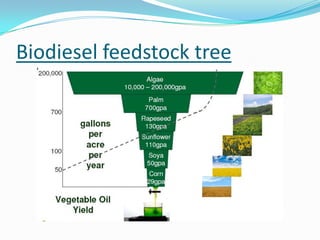

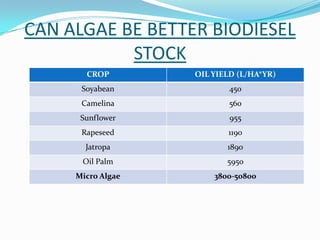

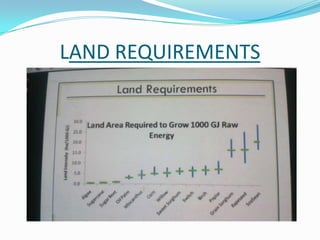

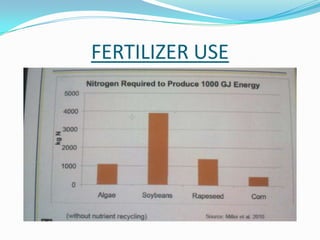

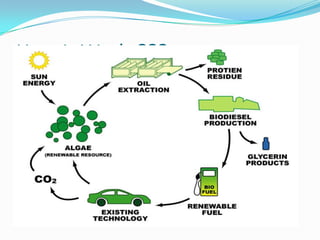

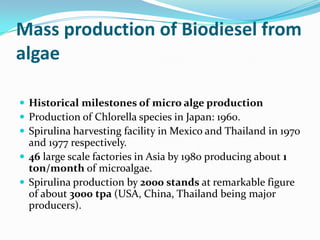

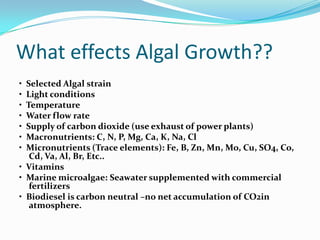

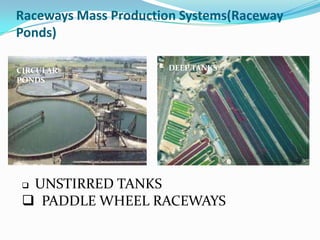

The document discusses the production of biodiesel from algae, highlighting its potential as a sustainable alternative to fossil fuels. Algae can yield significantly higher oil per acre compared to traditional crops and can help capture carbon dioxide, addressing environmental concerns. Challenges and strategies for improving the economics of microalgal biodiesel production, including biorefinery approaches and genetic engineering, are also explored.