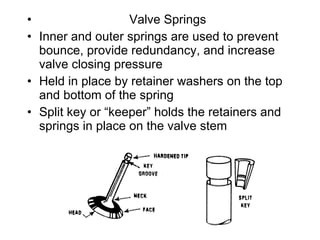

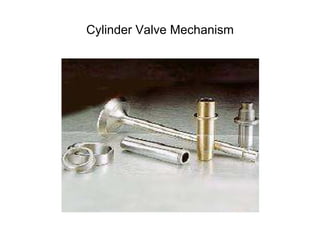

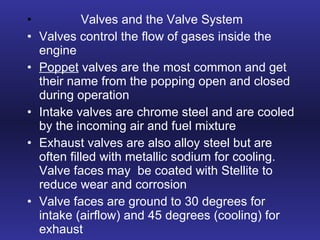

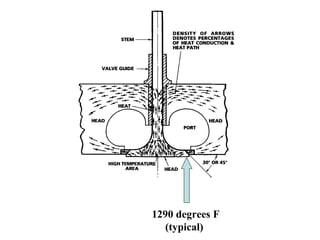

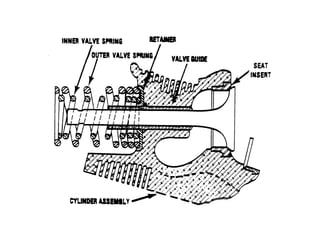

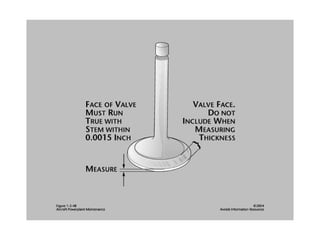

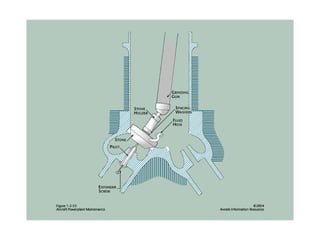

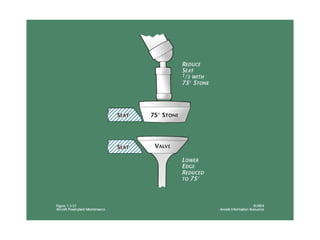

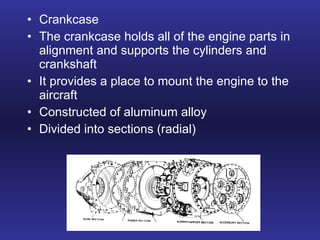

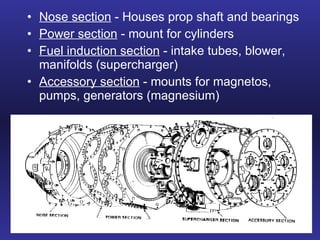

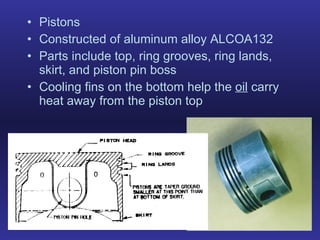

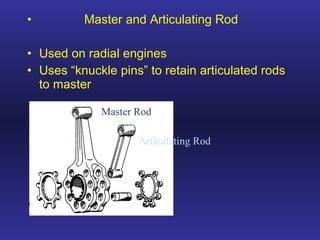

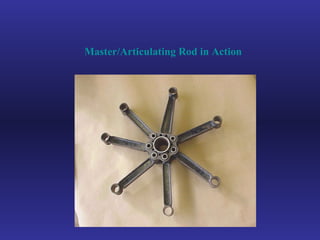

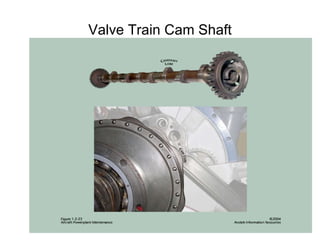

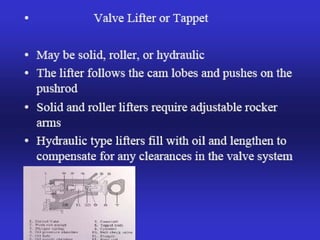

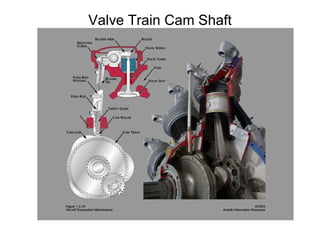

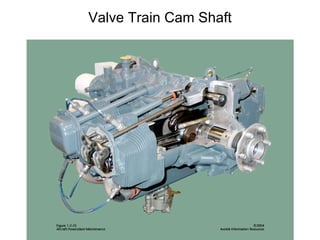

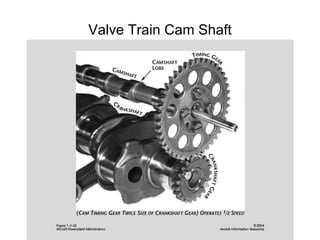

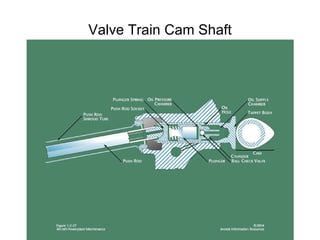

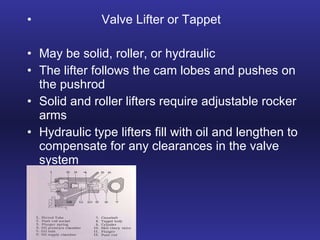

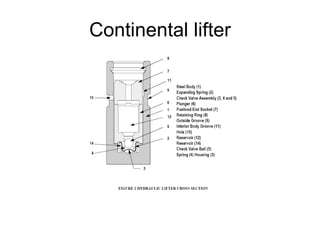

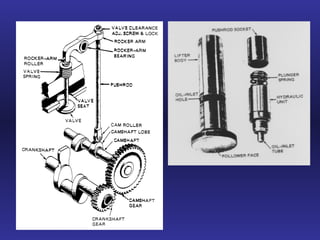

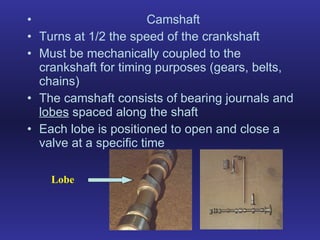

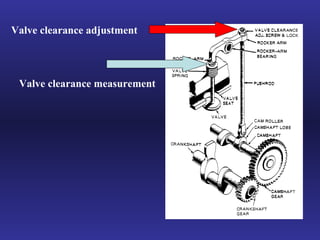

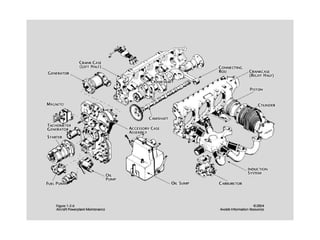

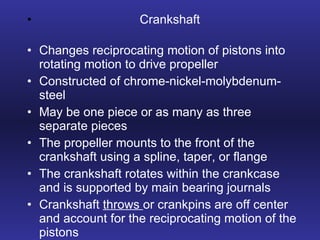

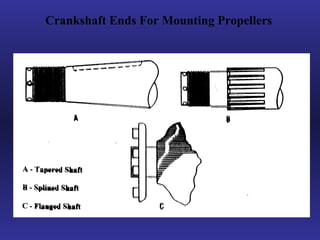

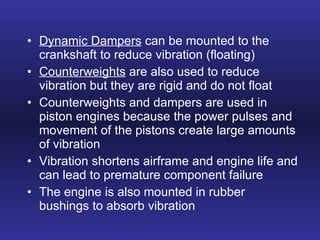

