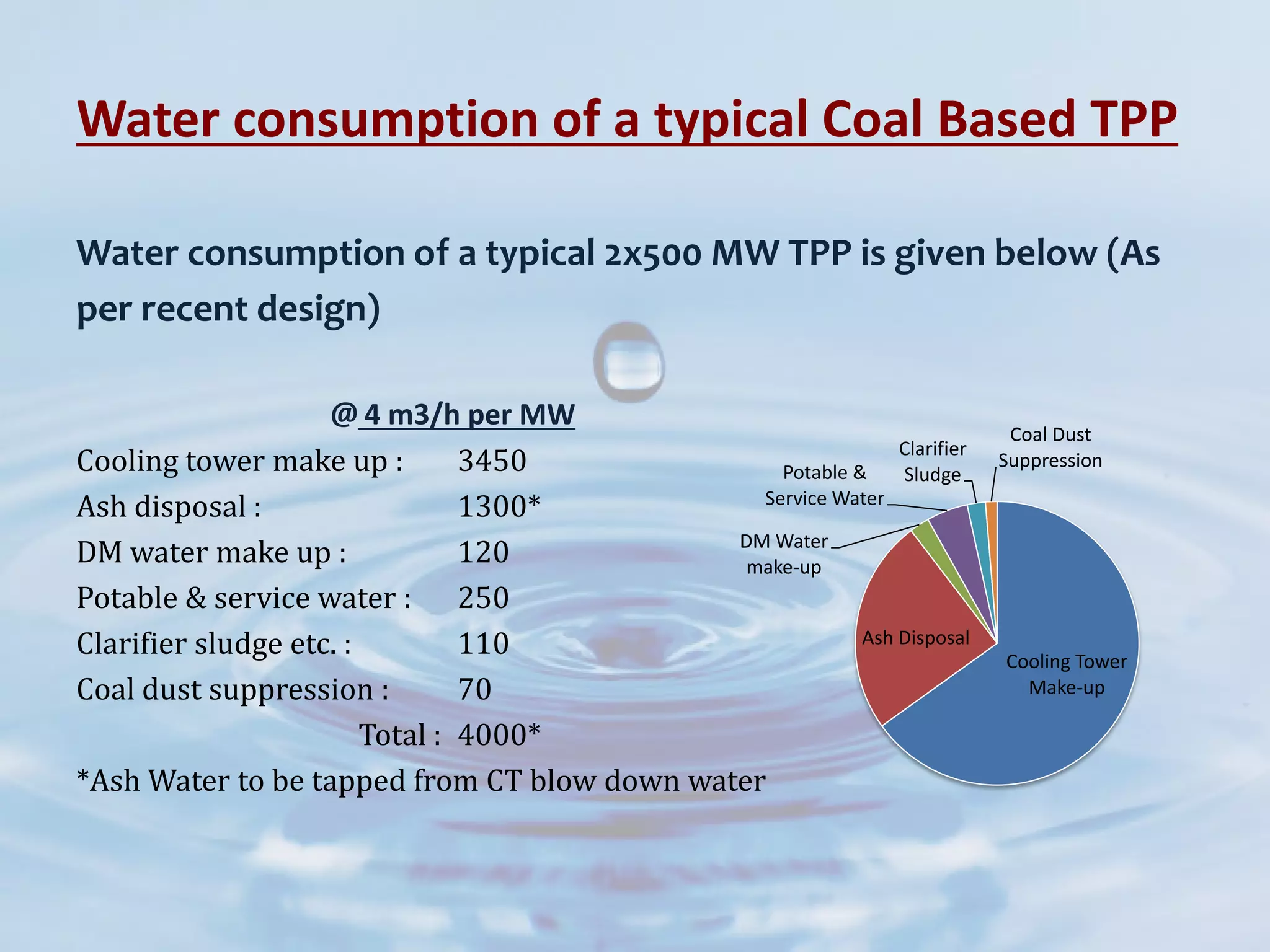

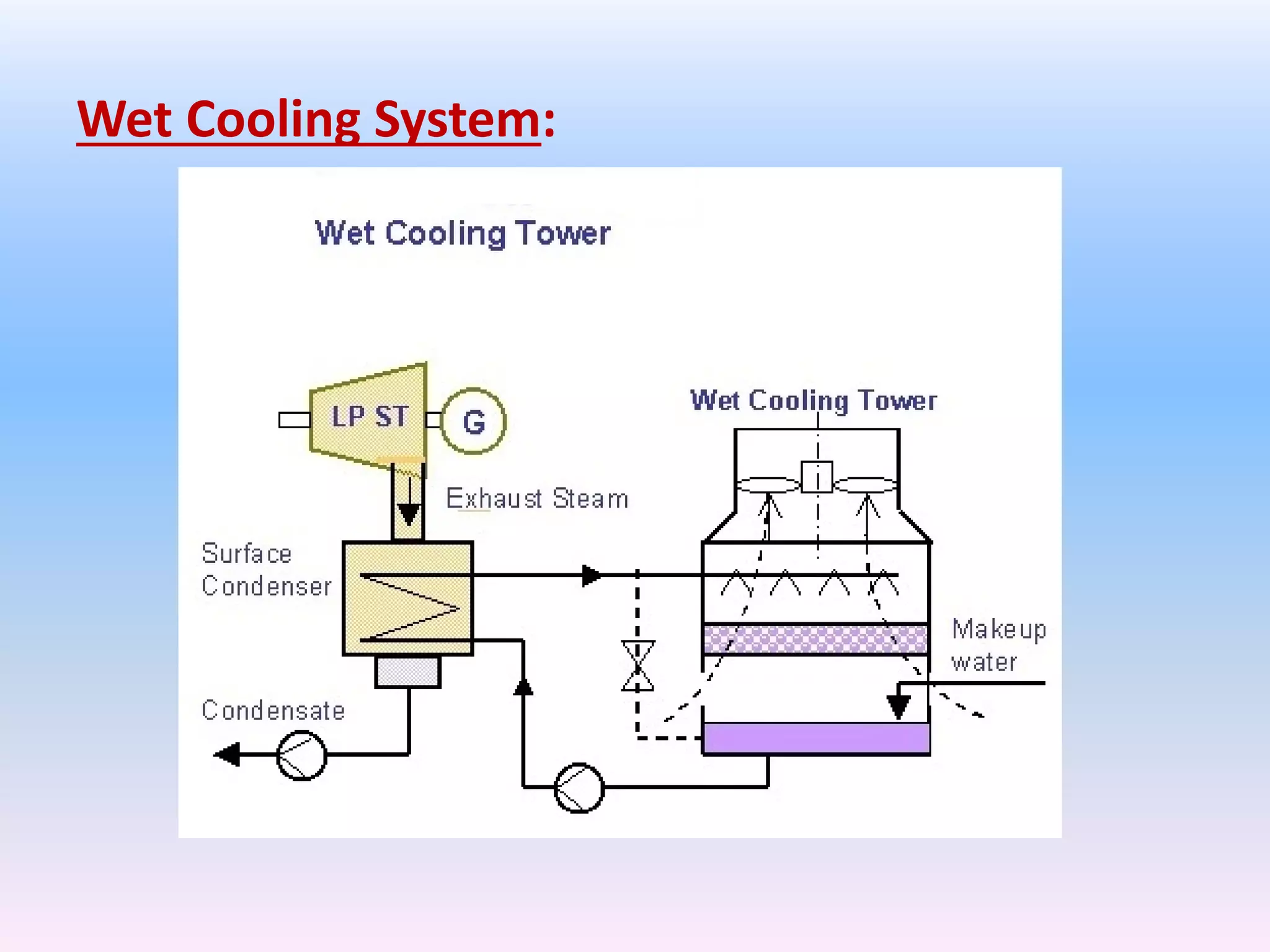

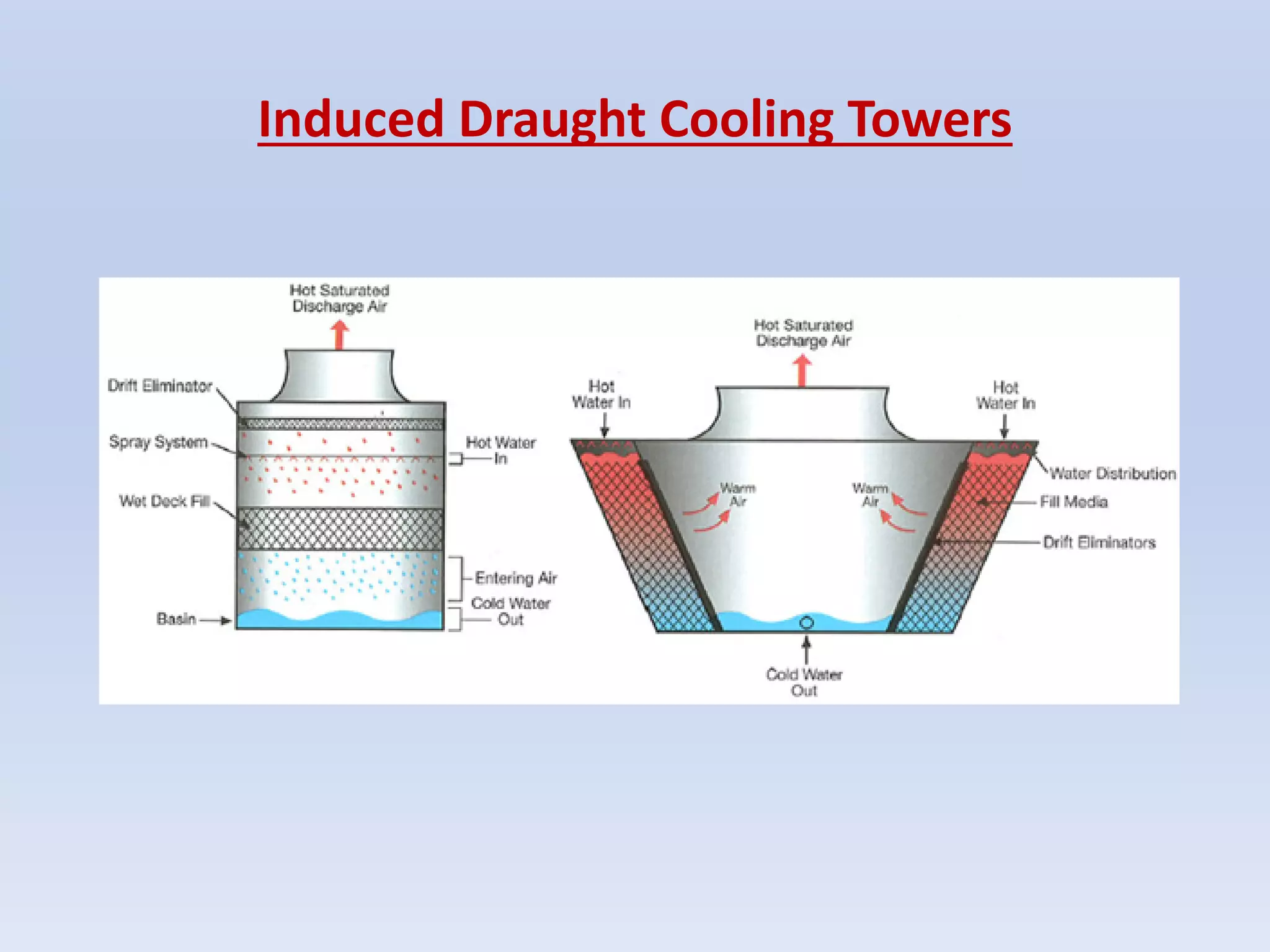

