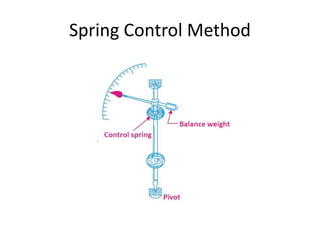

This document discusses the basic requirements of electrical instruments, including deflecting torque, controlling torque, and damping torque. Deflecting torque is produced using various effects like magnetic, electromagnetic induction, thermal, etc. and causes the pointer to move. Controlling torque opposes the deflecting torque and can be provided by spring or gravity methods. Damping torque reduces oscillations of the pointer and can be achieved through air friction, fluid friction, or eddy currents. Proper deflecting, controlling and damping torques are needed for accurate instrument operation and measurements.