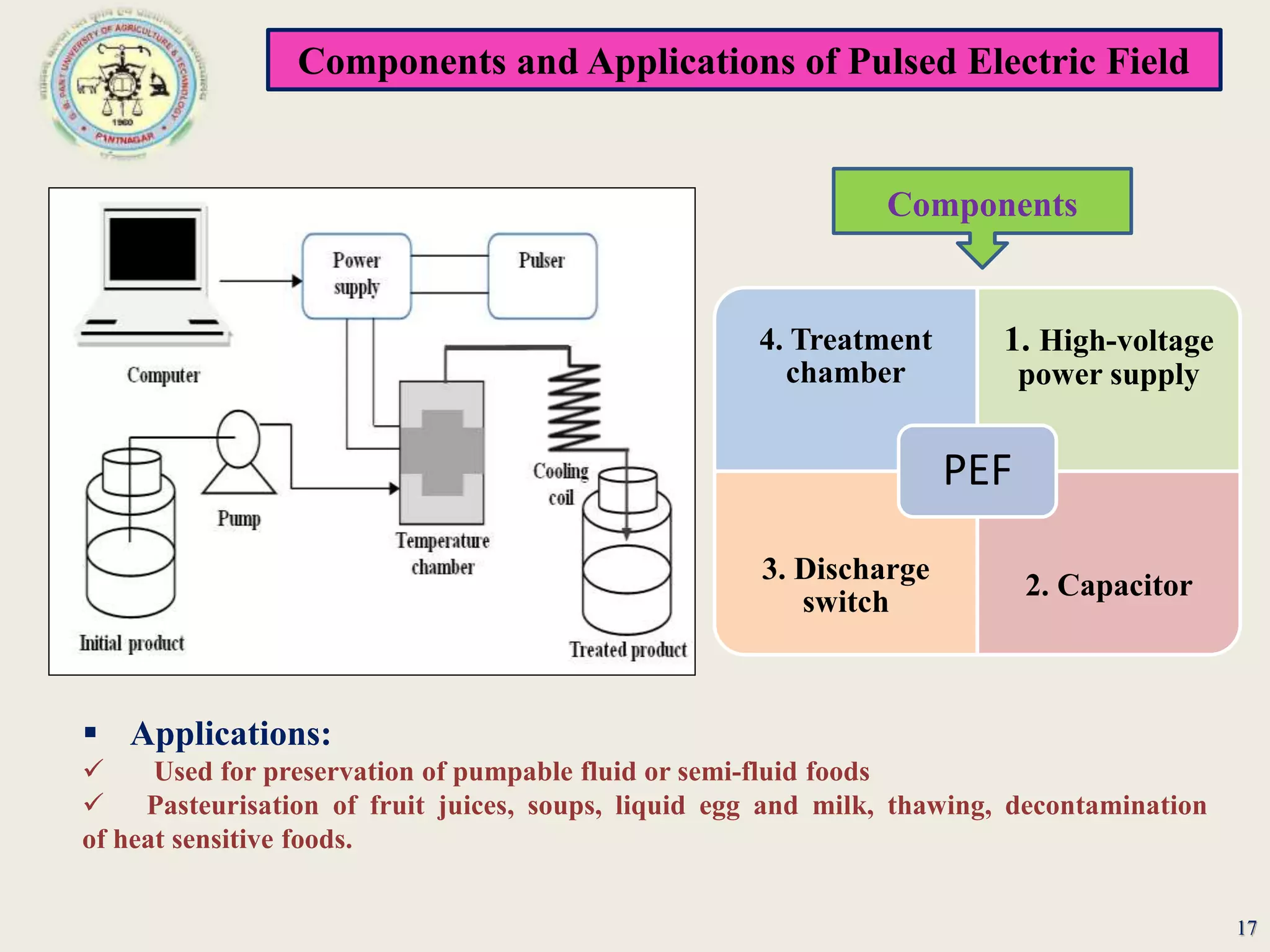

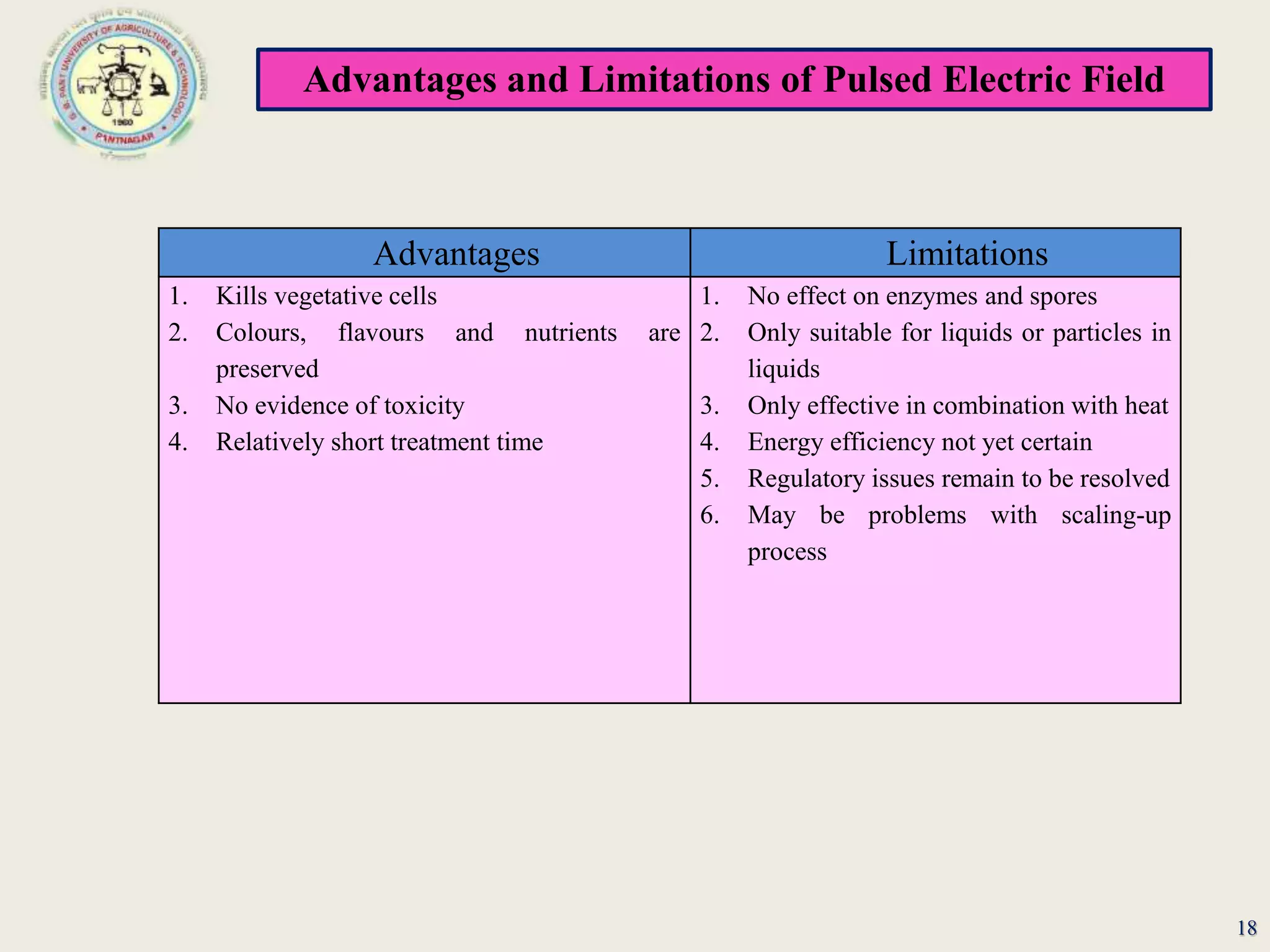

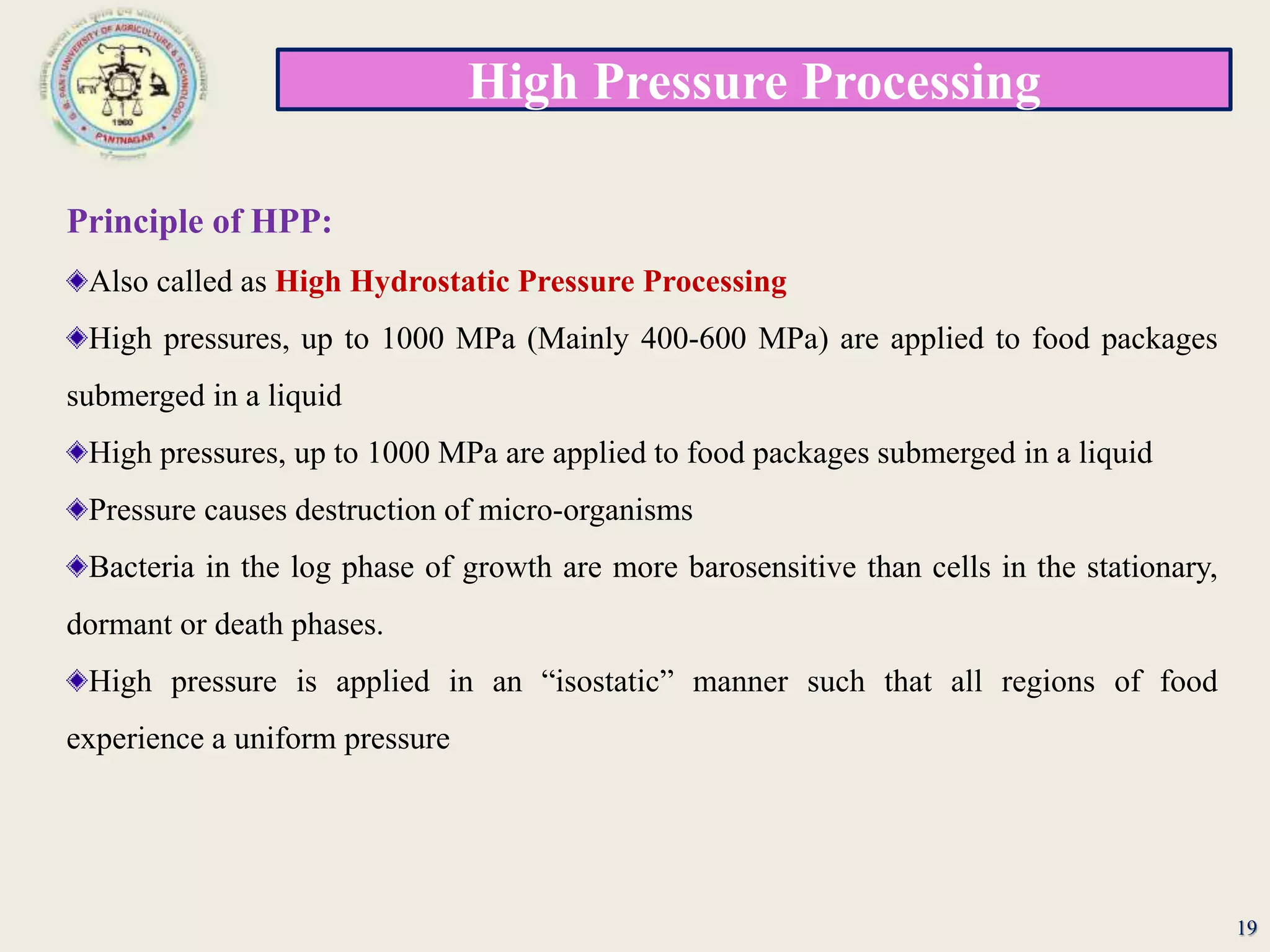