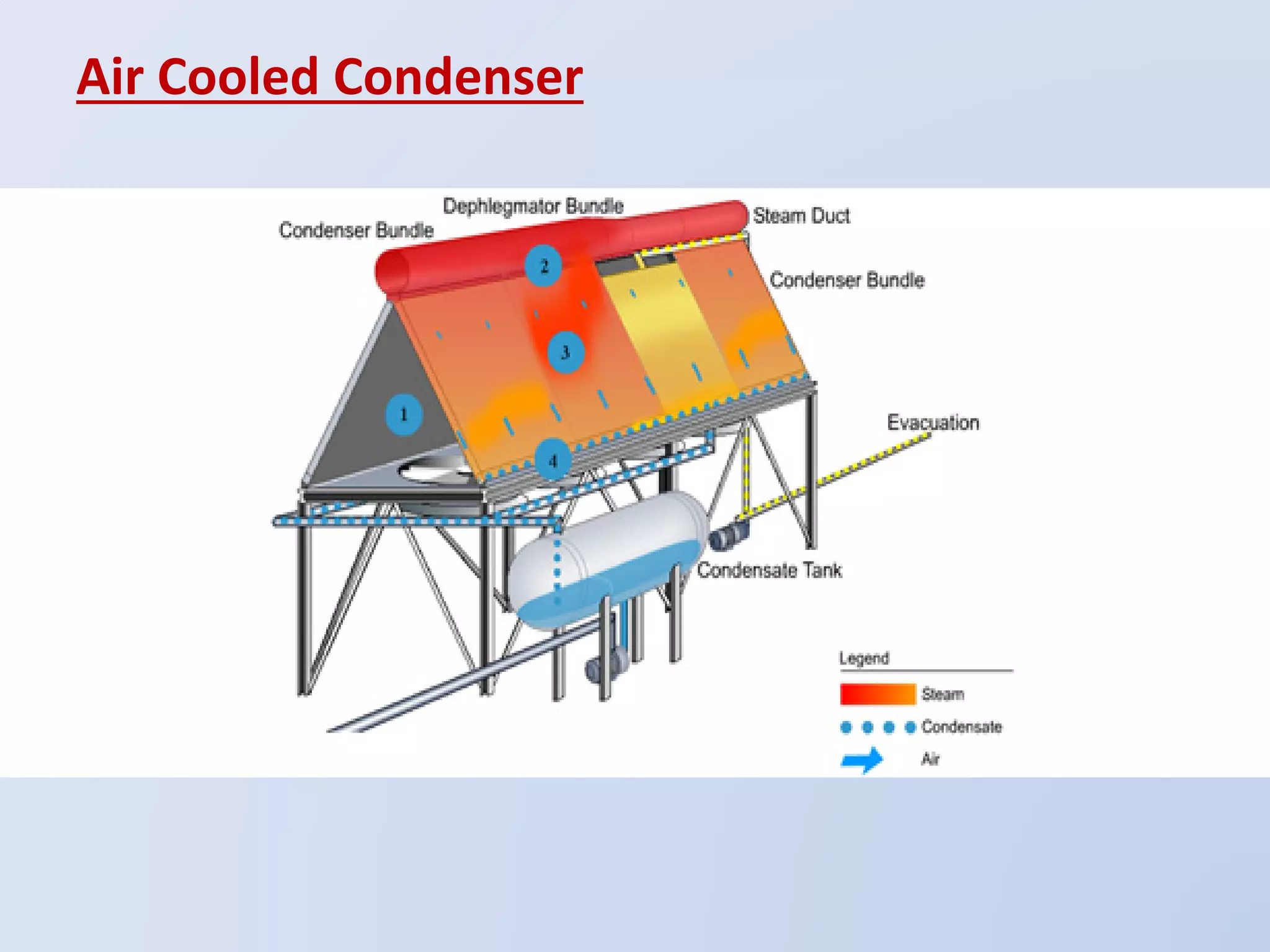

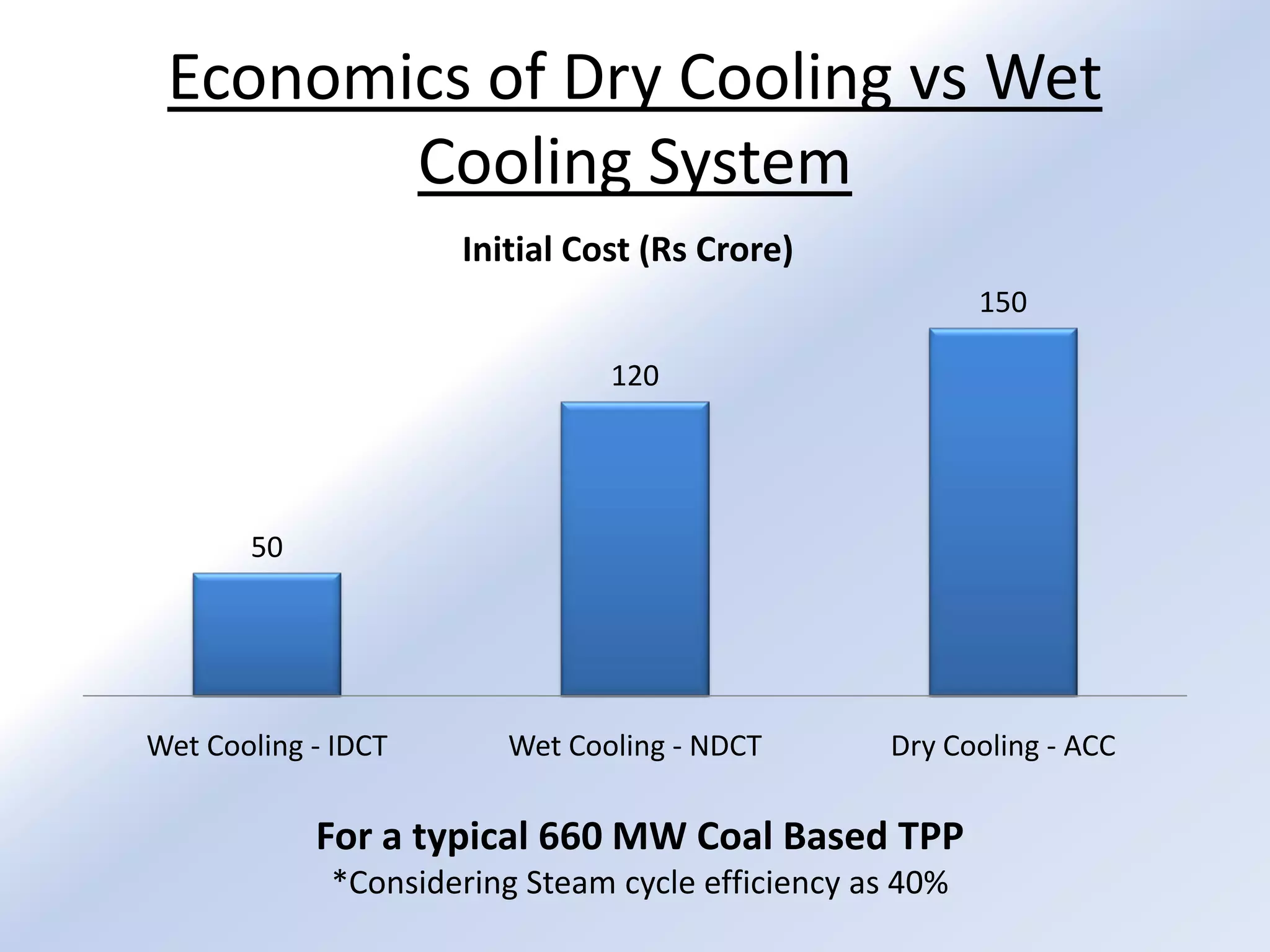

