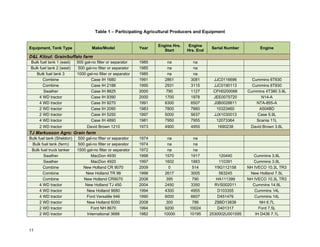

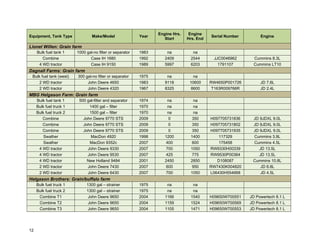

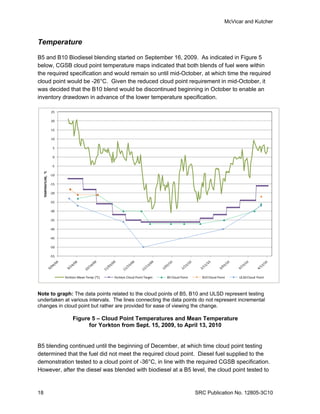

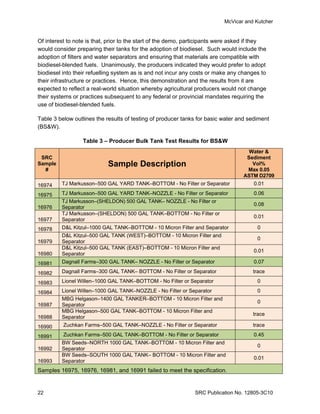

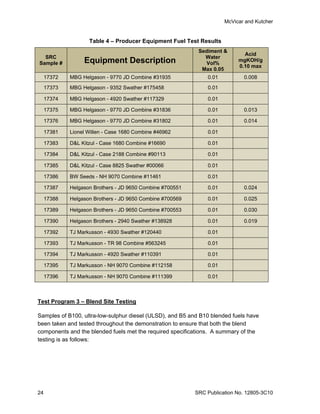

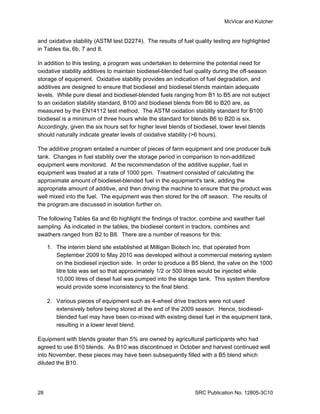

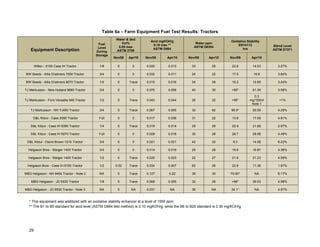

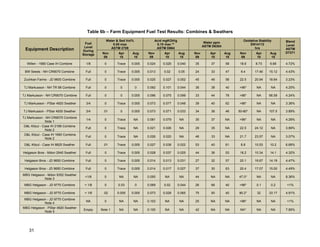

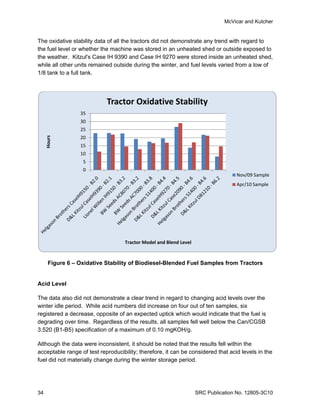

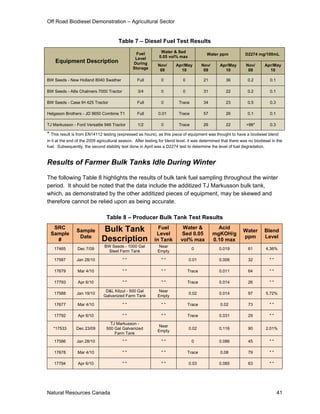

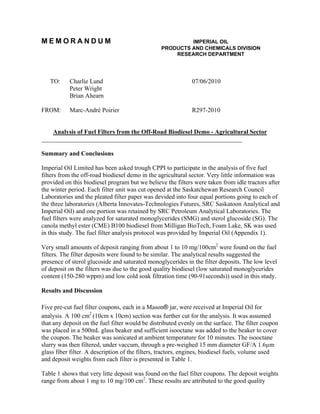

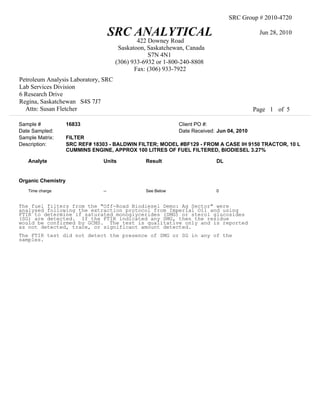

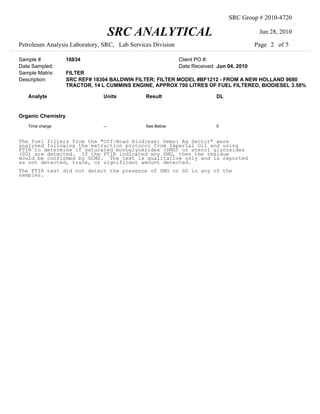

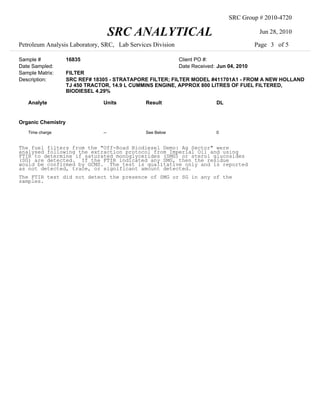

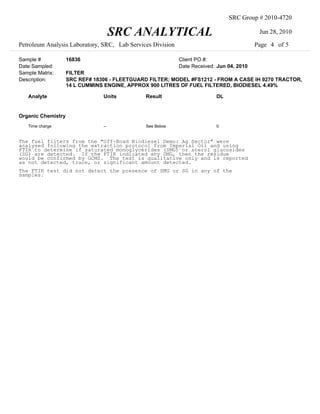

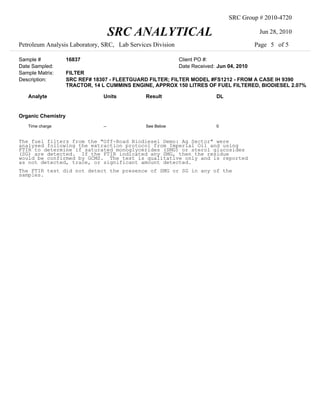

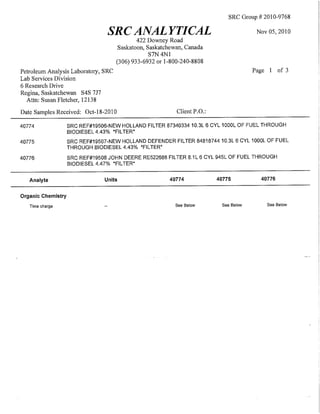

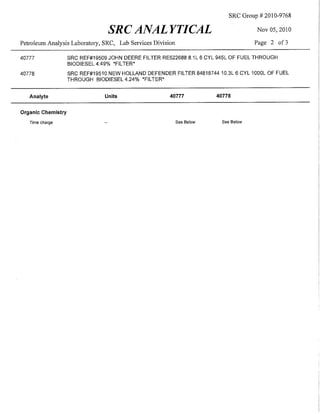

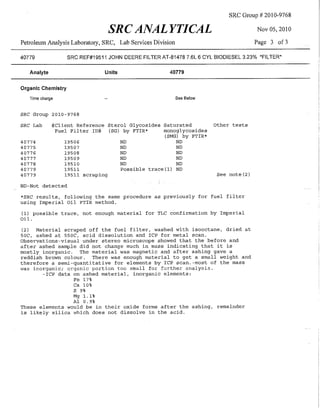

