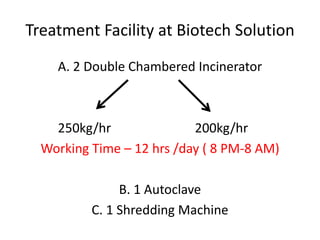

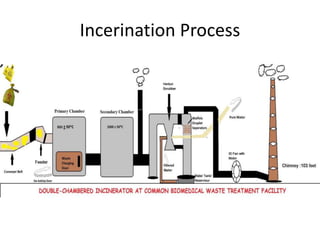

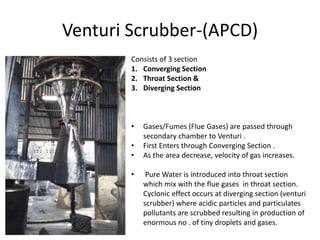

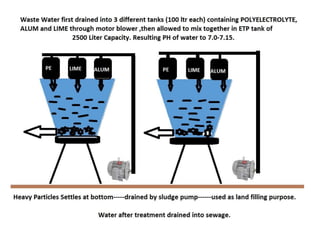

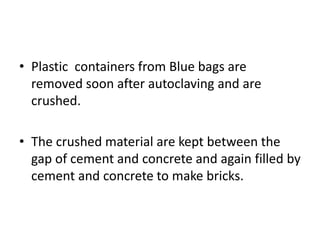

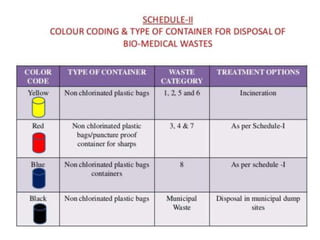

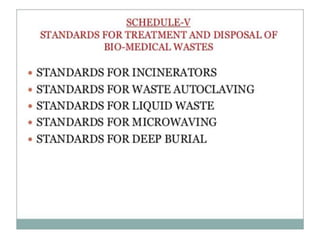

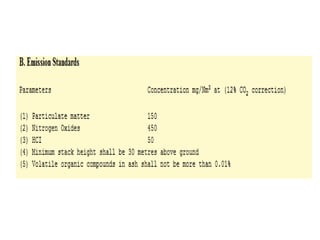

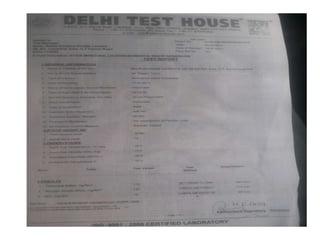

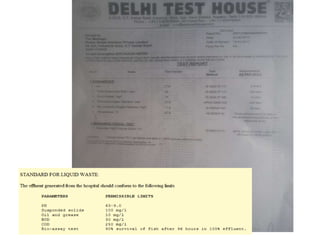

The document summarizes the common biomedical waste treatment process at BIOTIC WASTE SOLUTION in Delhi, India. It discusses that the facility treats waste from around 700 hospitals totaling around 7000 beds. The waste is collected, sorted by color coding, and treated using various processes. Yellow bag waste is incinerated, while blue/red bag waste is autoclaved and shredded. The incinerated ash and treated water undergo further processing before safe disposal. The facility aims to safely and effectively treat the biomedical waste generated at large healthcare centers in the region.