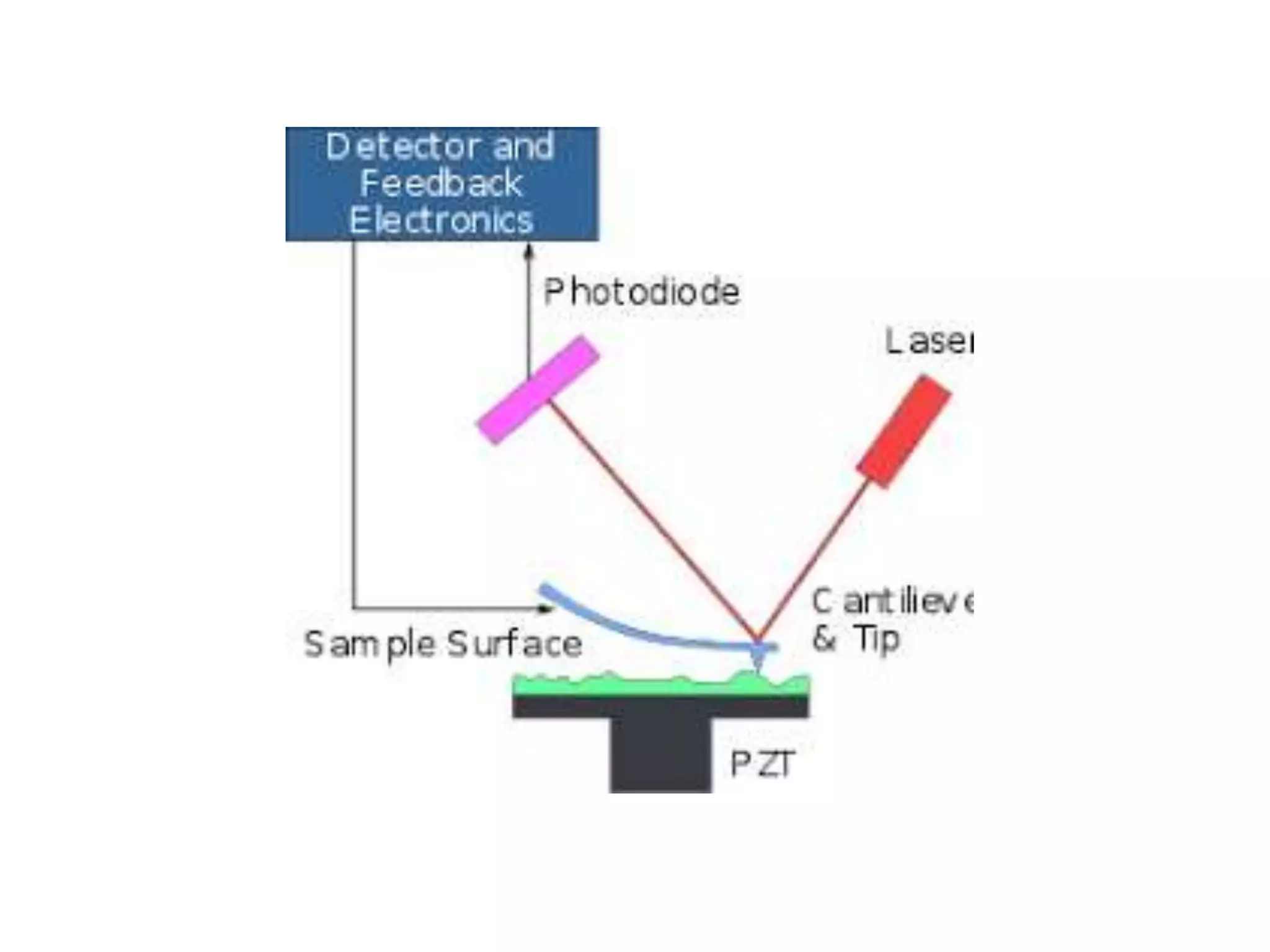

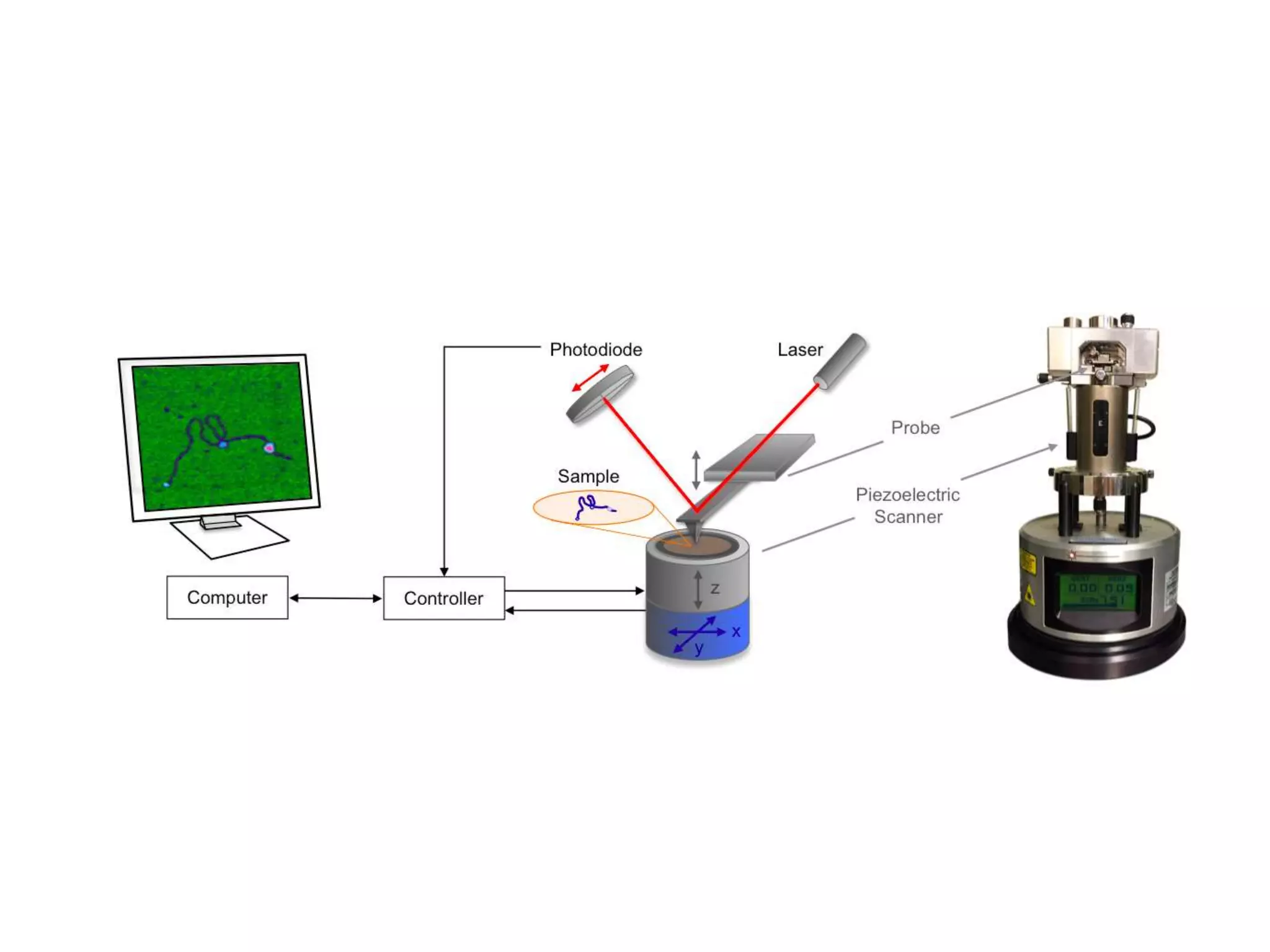

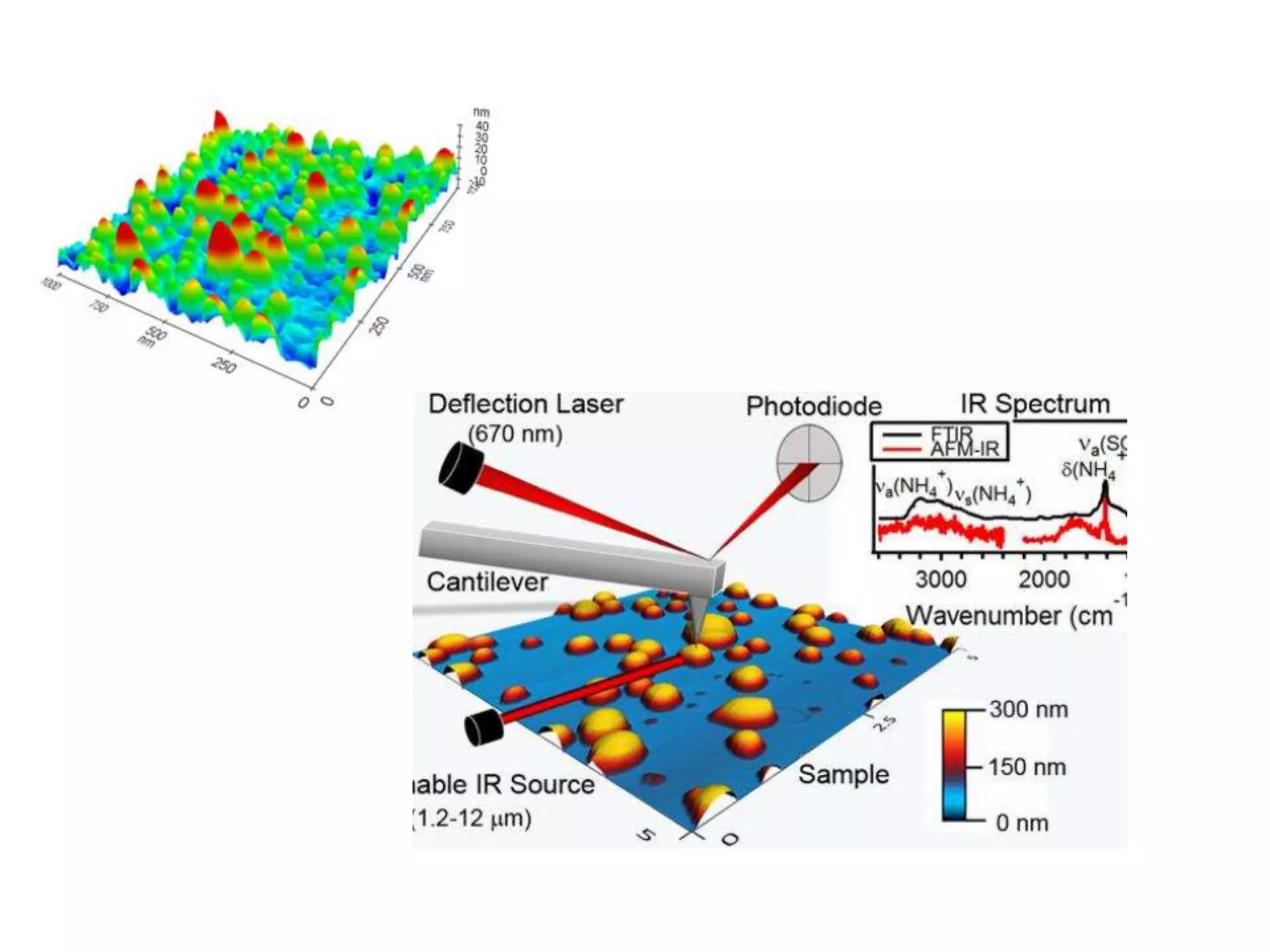

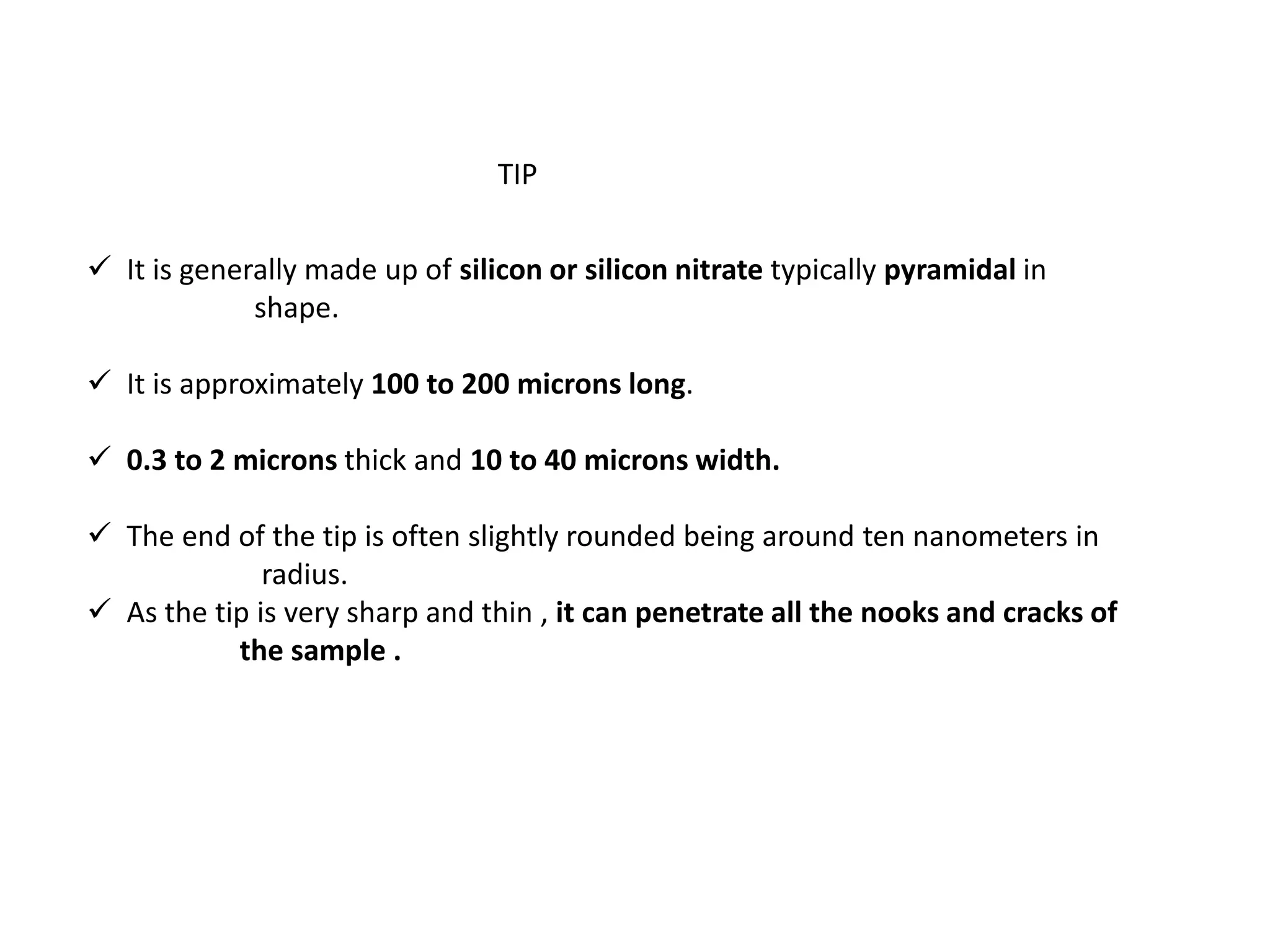

