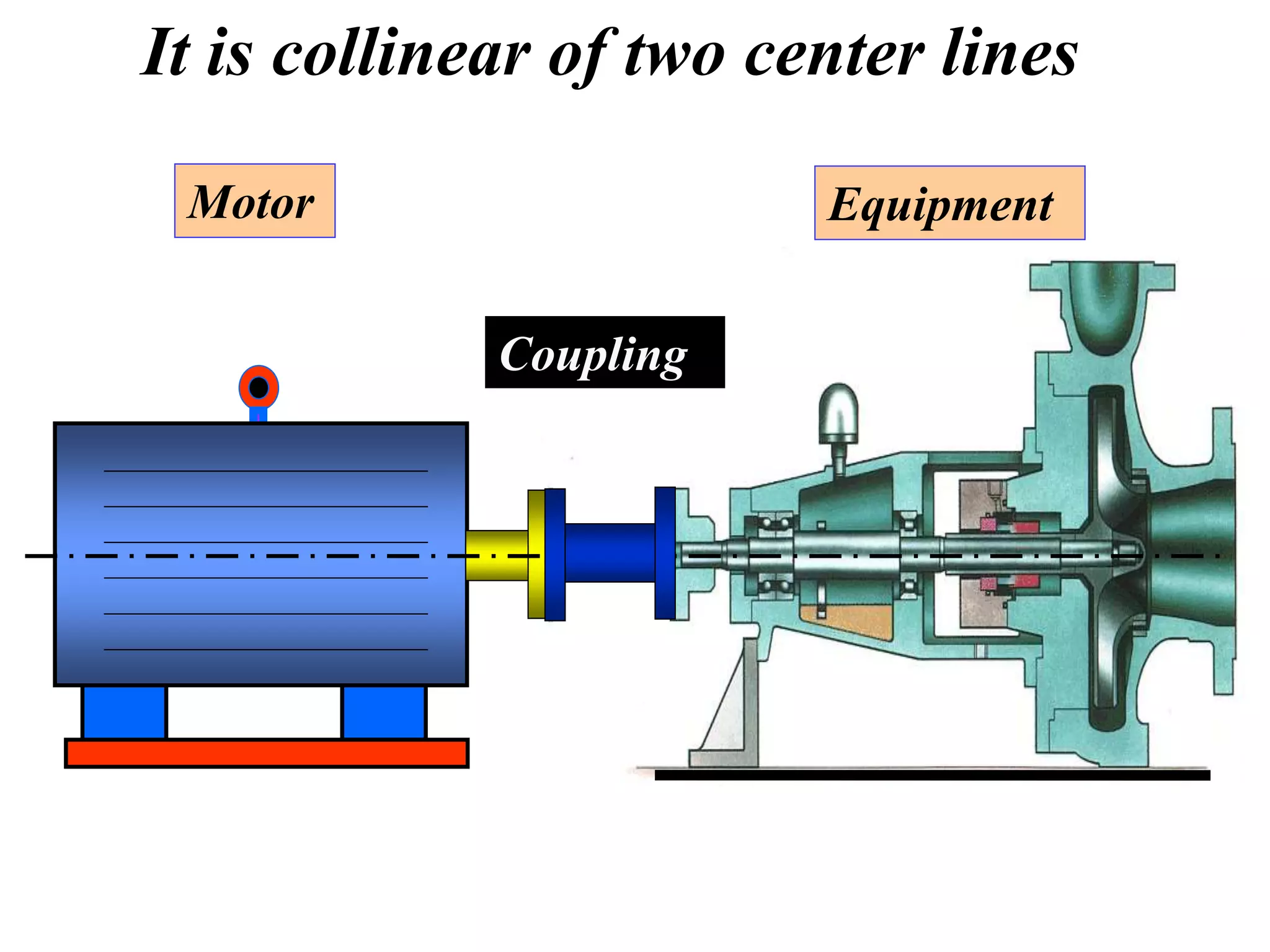

This document discusses rotating equipment alignment. It provides information on:

