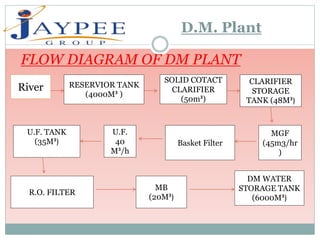

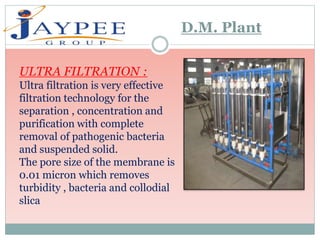

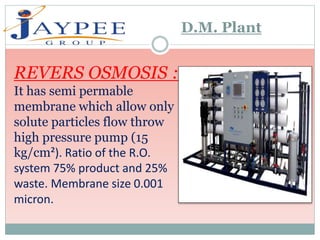

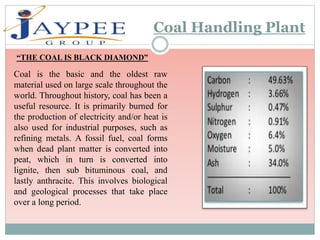

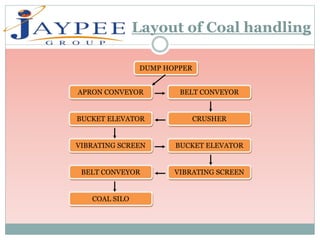

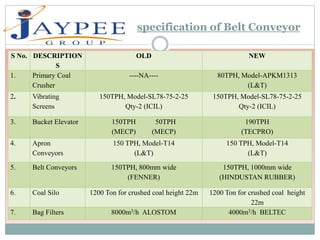

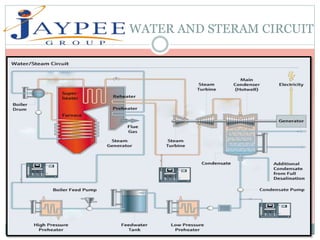

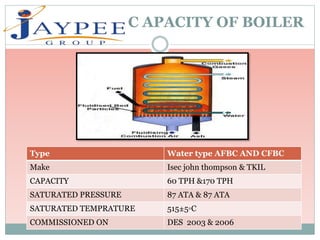

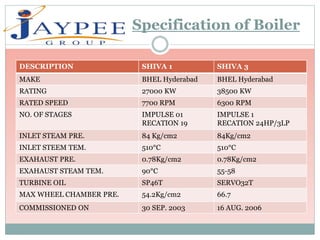

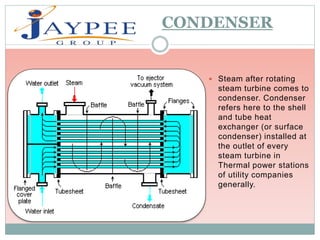

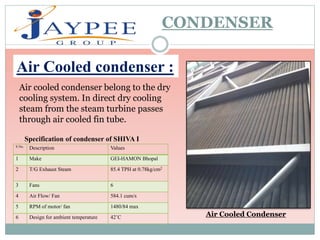

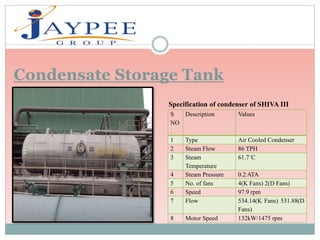

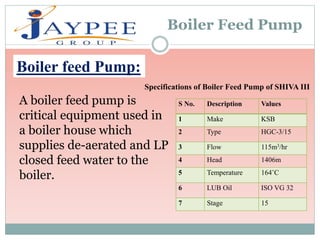

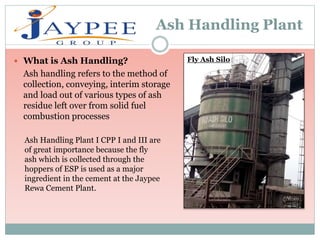

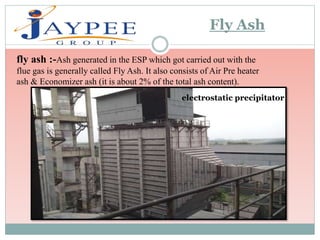

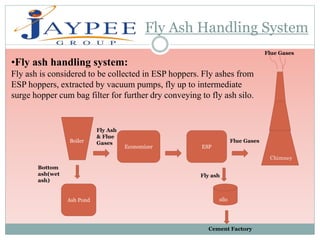

The document provides information about a thermal power plant and its various components. It discusses the coal handling plant, water treatment plant, boiler, steam turbine, condenser, ash handling plant and other key parts. It provides specifications for the boiler (60/170 TPH capacity), steam turbine (27/38.5 MW rating), and condenser. It also includes diagrams of the coal handling process, water treatment process and ash handling system to transport fly ash from the electrostatic precipitator to the silo.