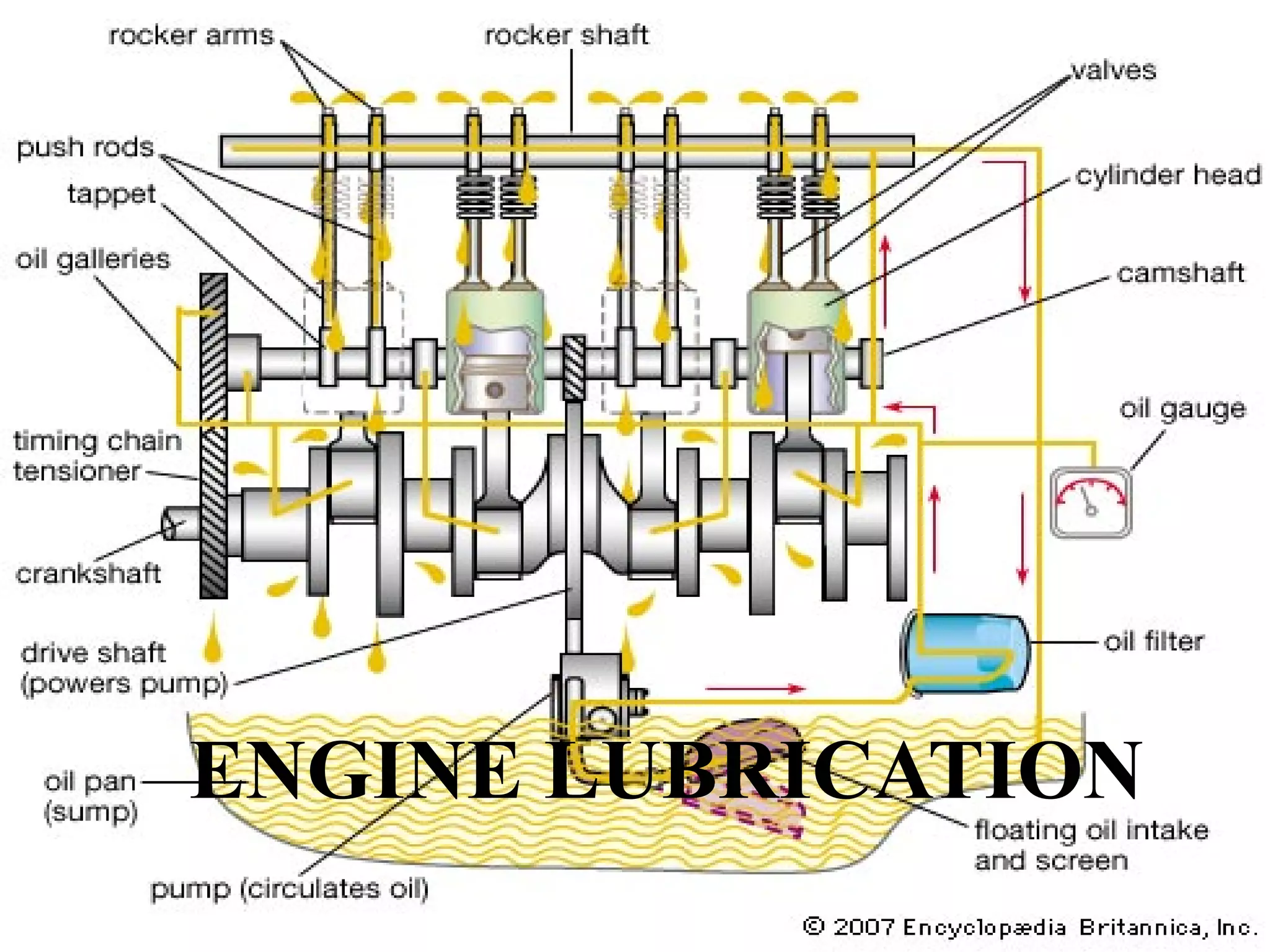

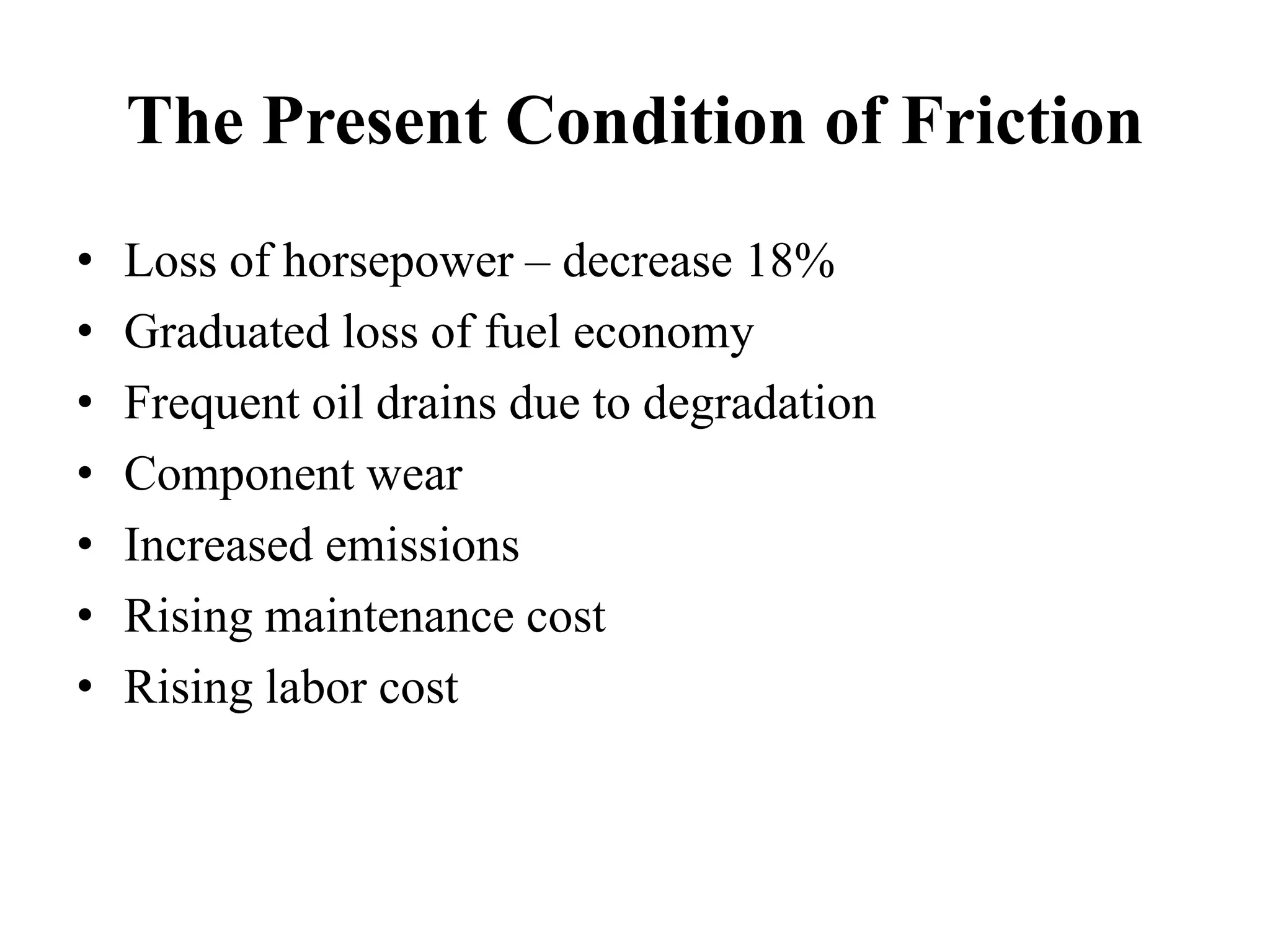

1) Proper engine lubrication is important to prevent friction and wear between moving parts. It is essential to use the correct type and weight of oil and regularly change it as recommended.