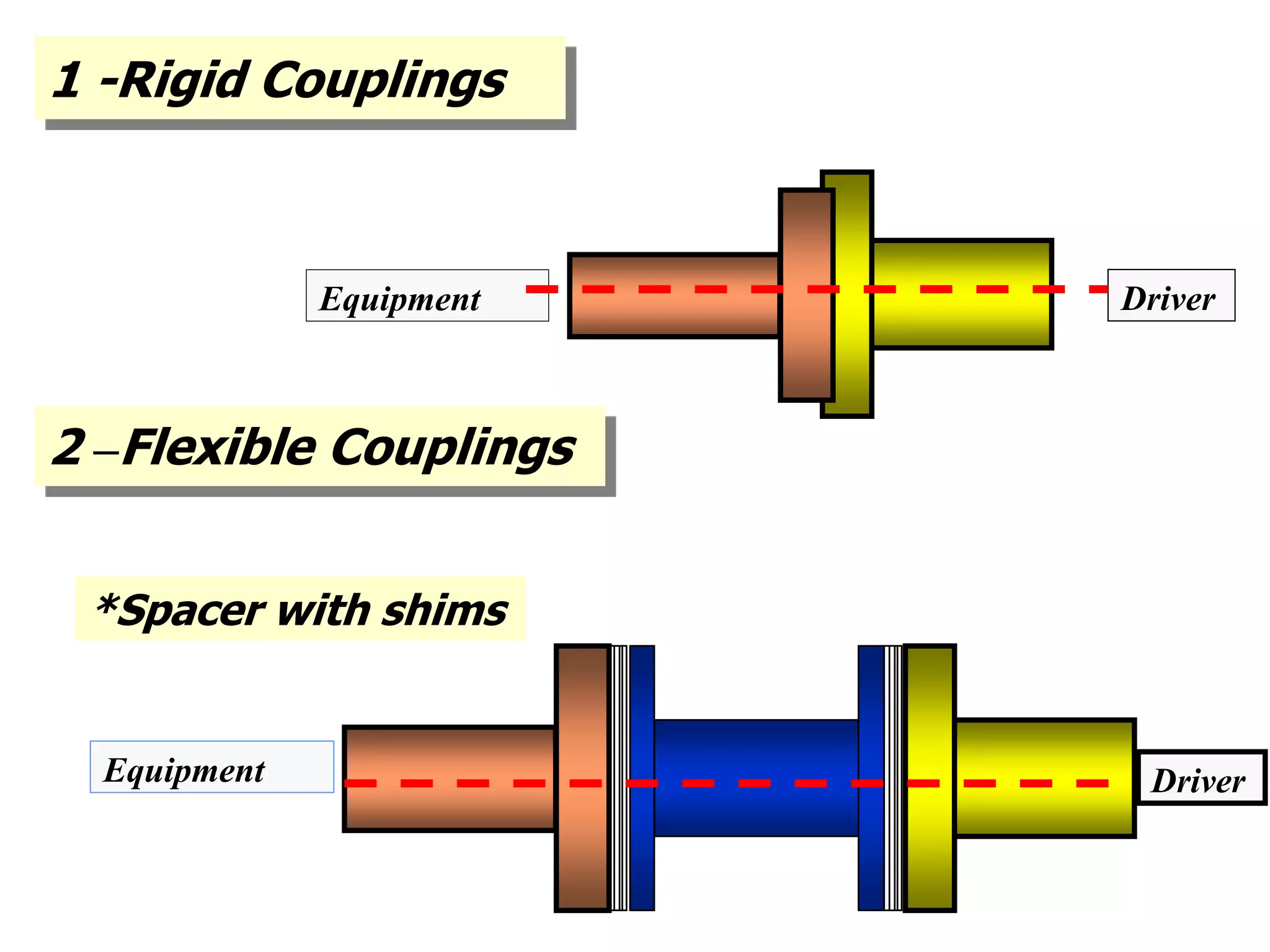

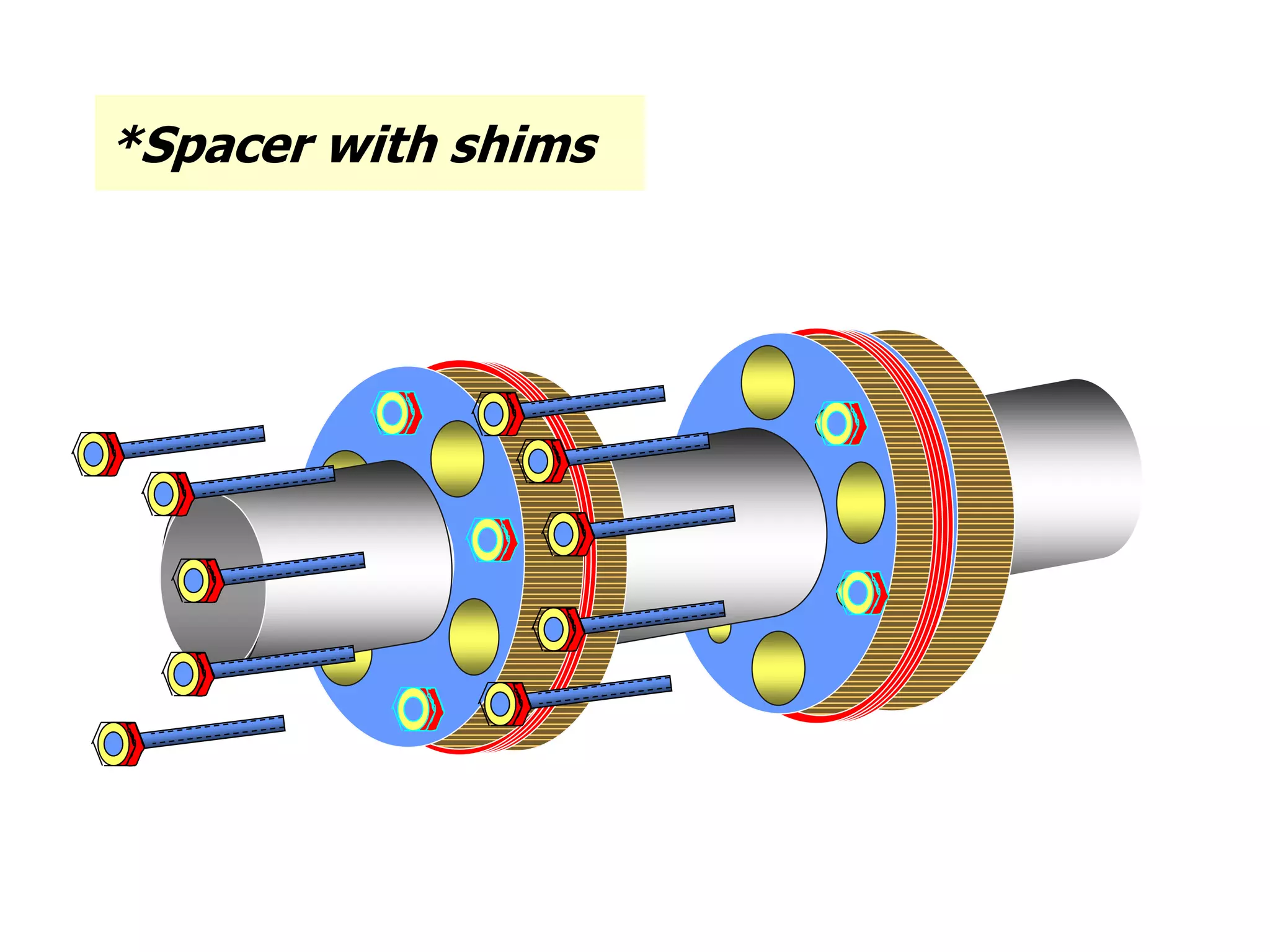

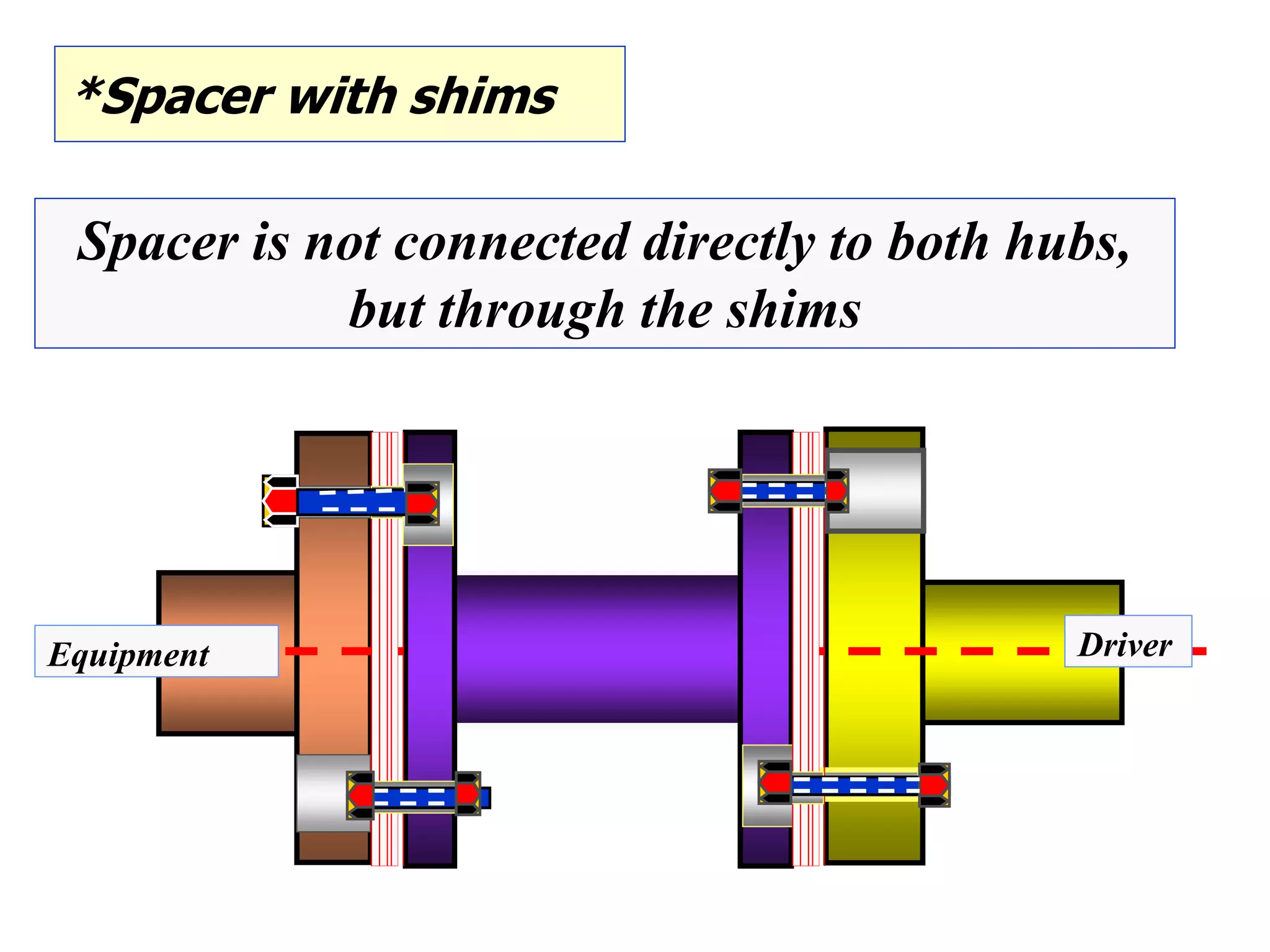

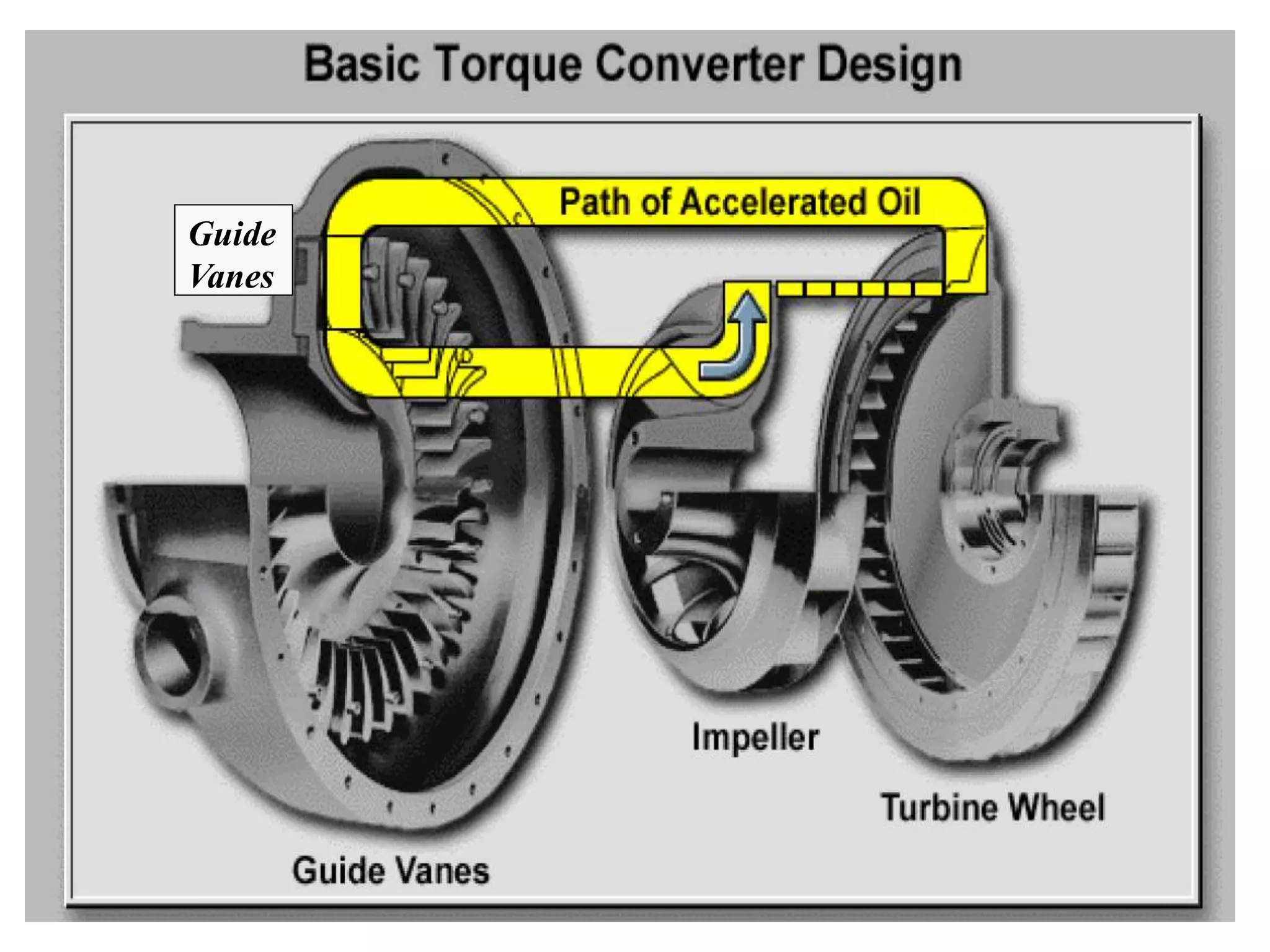

1. Types of couplings used in shaft alignment like rigid, flexible, gear, and torque converters.

2. The importance of proper shaft alignment to reduce vibration, heat, and maximize equipment life. Misalignment can cause early bearing failure.

