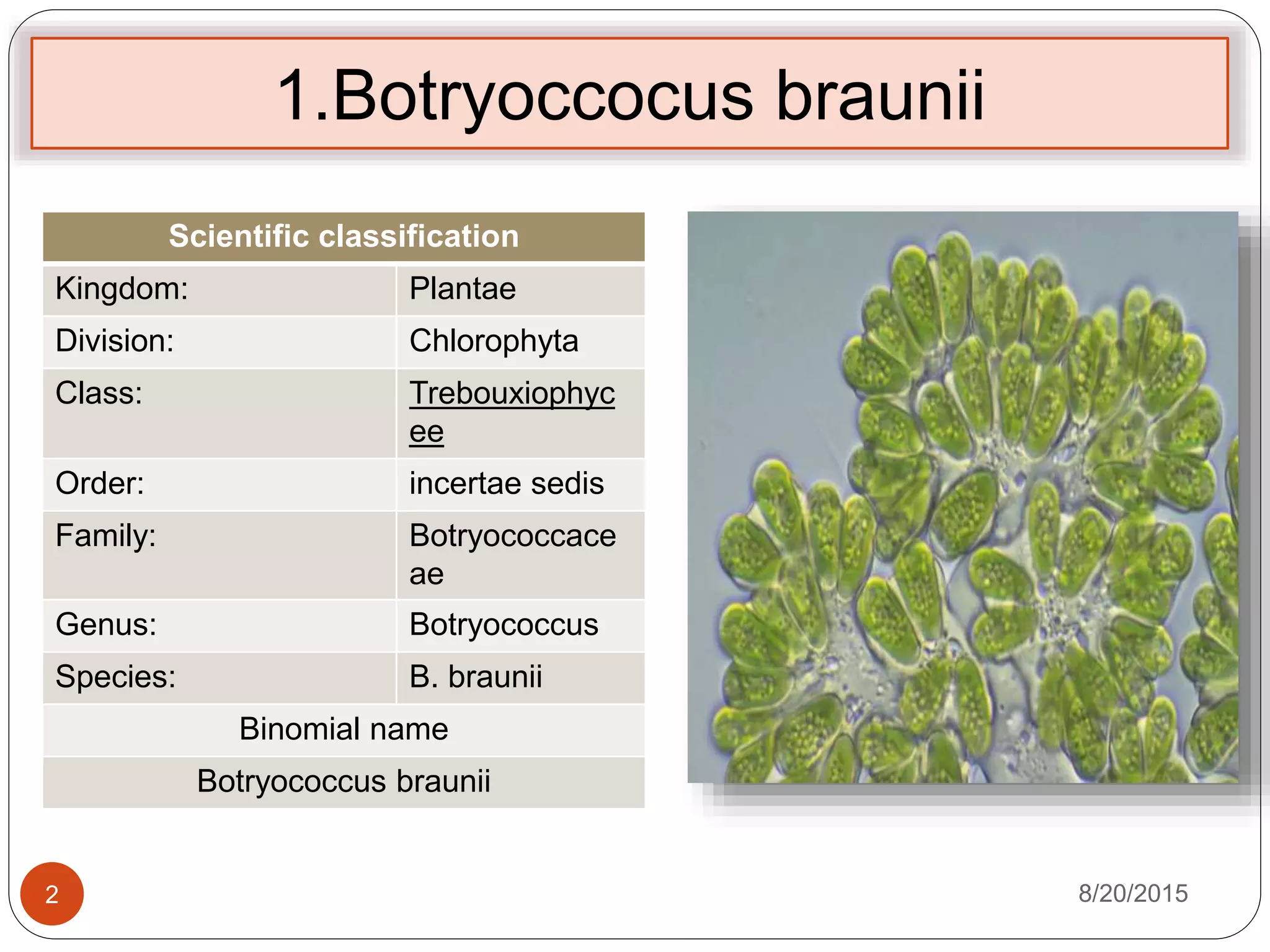

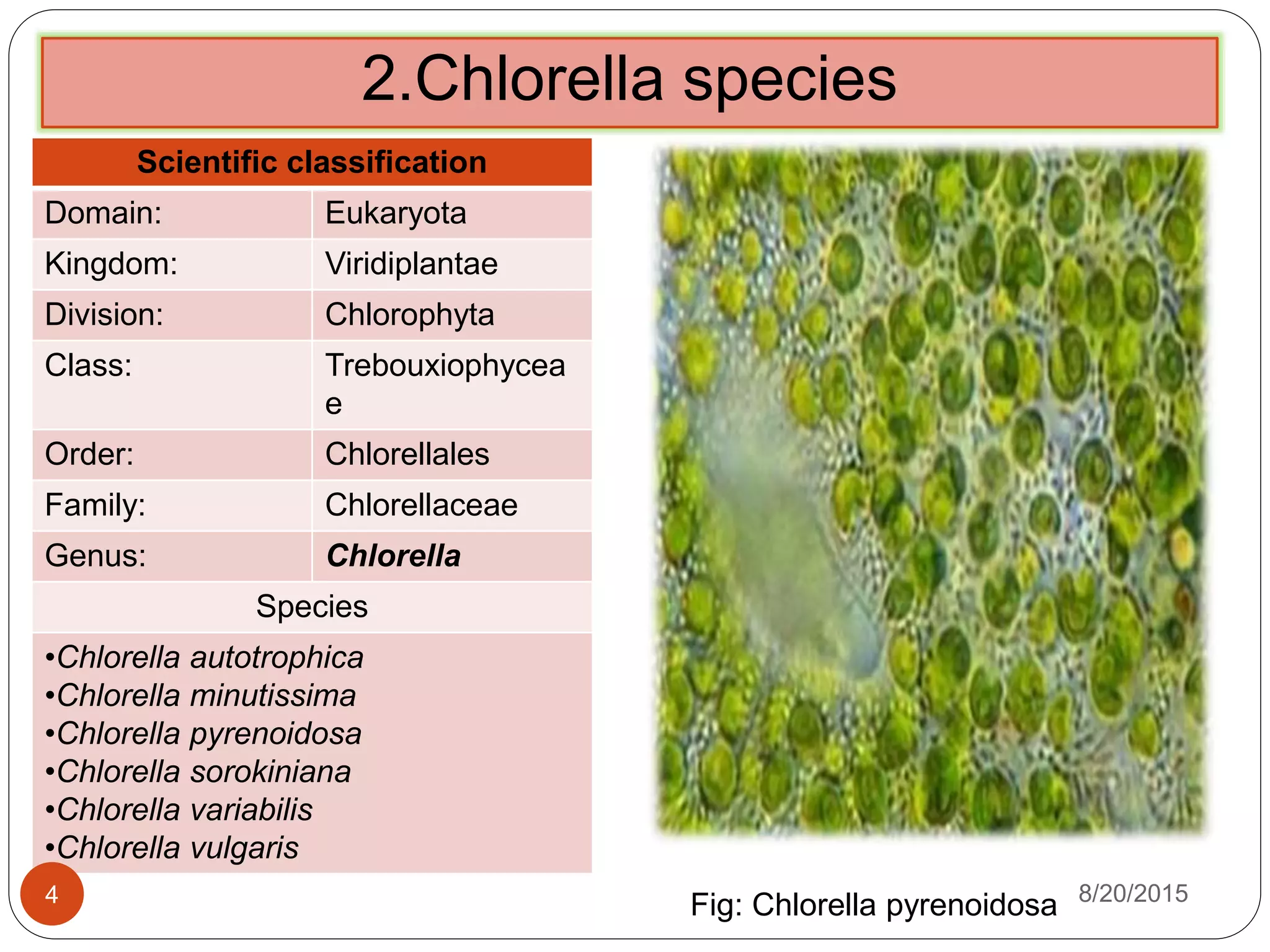

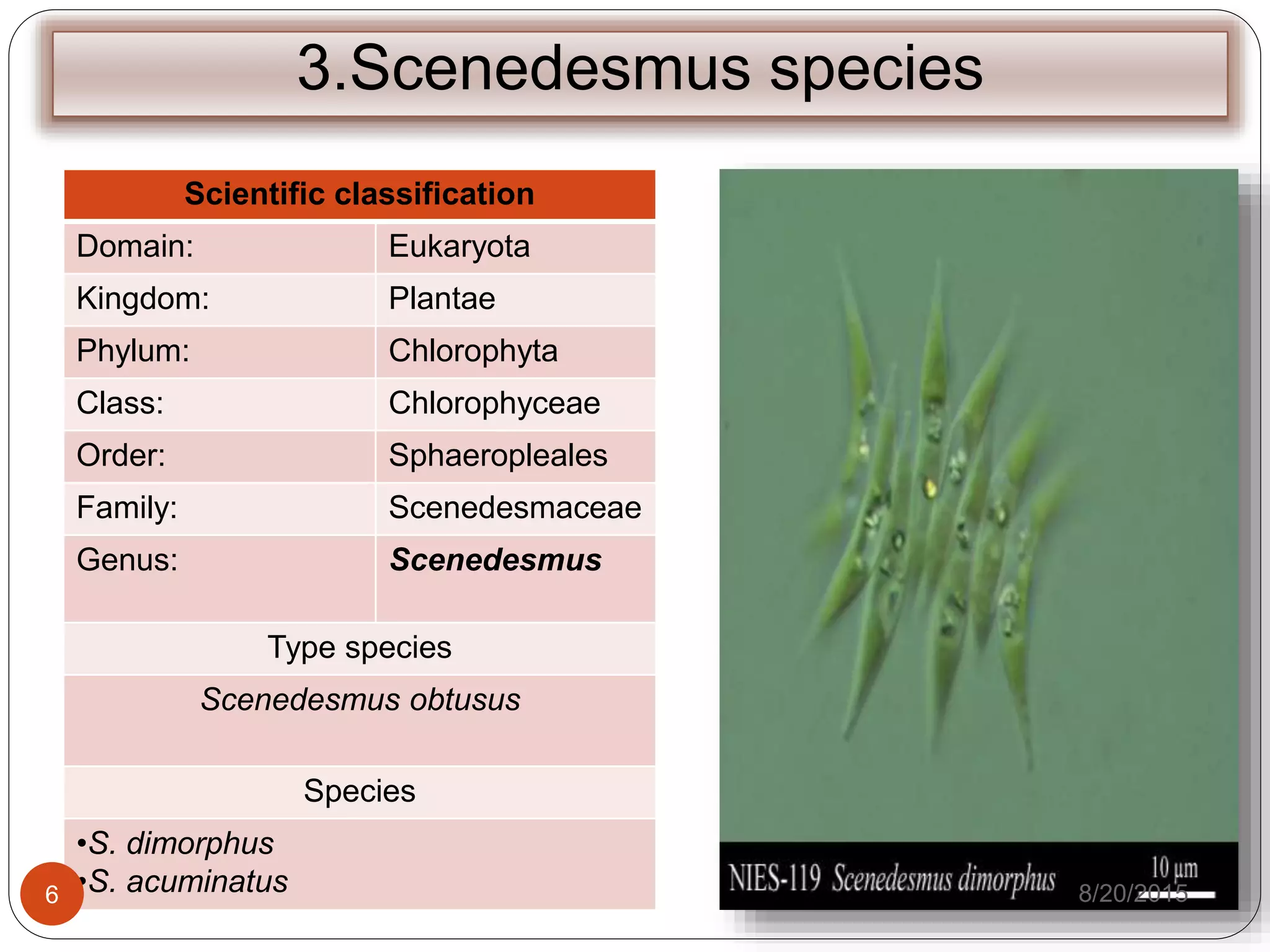

