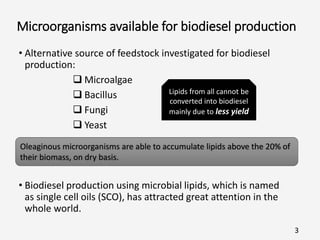

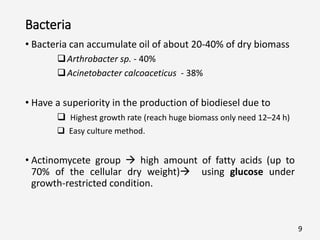

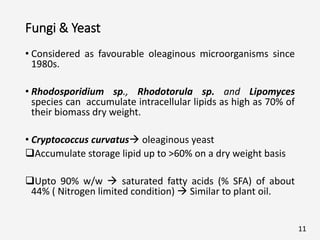

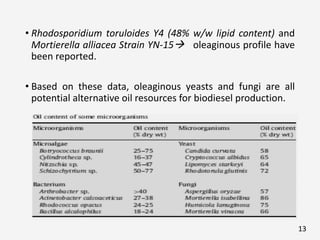

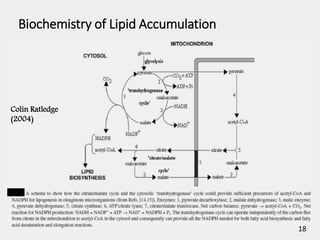

Microorganisms such as microalgae, fungi and bacteria have the potential to be used for biodiesel production as they can accumulate high amounts of lipids. Oleaginous microorganisms accumulate over 20% of their dry weight as lipids. While microalgae and some fungi have been shown to accumulate over 60% lipids, genetic engineering and screening methods aim to further improve lipid yields. The biodiesel produced from microbial lipids has properties that meet biodiesel standards but the high costs of production need to be reduced for microbial biodiesel to compete with conventional fuels.