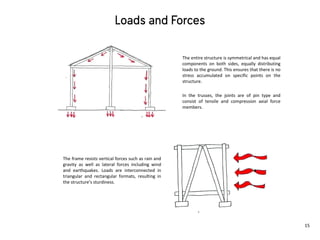

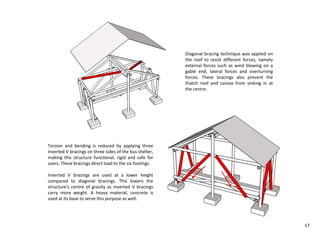

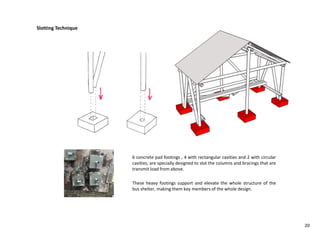

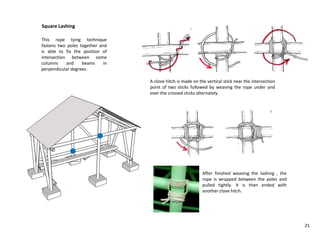

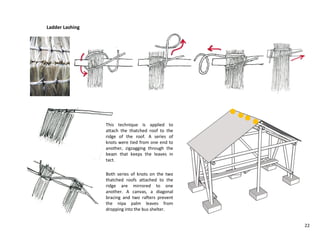

This document discusses the design process of a 1:5 scale model of a bamboo bus shelter. It describes the evolution of the design through several iterations to improve structural stability and accommodate user needs. The final design utilizes bamboo, bracings, and a thatched roof to create a simple yet efficient structure. Joints and connections are detailed, along with how they distribute loads to make the shelter resistant to various forces. Construction of the model is also outlined.