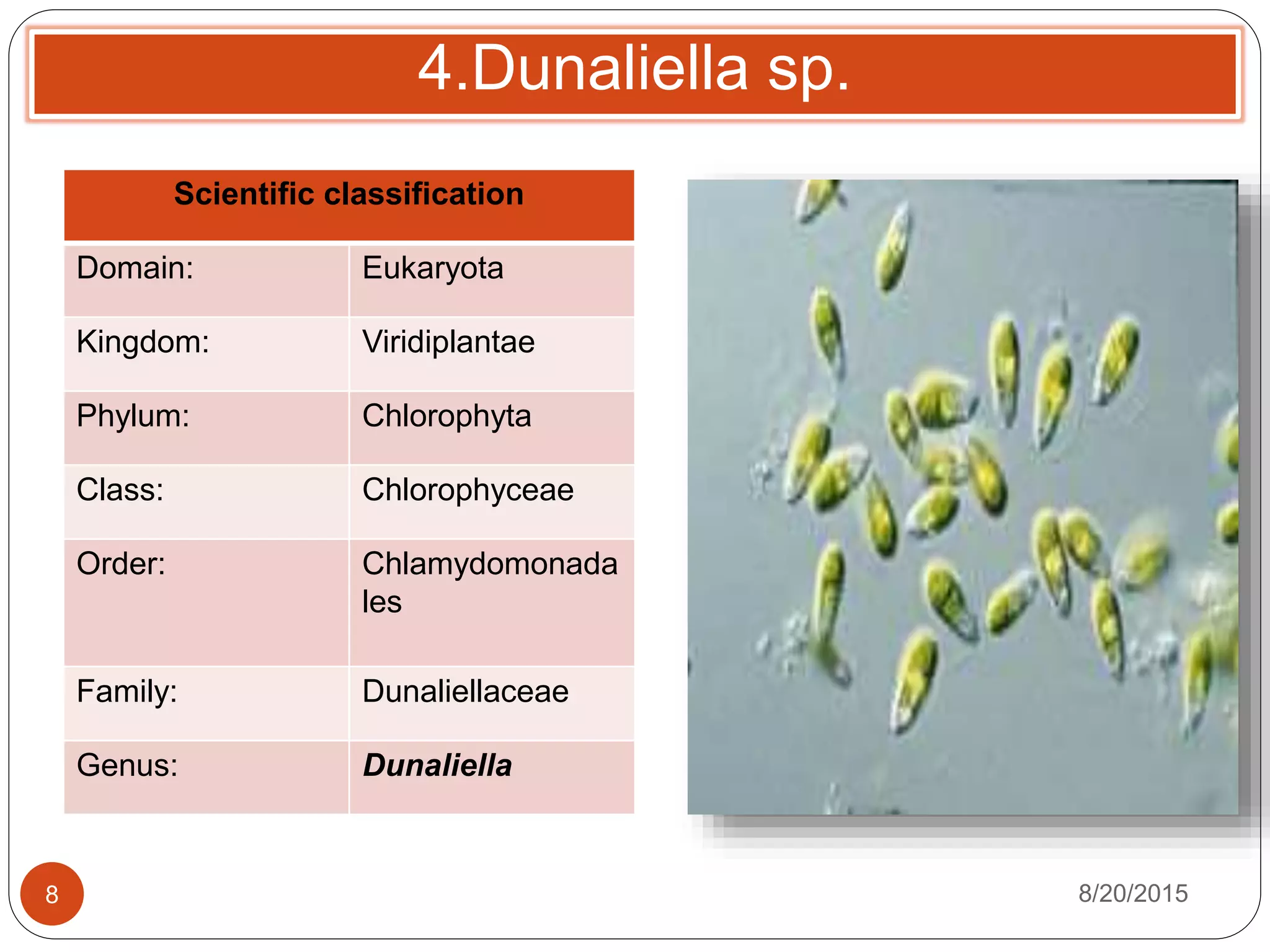

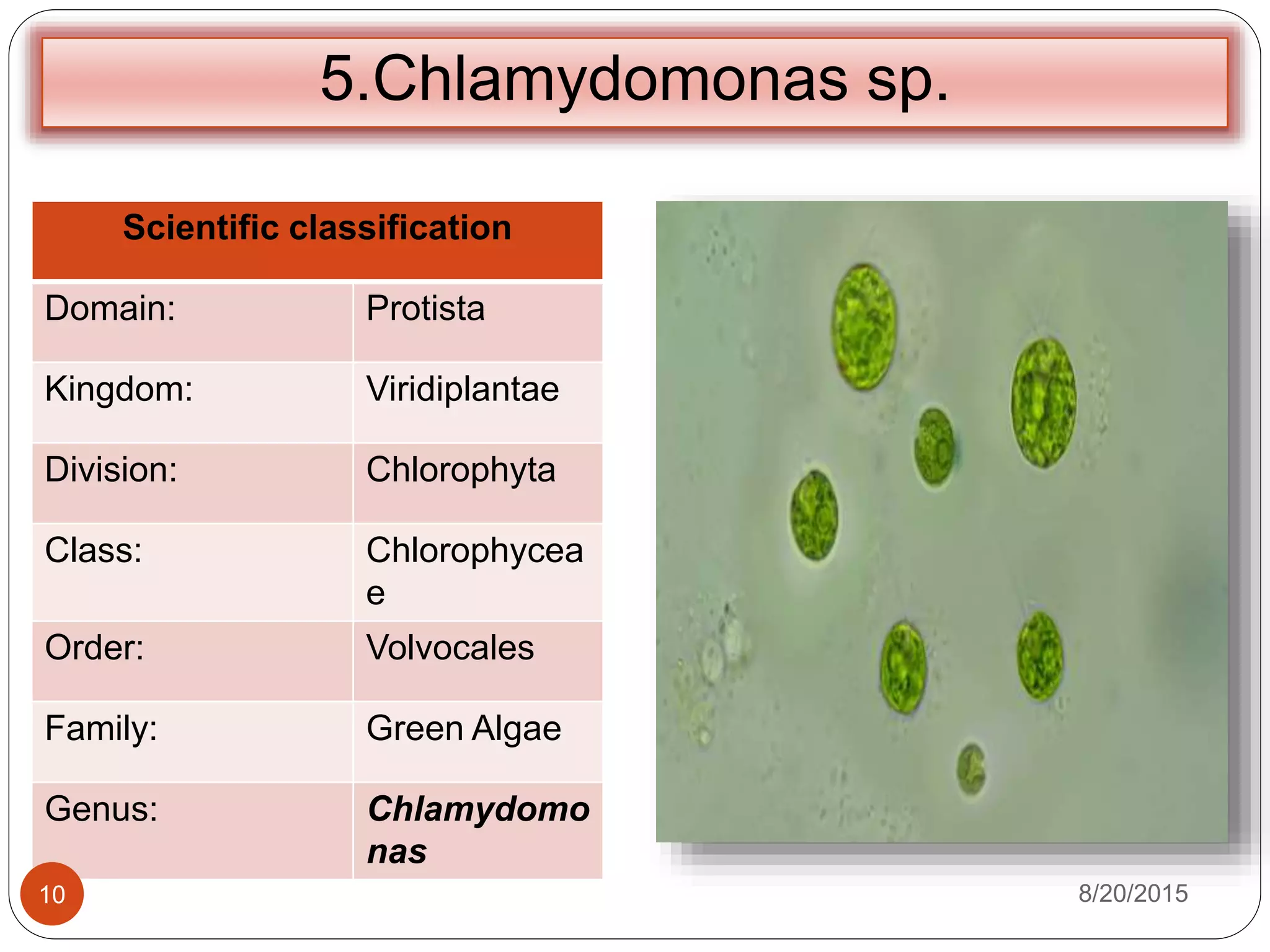

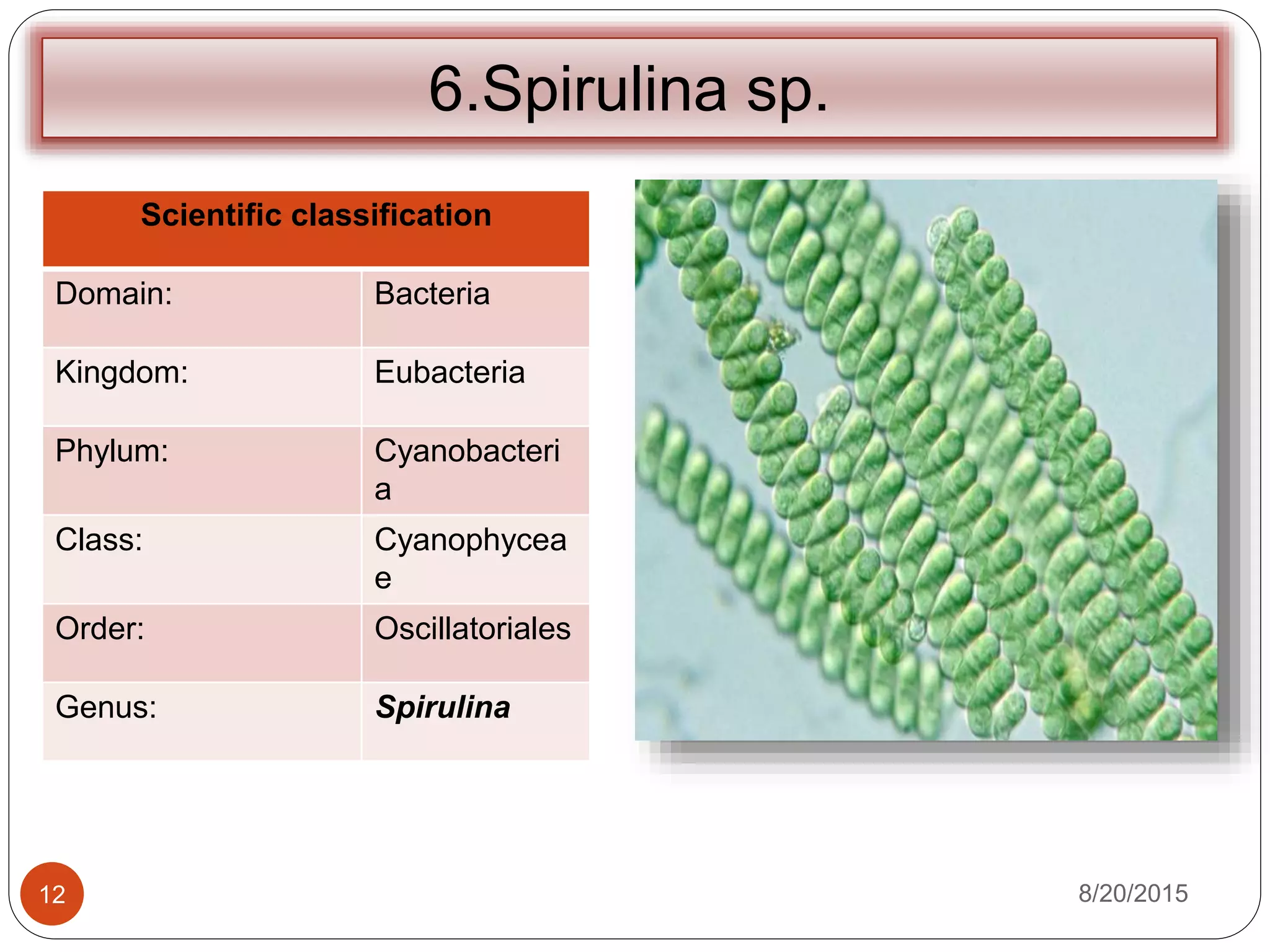

