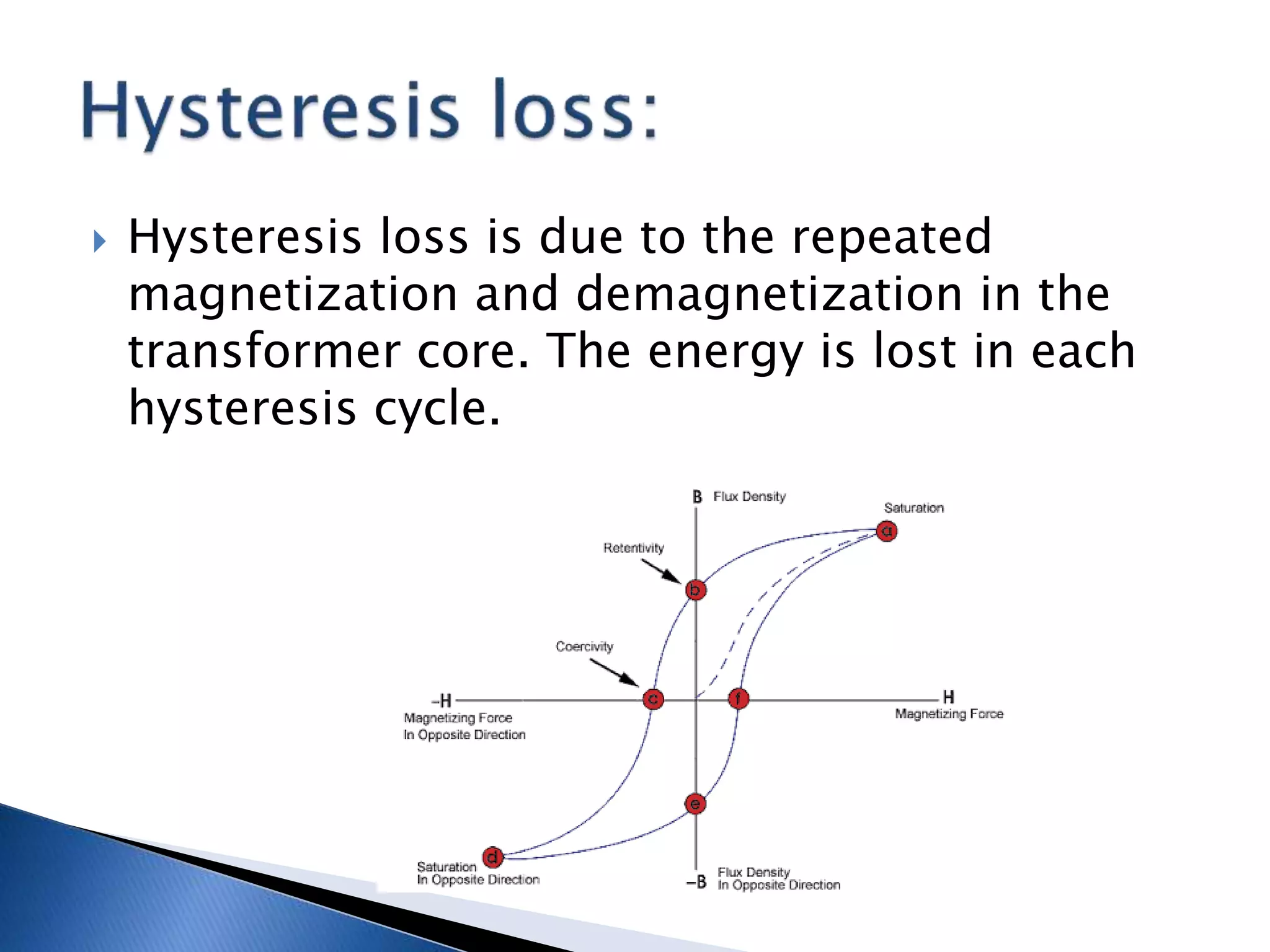

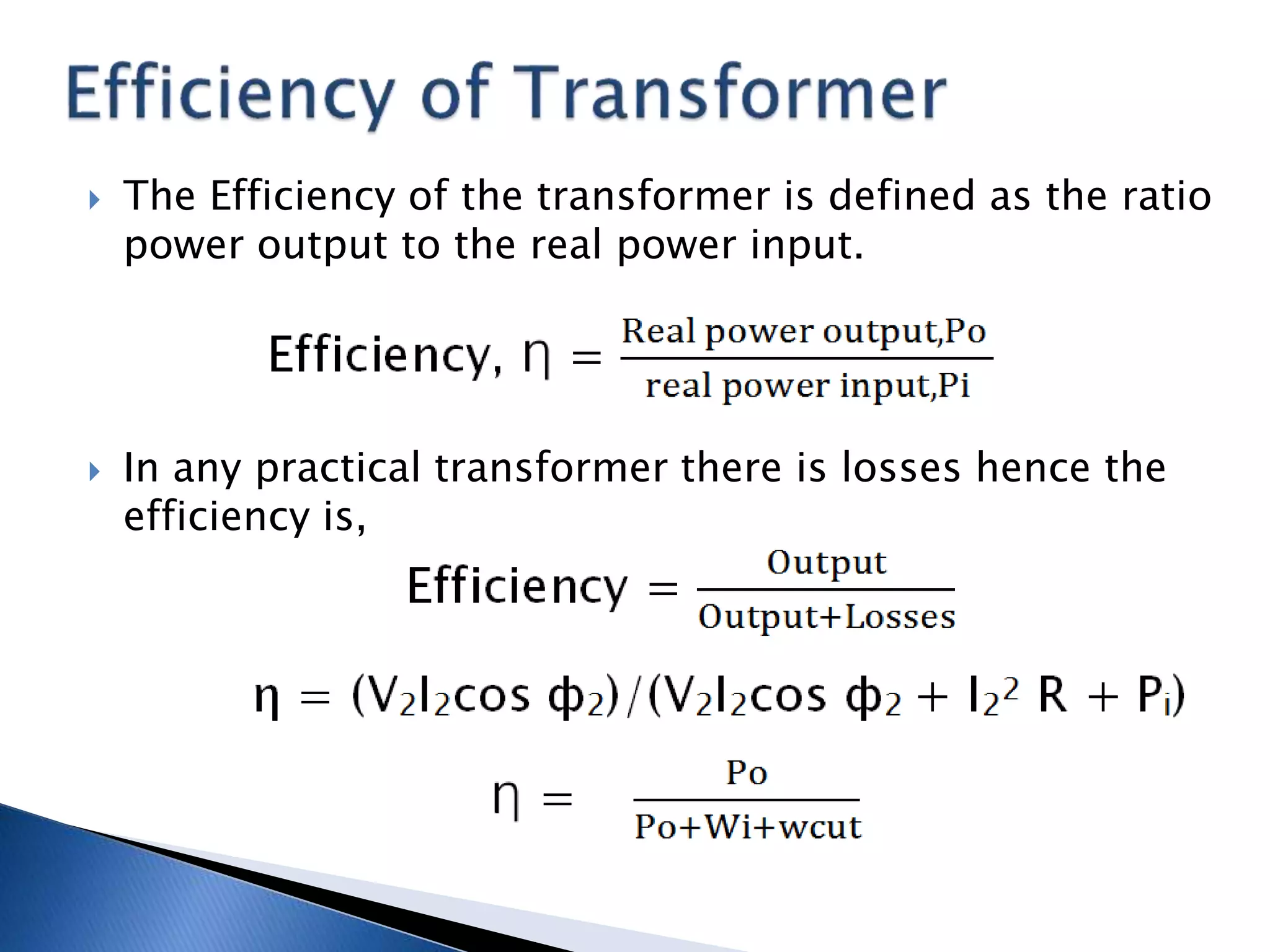

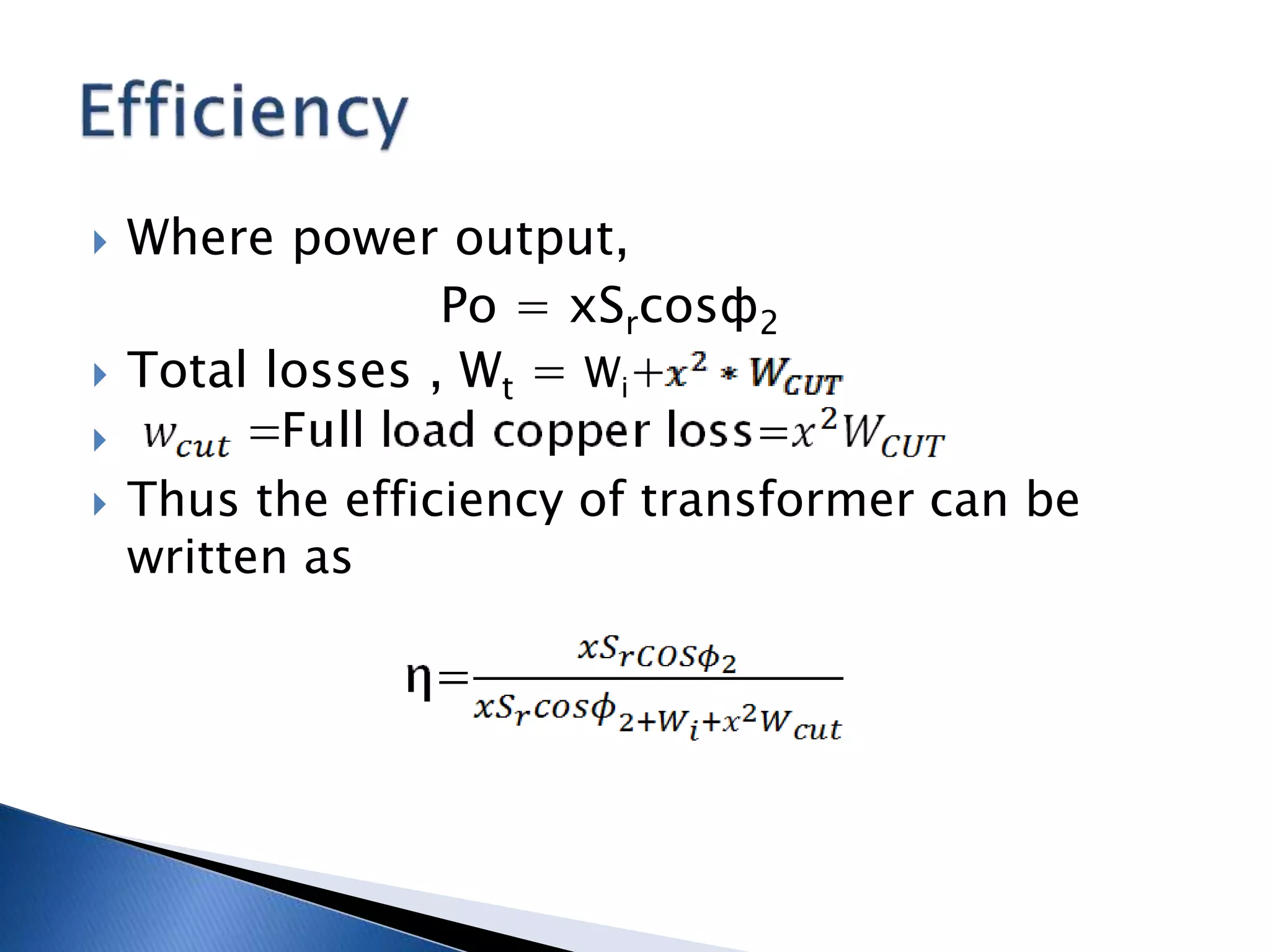