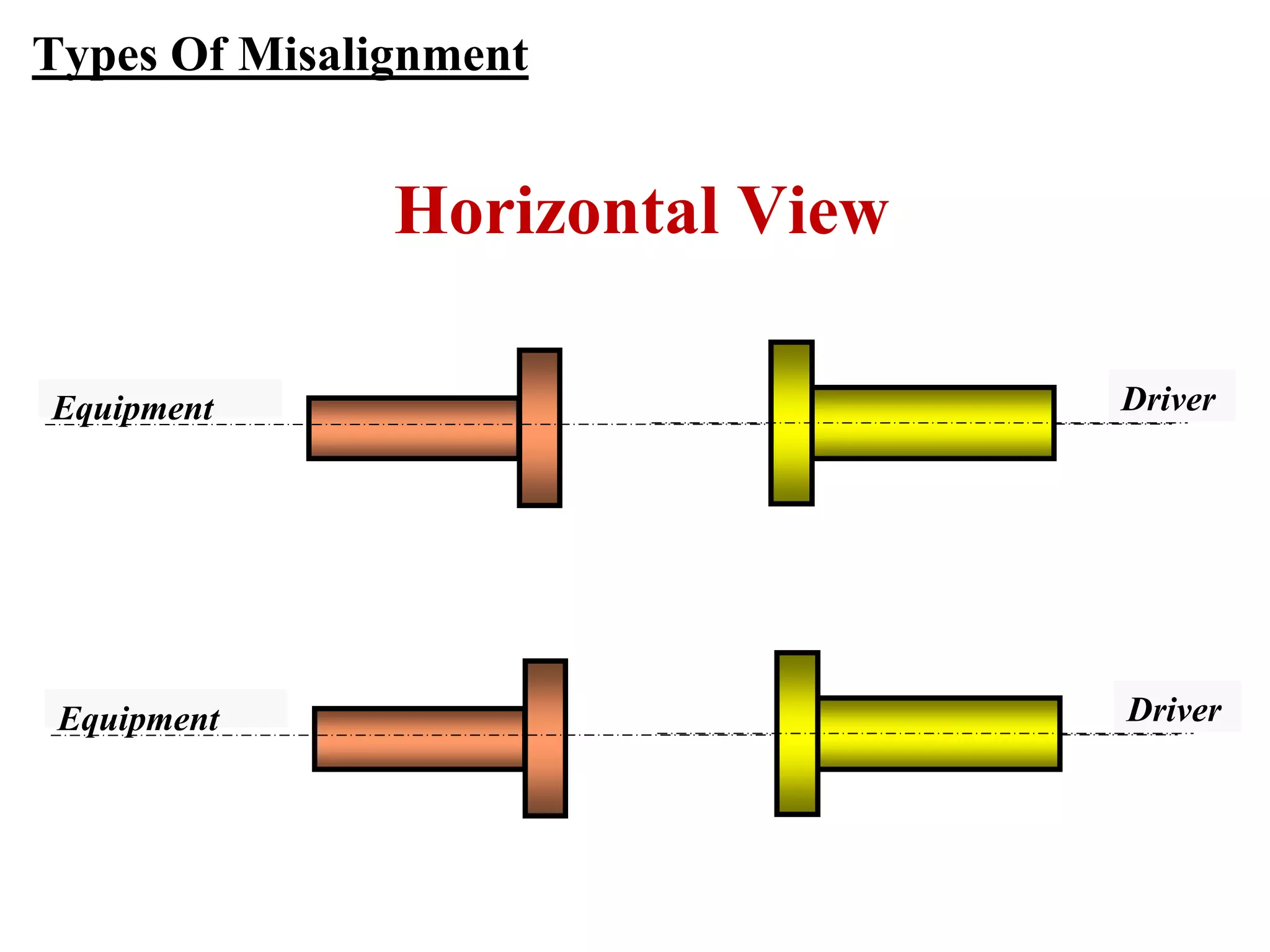

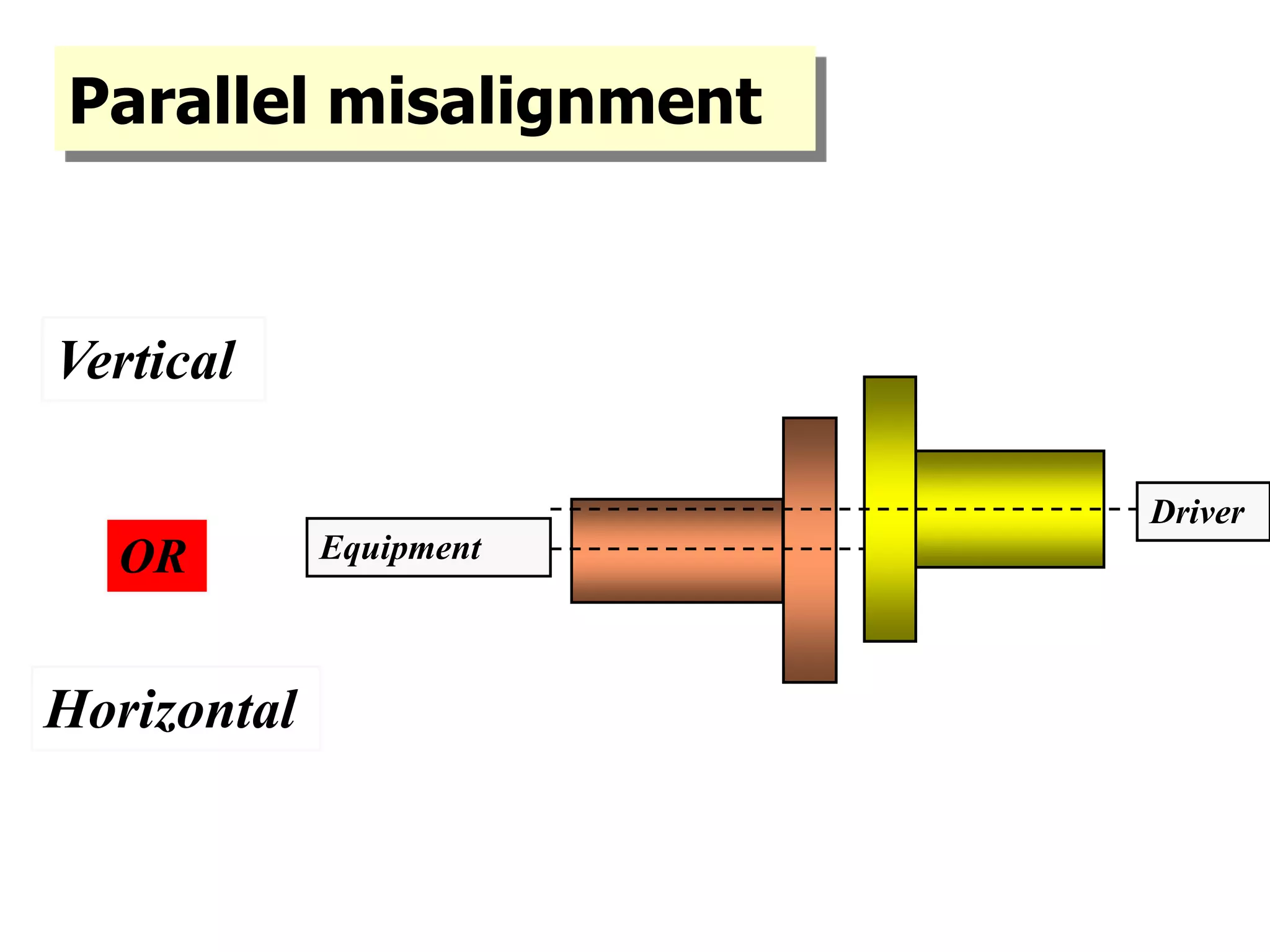

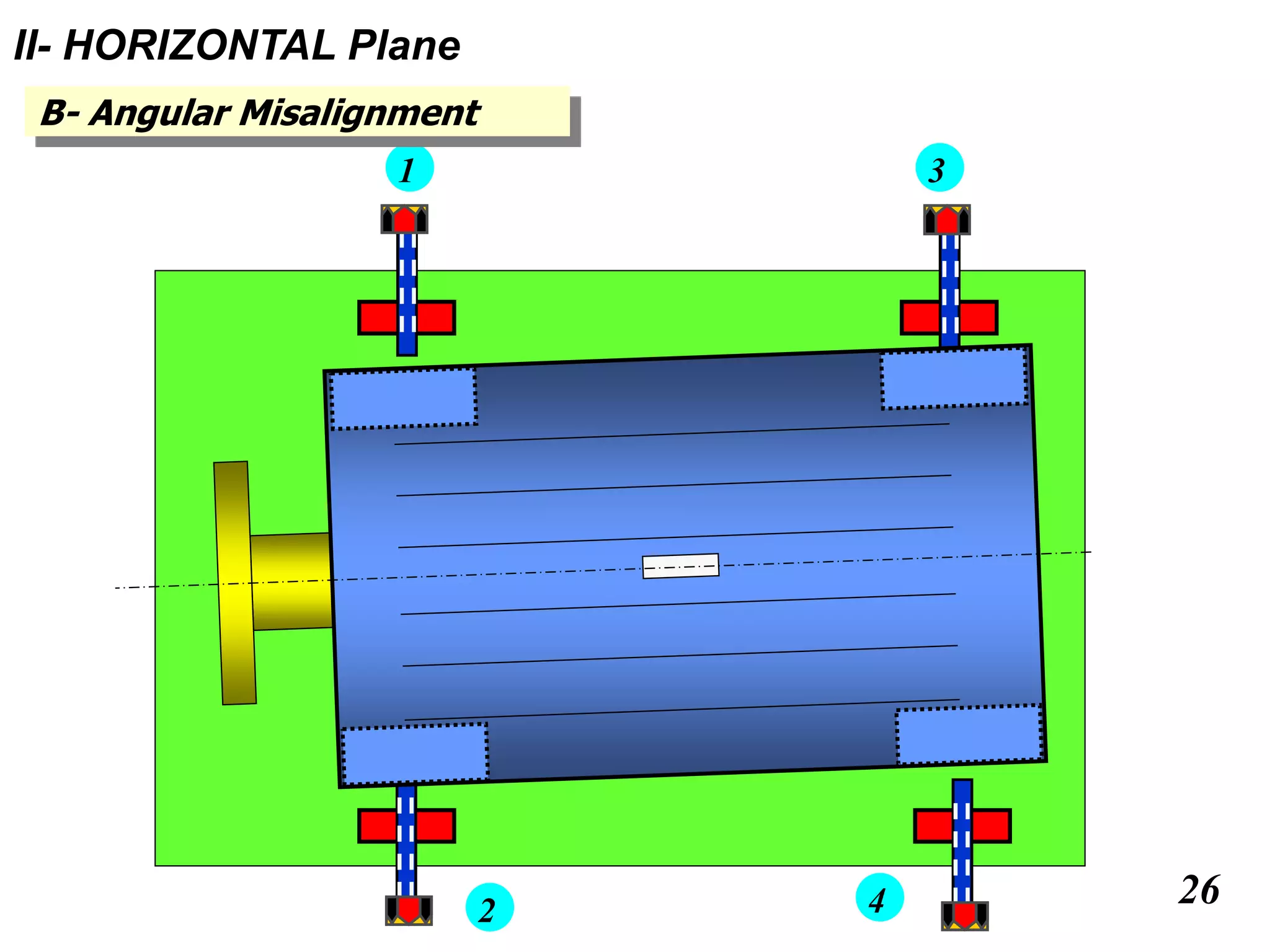

