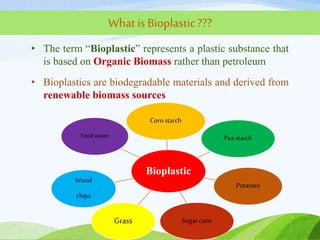

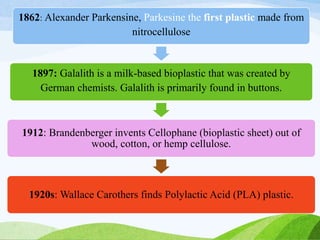

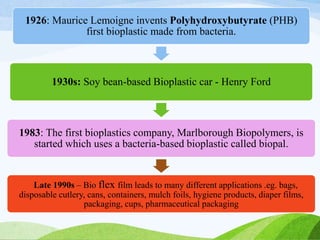

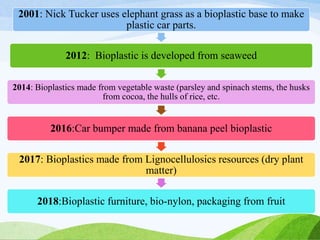

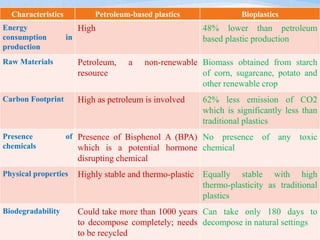

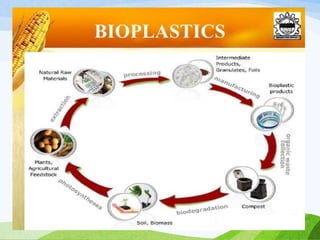

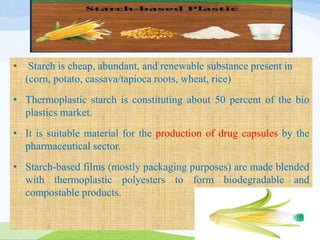

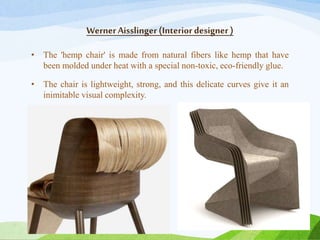

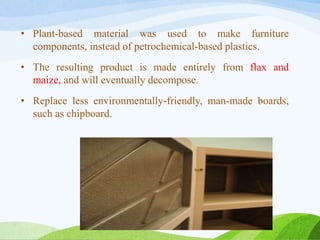

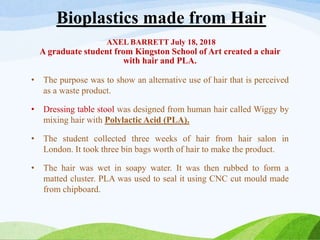

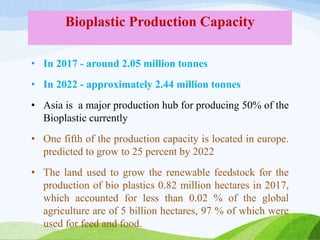

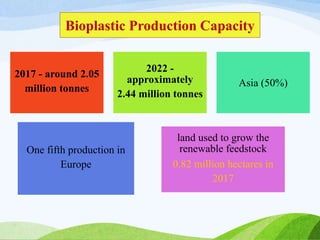

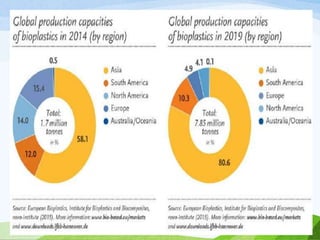

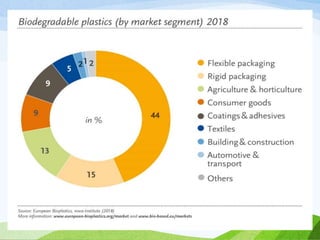

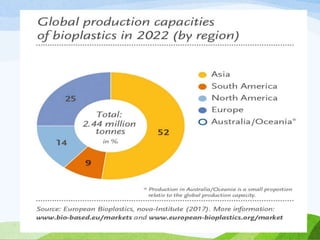

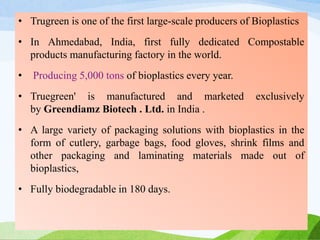

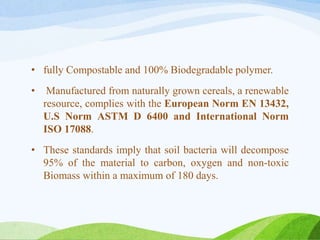

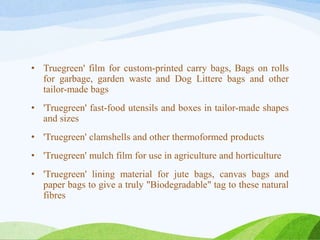

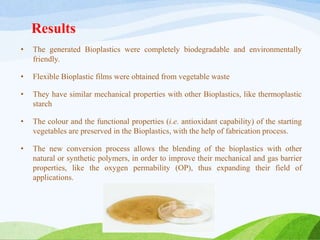

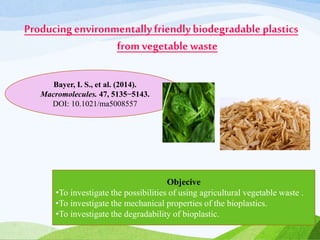