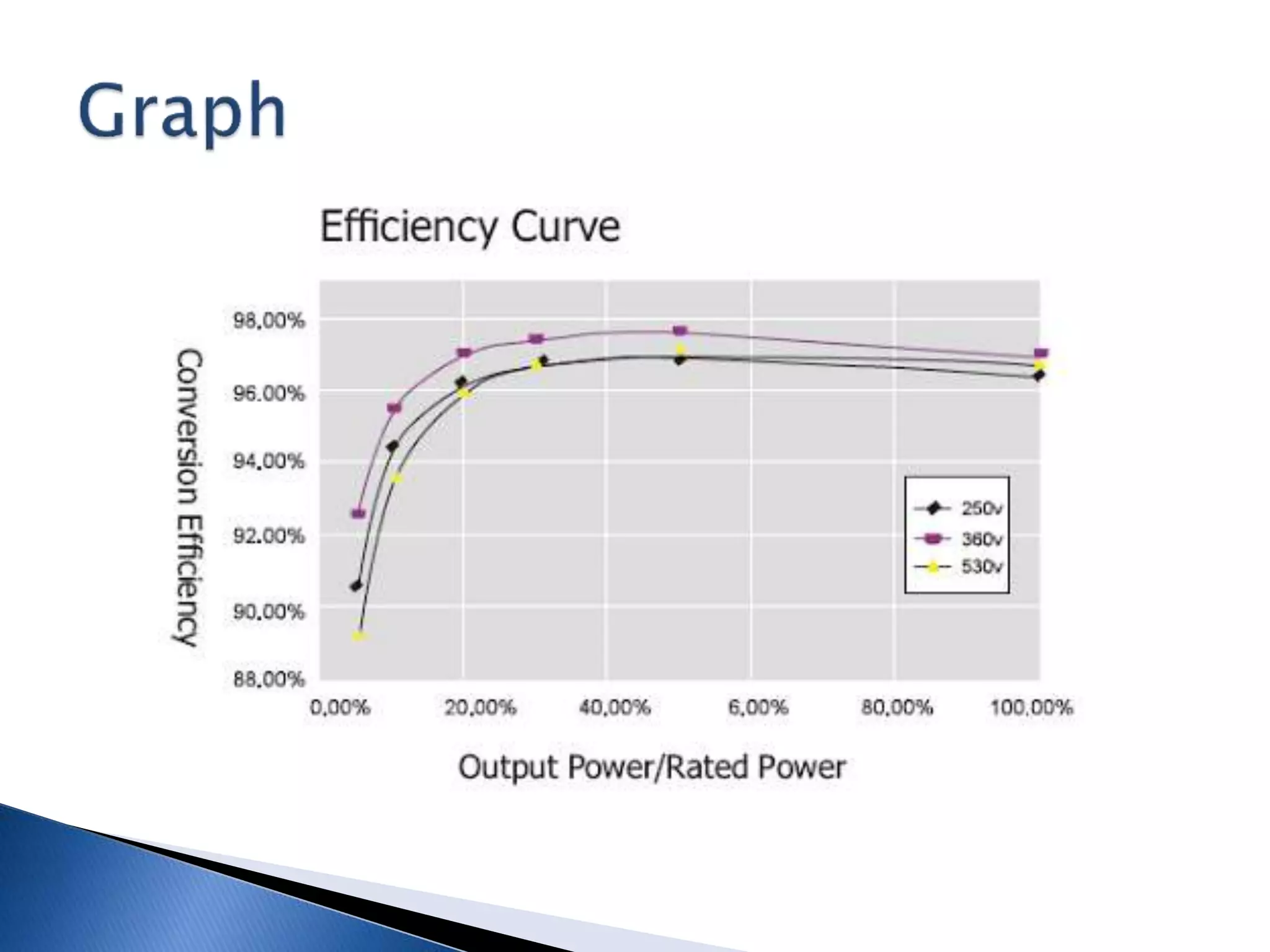

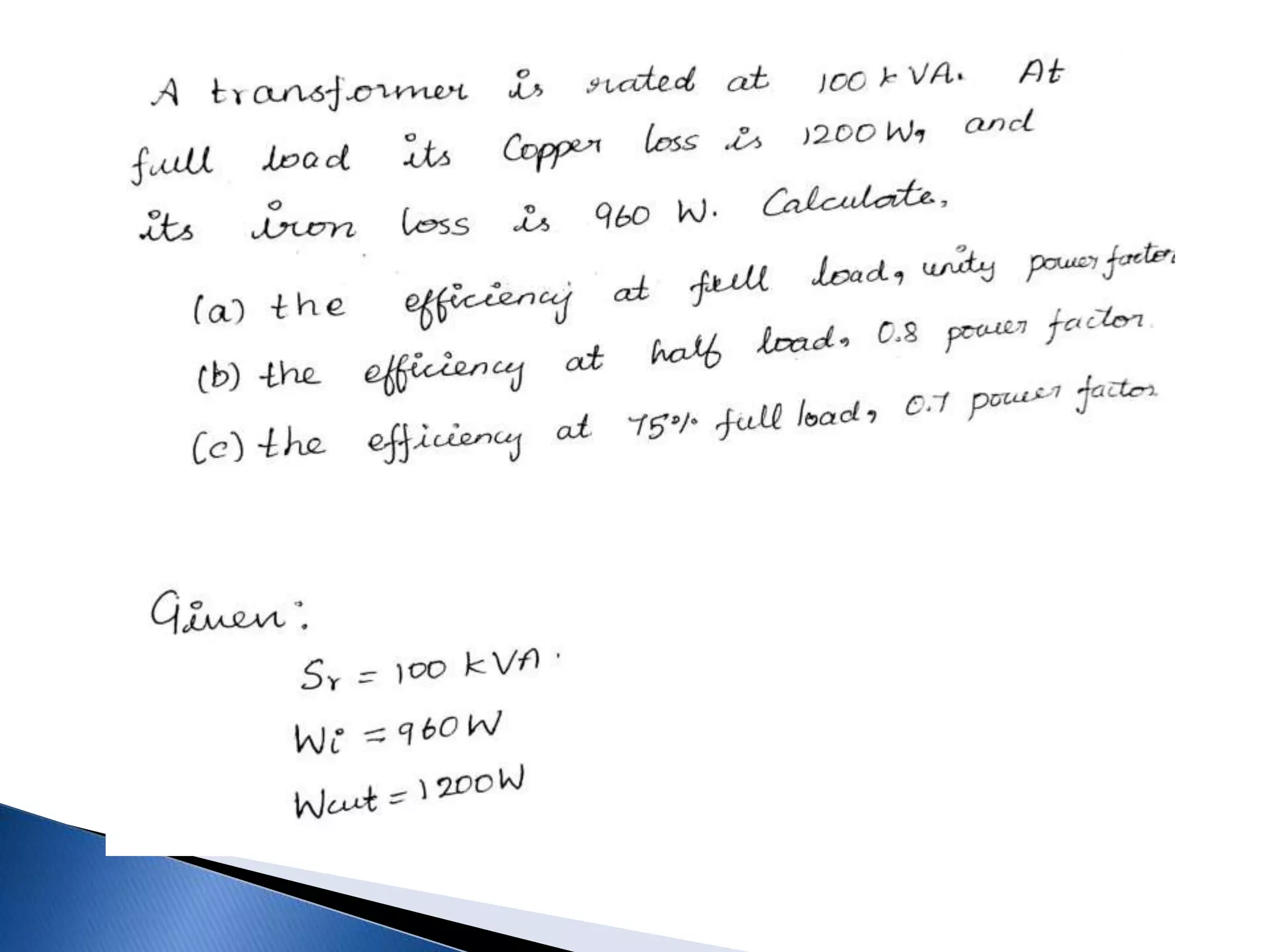