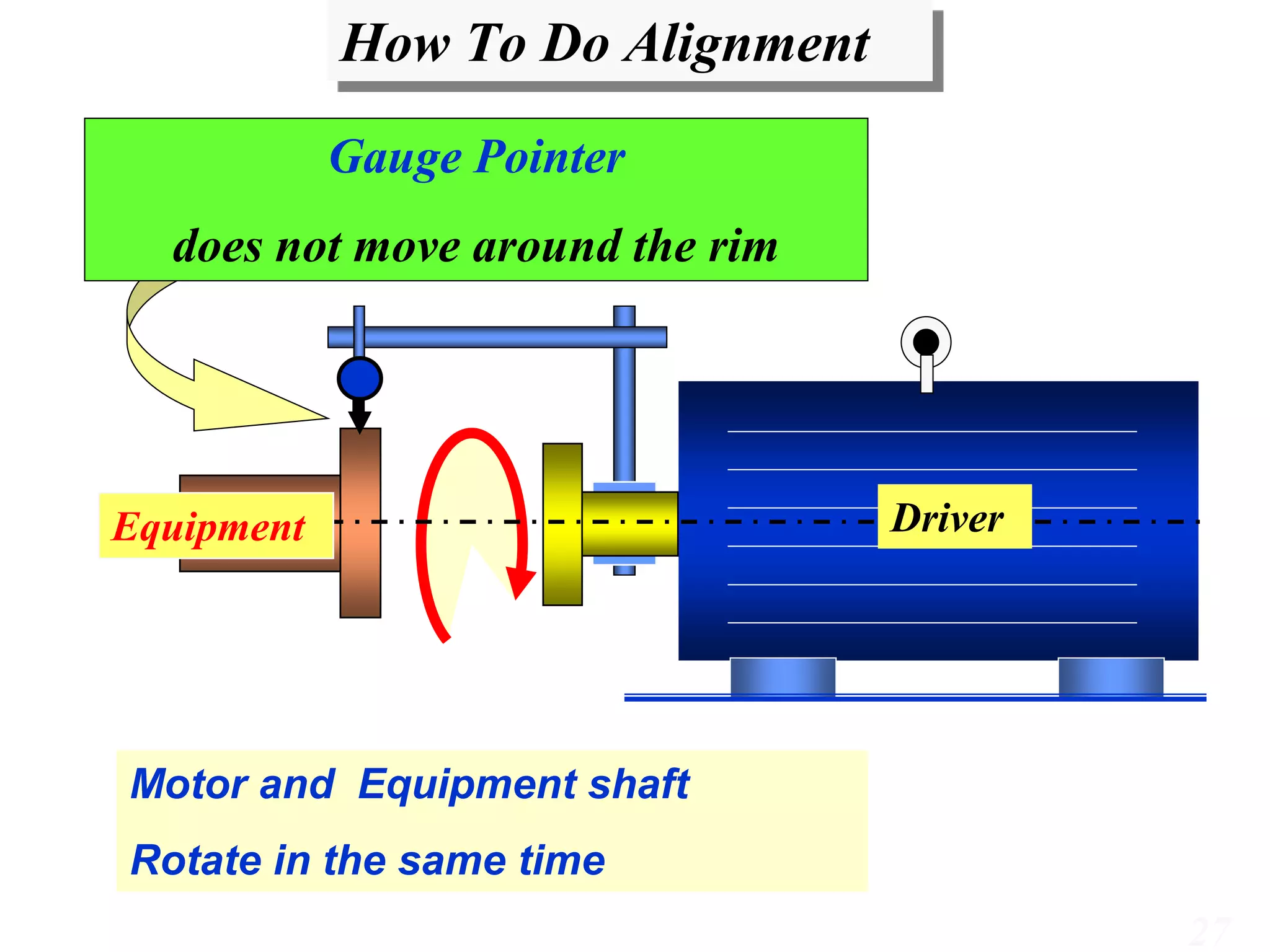

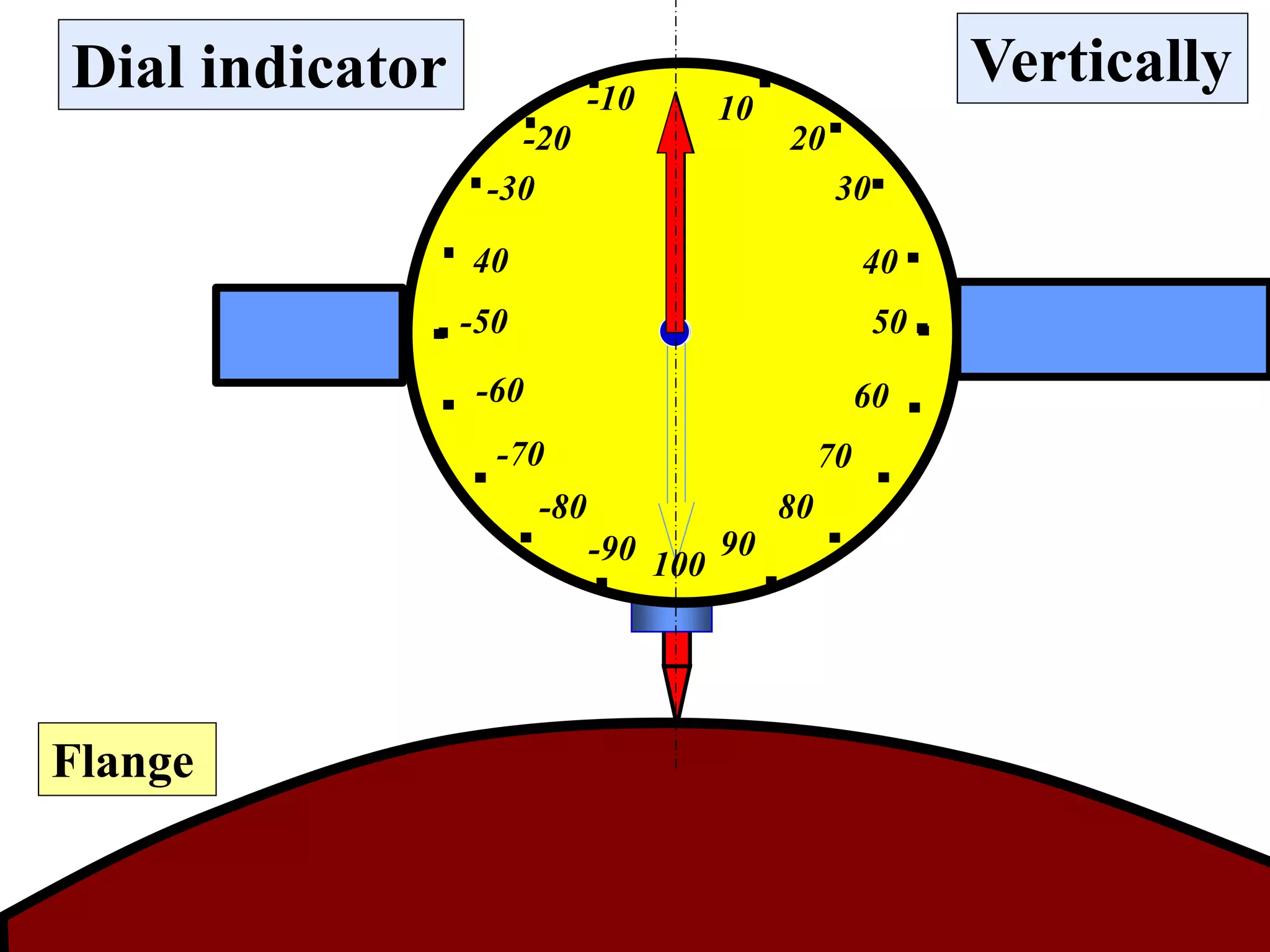

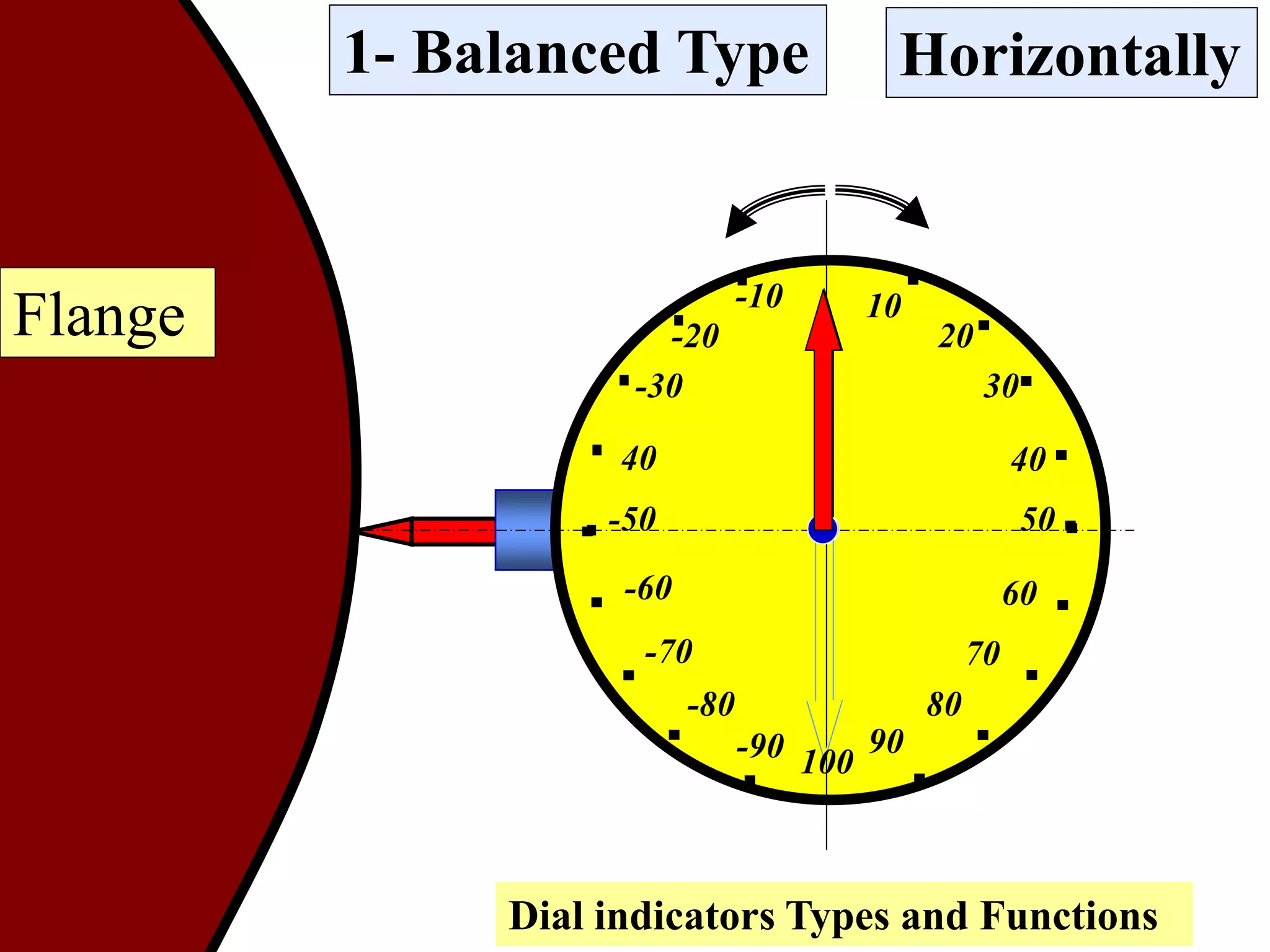

