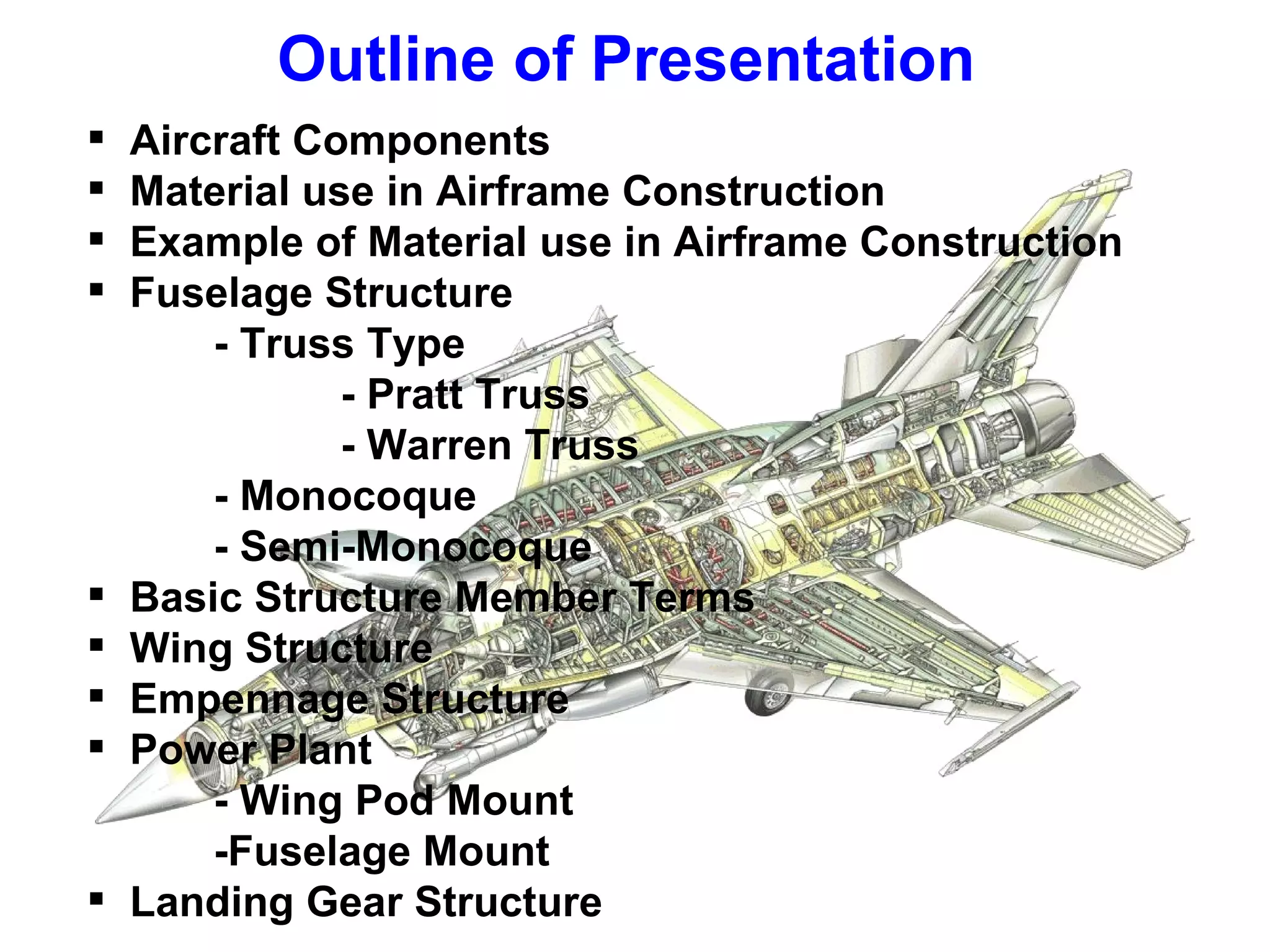

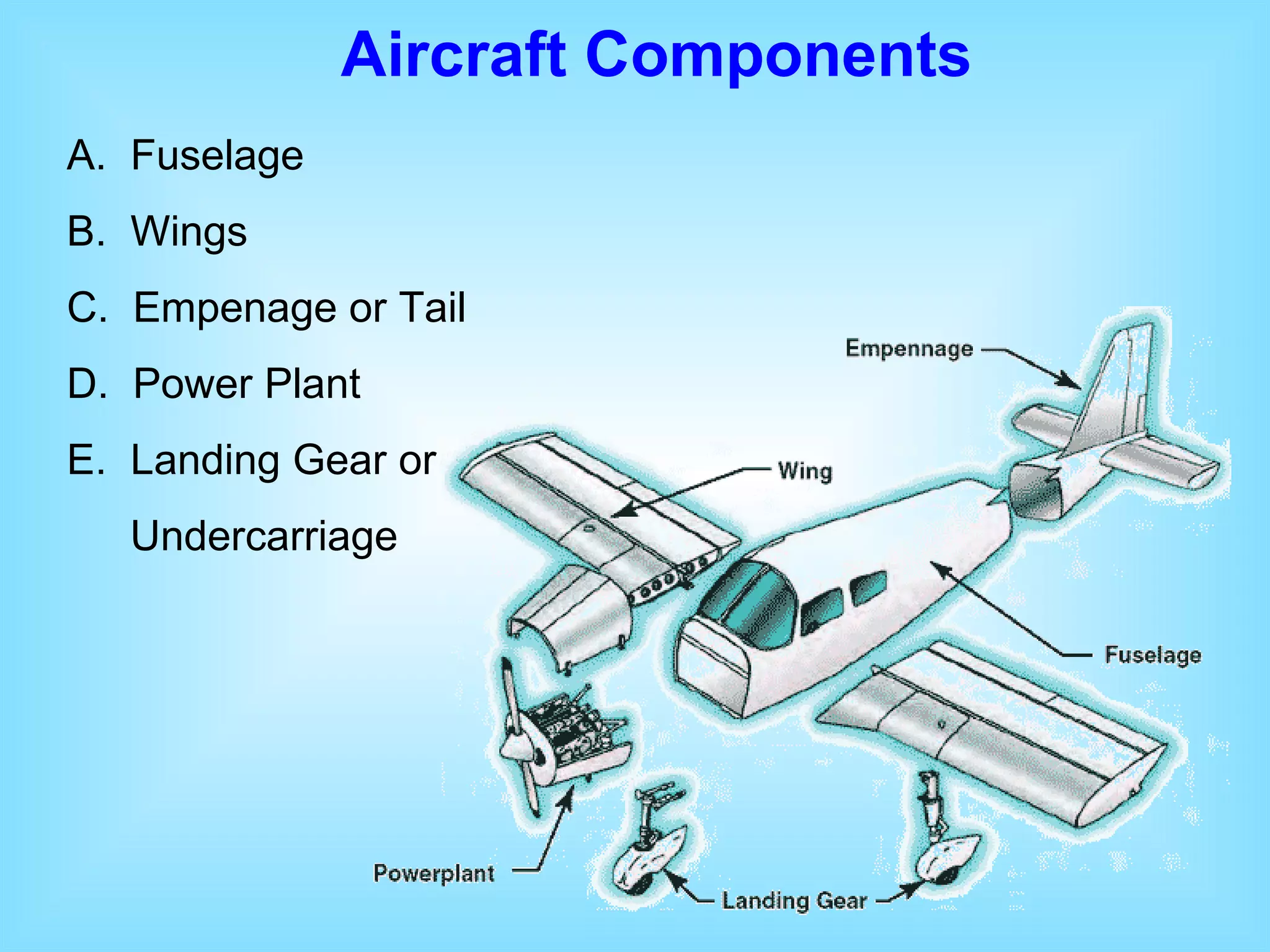

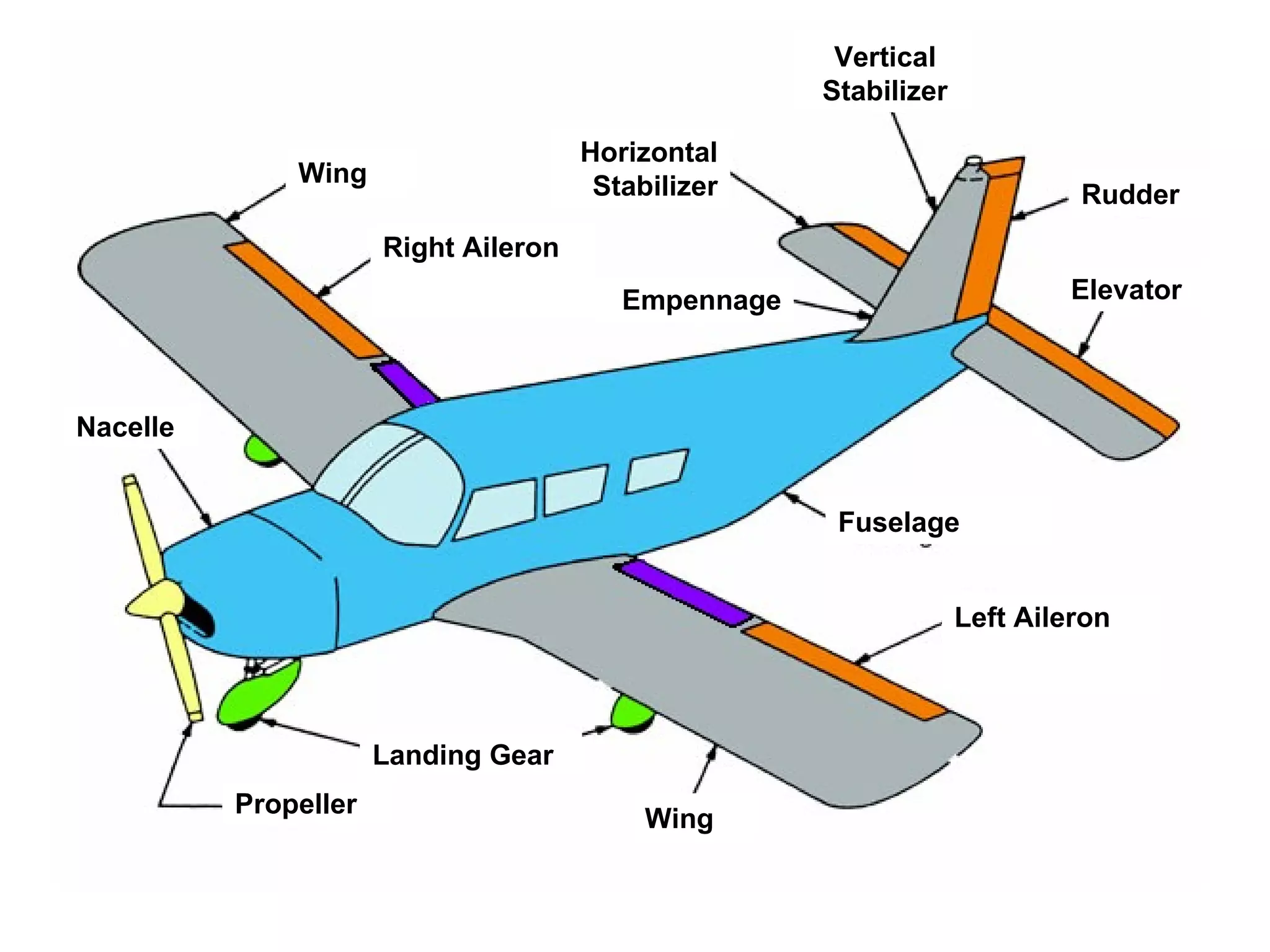