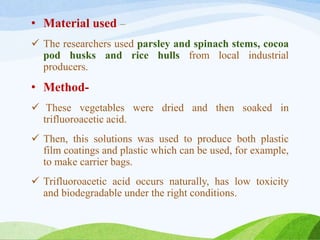

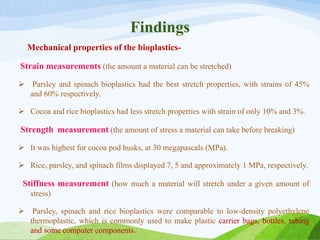

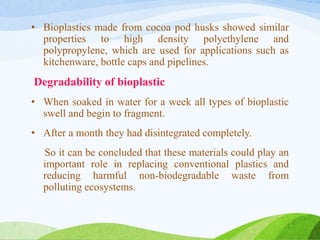

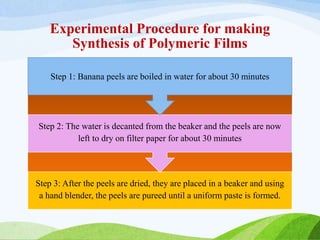

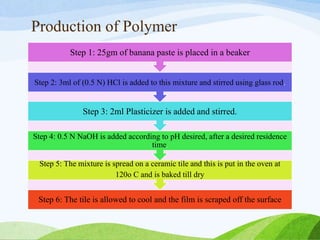

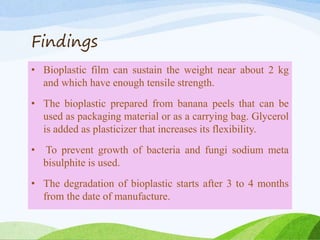

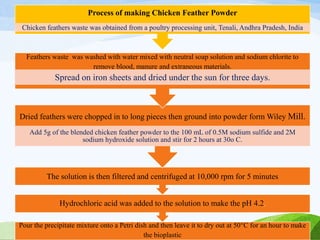

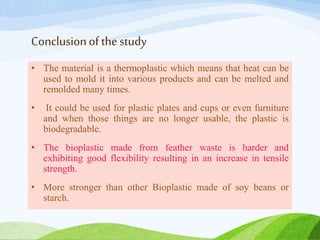

The document outlines the importance and development of bioplastics as an alternative to conventional plastics, highlighting their biodegradability and renewable biomass sources. It details the history, types, applications, and environmental impact of bioplastics while showcasing their growing market, particularly in India. The advantages include reduced greenhouse gas emissions and lower carbon footprints compared to petroleum-based plastics, although challenges related to production processes and environmental concerns are also noted.