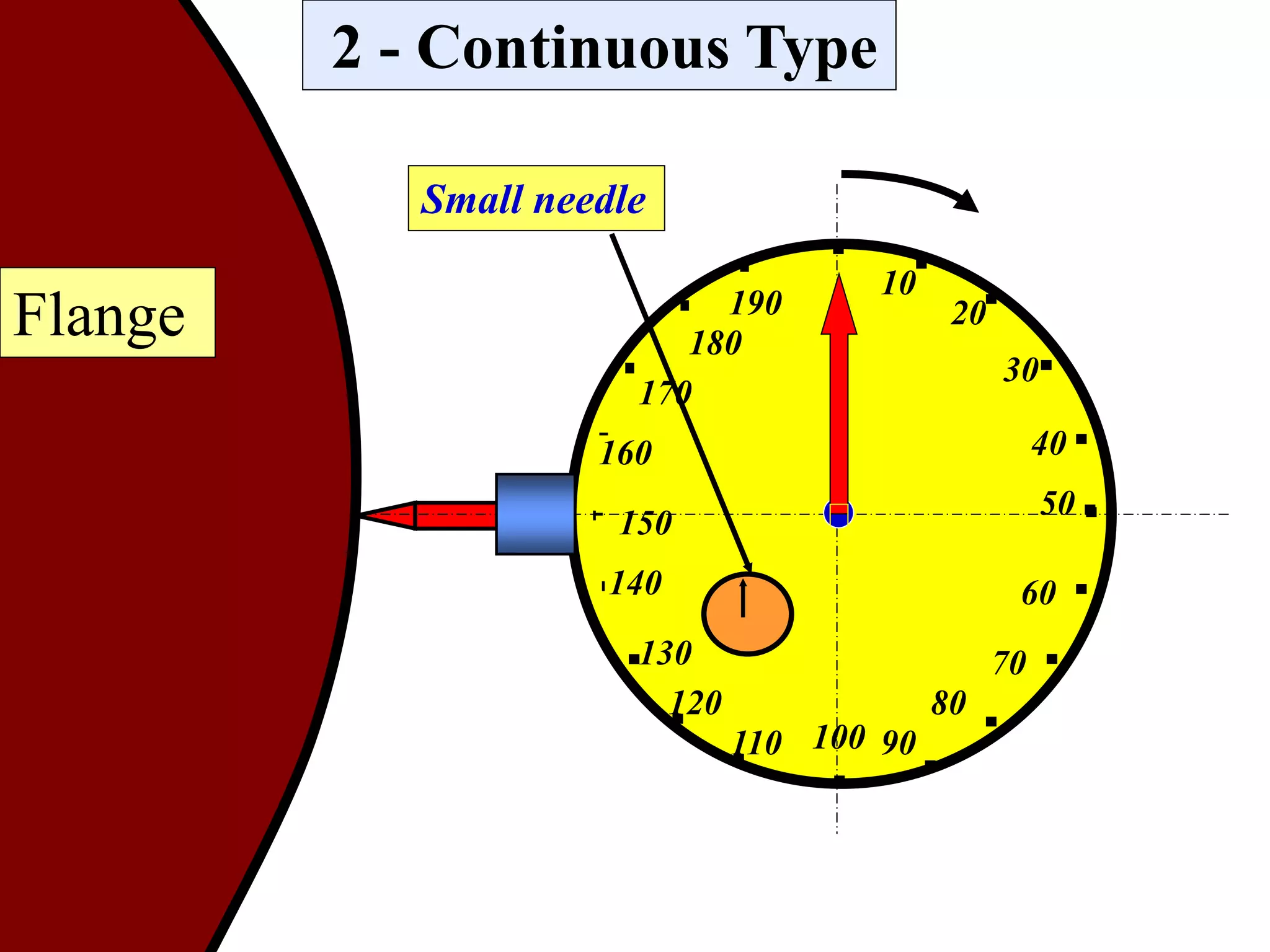

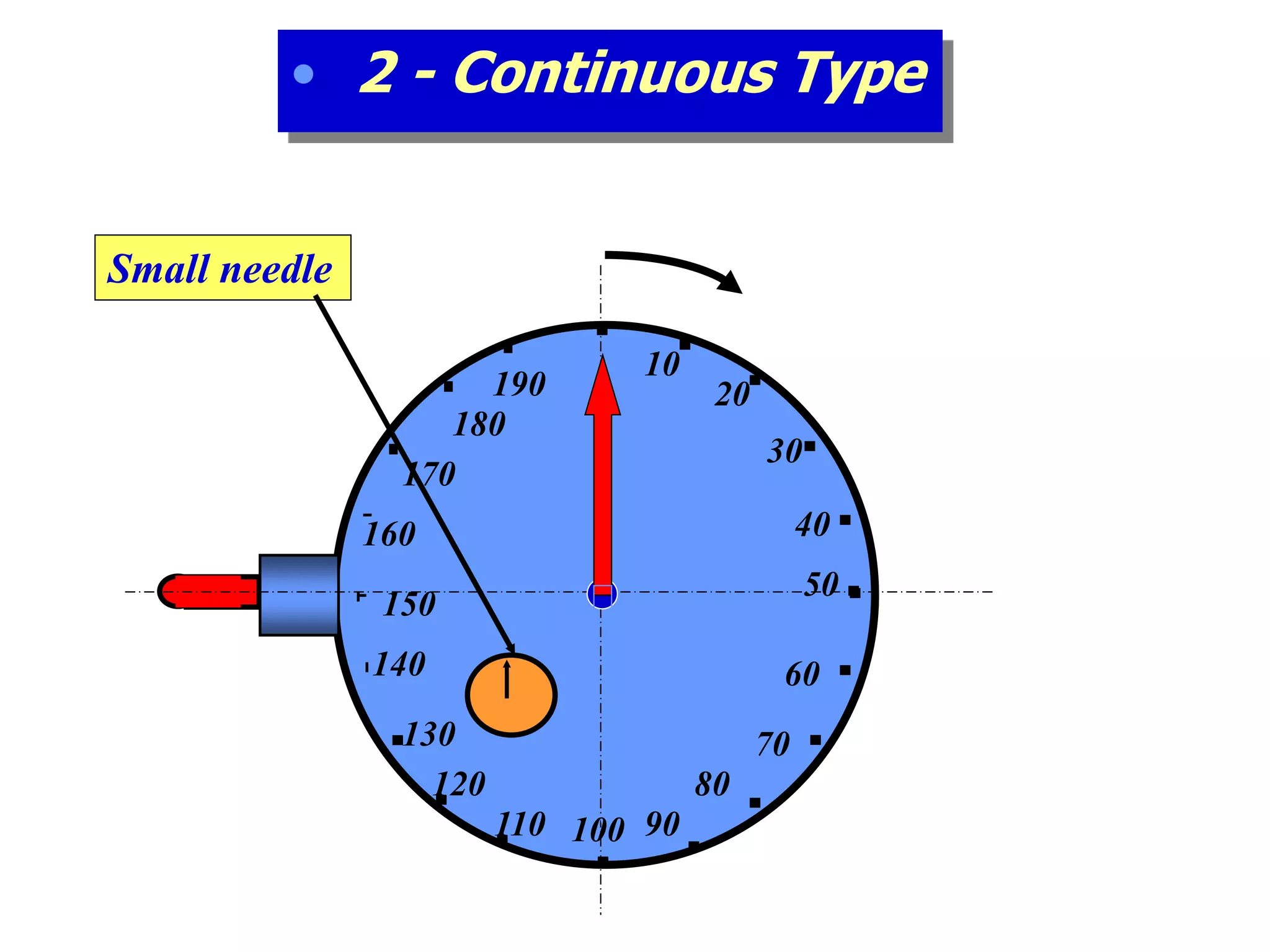

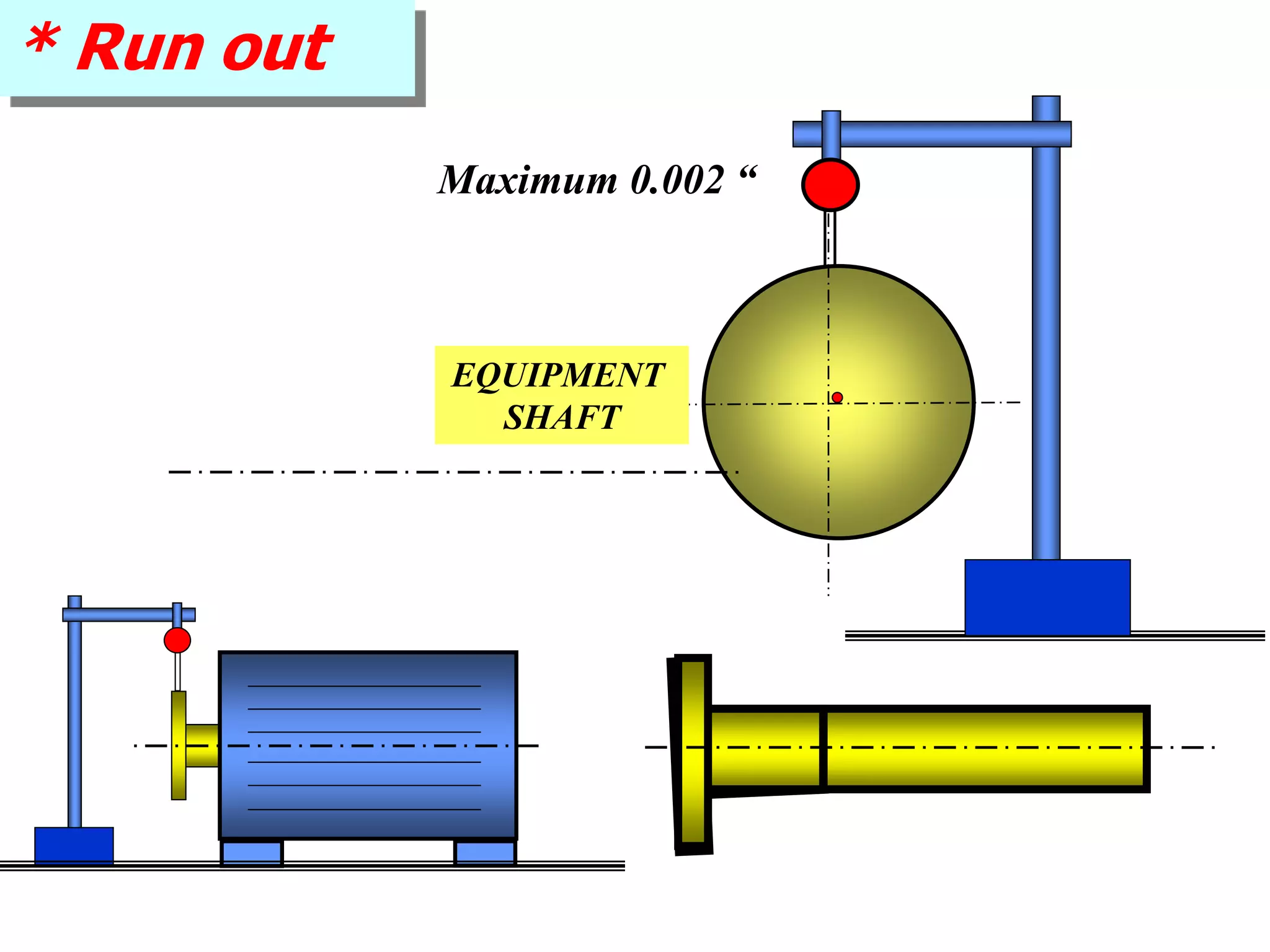