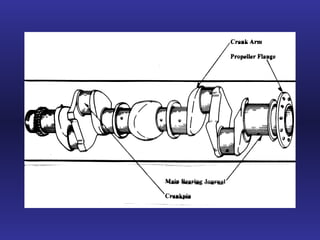

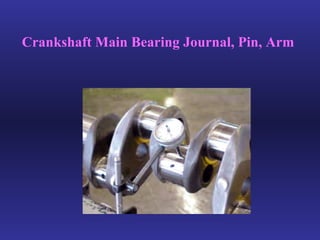

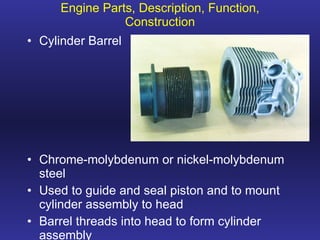

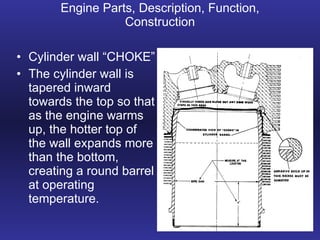

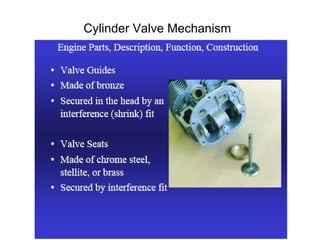

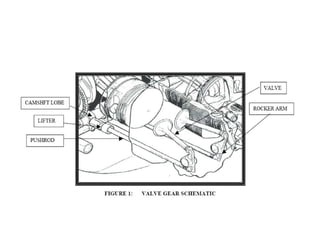

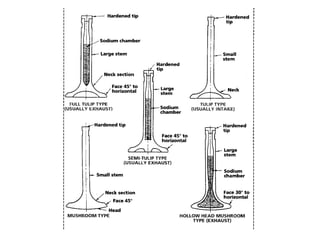

The document summarizes key reciprocating engine components. It describes how the crankshaft converts the reciprocating motion of the pistons into rotation to drive the propeller. It also discusses the cylinder head, barrels, valves and valve train including camshafts, lifters, pushrods and rocker arms that control airflow into and out of the cylinders. The crankcase houses and supports these components to transfer power from the pistons.

![Valve and Guide Face Stellite alloy is a range of cobalt - chromium alloys designed for wear resistance. It may also contain tungsten and a small but important amount of carbon . It is a trademarked name of the Deloro Stellite Company and was invented by Elwood Haynes [1] in the early 1900s as a substitute for flatware that stained (or that had to be constantly cleaned).](https://image.slidesharecdn.com/reciptengcomp3-091209090222-phpapp02/85/Reciptengcomp3-37-320.jpg)