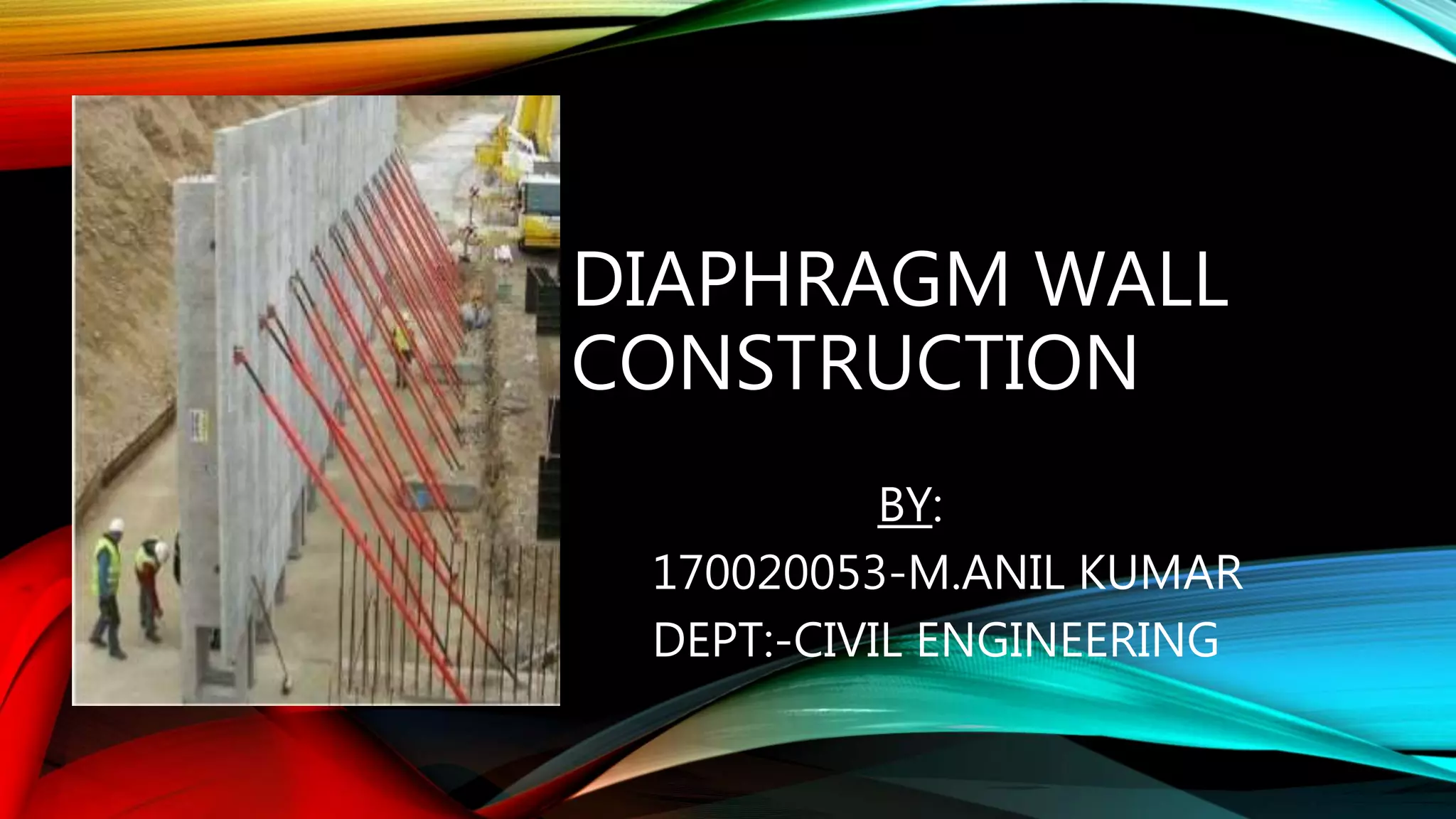

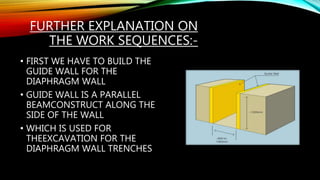

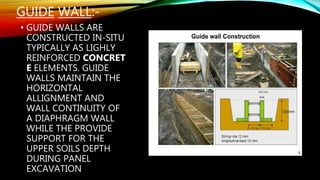

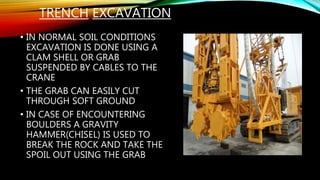

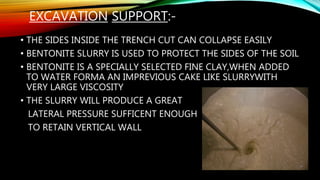

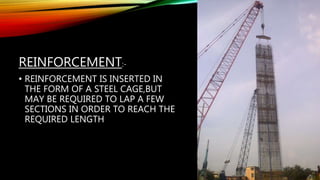

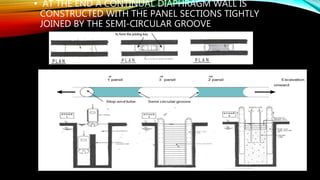

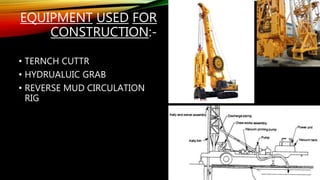

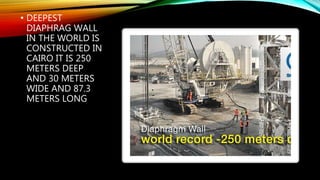

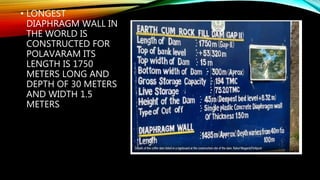

The document discusses the construction of diaphragm walls. It begins by defining a diaphragm wall as a continuous reinforced concrete structure constructed panel by panel using an in-situ method. It then describes the typical construction sequence which involves building a guide wall, excavating the trench using a grab, supporting the trench with bentonite slurry, placing reinforcement, and pouring concrete to form each wall panel. The document provides details on the equipment used and explains steps like slurry cleaning and panel joining. It concludes by listing some advantages of diaphragm walls and providing examples of some deep walls constructed worldwide.