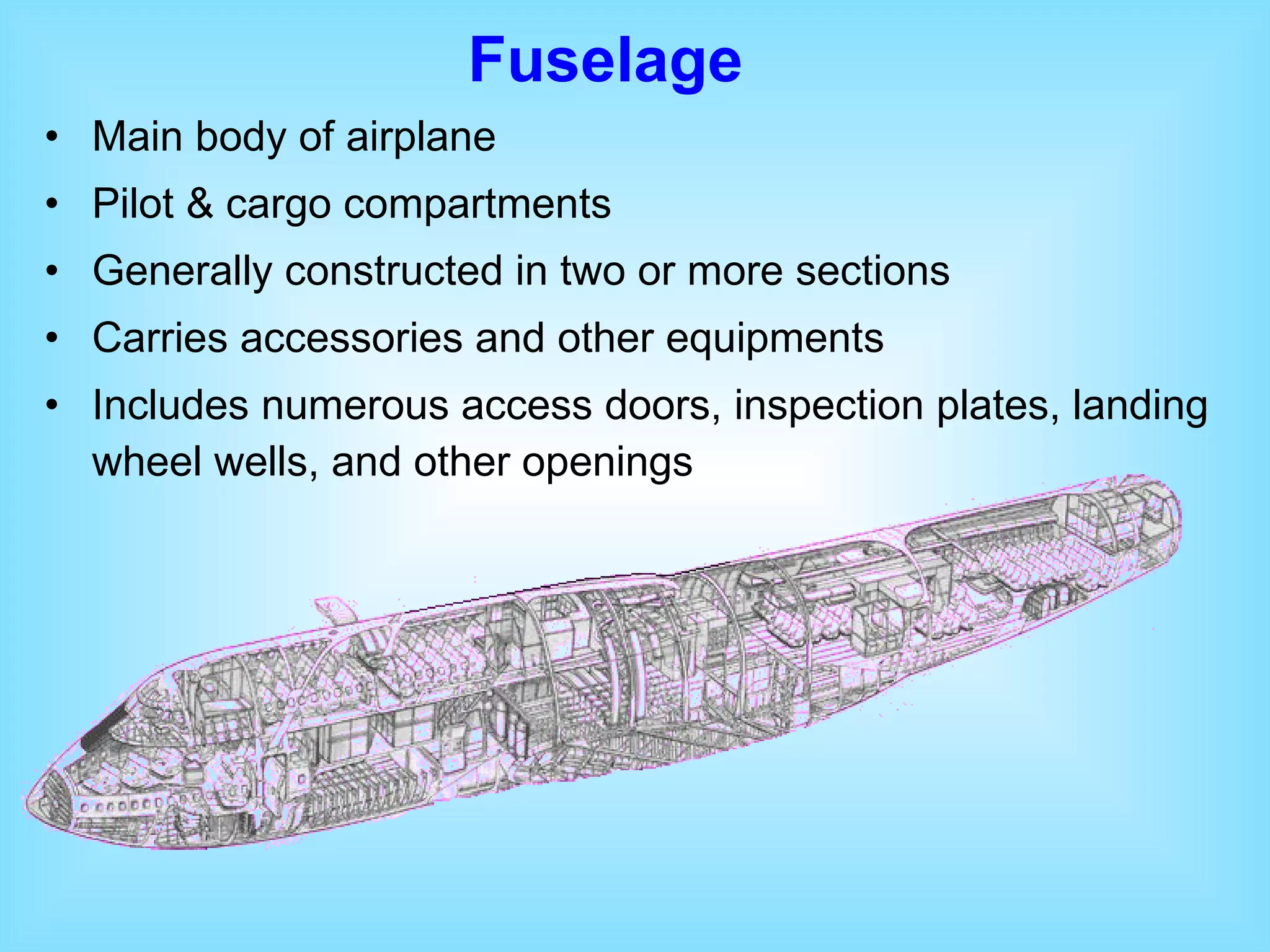

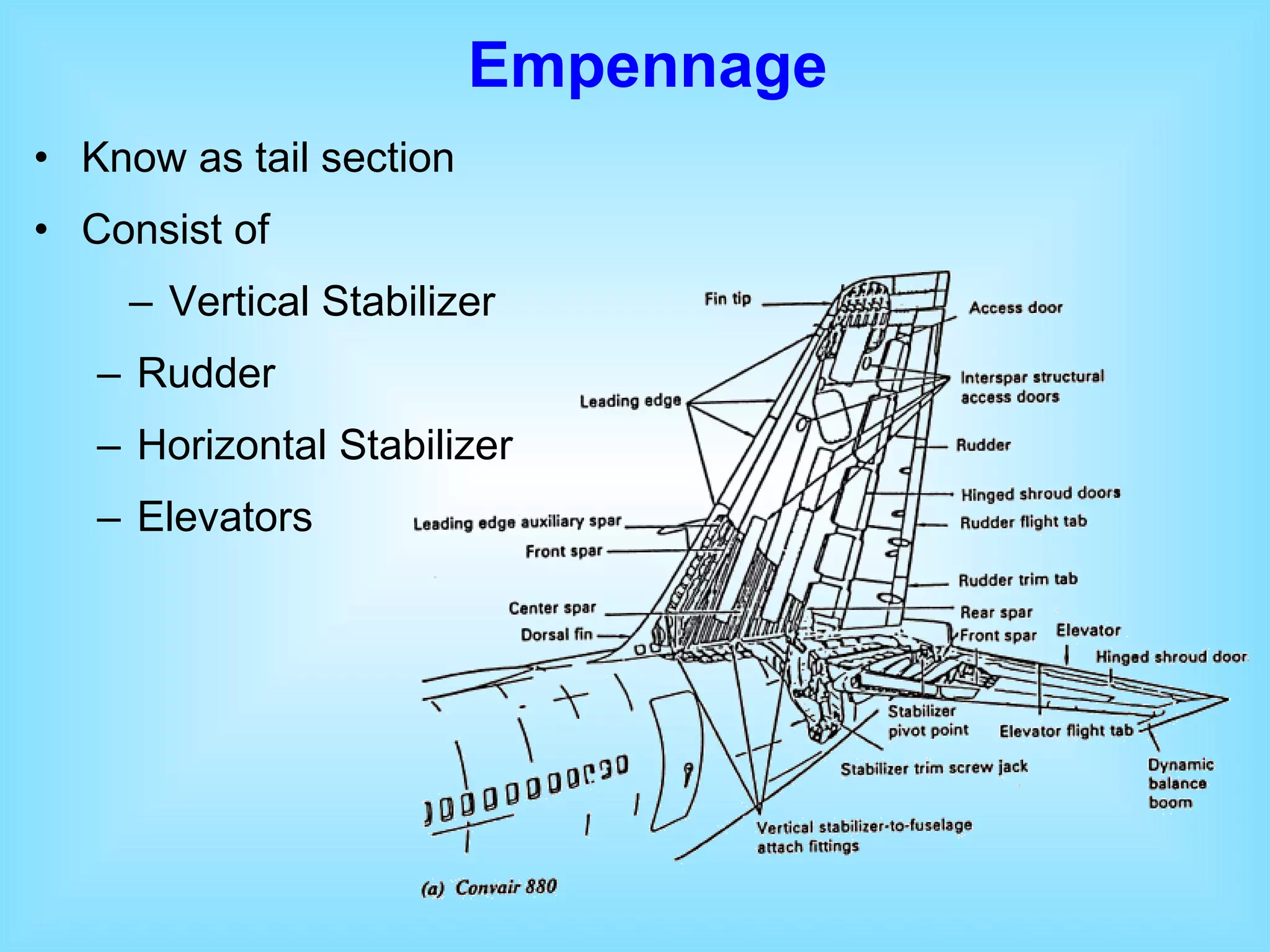

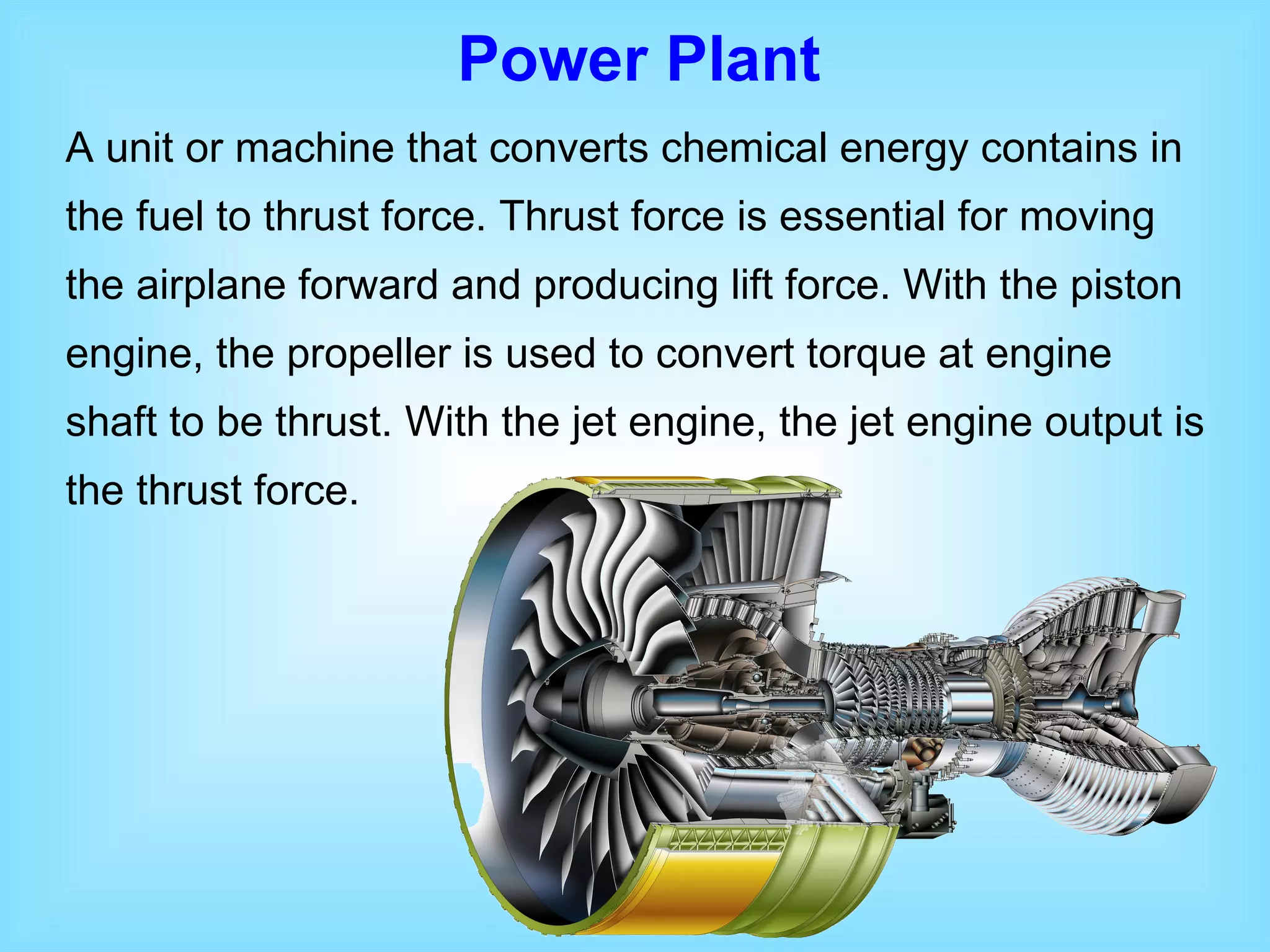

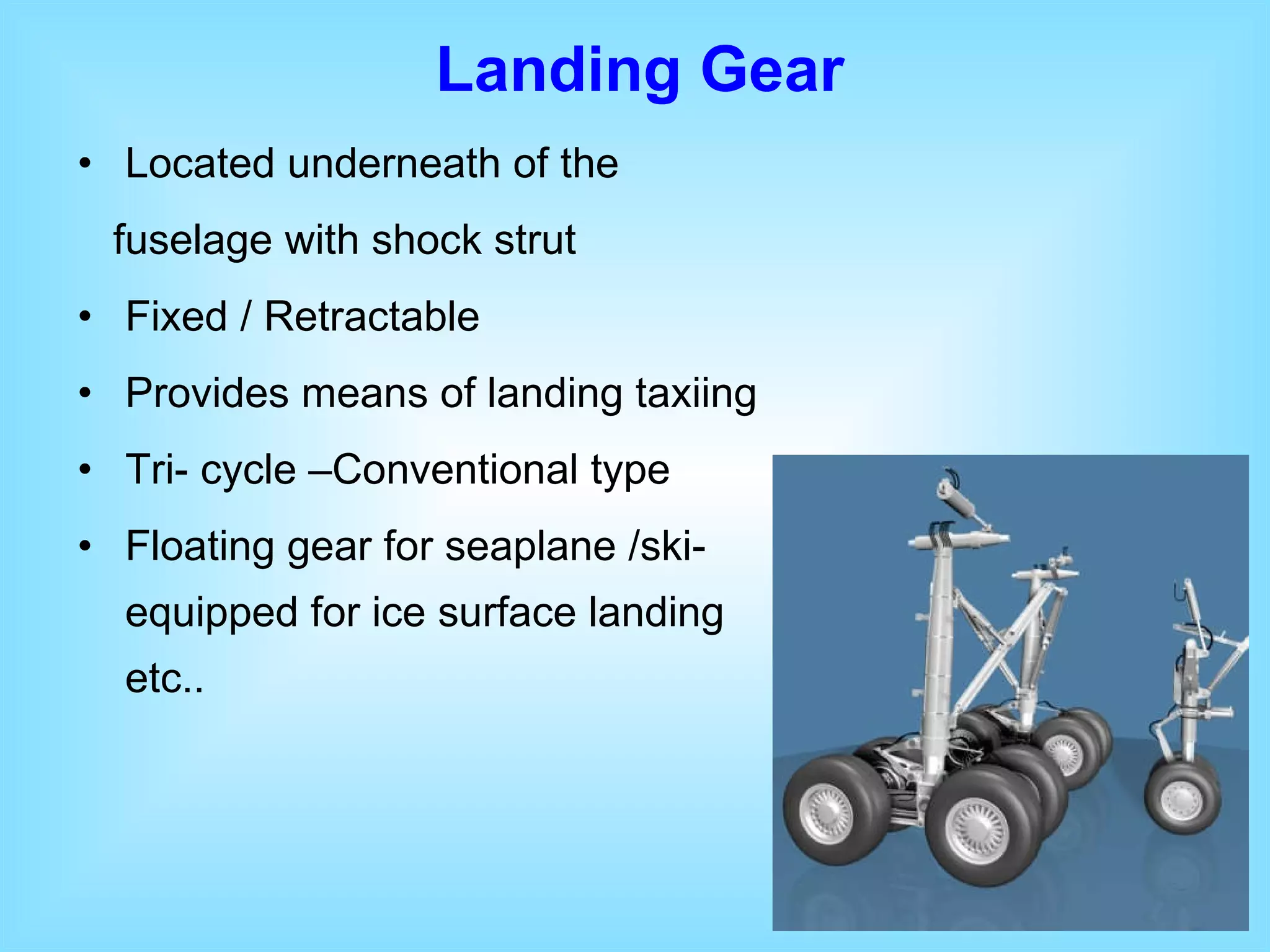

