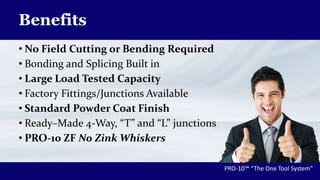

This document summarizes the key features and benefits of Wiremaid cable tray systems, specifically the PRO-10 system. It discusses that cable trays are used to securely support electric cables for power distribution and communication. The PRO-10 system provides UL classified fittings that assure proper bonding and grounding without needing additional hardware. Benefits highlighted include being lightweight, easy to install, reducing installation time by up to 50%, and being compliant with relevant electrical codes and standards.