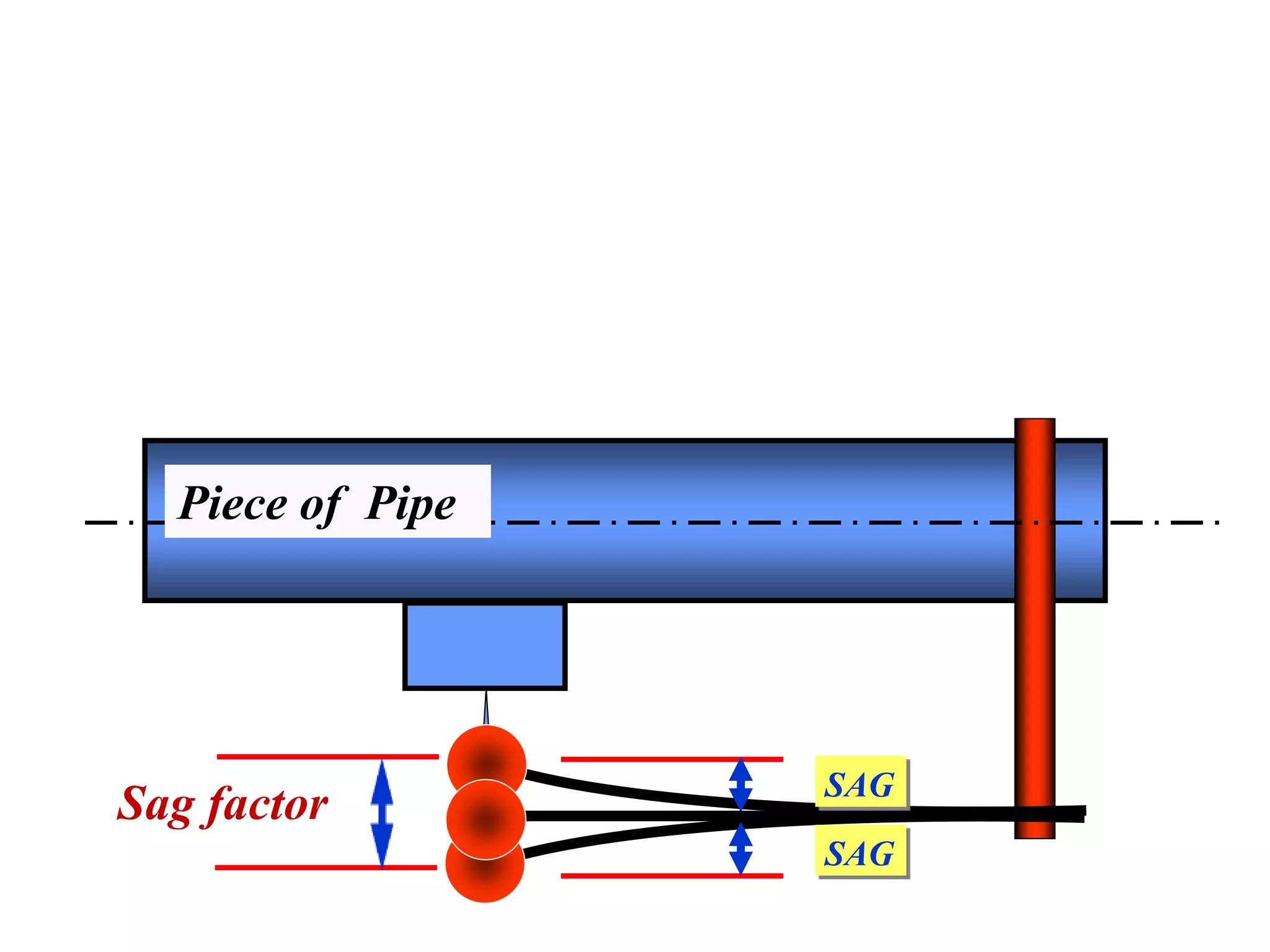

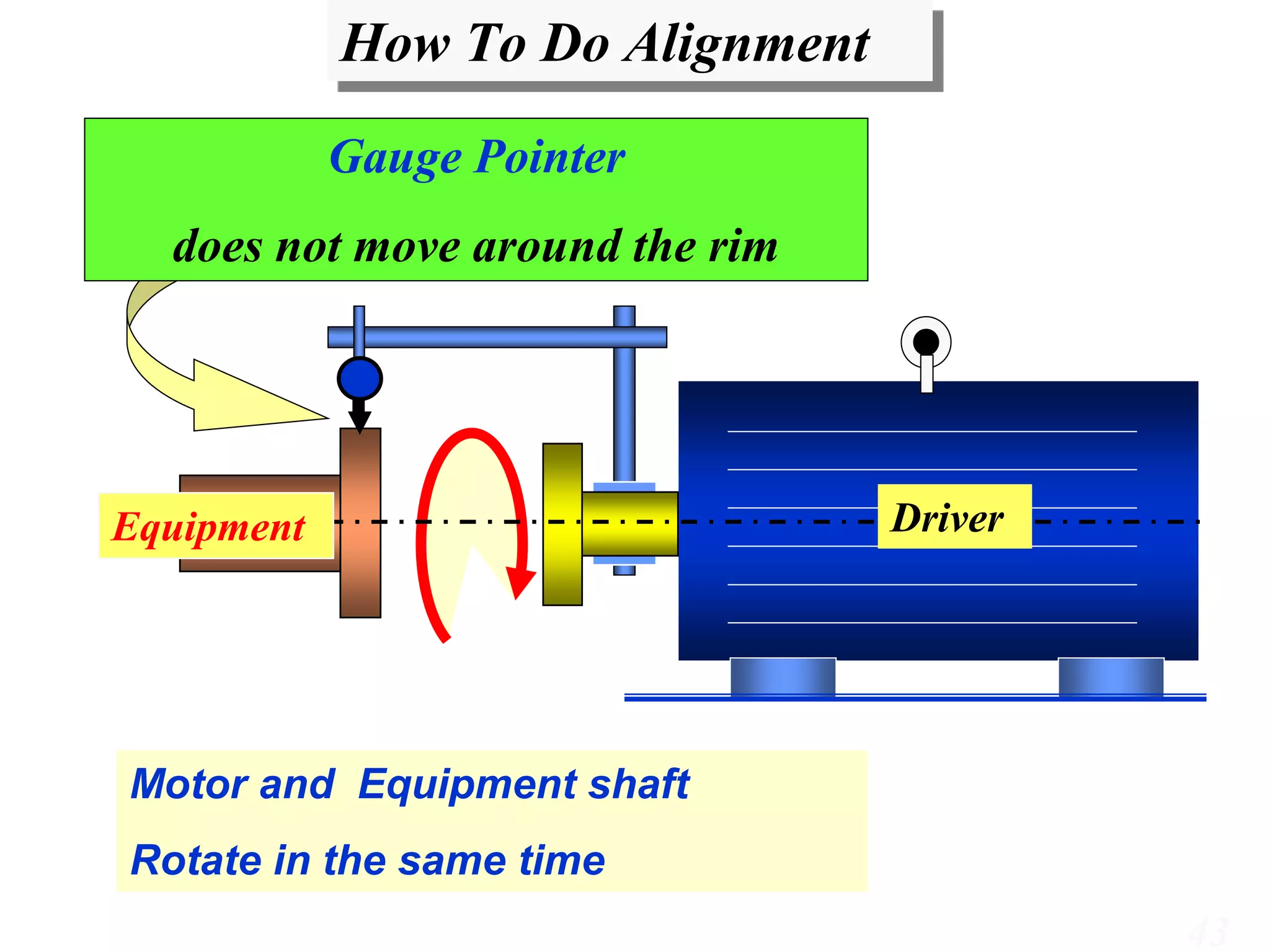

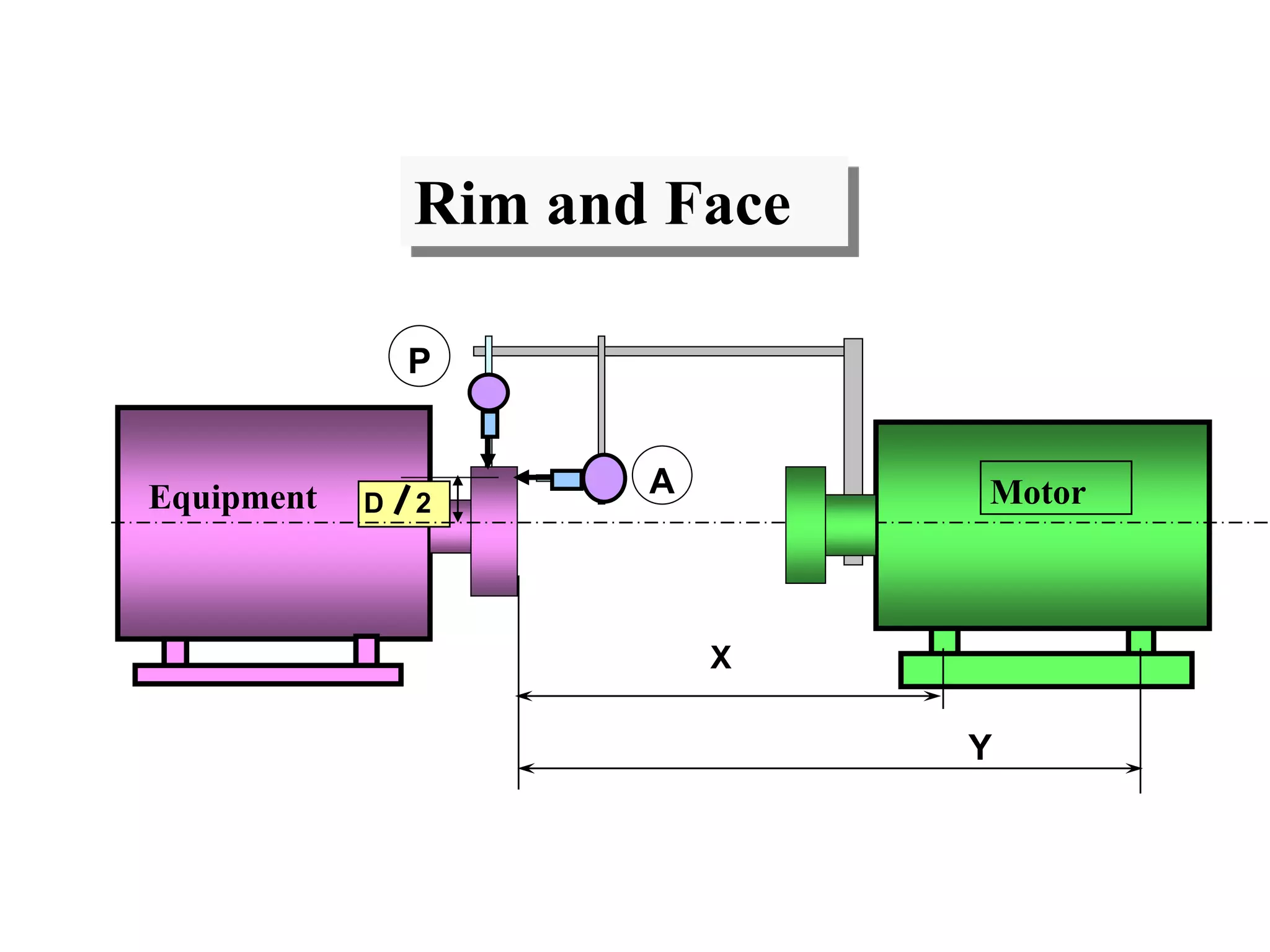

3. Alignment procedures including preparation checks, use of dial indicators, and correction of parallel and angular misalignments.