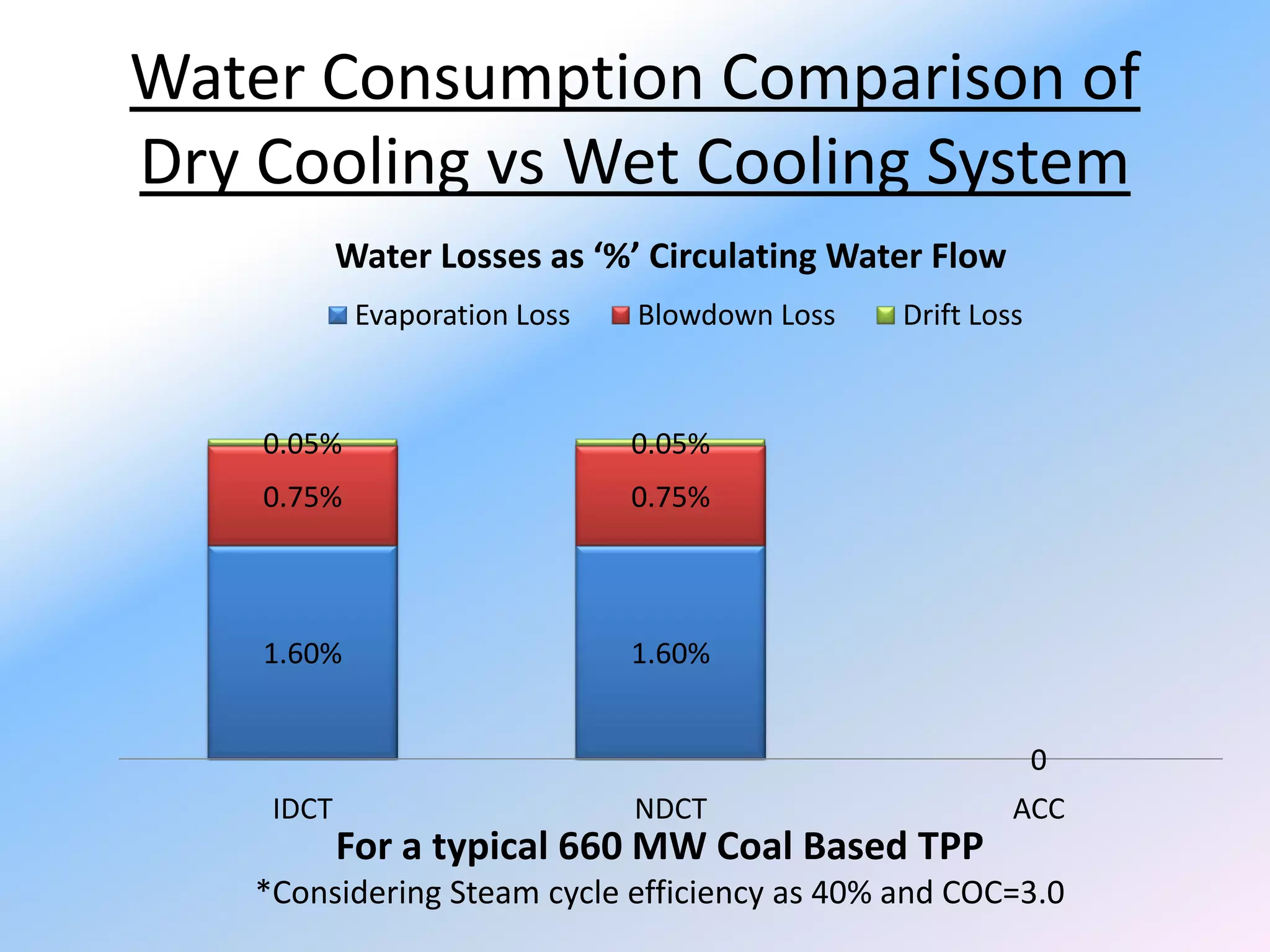

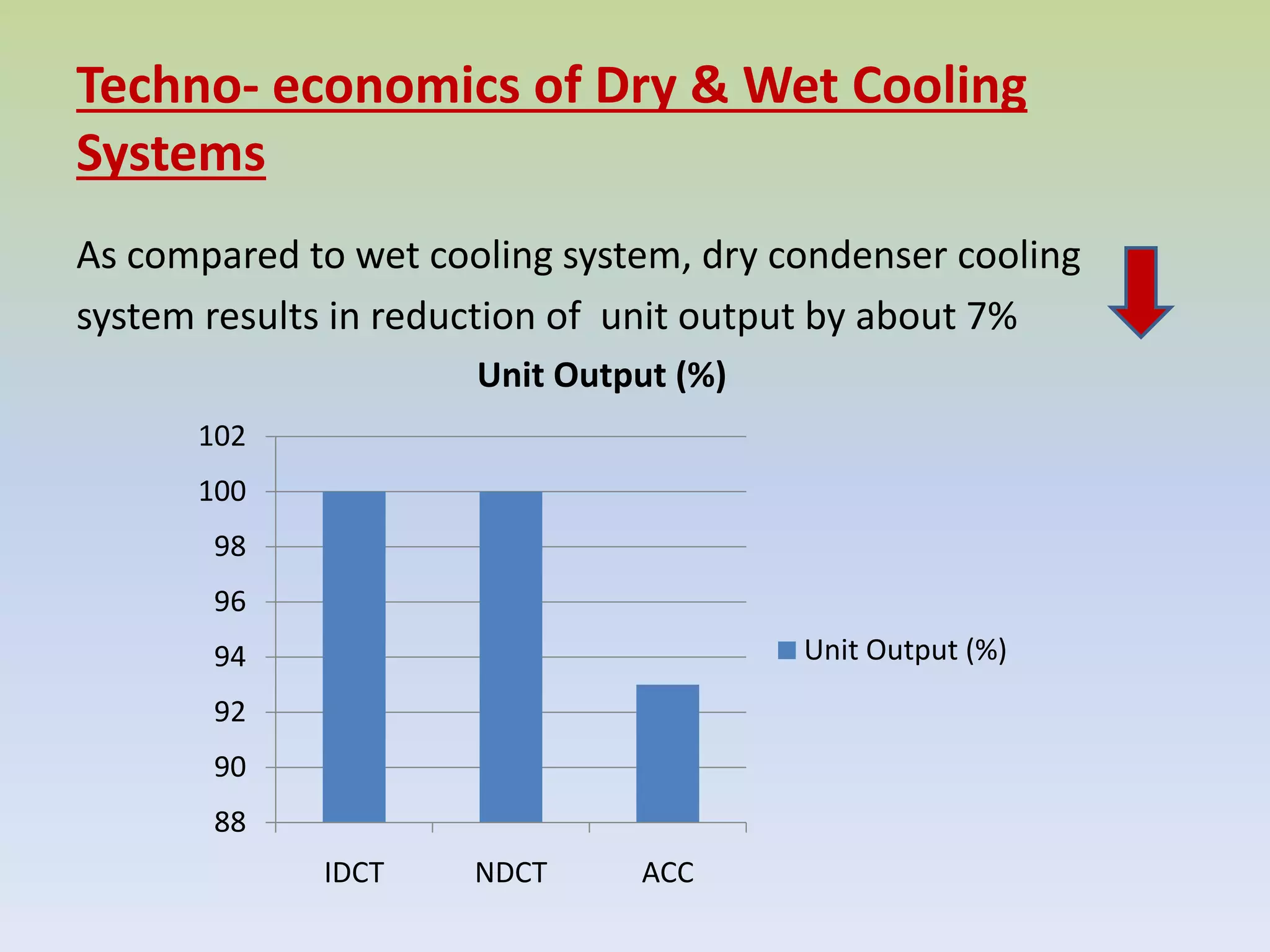

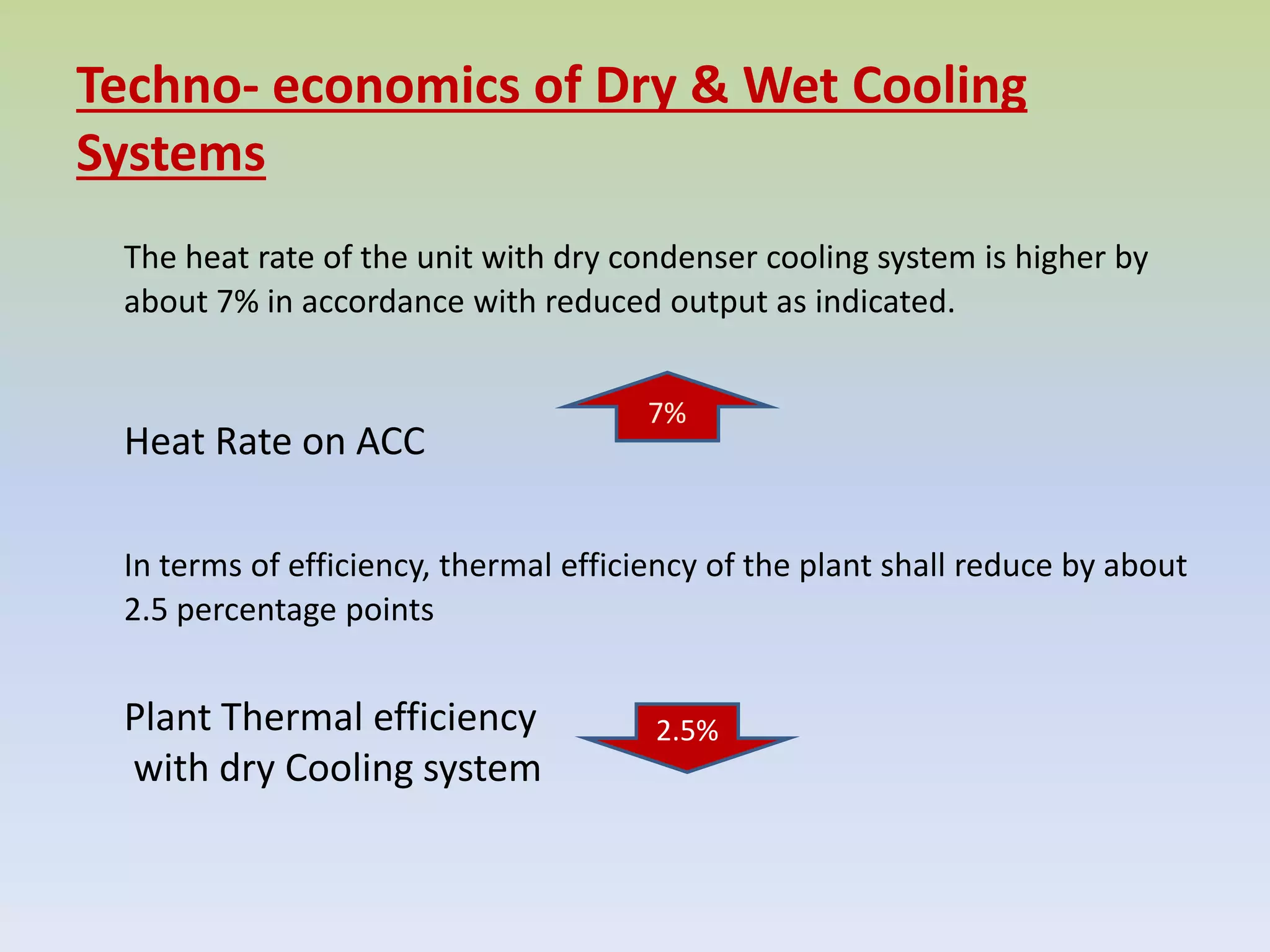

The document outlines the critical role of water efficiency in thermal power plants in India, emphasizing the increasing challenges of water availability for cooling and operational needs. It discusses various cooling technologies and their water consumption, highlighting regulatory requirements for reducing specific water consumption in existing and new plants. The use of dry cooling systems is recommended in water-scarce areas, though they may result in higher capital costs and reduced plant efficiency compared to traditional wet cooling systems.