This document discusses various technological properties of materials:

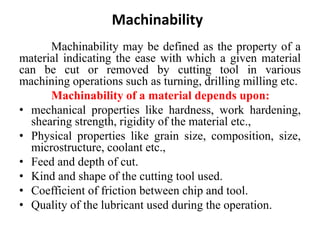

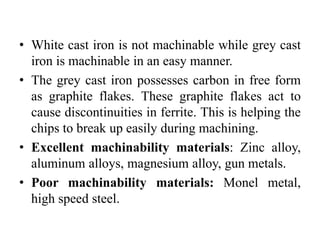

Machinability is defined as how easily a material can be cut or shaped by tools. It depends on properties like hardness, grain size, lubricants used. White cast iron is not machinable while grey cast iron is easy to machine.

Weldability is how easily a material can be joined to itself or other materials through welding. It depends on properties like composition, strength at high temperatures, and thermal properties.

Workability/formability is how easily a material can be shaped while solid through processes like forging and extrusion without cracking. Cold workability refers to shaping cold materials while hot workability is shaping hot materials.

Castability is how easily