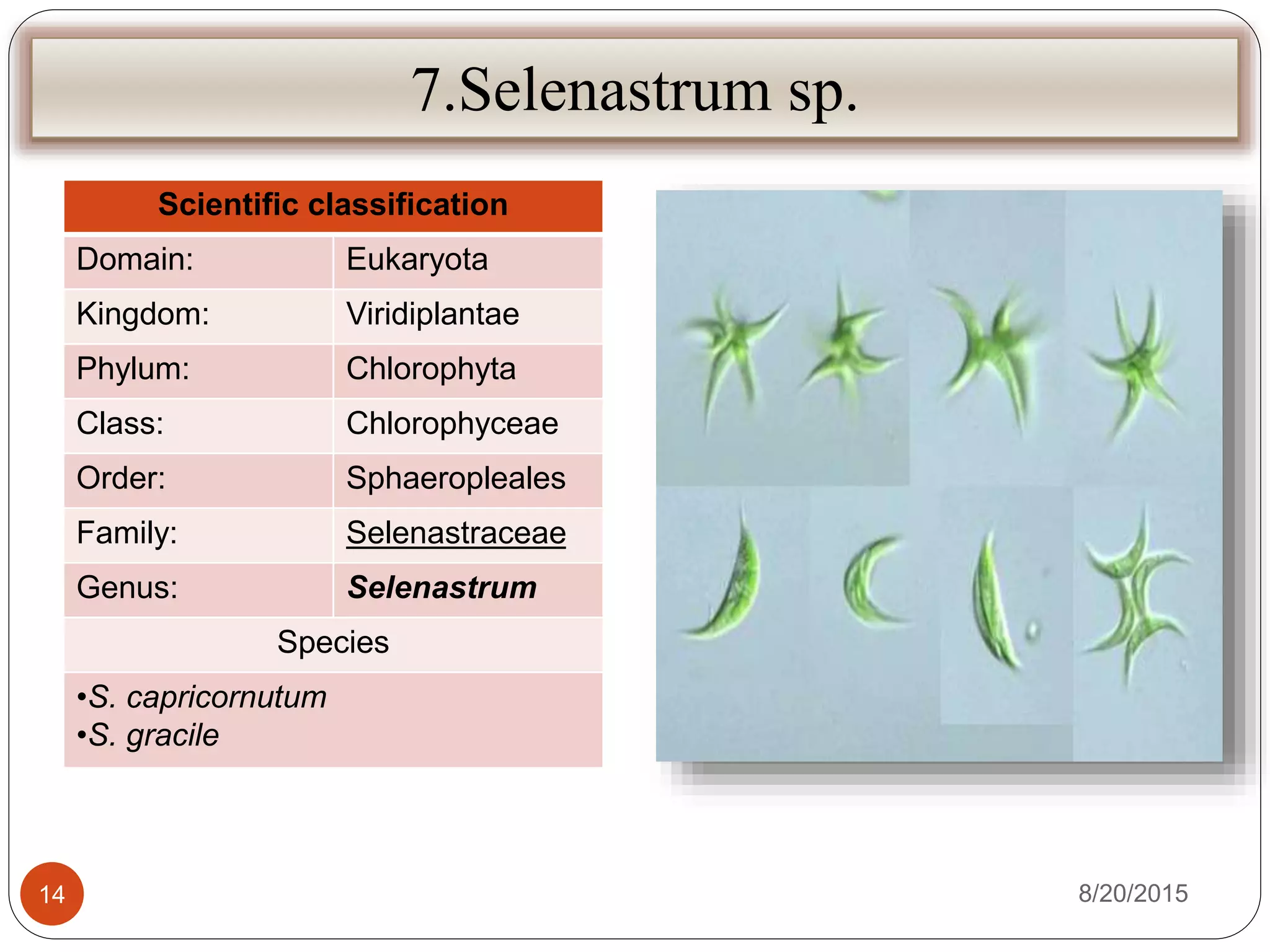

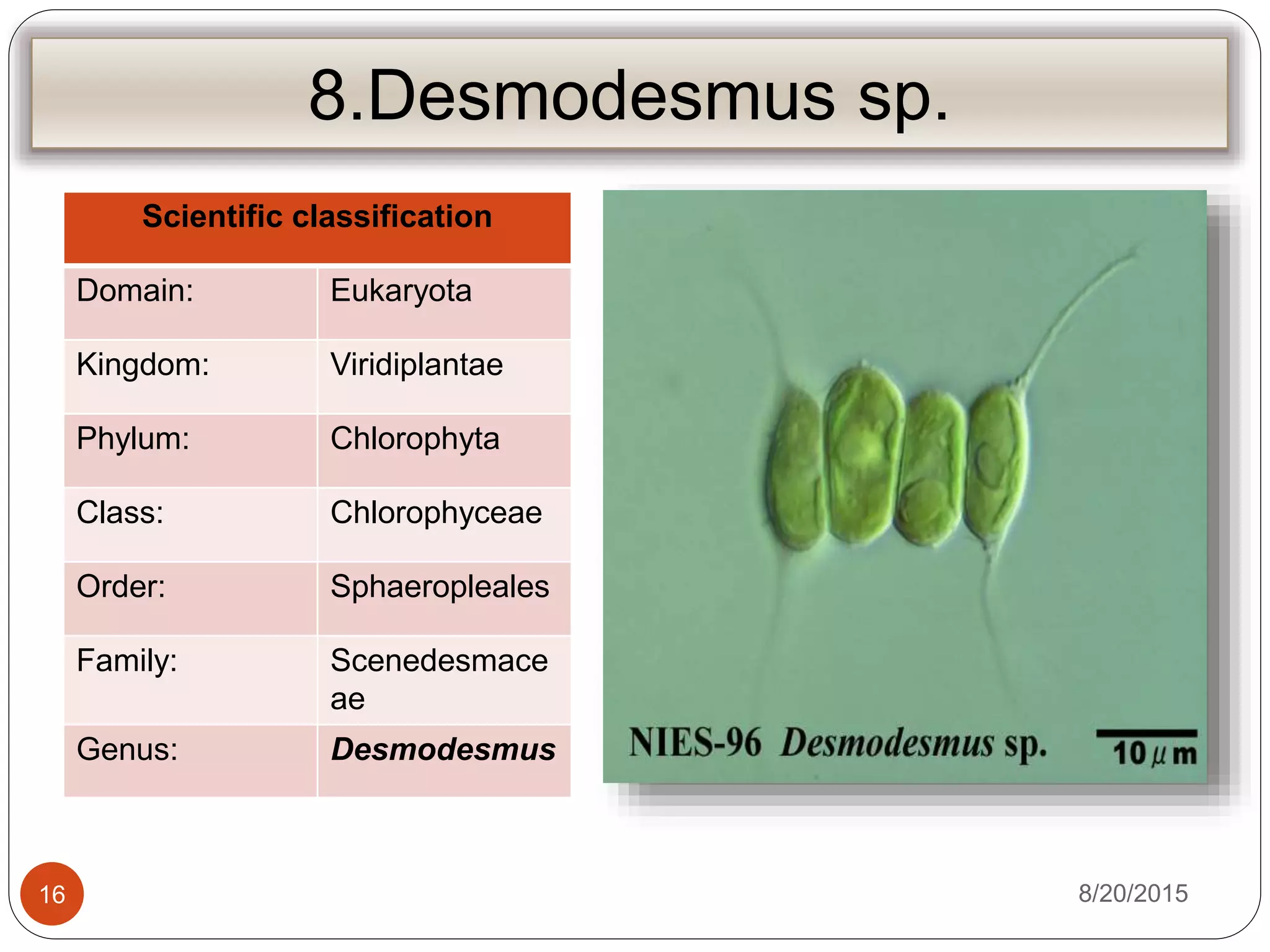

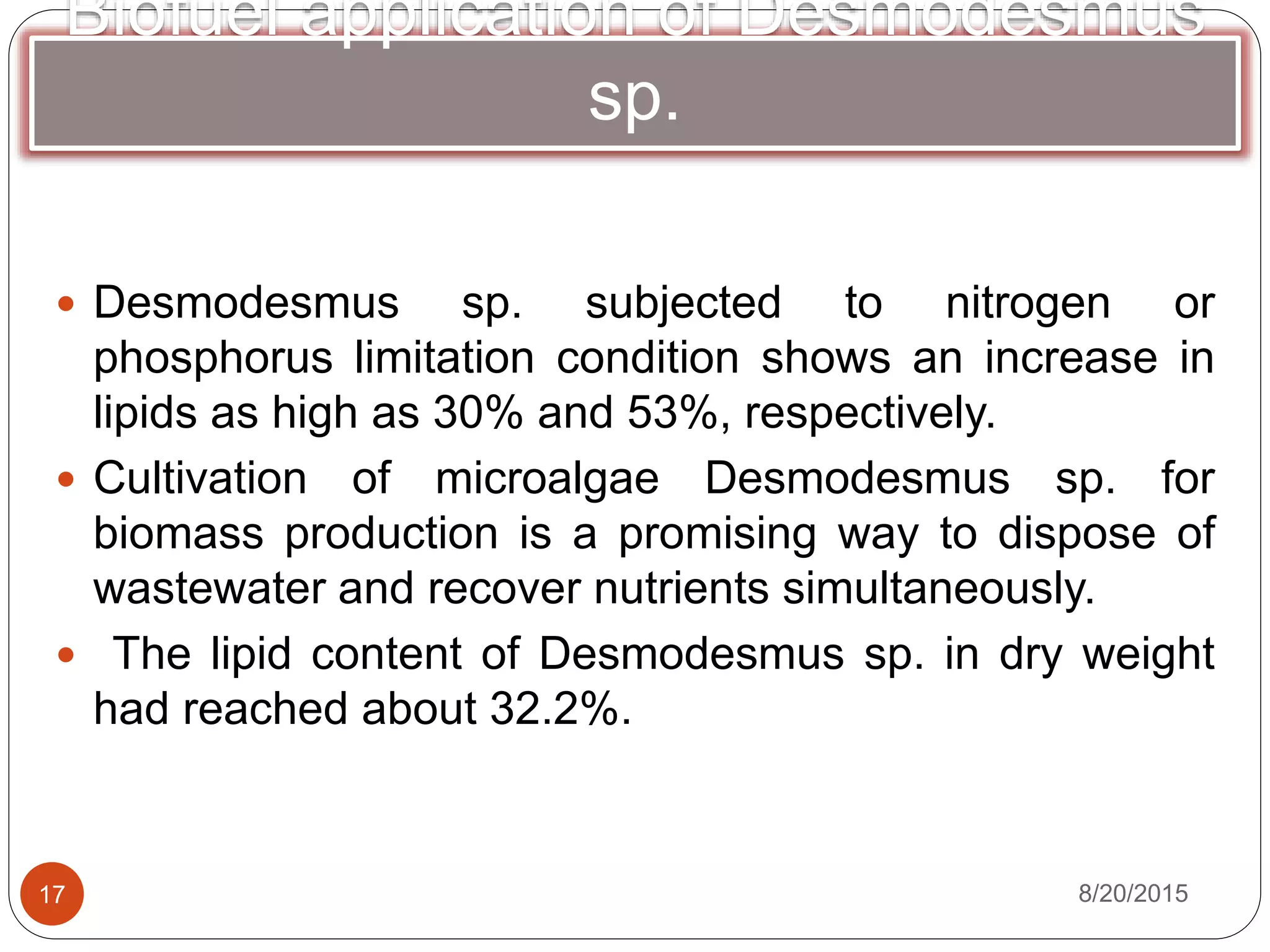

