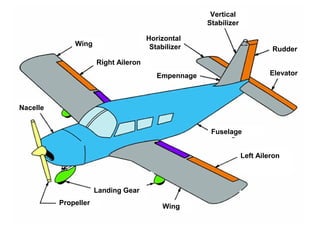

The document discusses the key components and structures of aircraft, including:

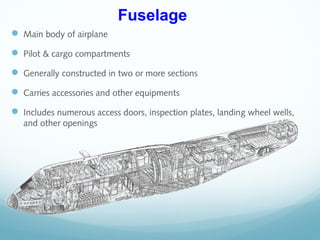

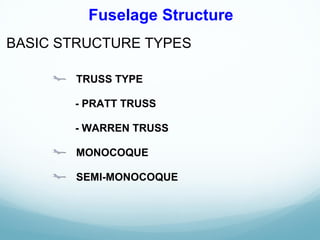

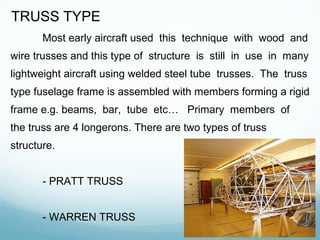

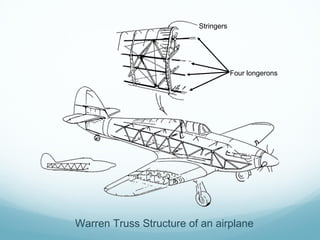

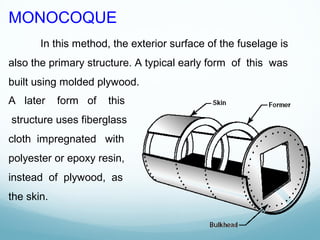

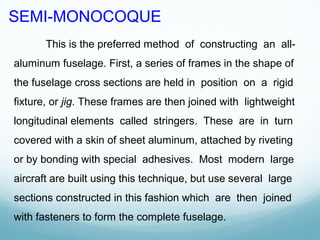

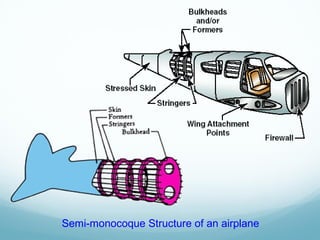

1) The fuselage, which is the main body and includes different structural types like truss, monocoque, and semi-monocoque.

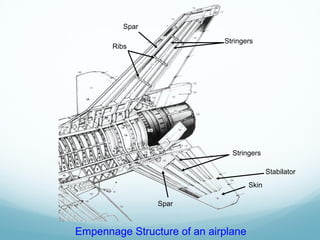

2) Wings, which provide lift and include various designs attached at different positions on the fuselage, as well as wing structures using spars, ribs, and stringers.

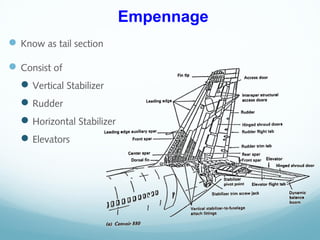

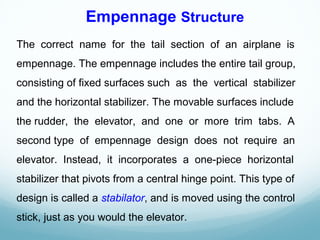

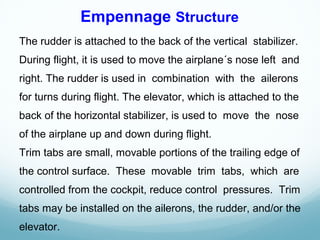

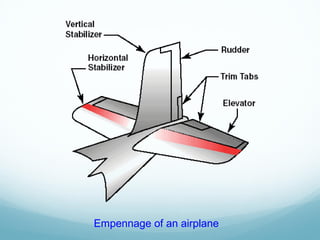

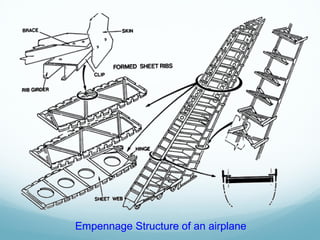

3) The empennage or tail section, consisting of the vertical and horizontal stabilizers along with movable surfaces like the rudder and elevators.

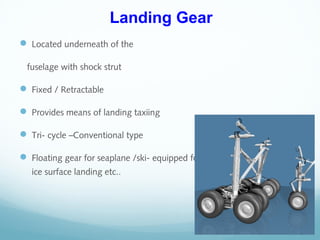

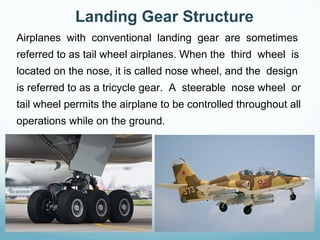

4) The landing gear, usually a wheeled structure but sometimes floats or skis, which supports the airplane during takeoff, landing,