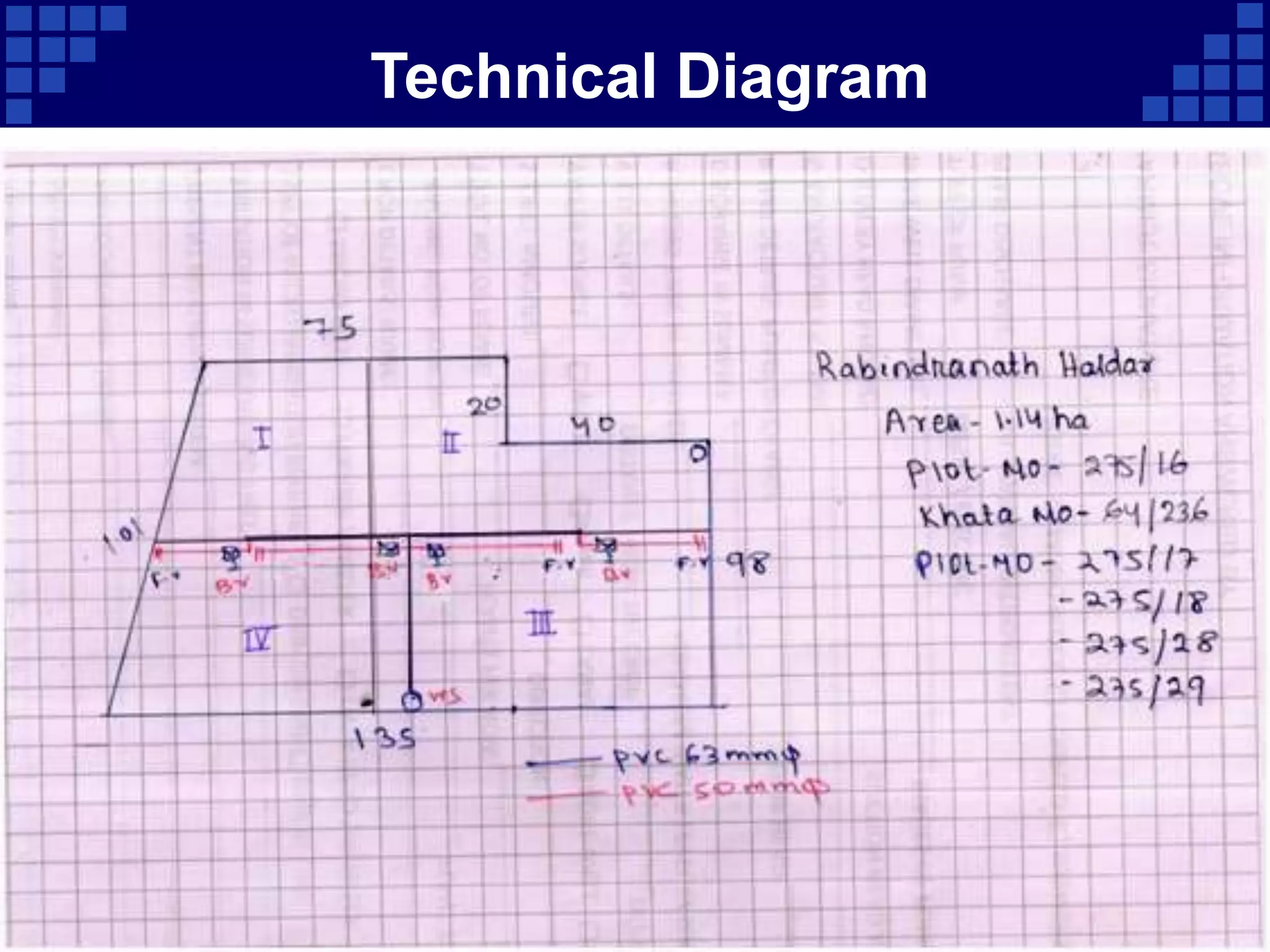

The document summarizes an in-plant training presentation on drip irrigation systems. It describes the components and advantages of drip irrigation, classifications of drippers, the process of surveying land and water sources, designing a drip irrigation system, estimating costs, applying for subsidies, and installing drip lines and components. It also provides graphs on the adoption of drip irrigation in different Indian states and the history of the company Jain Irrigation Systems in the district of Nabarangpur.