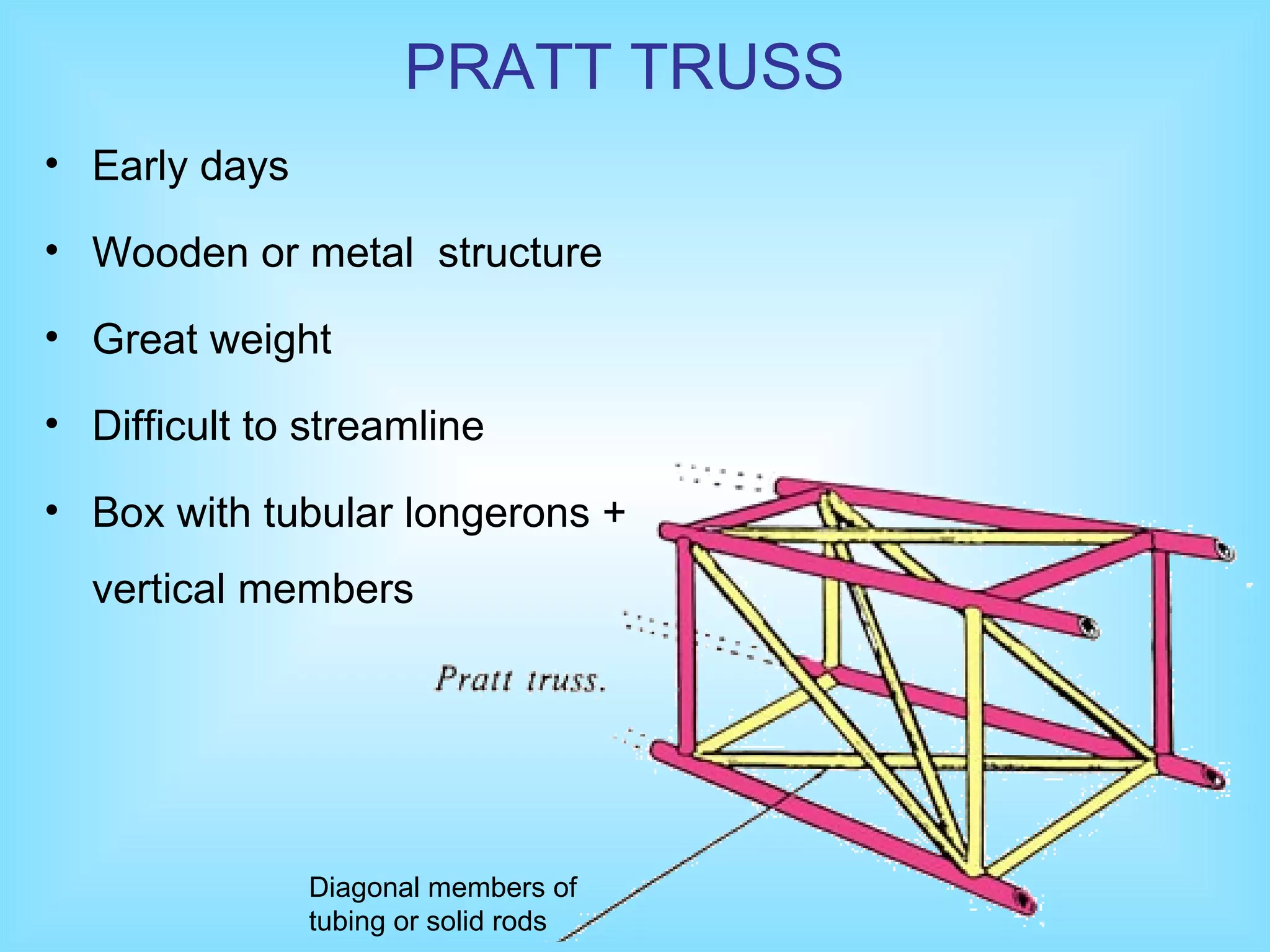

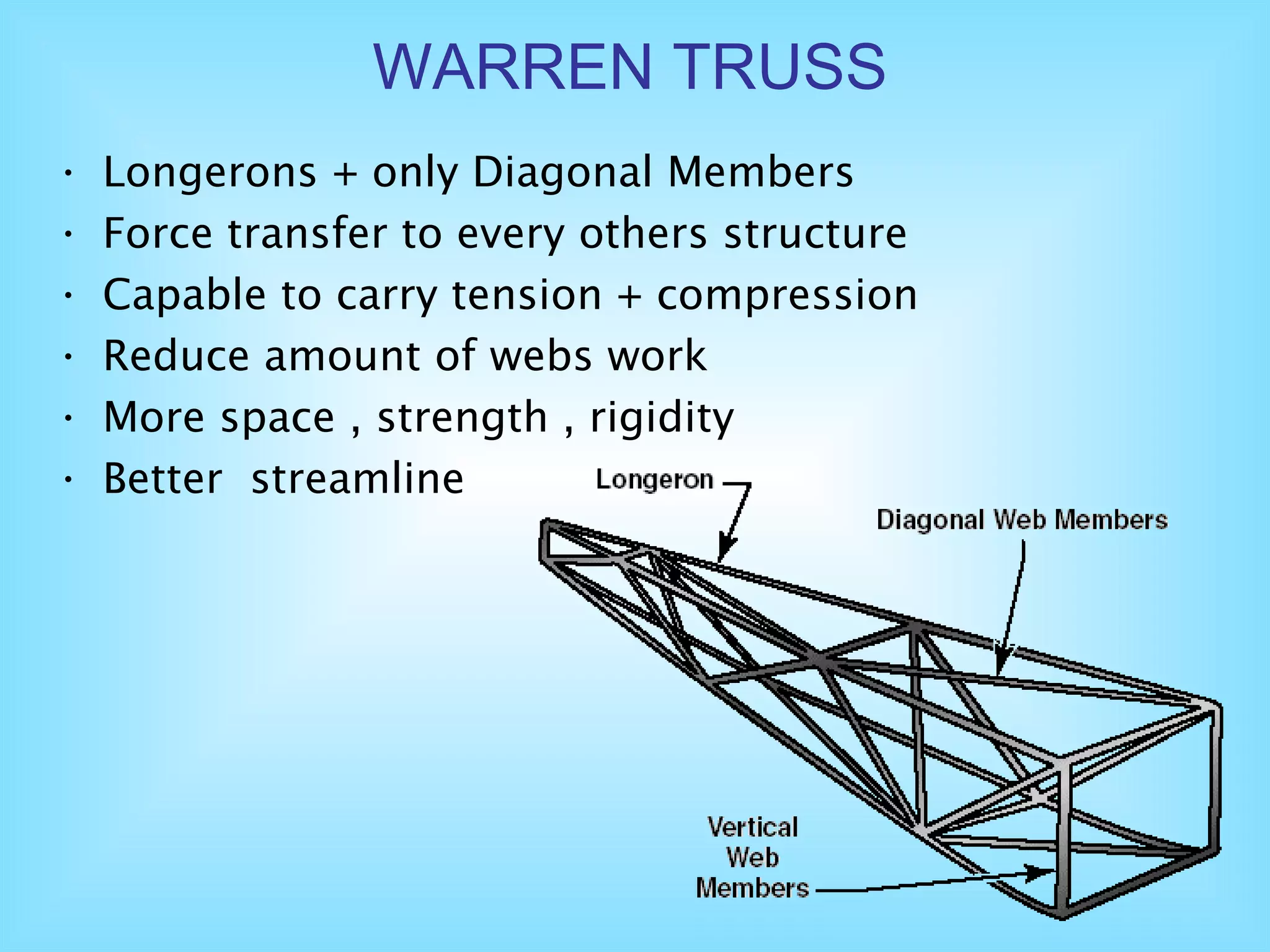

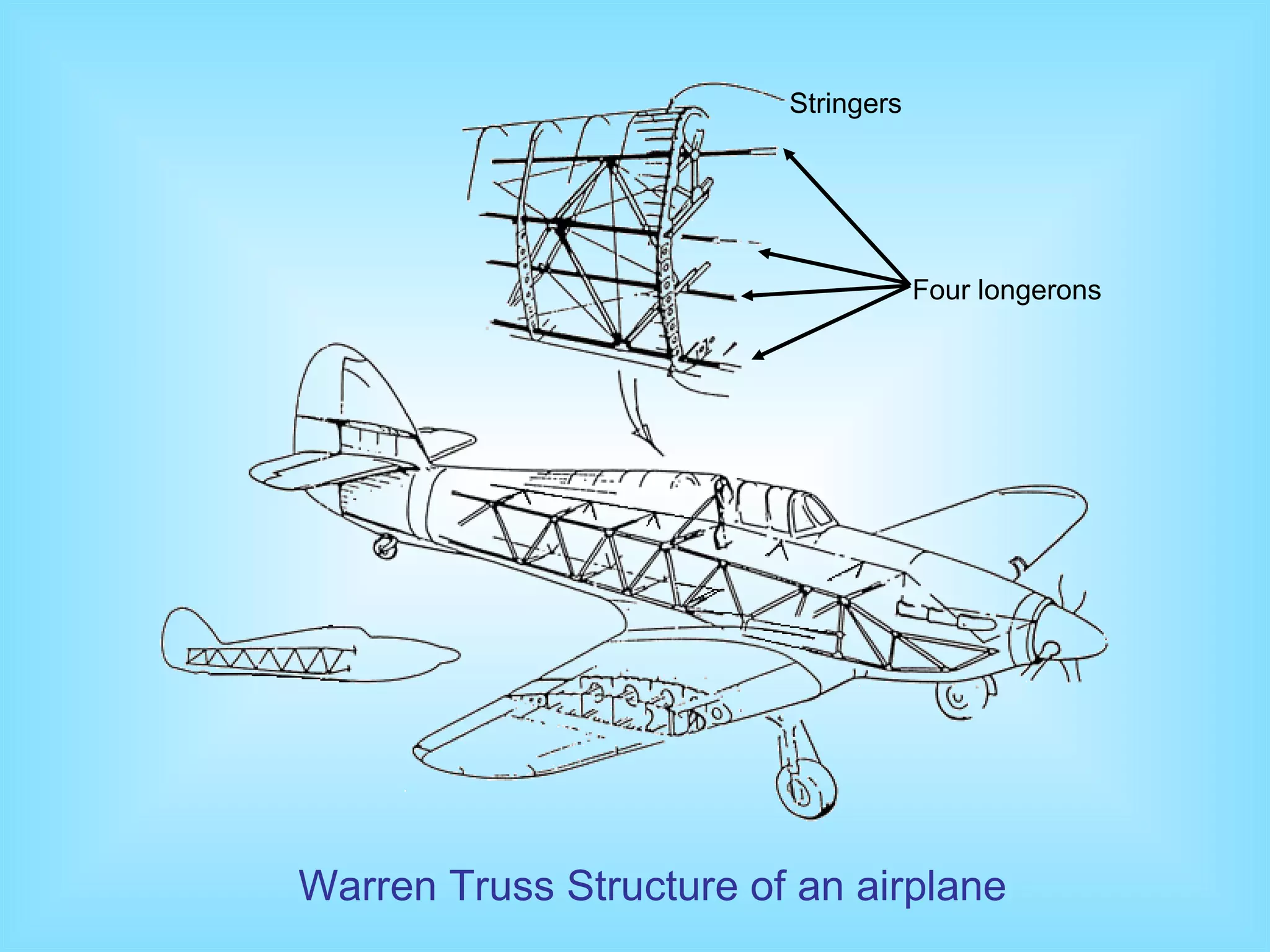

