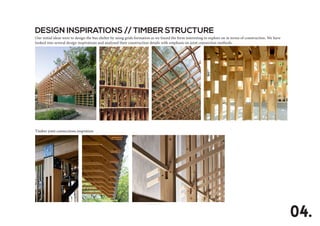

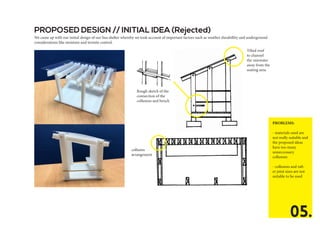

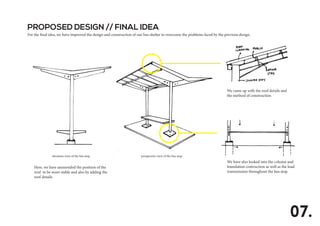

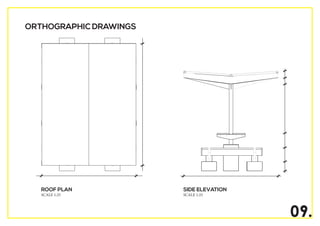

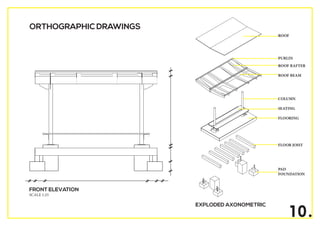

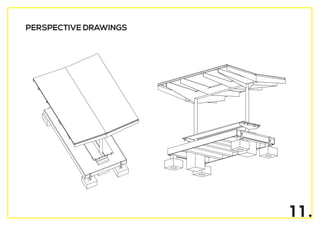

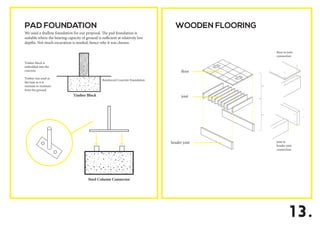

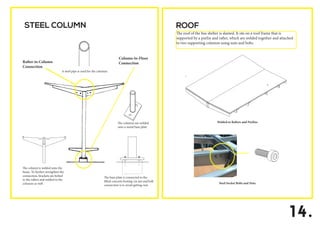

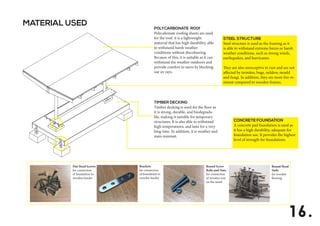

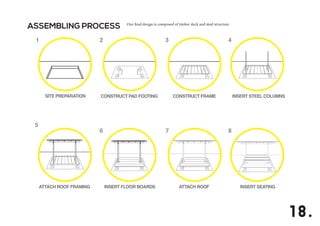

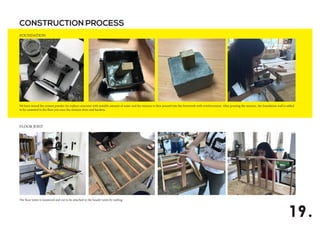

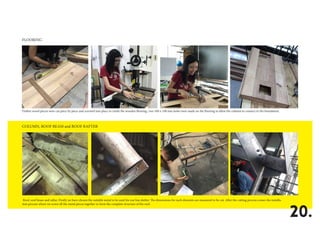

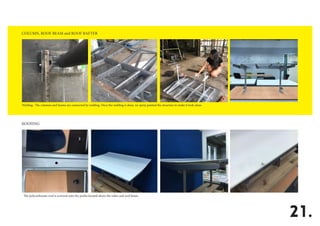

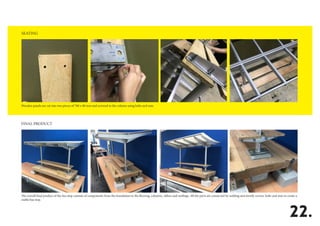

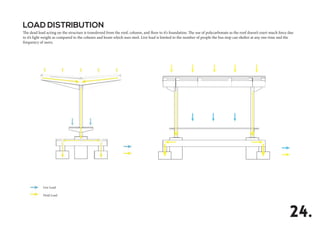

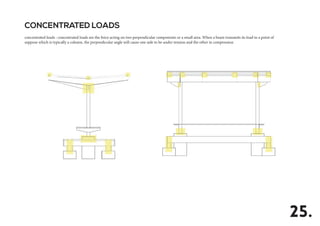

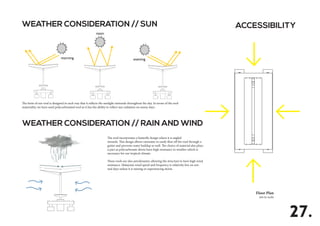

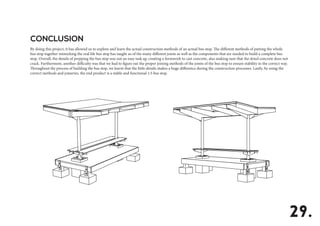

The document describes a student group project to design and construct a 1:5 scale model of a temporary bus shelter. It includes sections on design process, technical drawings, construction details, material selection, construction process, force analysis, and accessibility considerations. The group's final design uses a steel frame structure with a timber deck floor and polycarbonate roof. Key joints include a pad foundation, floor joist connections, and welded column-beam connections. The construction process is documented, highlighting the foundation pouring, floor assembly, and roof installation. Force analysis examines load distribution and concentrated loads. Weather resistance and sun orientation are also addressed.