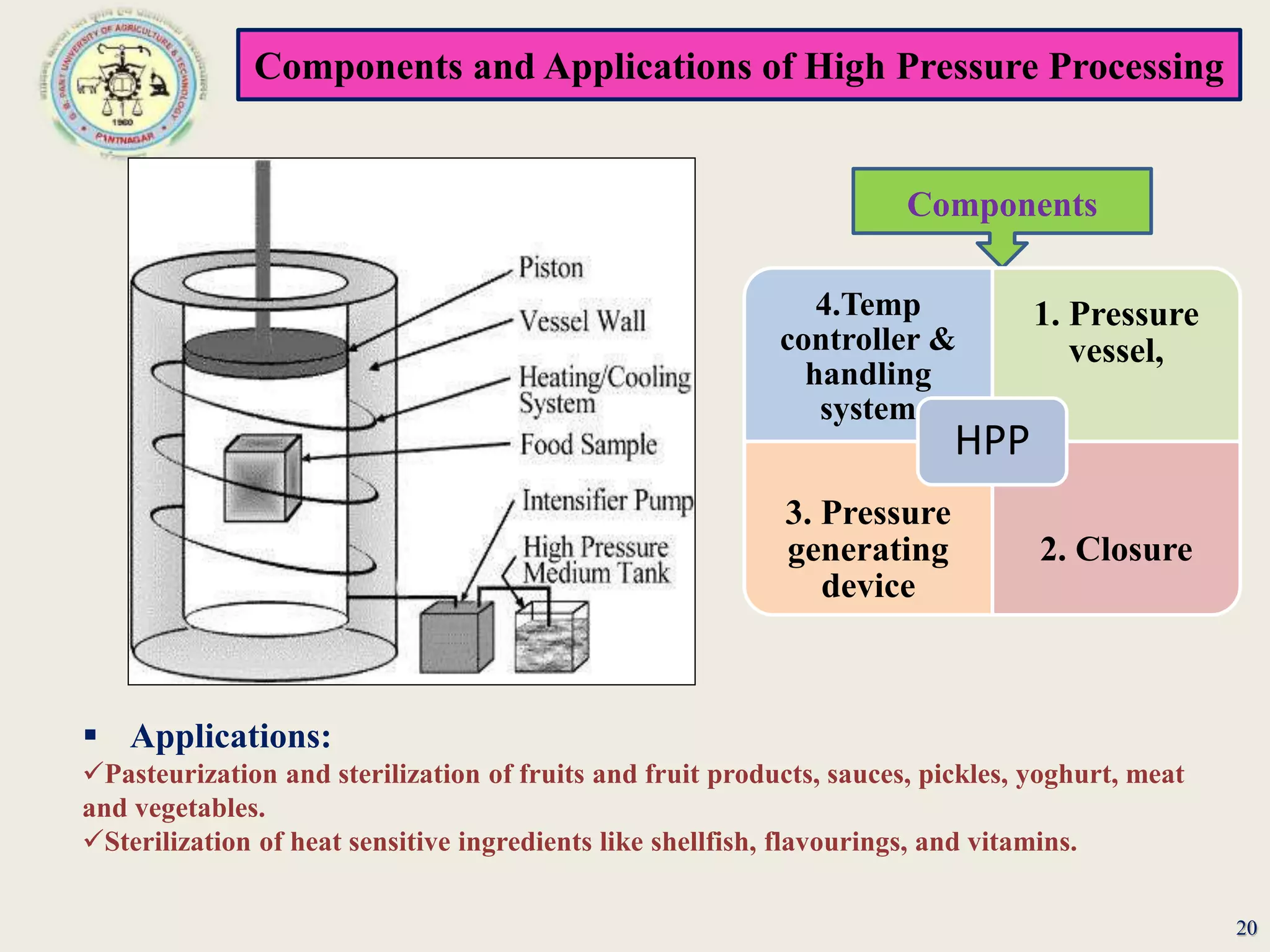

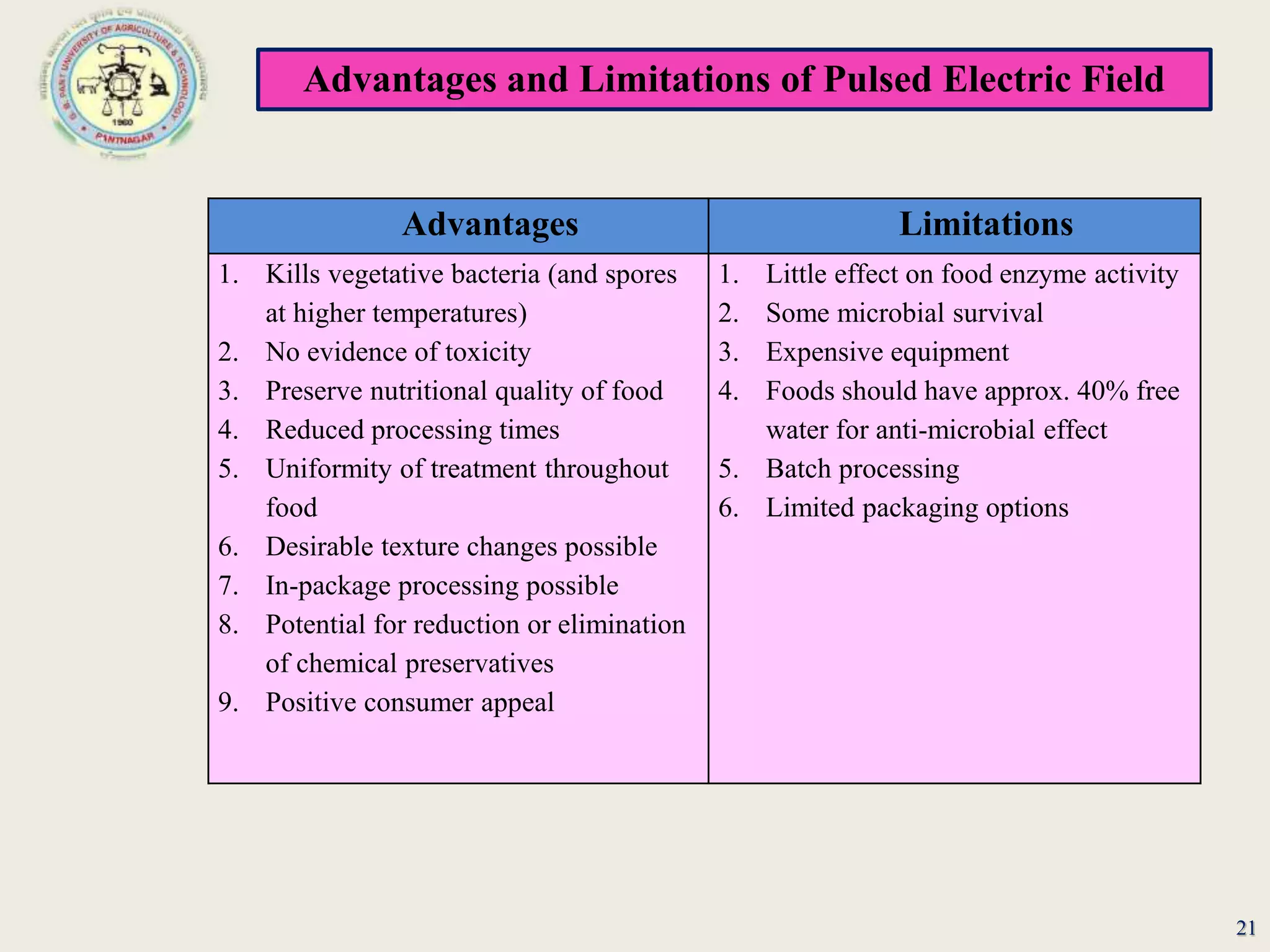

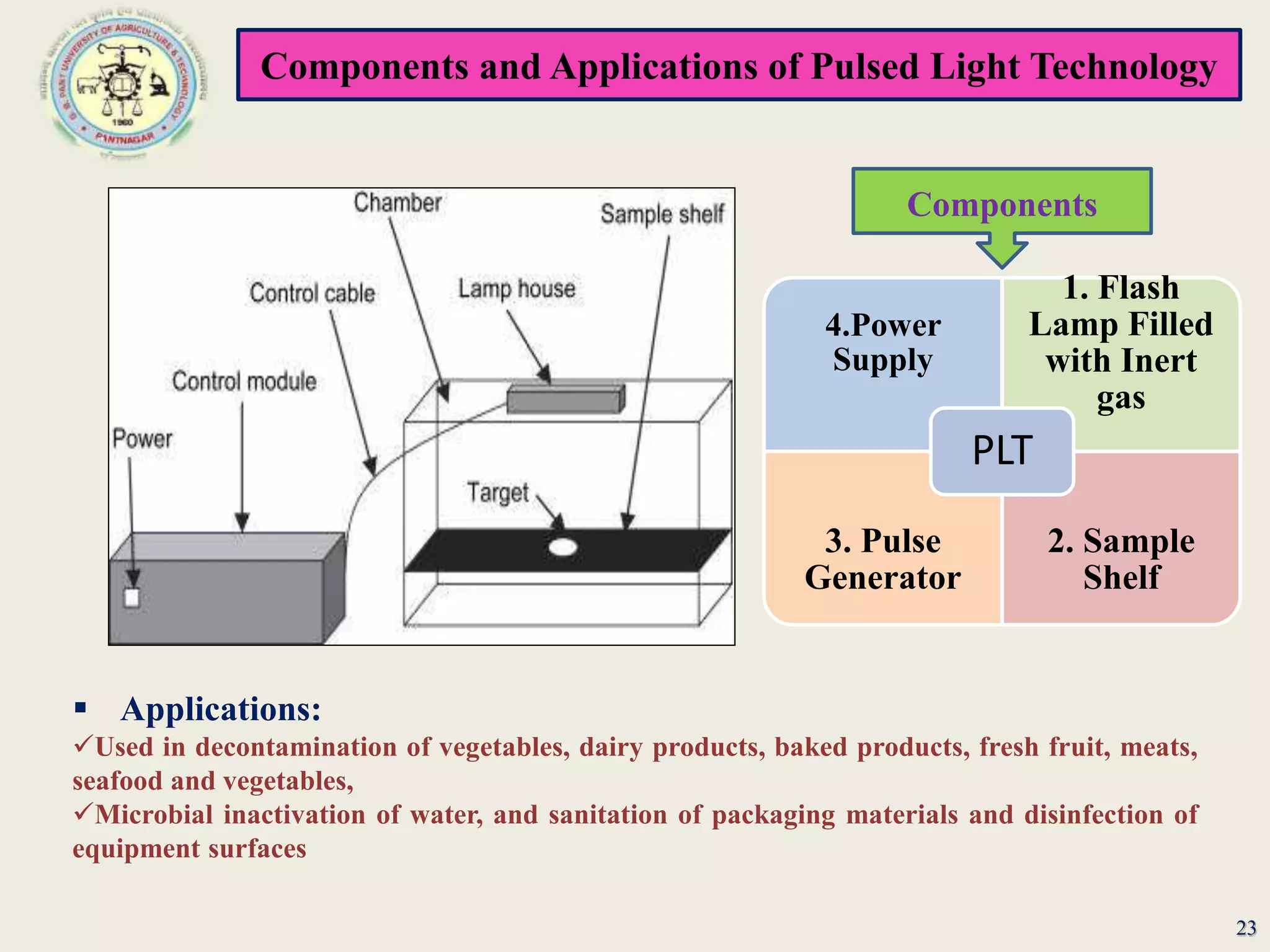