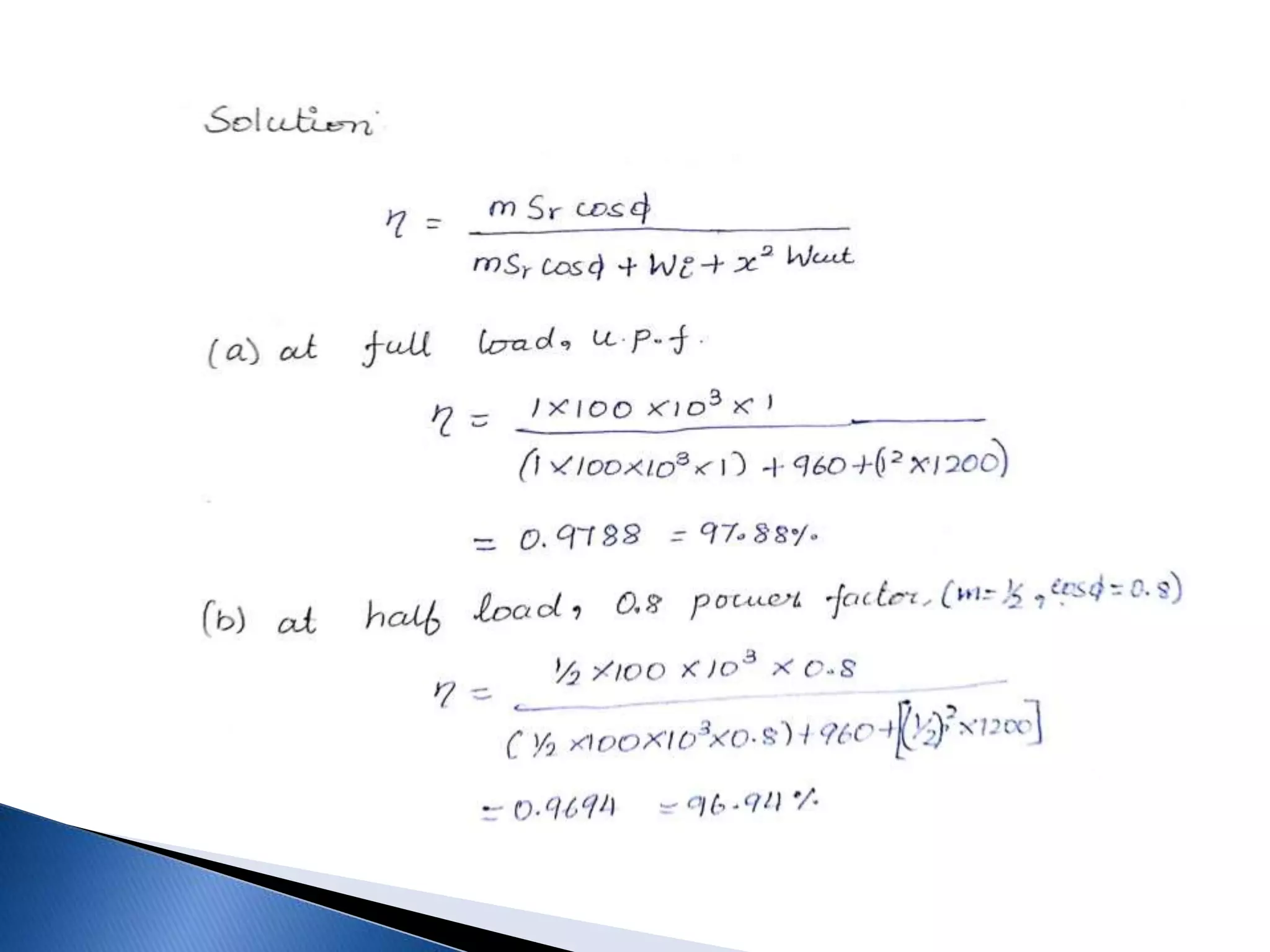

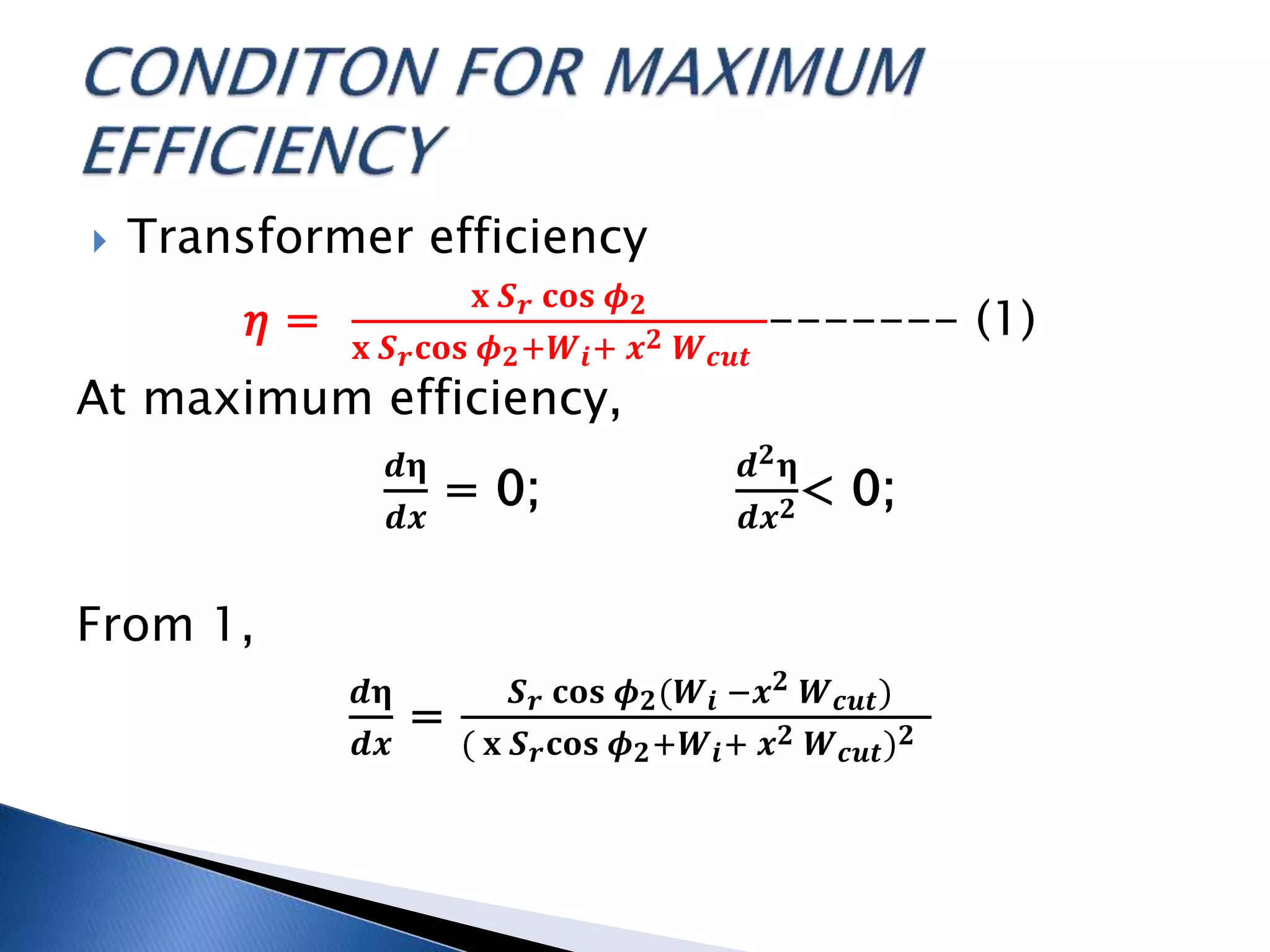

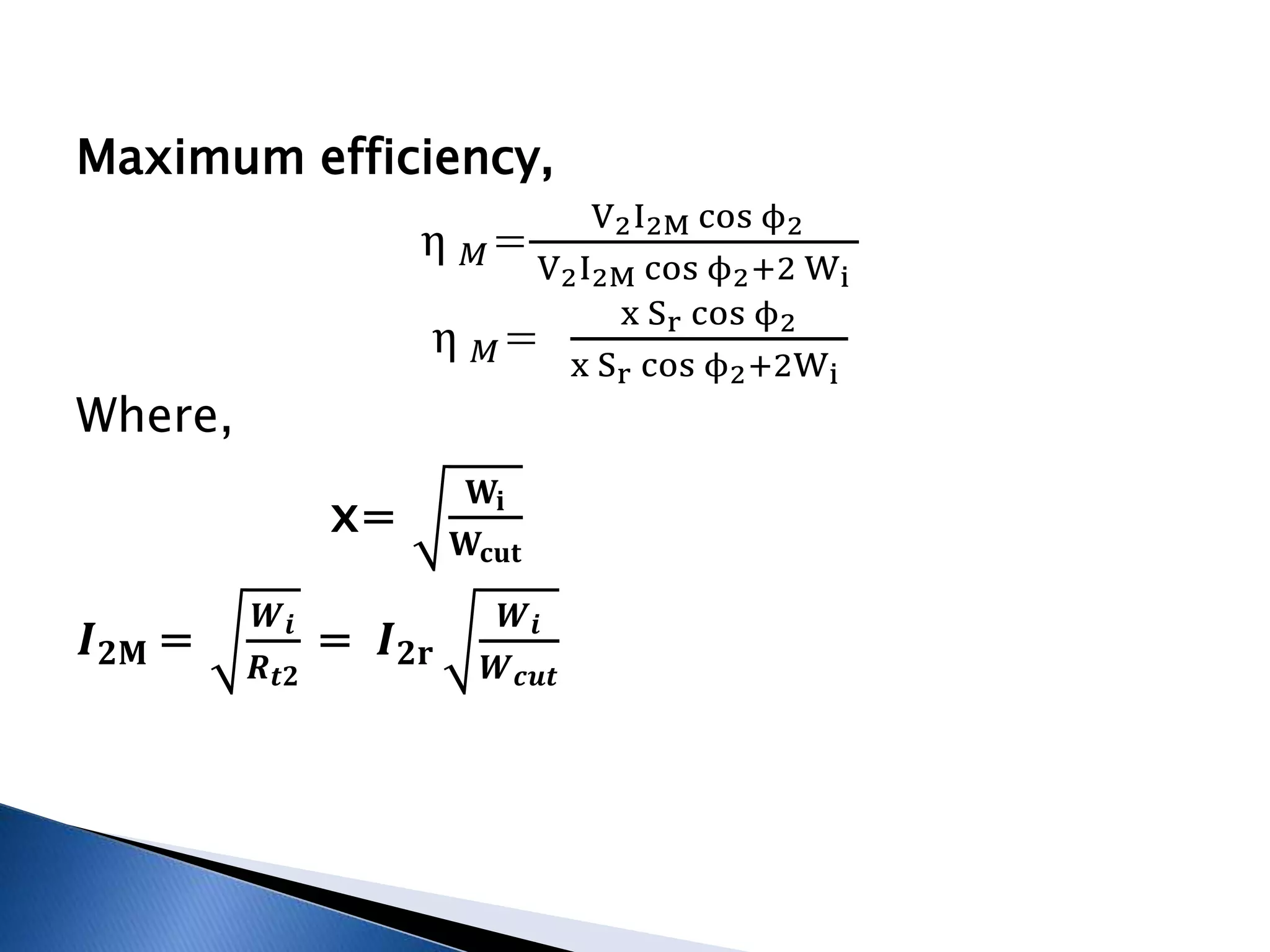

