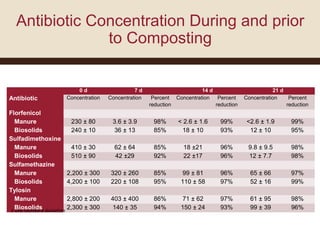

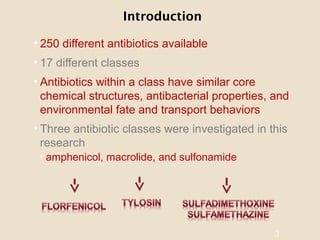

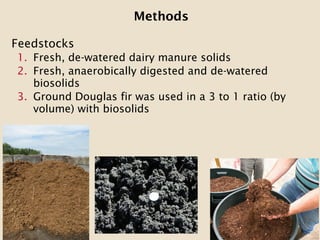

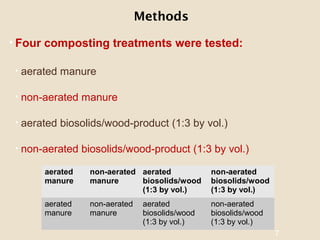

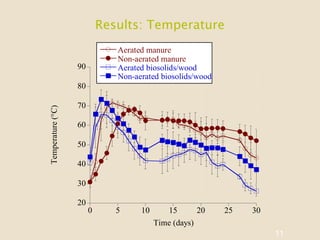

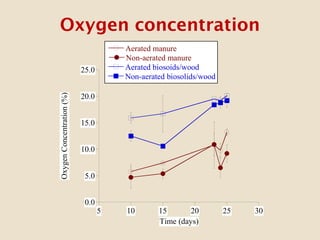

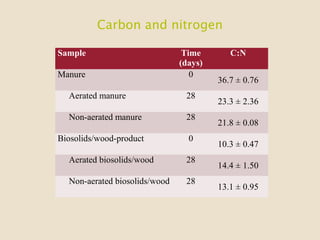

This study investigates the degradation of antibiotics during the composting of dairy manure solids and biosolids, revealing that 90-95% of antibiotics are eliminated within four weeks. Different composting treatments were tested, which showed significant reductions in concentrations of various antibiotics such as florfenicol, sulfadimethoxine, sulfamethazine, and tylosin. The findings suggest that the compost produced under these conditions poses minimal health risks when applied to the environment.

![Antibiotic concentration over time

17

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 4 8 12 16 20 24 28

Aerated manure

Non-aerated manure

Aerabted biosolids

Non-aerated biosolids

[Florfenicol]/[Florfenicol]

0

Time (days)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 4 8 12 16 20 24 28

[Sulfadimethoxine]/[Sulfadimethoxine]

0

Time (days)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 4 8 12 16 20 24 28

[Sulfamethazine]/[Sulfamethazine]

0

Time (days)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 4 8 12 16 20 24 28

[Tylosin]/[Tylosin]

0

Time (days)](https://image.slidesharecdn.com/barry-150504121534-conversion-gate01/85/Antibiotic-Losses-during-Thermophilic-Composting-17-320.jpg)