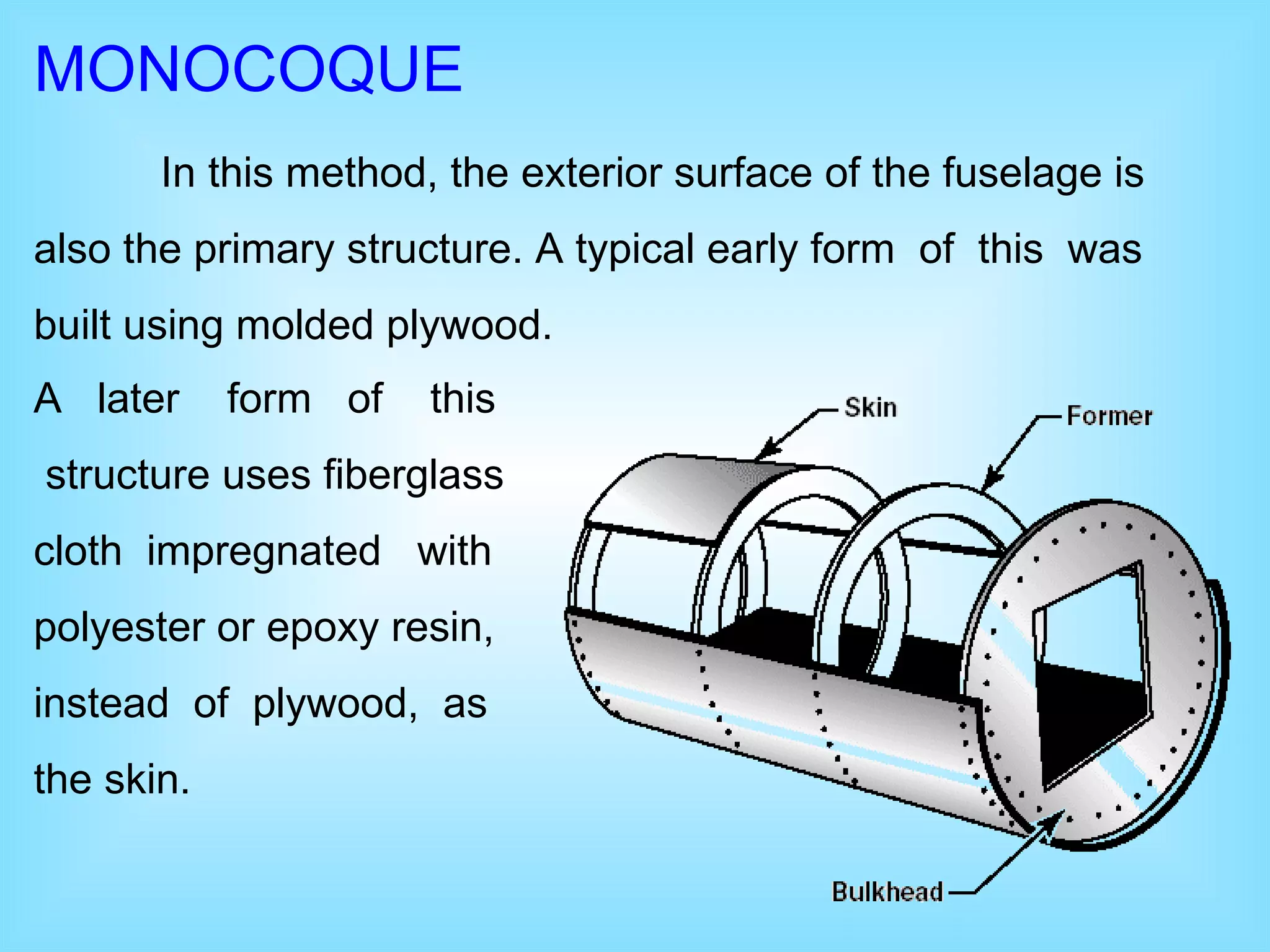

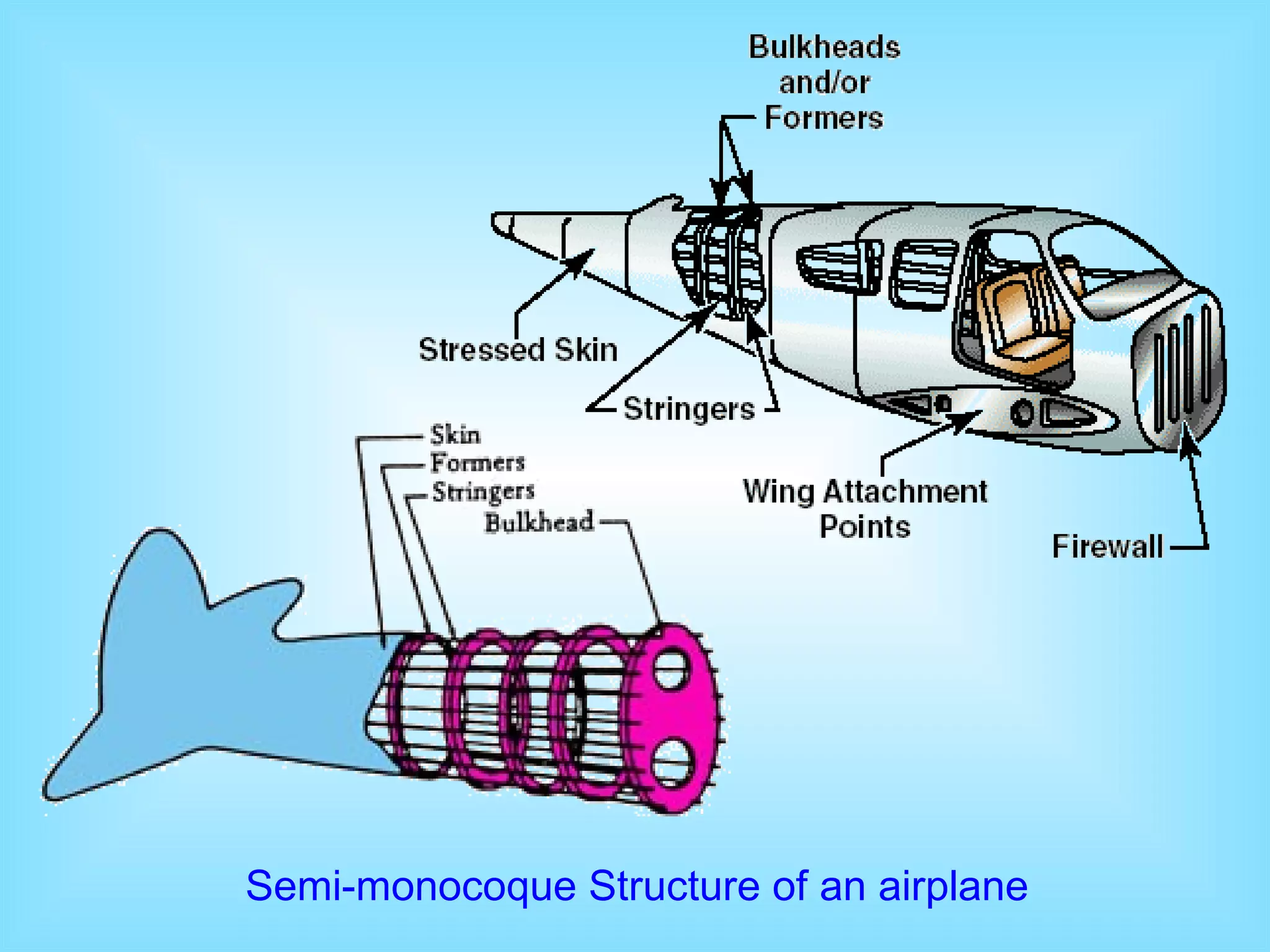

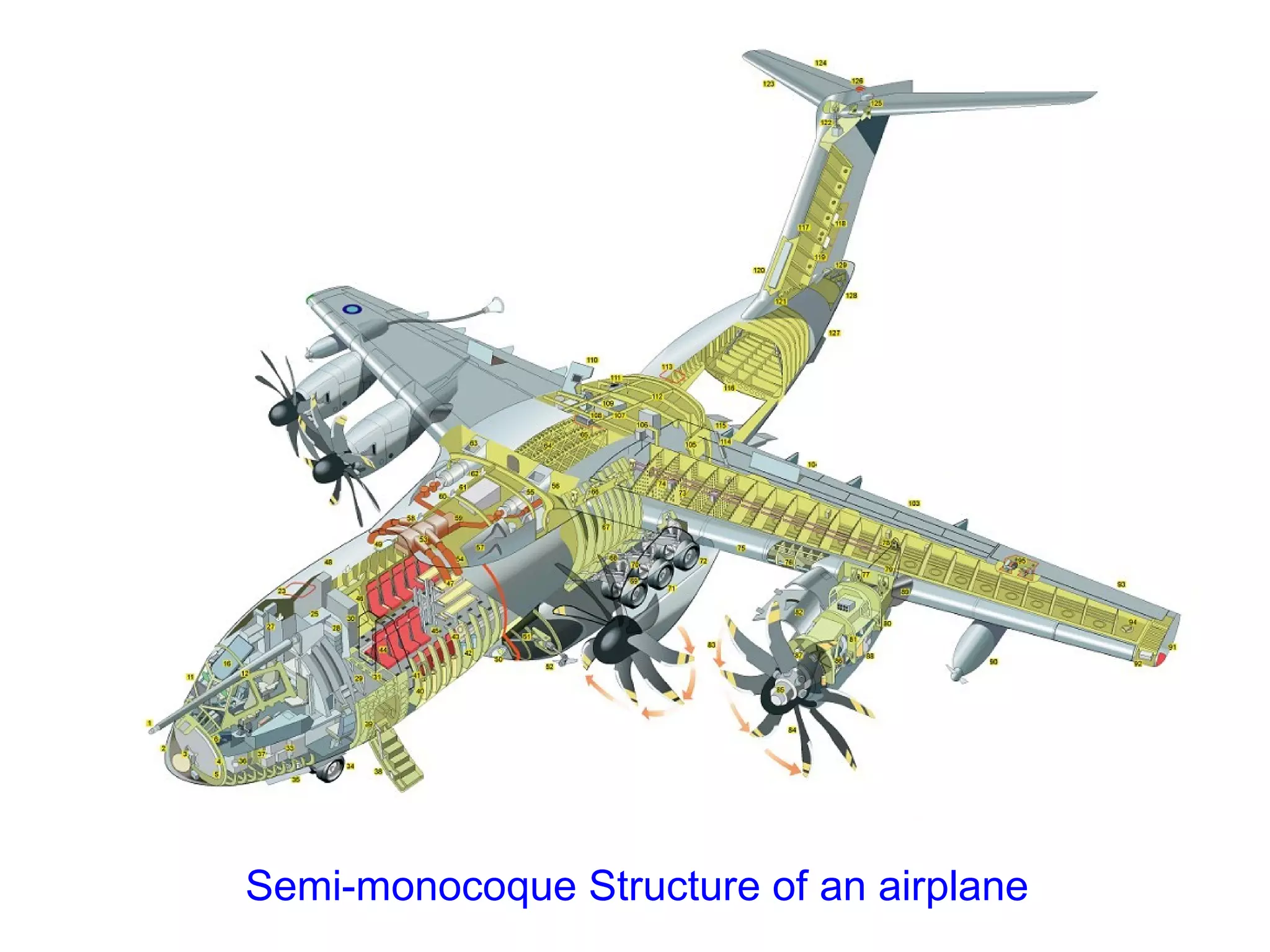

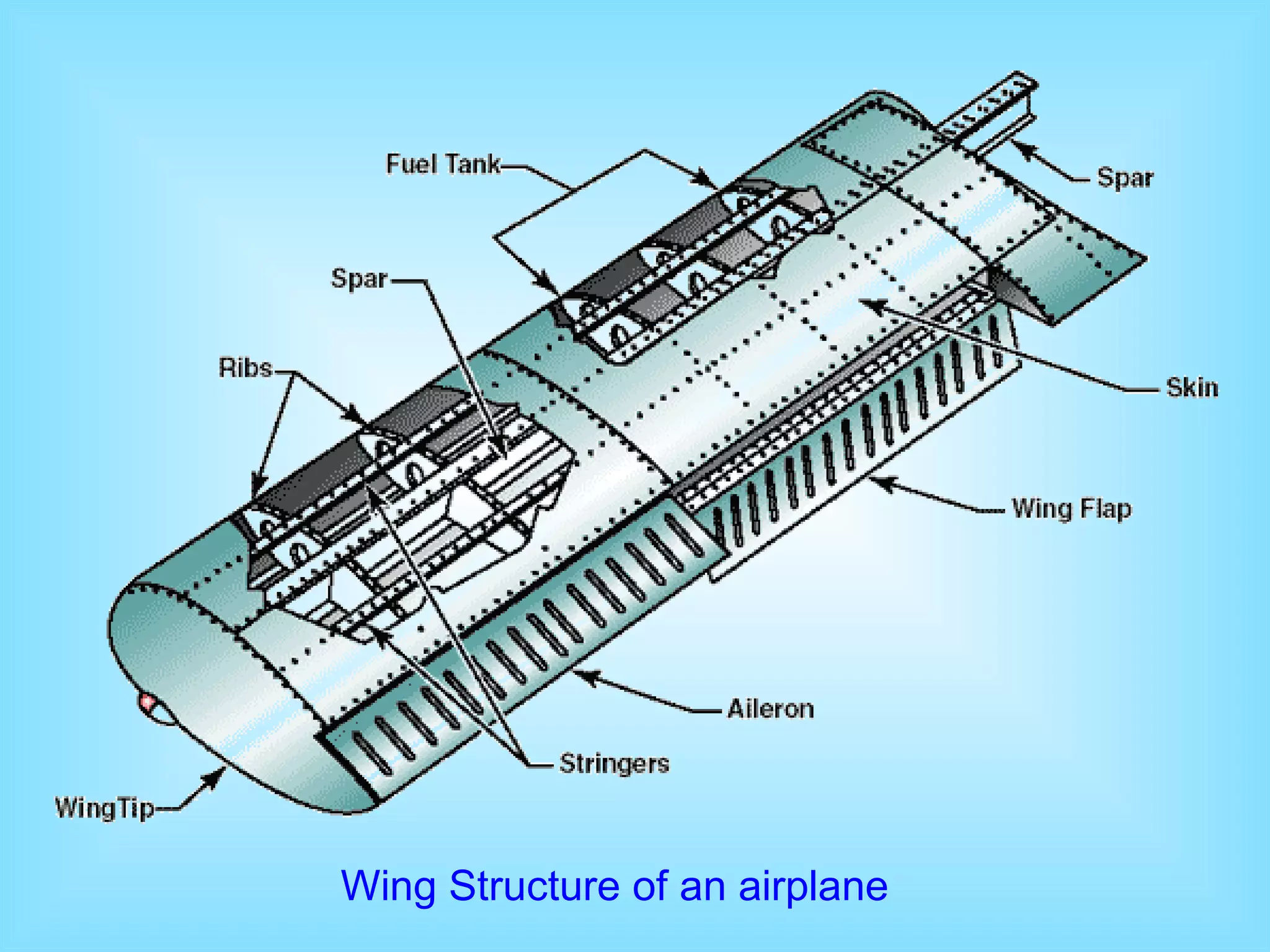