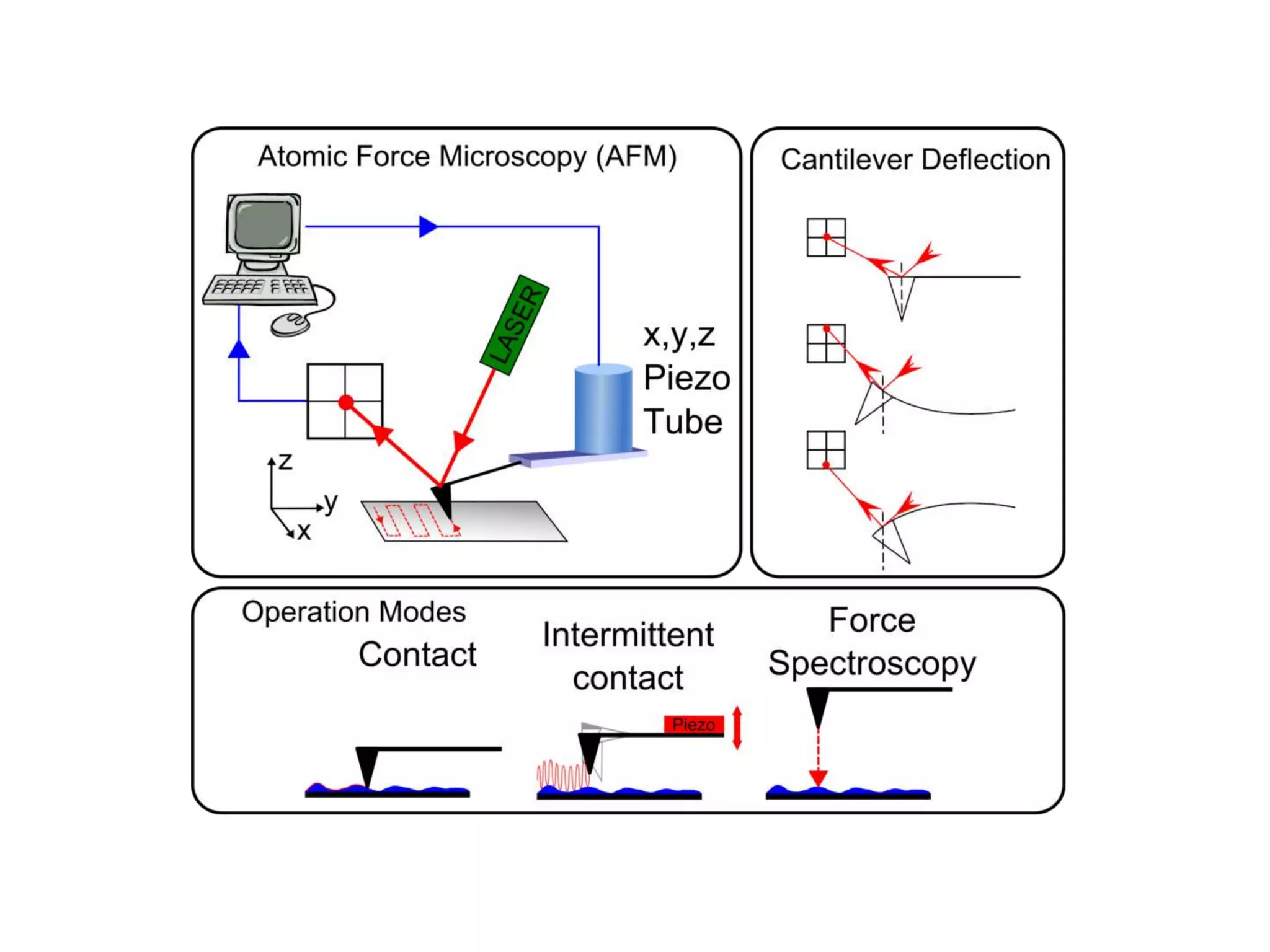

Atomic force microscopy (AFM) uses a sharp tip attached to a flexible cantilever to scan the surface of a sample and map its topography with nanoscale resolution. As the tip is scanned across the surface, interactions between the tip and sample cause the cantilever to deflect, and these deflections are used to construct a 3D image of the surface. AFM can operate in contact, non-contact, or tapping mode and is capable of measuring properties like roughness, elasticity, and adhesion in addition to topography. It provides magnification from 100X to over 100 million X with nanometer scale resolution and does not require complex sample preparation, making AFM a versatile high-resolution imaging tool.