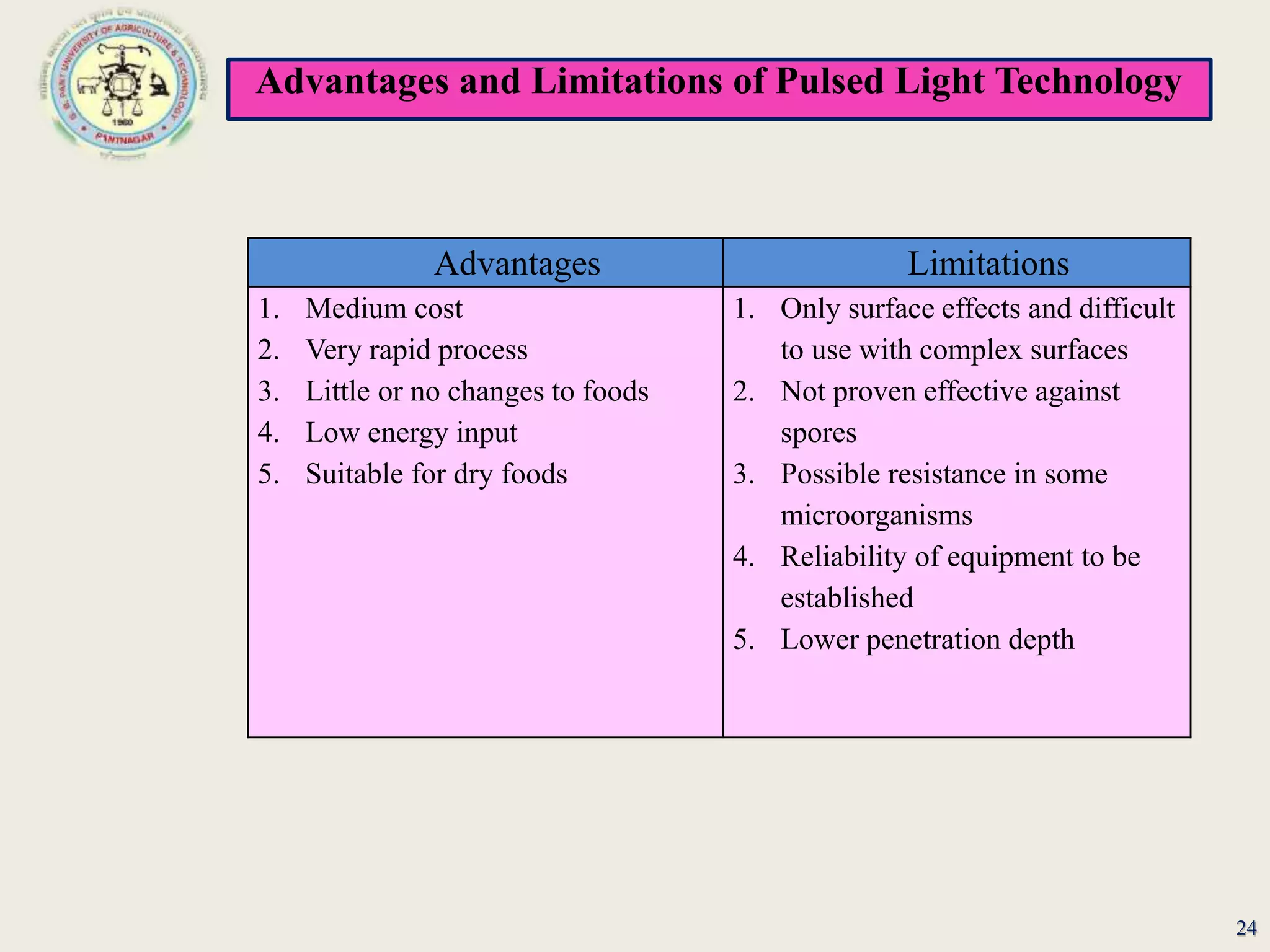

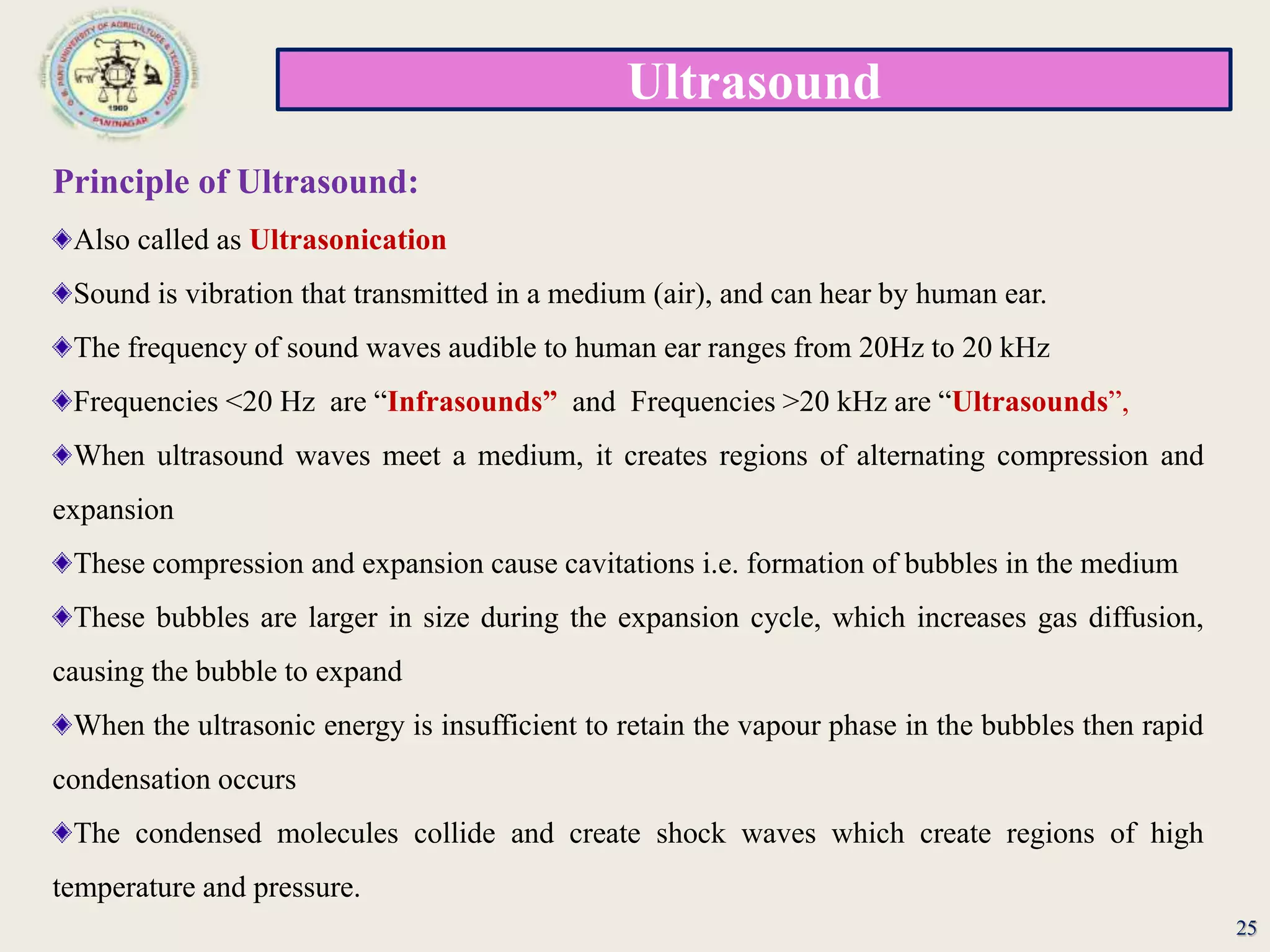

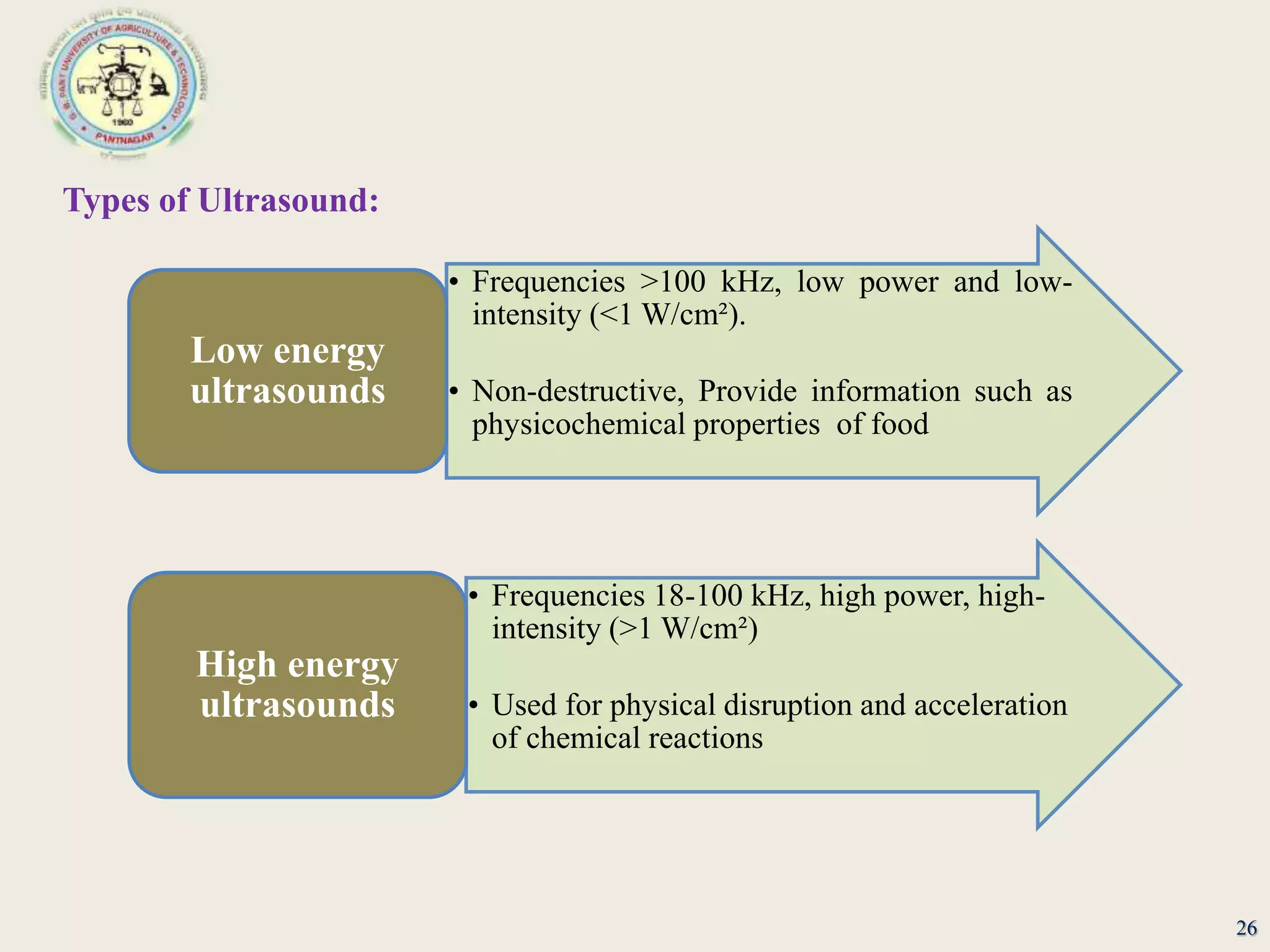