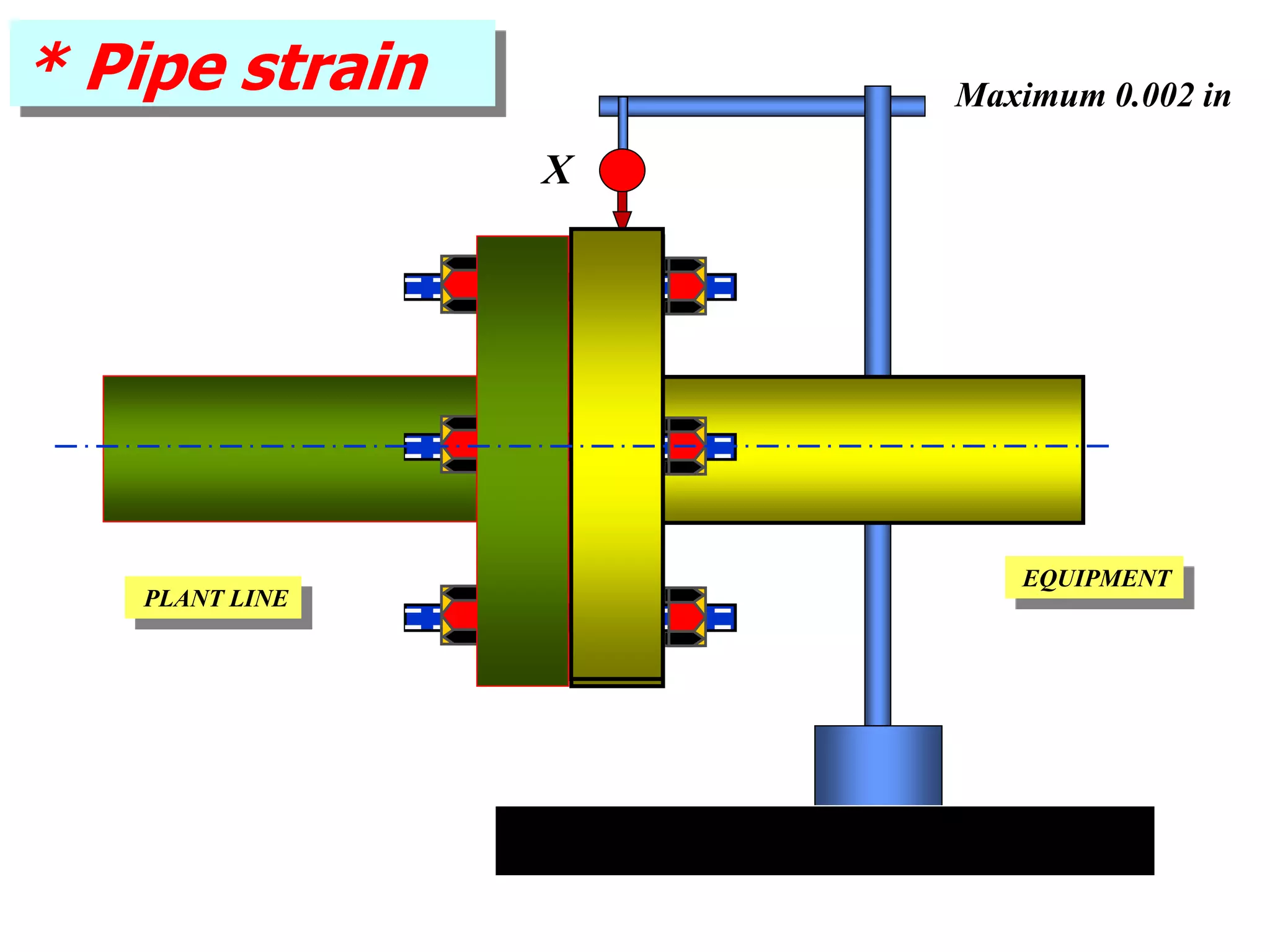

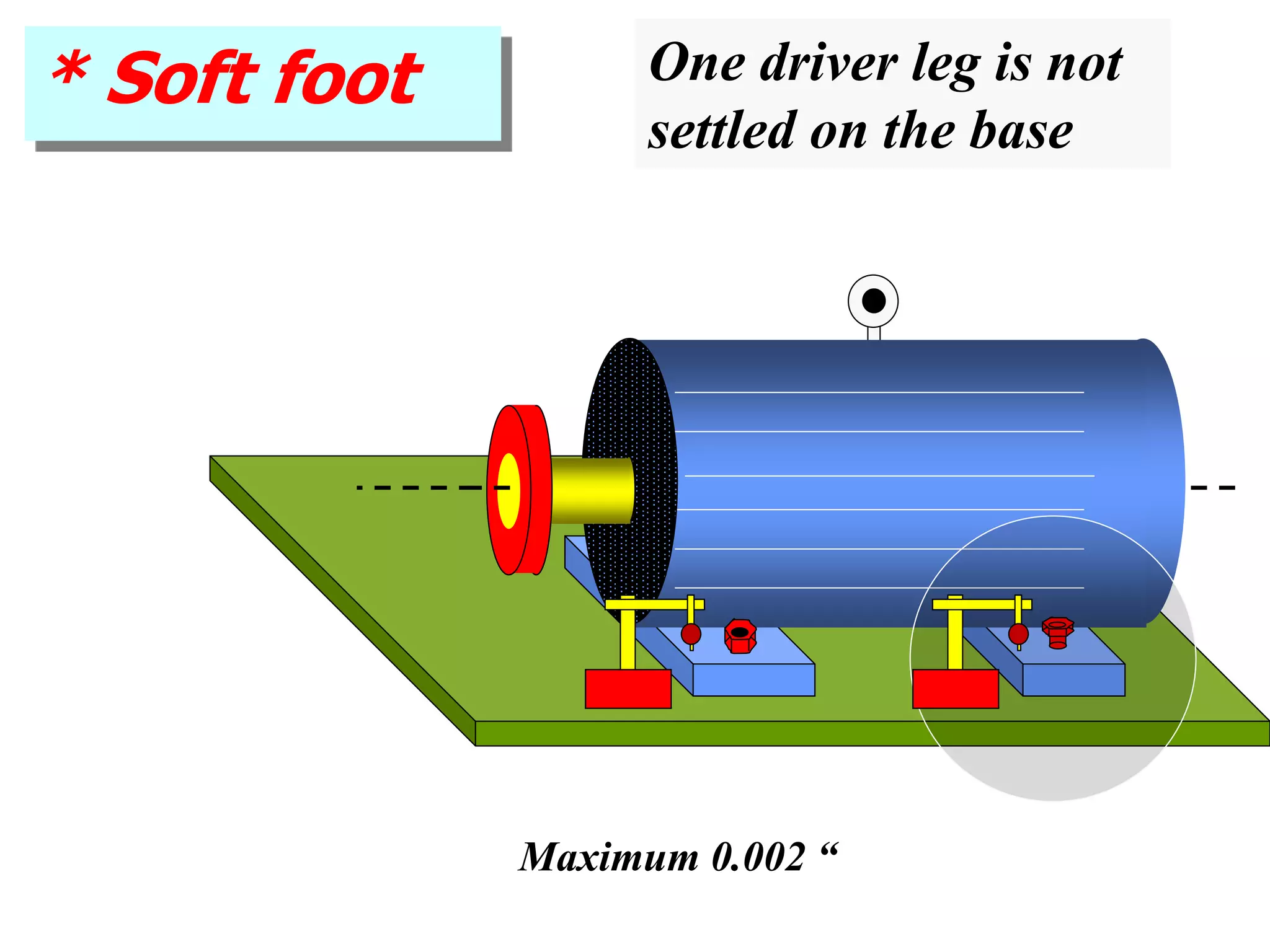

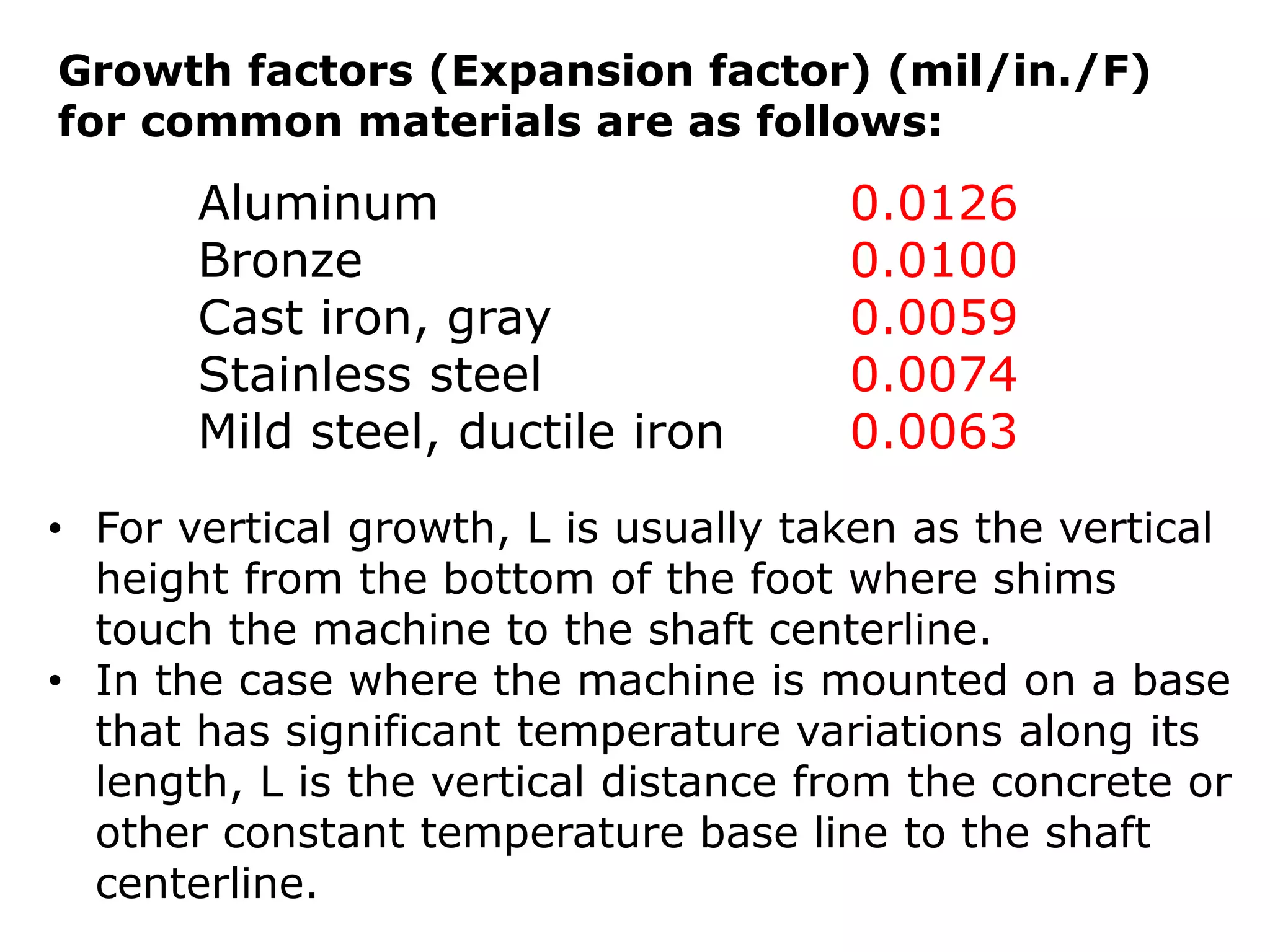

4. Factors that affect alignment like thermal growth, soft foot, pipe strain, and runout must be considered.