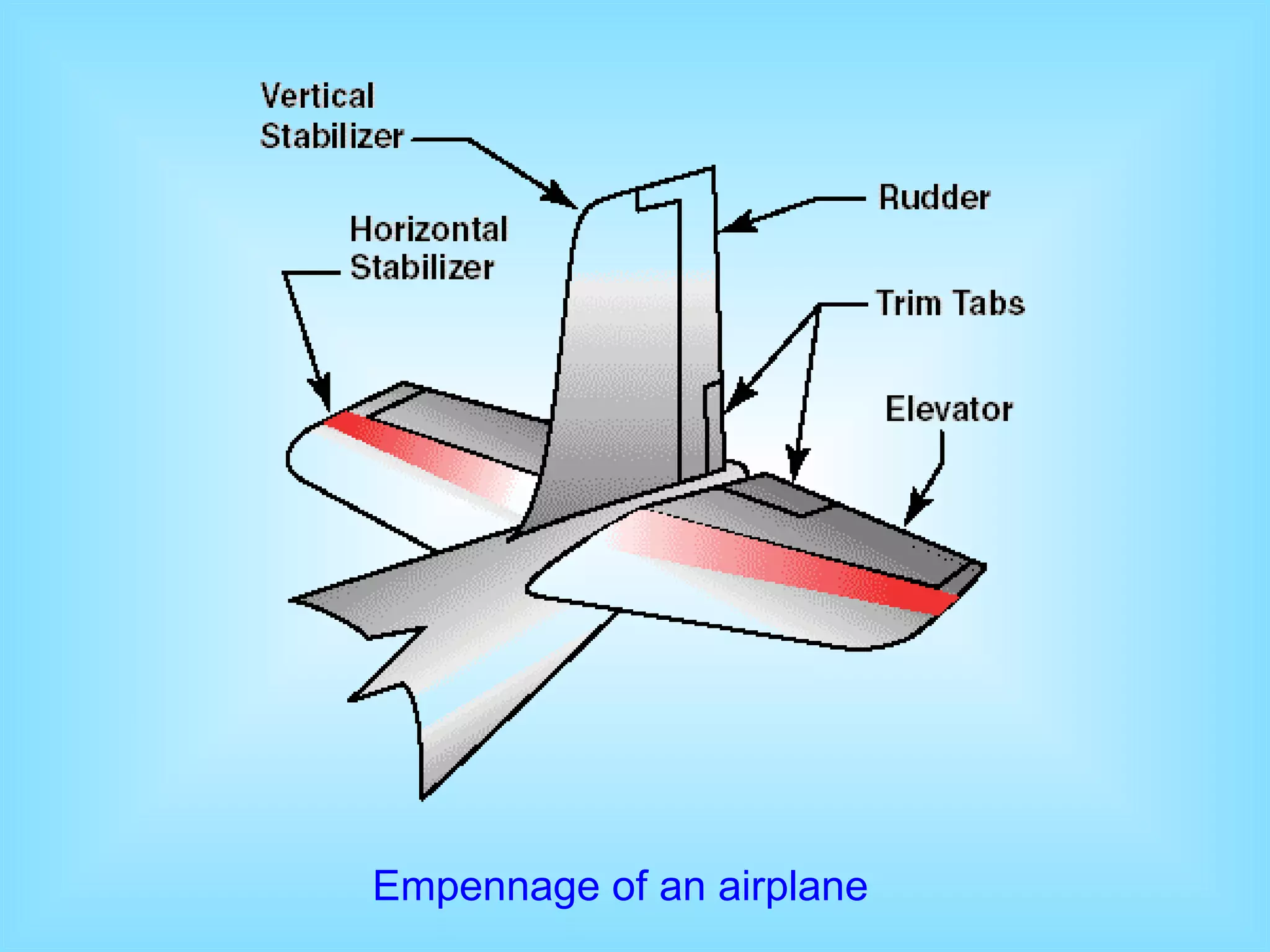

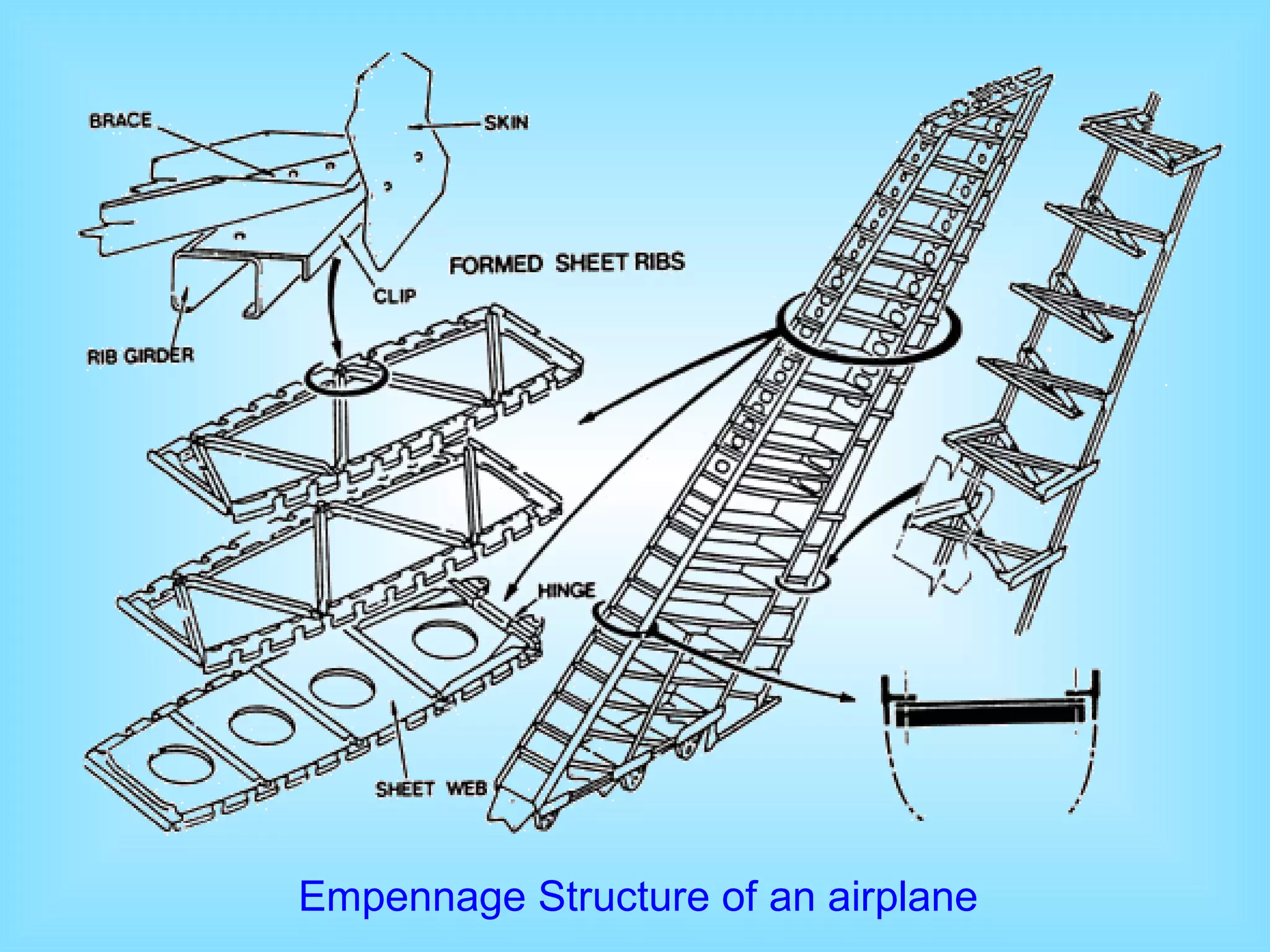

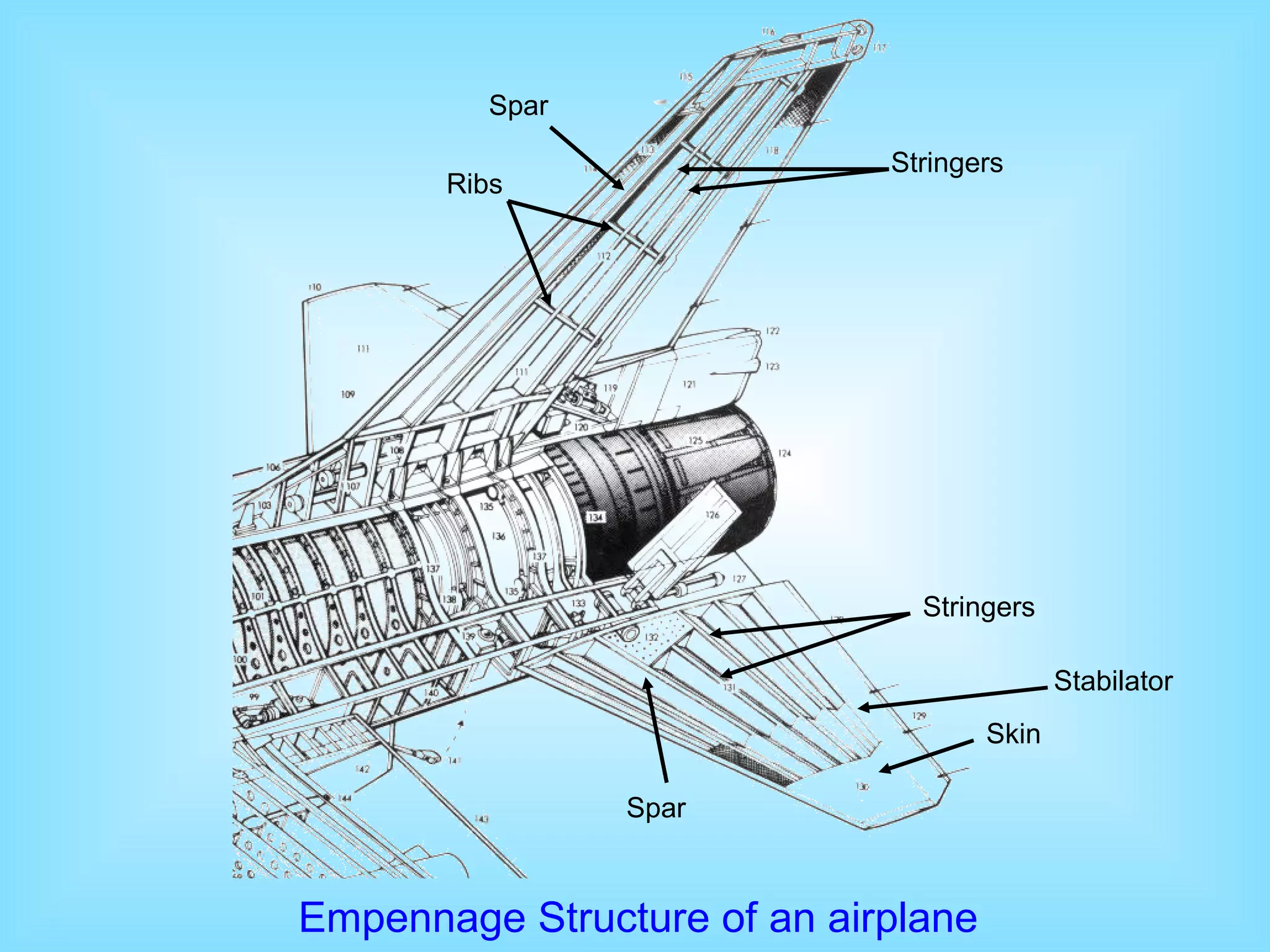

