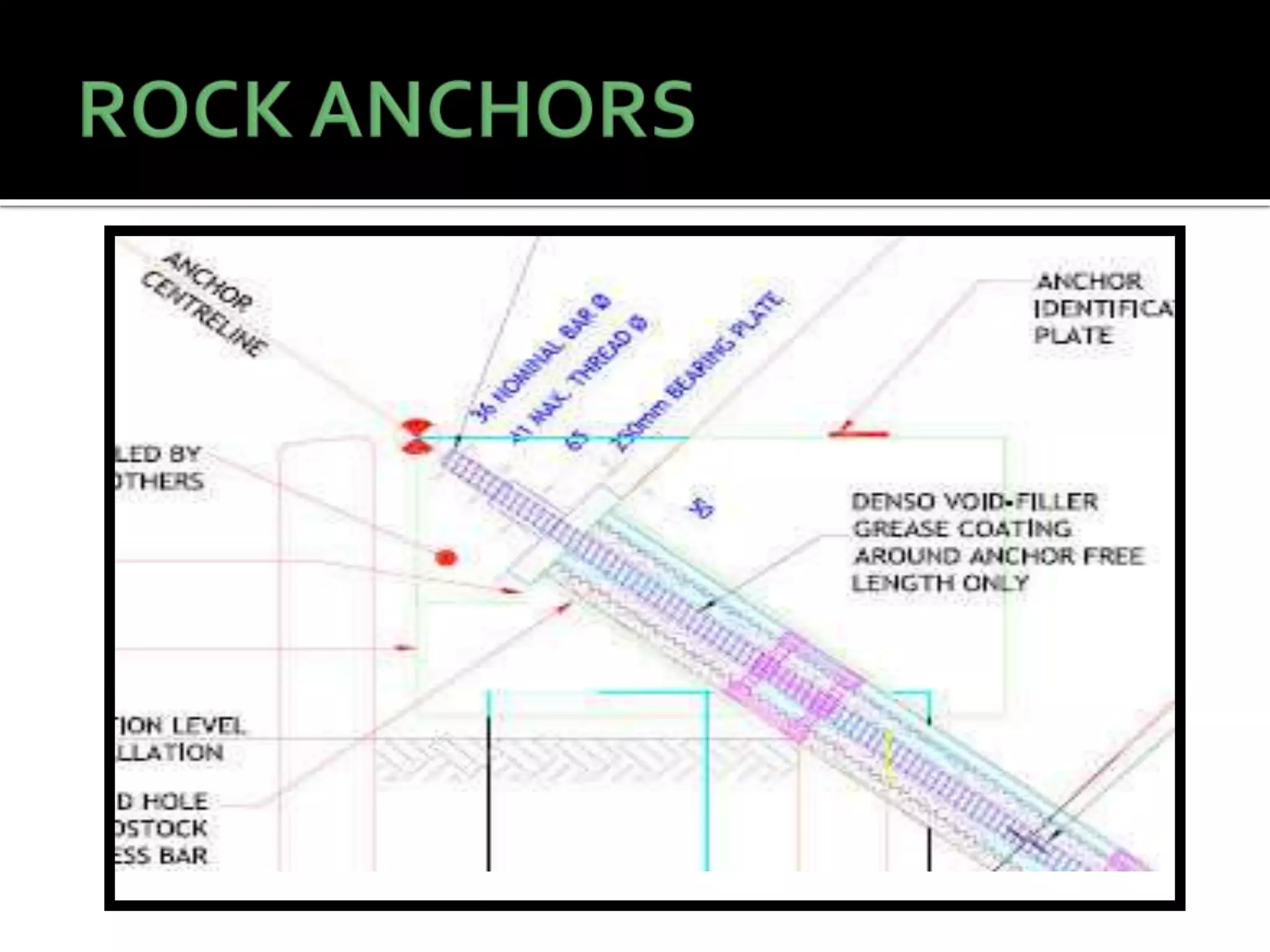

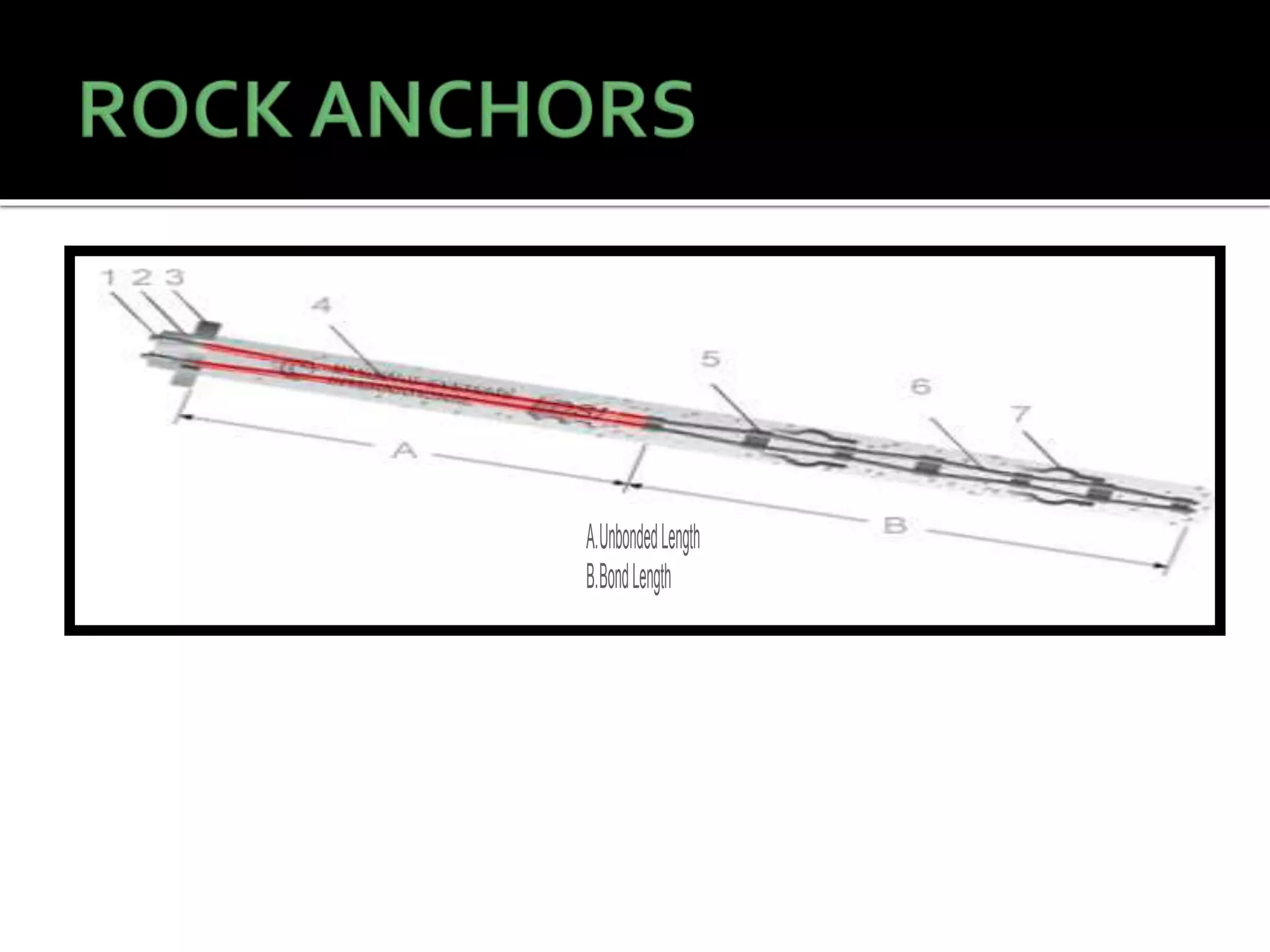

Rock anchors have been used in the United States since the early 1960s as temporary tie backs and permanently in dams since 1968. Permanent anchors are designed to last up to 100 years with sophisticated corrosion protection systems. There are various types of permanent anchors including multi-strand systems with up to 27 strands and over 4000 kN of tension capacity, as well as permanent stressbar anchors and rock bolts used in infrastructure retention. Proper corrosion protection involving encapsulation and sheathing is necessary for permanent anchors to achieve their long design life.