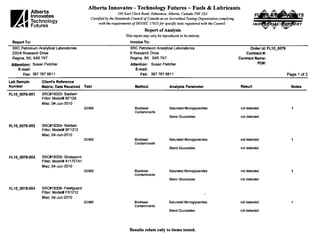

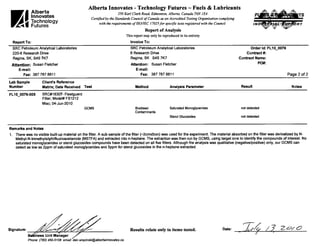

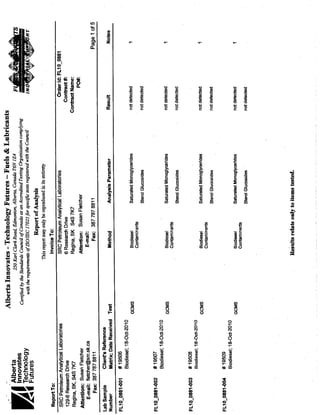

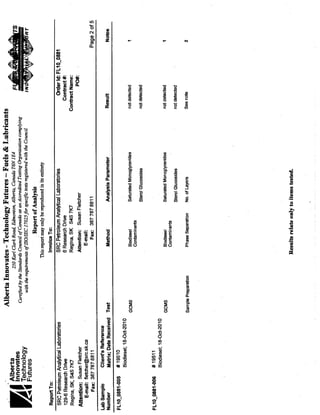

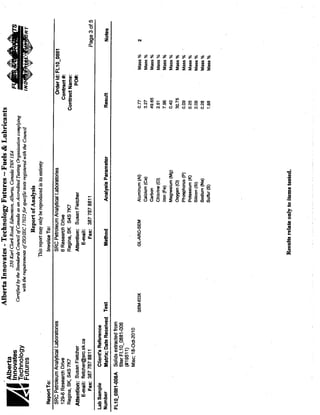

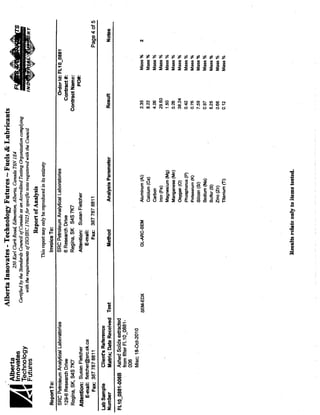

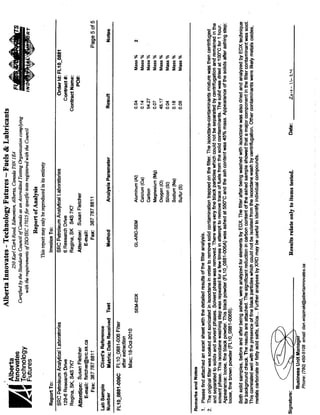

The document presents the findings of an agricultural off-road biodiesel demonstration project in Saskatchewan. It evaluates the use of biodiesel blends (B5-B20) in agricultural tractors and equipment. Fuel was sampled from producer bulk tanks and equipment fuel tanks at various farms. Testing evaluated fuel quality parameters such as oxidation stability, acid levels, and water content. Results showed biodiesel blends maintained acceptable fuel quality with no operational issues reported throughout the winter demonstration period.