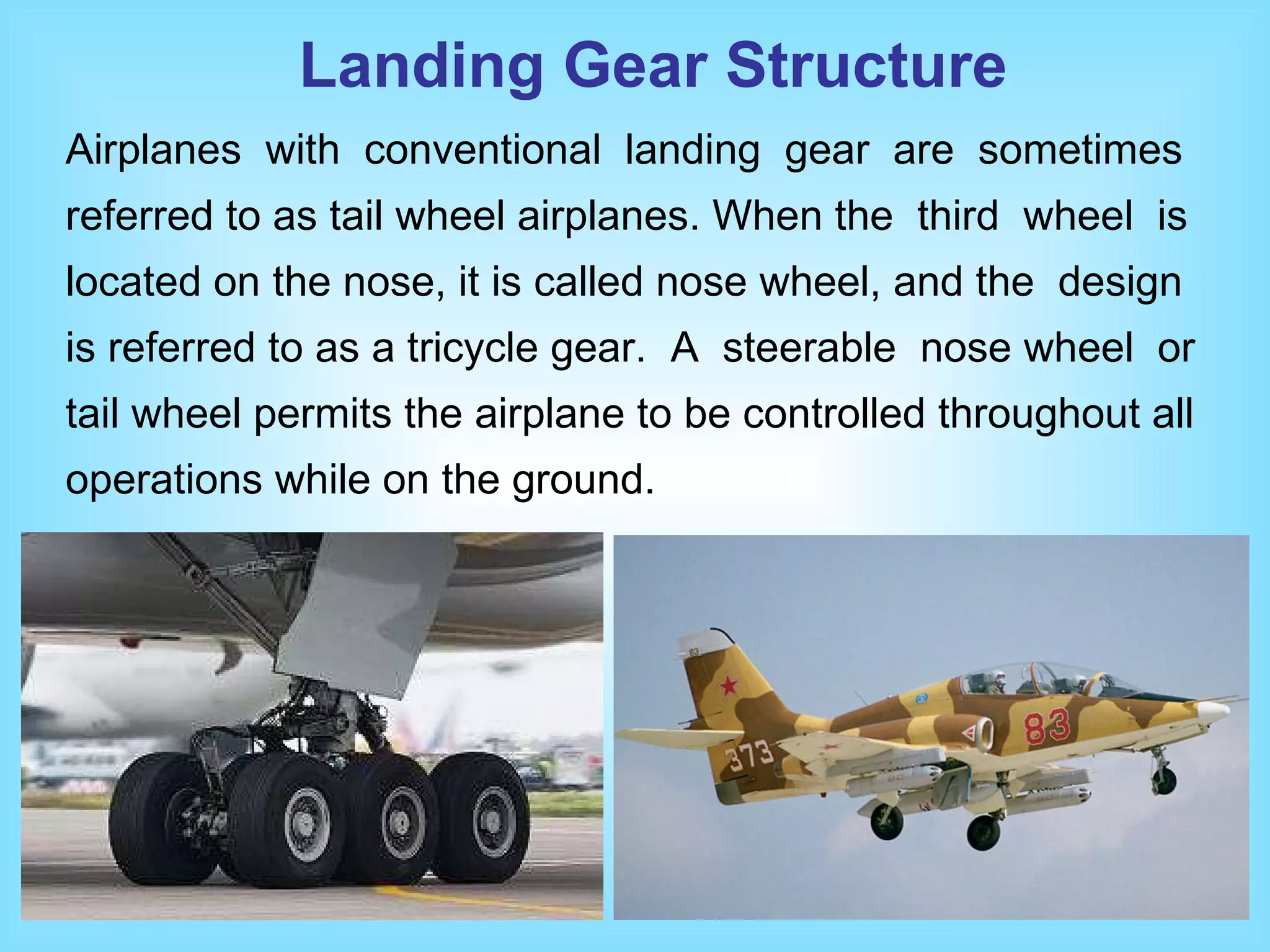

The document provides an overview of the basic components and structures of aircraft, including the fuselage, wings, empennage, power plant, and landing gear. It describes the typical materials used in aircraft construction and gives examples of different structural designs for the fuselage, wings, empennage, and landing gear. Key terms related to aircraft components and structures are also defined.