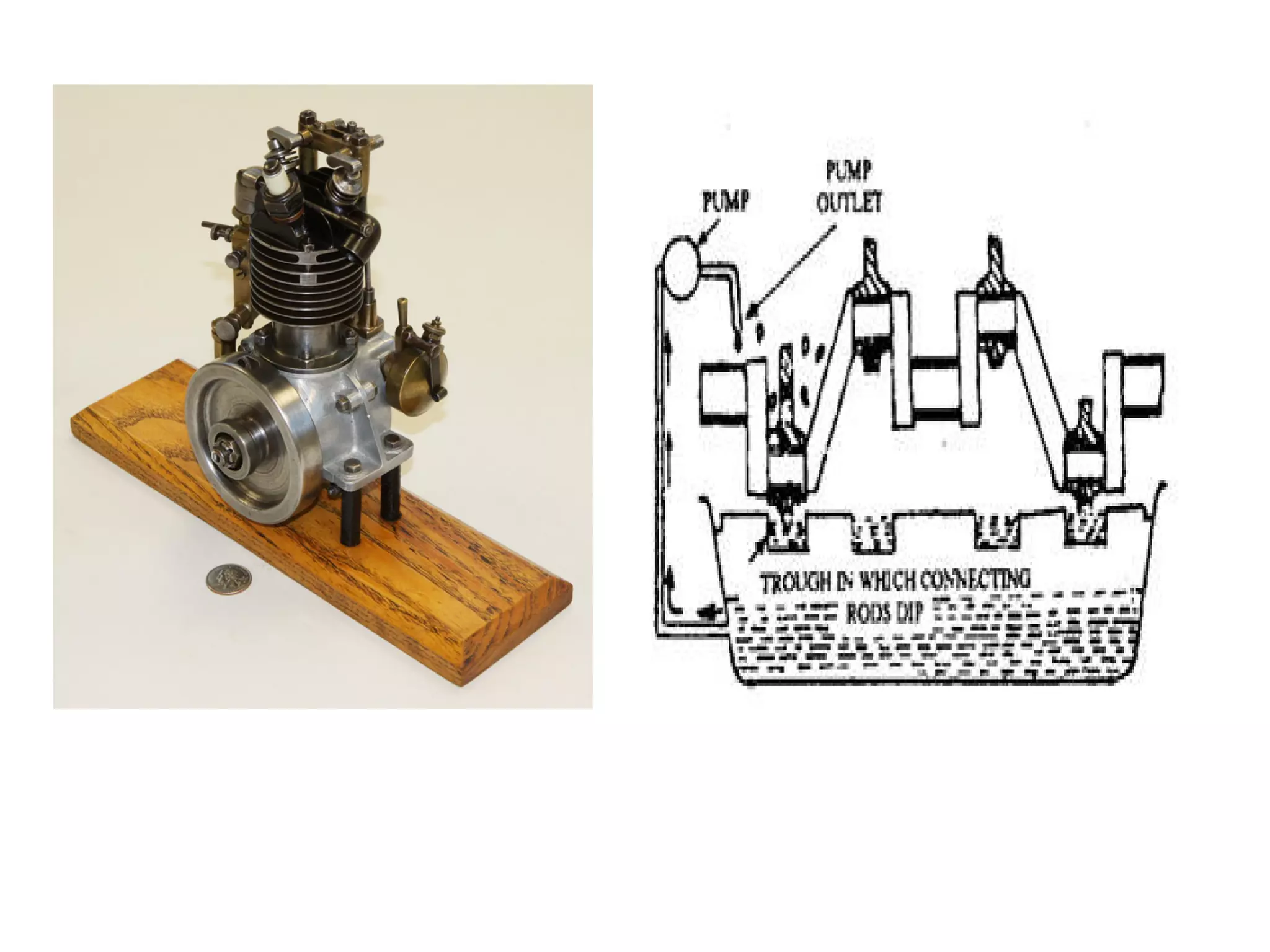

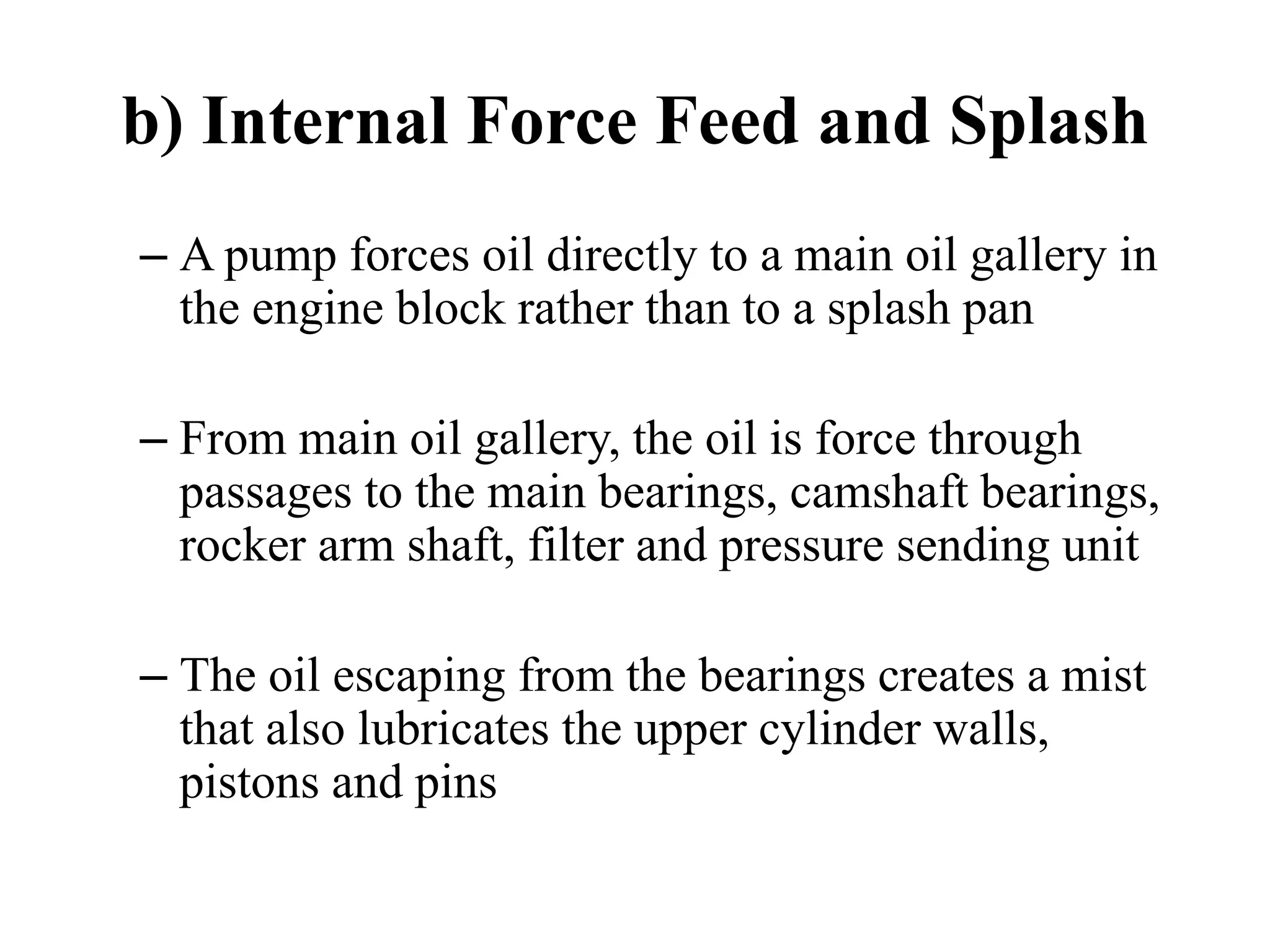

