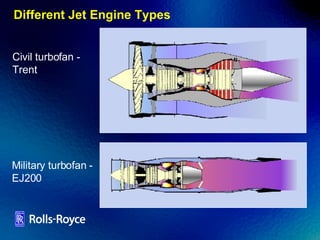

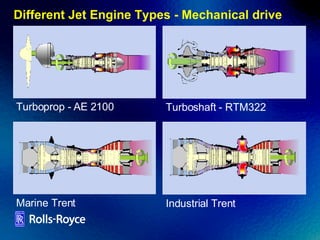

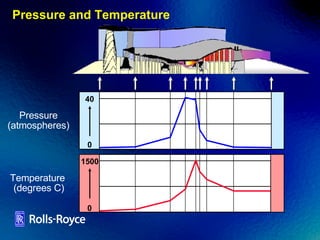

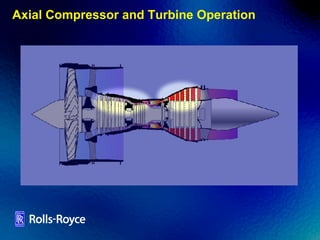

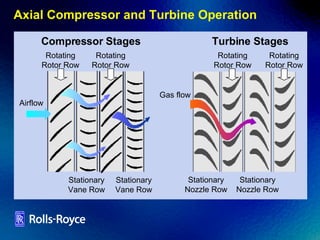

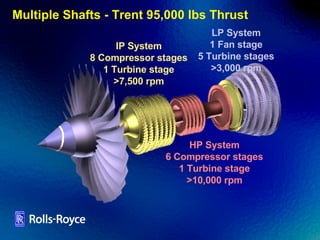

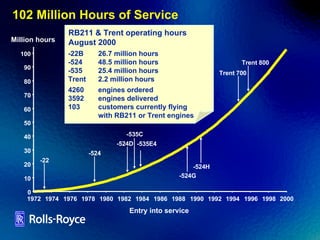

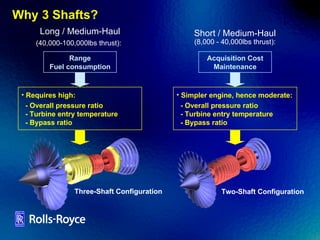

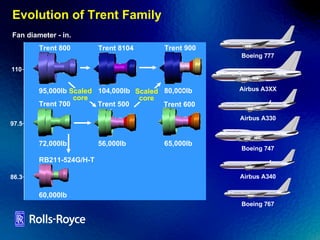

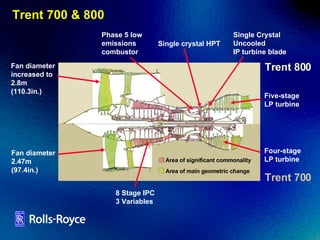

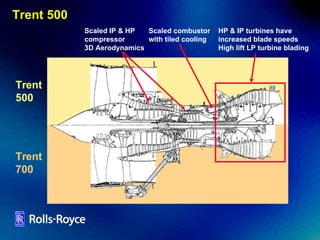

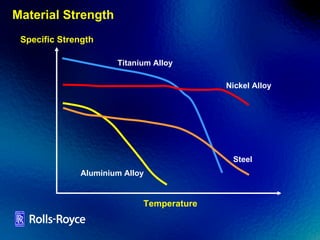

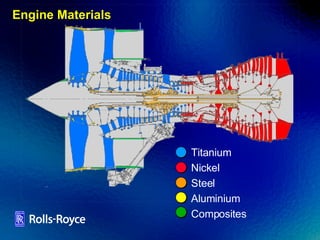

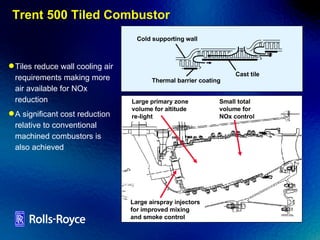

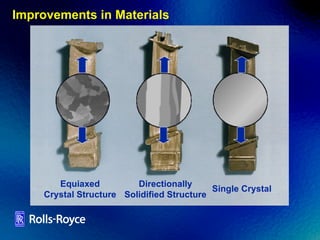

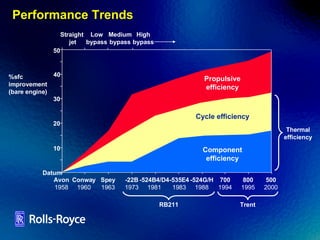

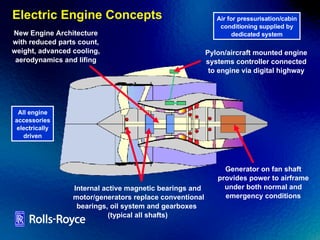

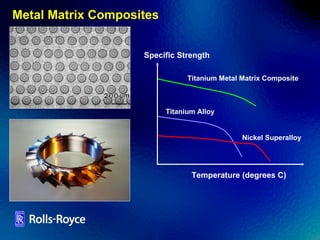

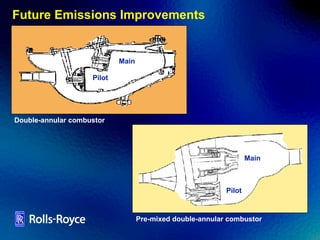

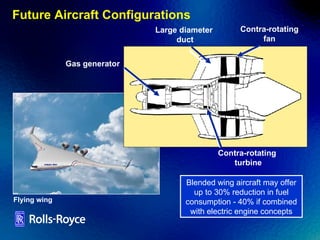

Rolls-Royce is a world leader in aero-engines and marine propulsion systems. The Trent engine family uses a three-shaft design that allows for higher pressure ratios and temperatures needed for long-haul flights. Material and design advances like single crystal alloys and ceramic composites have improved efficiency. Future concepts may use electric engines and contra-rotating fans to further reduce emissions and fuel consumption.