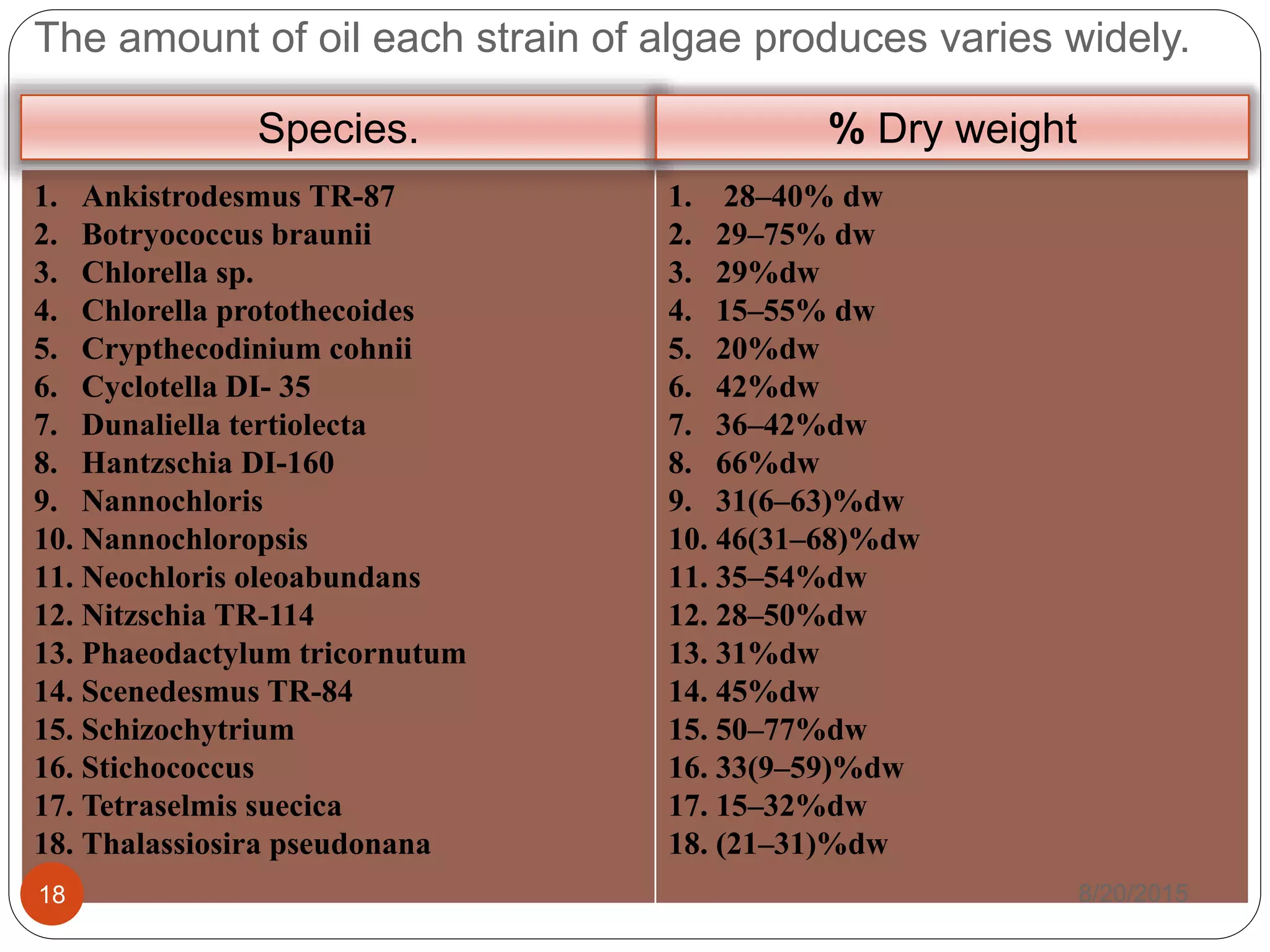

1. The document discusses 8 different microalgae strains suitable for biodiesel production: Botryococcus braunii, Chlorella species, Scenedesmus species, Dunaliella sp., Chlamydomonas sp., Spirulina sp., Selenastrum sp., and Desmodesmus sp.

2. For each microalgae, it provides the scientific classification and describes applications for biodiesel production. Key applications discussed include using the microalgae oils for transesterification to produce biodiesel, growing the algae to produce biomass that can then be converted to fuels, and optimizing growth conditions to increase lipid content.

3. The micro