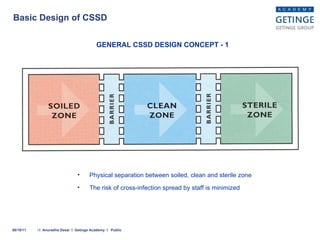

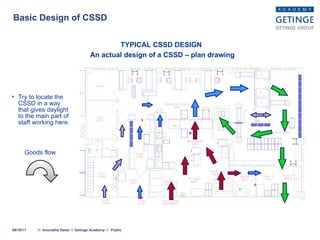

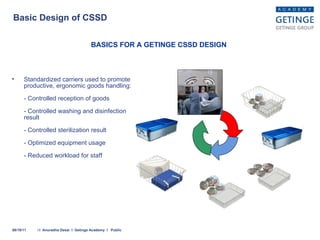

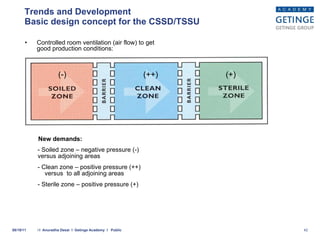

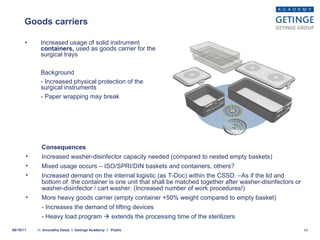

The document discusses trends in central sterile supply department (CSSD) design and operations. Key points include a movement toward larger, centralized "super CSSDs" to improve efficiency. New equipment allows for faster reprocessing times and integrated drying. There is also a trend toward more automated equipment and standardized carriers to streamline goods handling. Centralization and automation aim to reduce costs while improving ergonomics and the working environment.