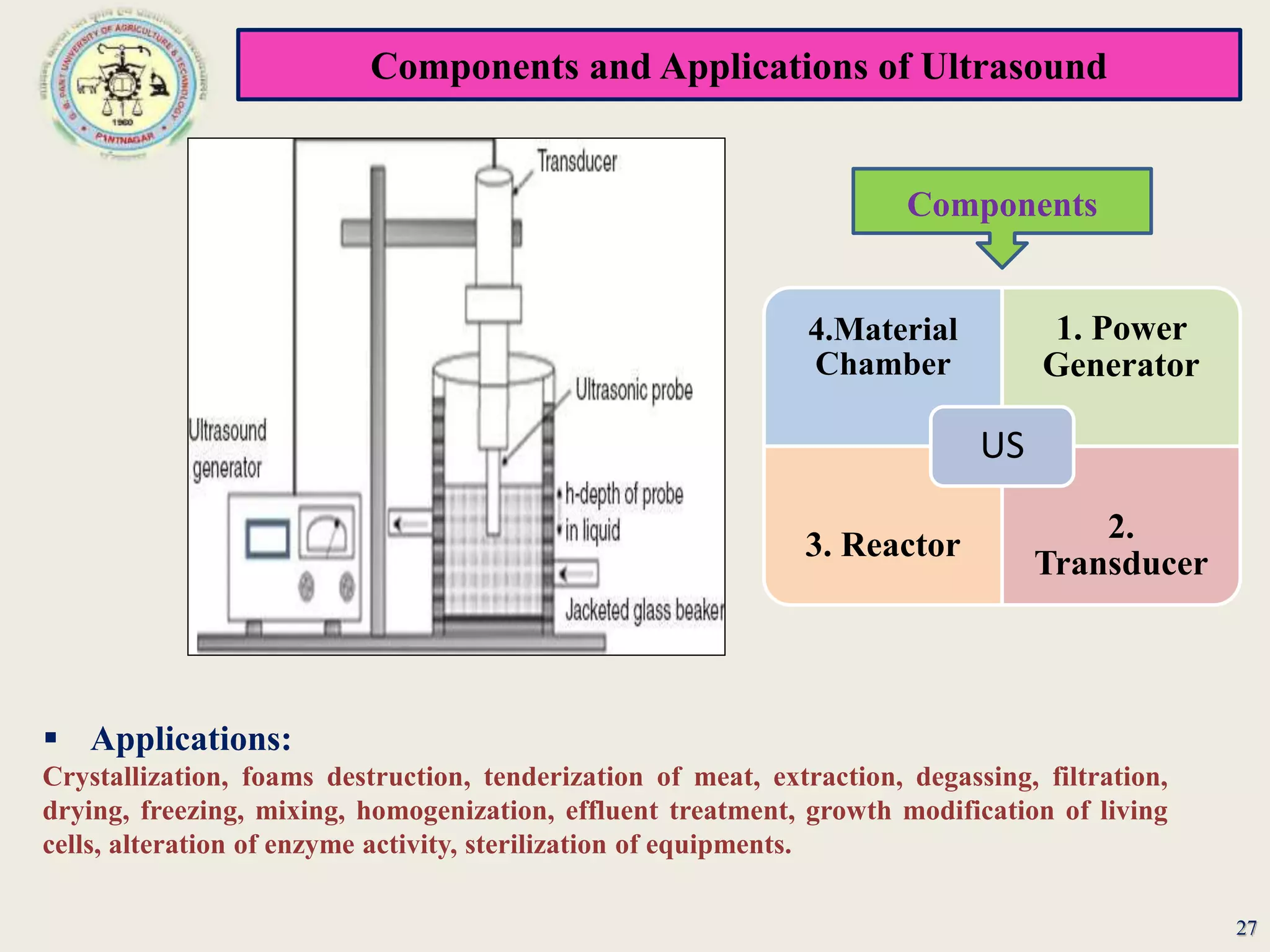

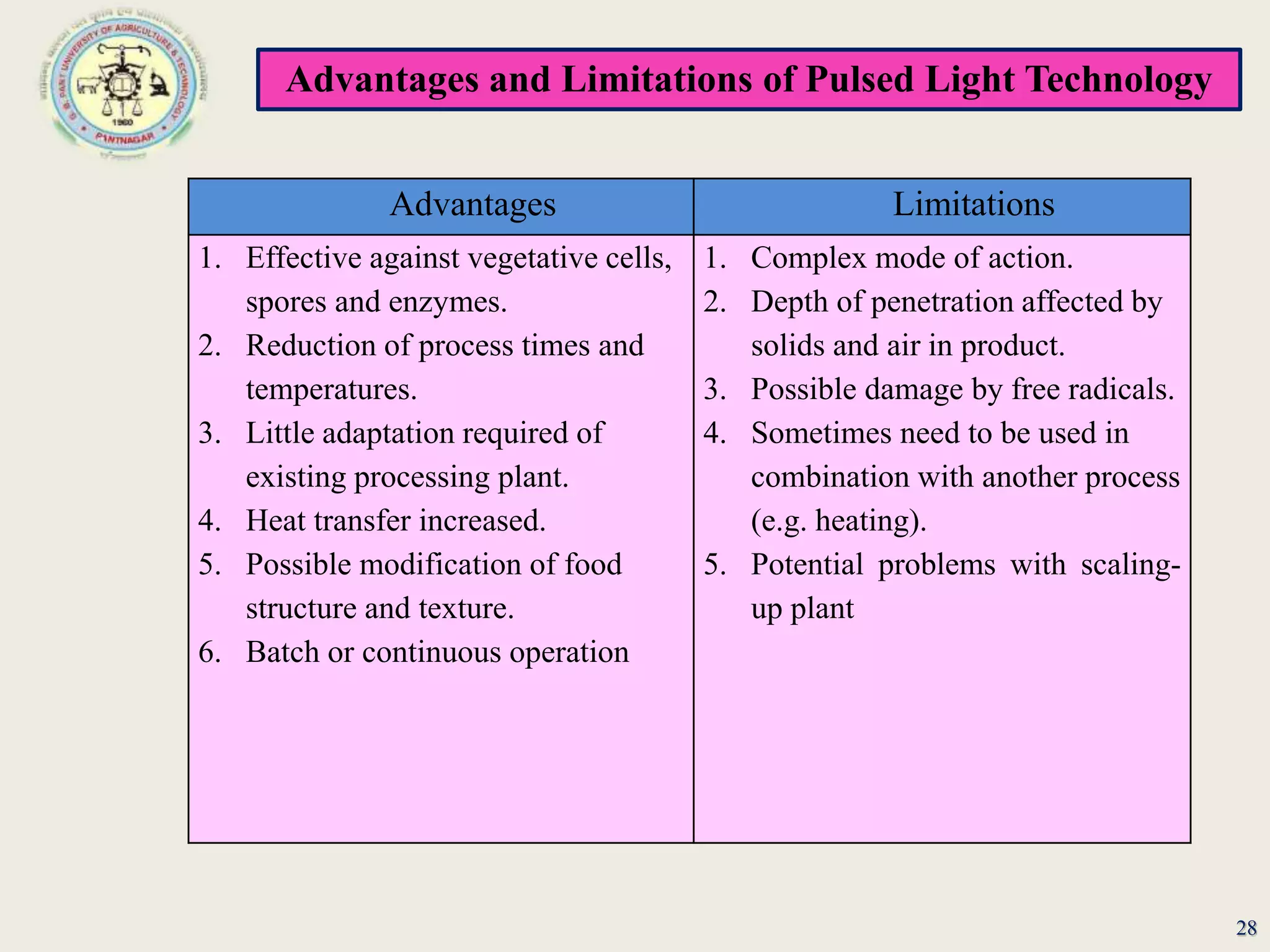

The document discusses emerging food processing technologies that can help reduce post-harvest losses of fruits and vegetables in India. It provides an overview of technologies like ohmic heating, microwave heating, pulsed electric field, high pressure processing, ultrasound, and pulsed light and explains their principles, components, applications, advantages, and limitations. These emerging technologies can help maintain the quality and safety of foods while being more energy efficient alternatives to conventional thermal processing methods.