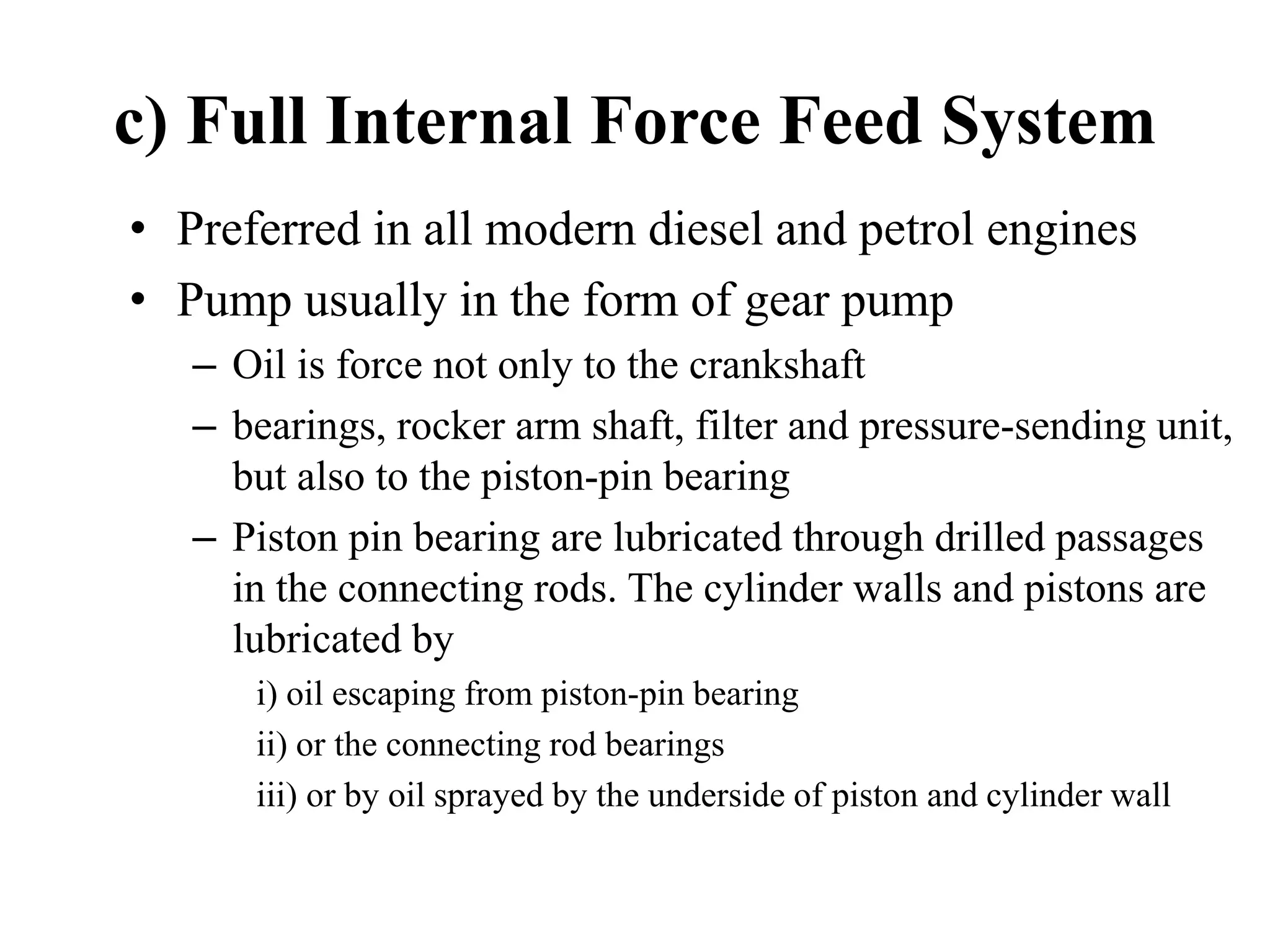

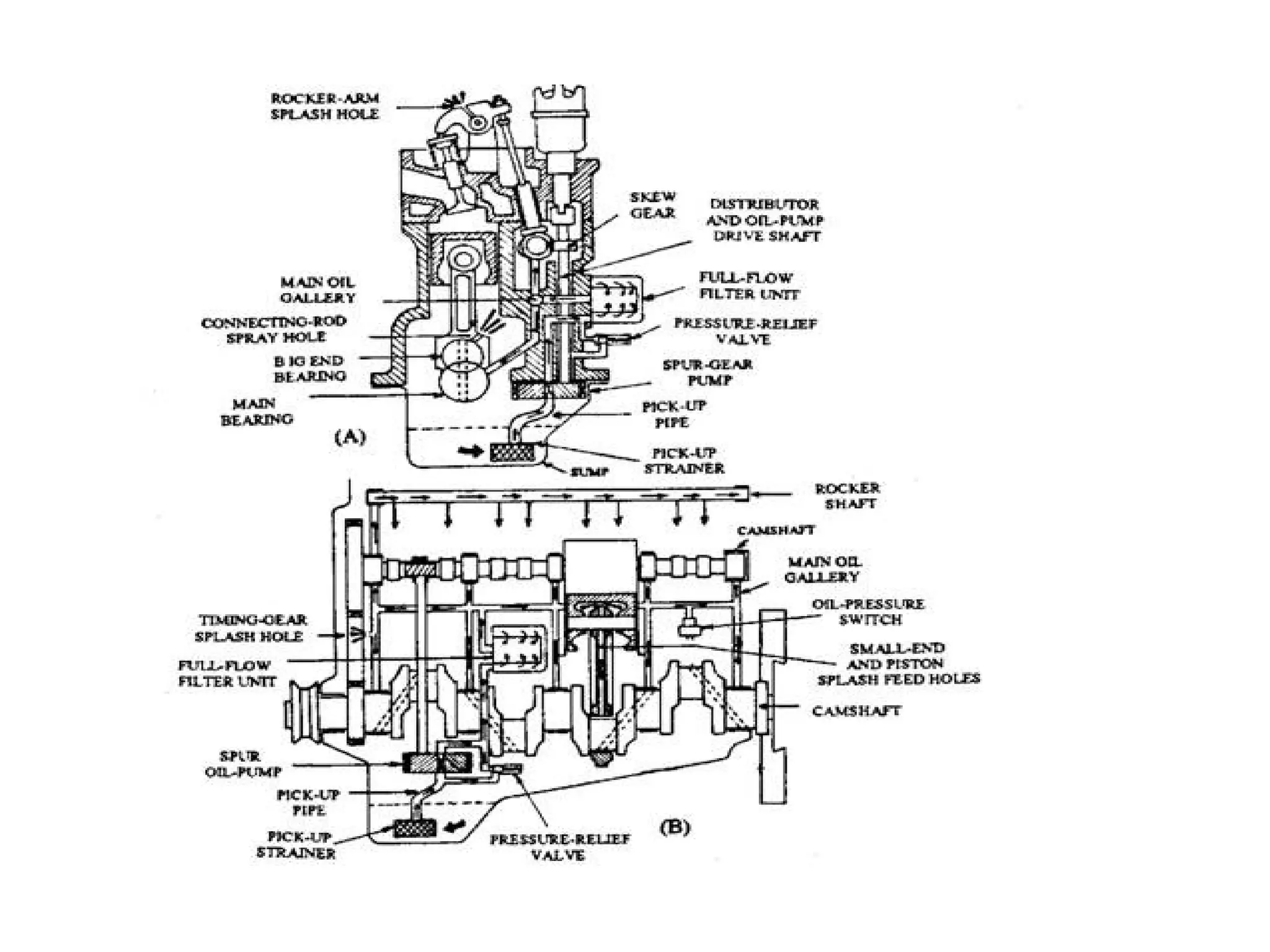