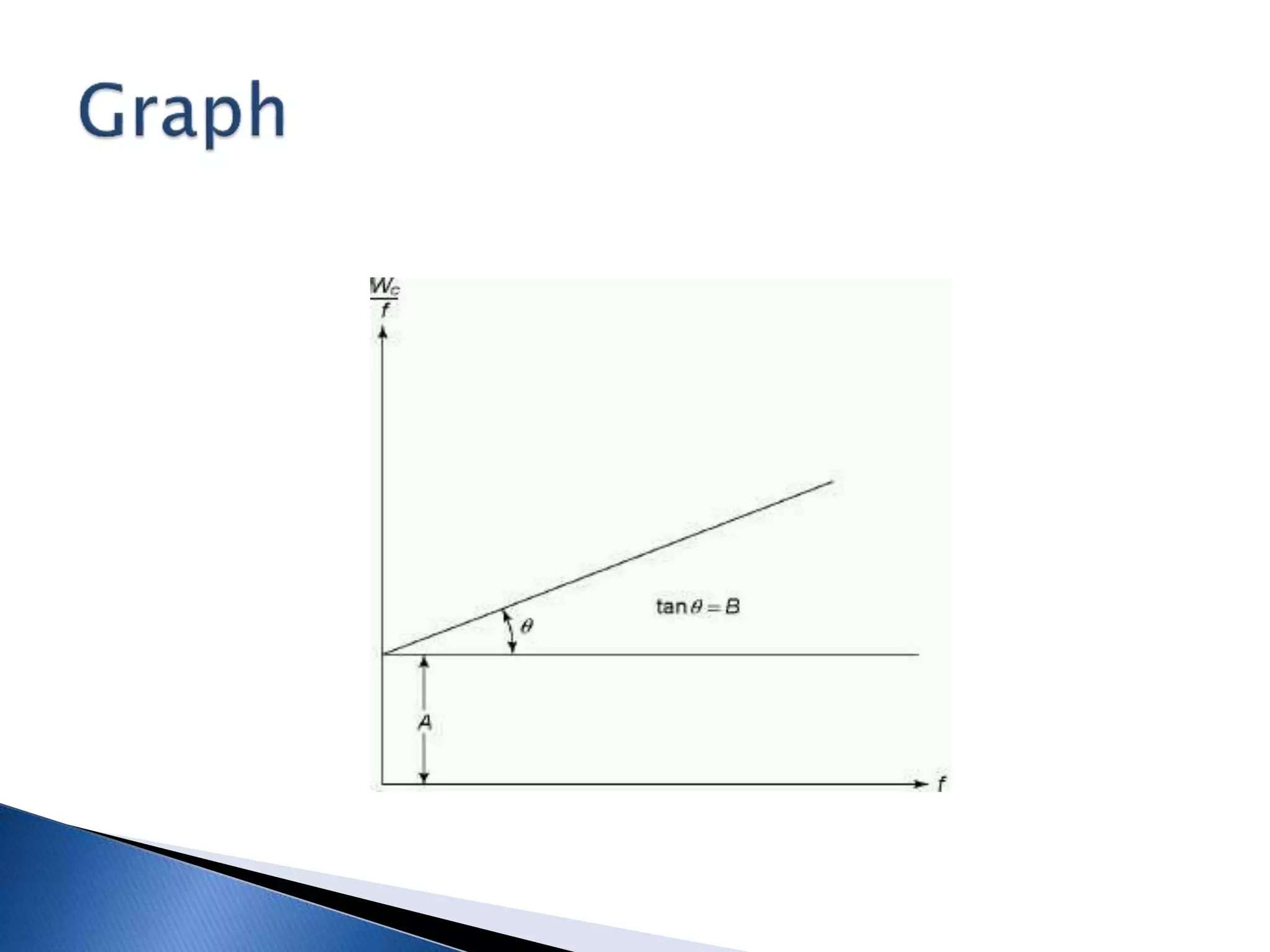

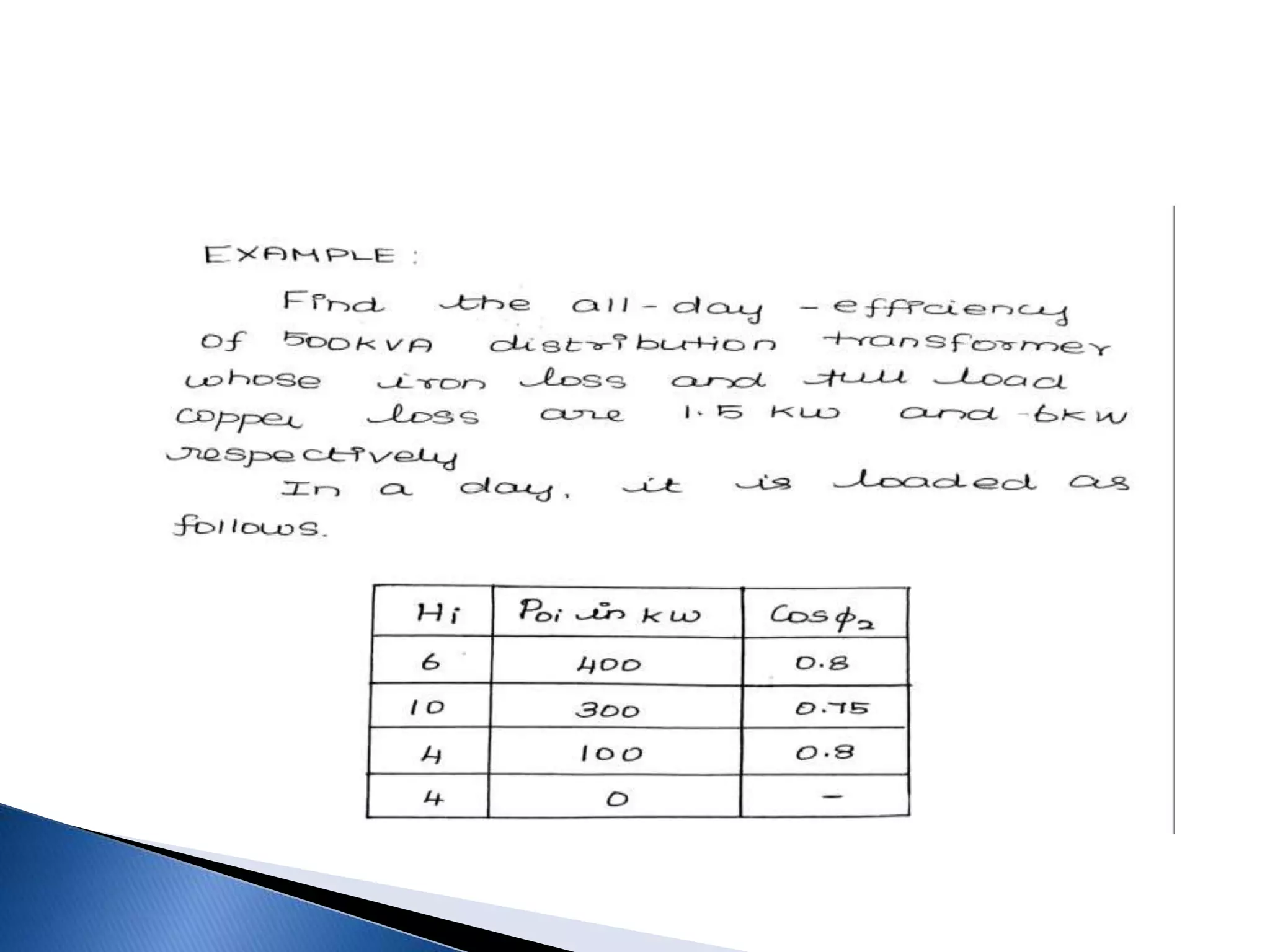

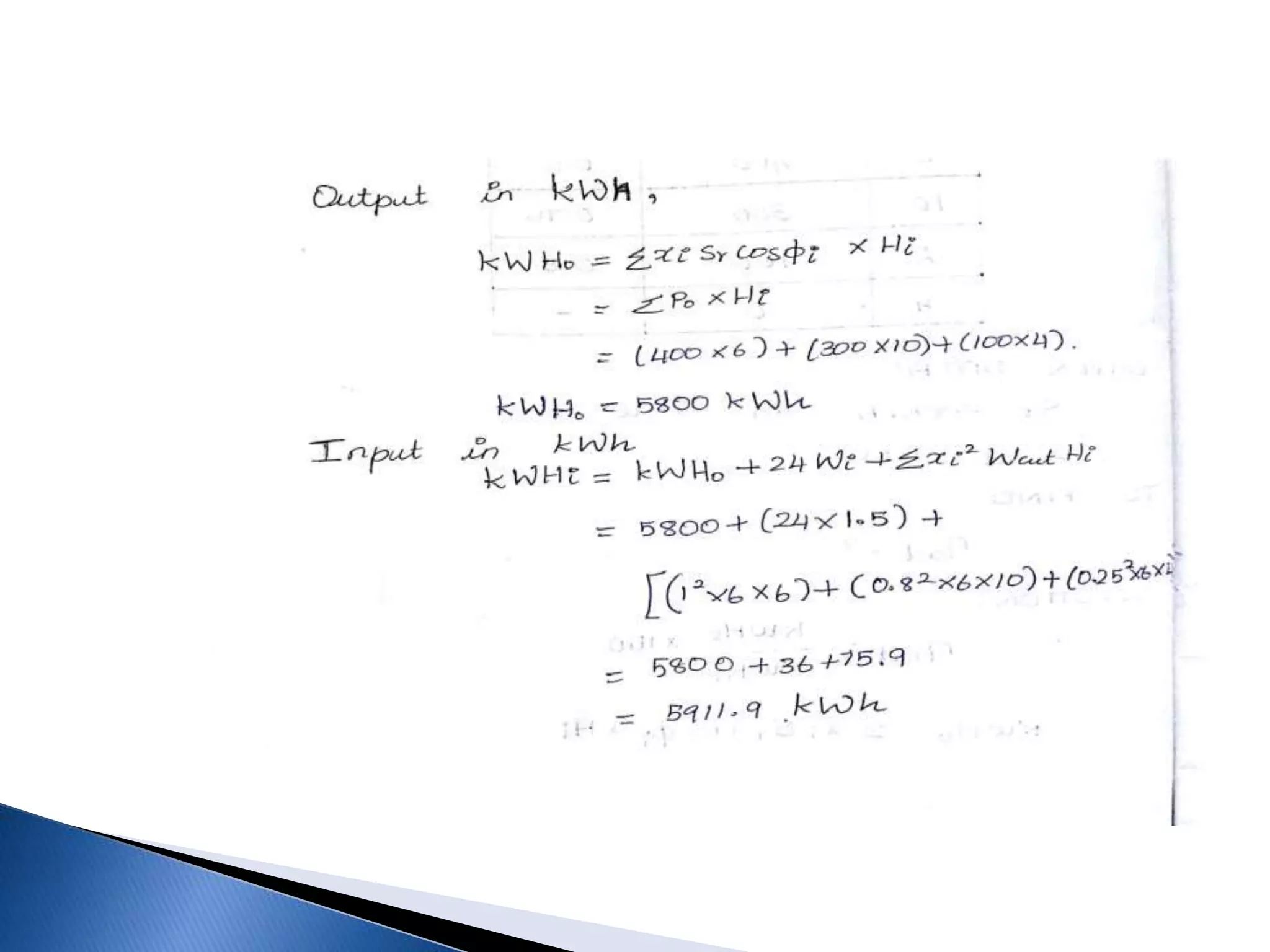

The document discusses transformer losses, including copper and iron losses, which dissipate energy primarily as heat. It outlines the conditions for maximum efficiency and describes factors affecting losses, such as eddy currents and hysteresis in the core materials. Additionally, it introduces the concept of all-day efficiency, emphasizing its importance for distribution transformers that operate under varying load conditions.