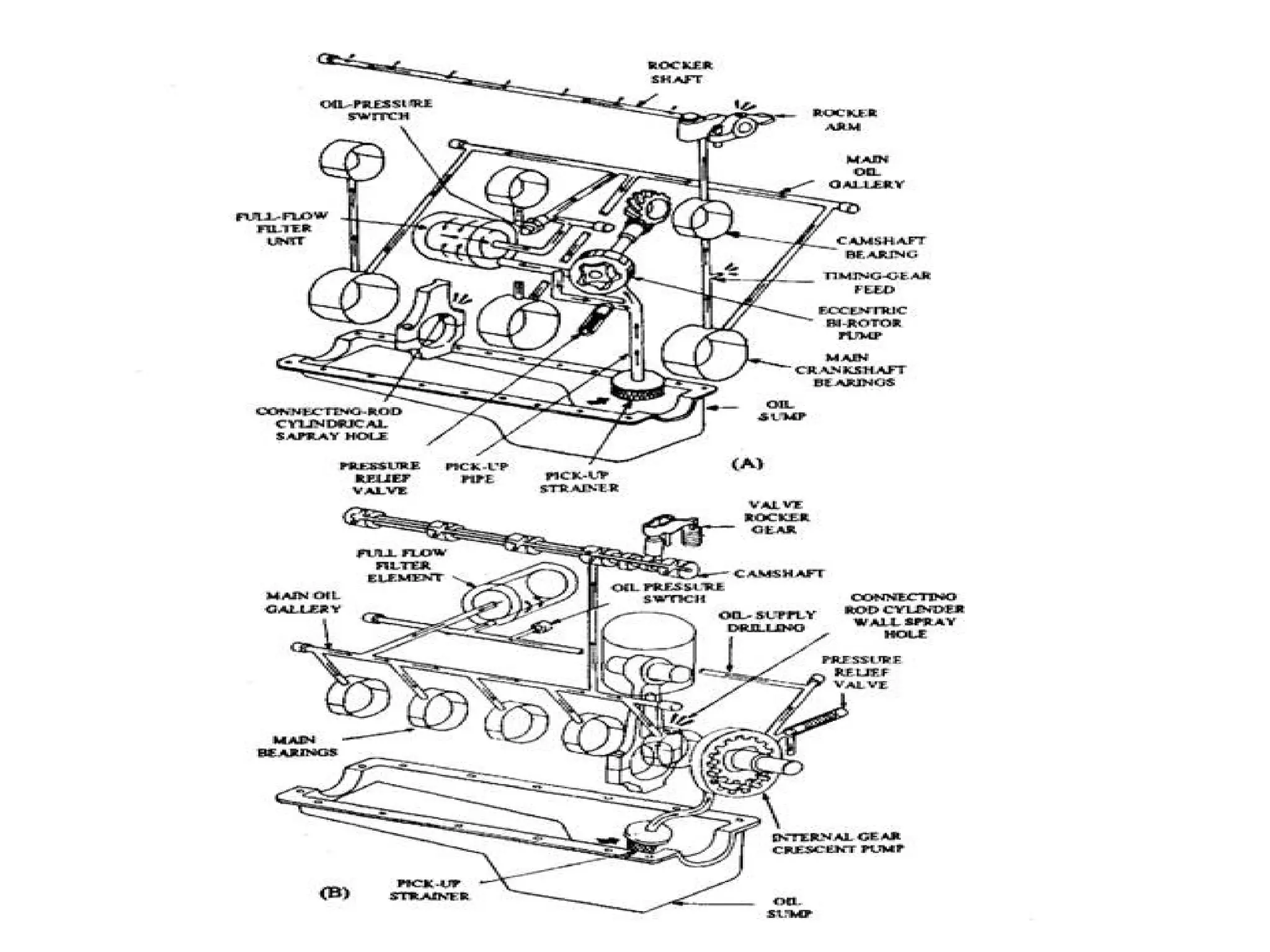

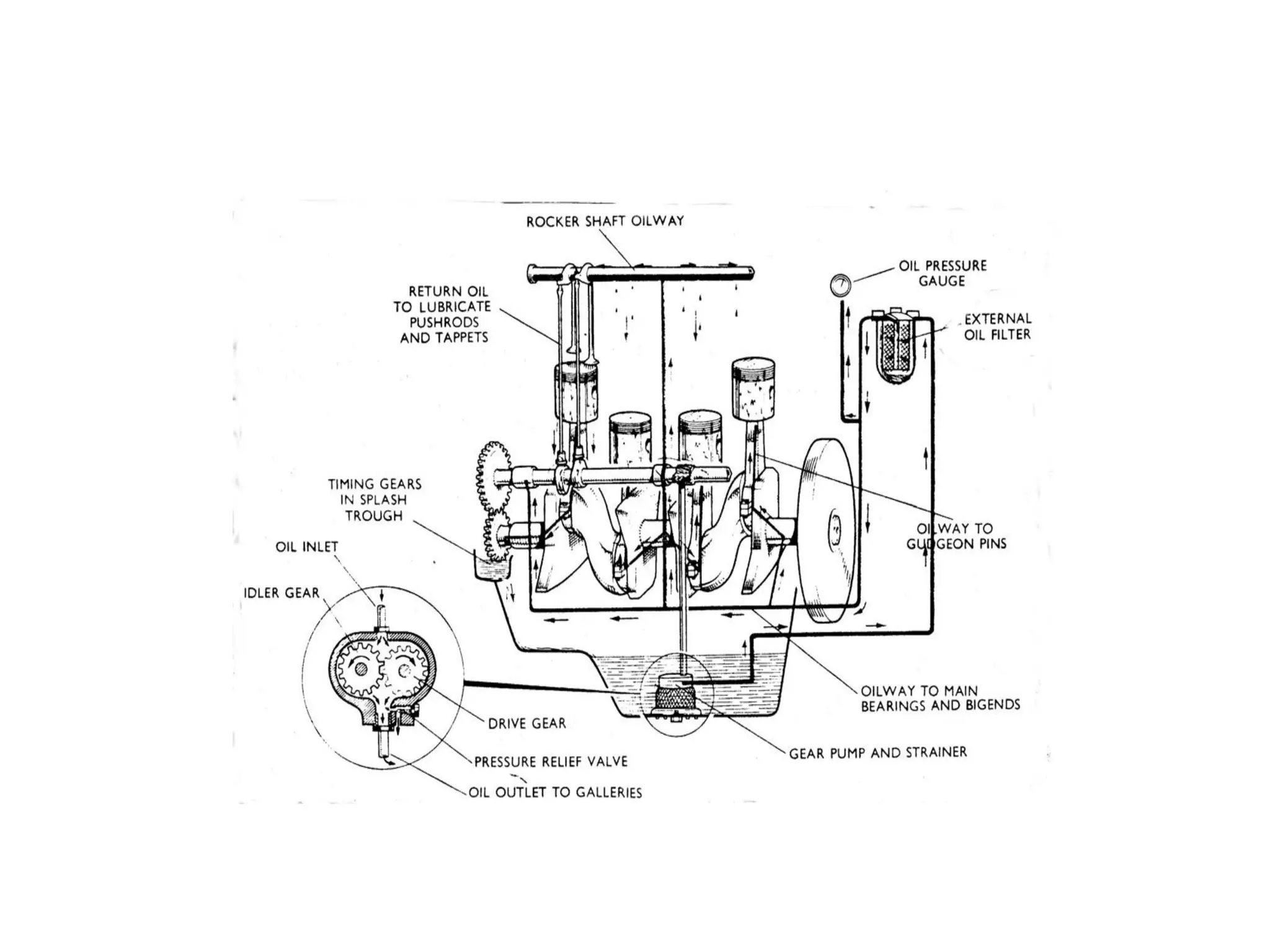

2) There are three main types of engine lubrication systems - circulating splash, internal force feed and splash, and full internal force feed. Modern engines primarily use the full internal force feed system.

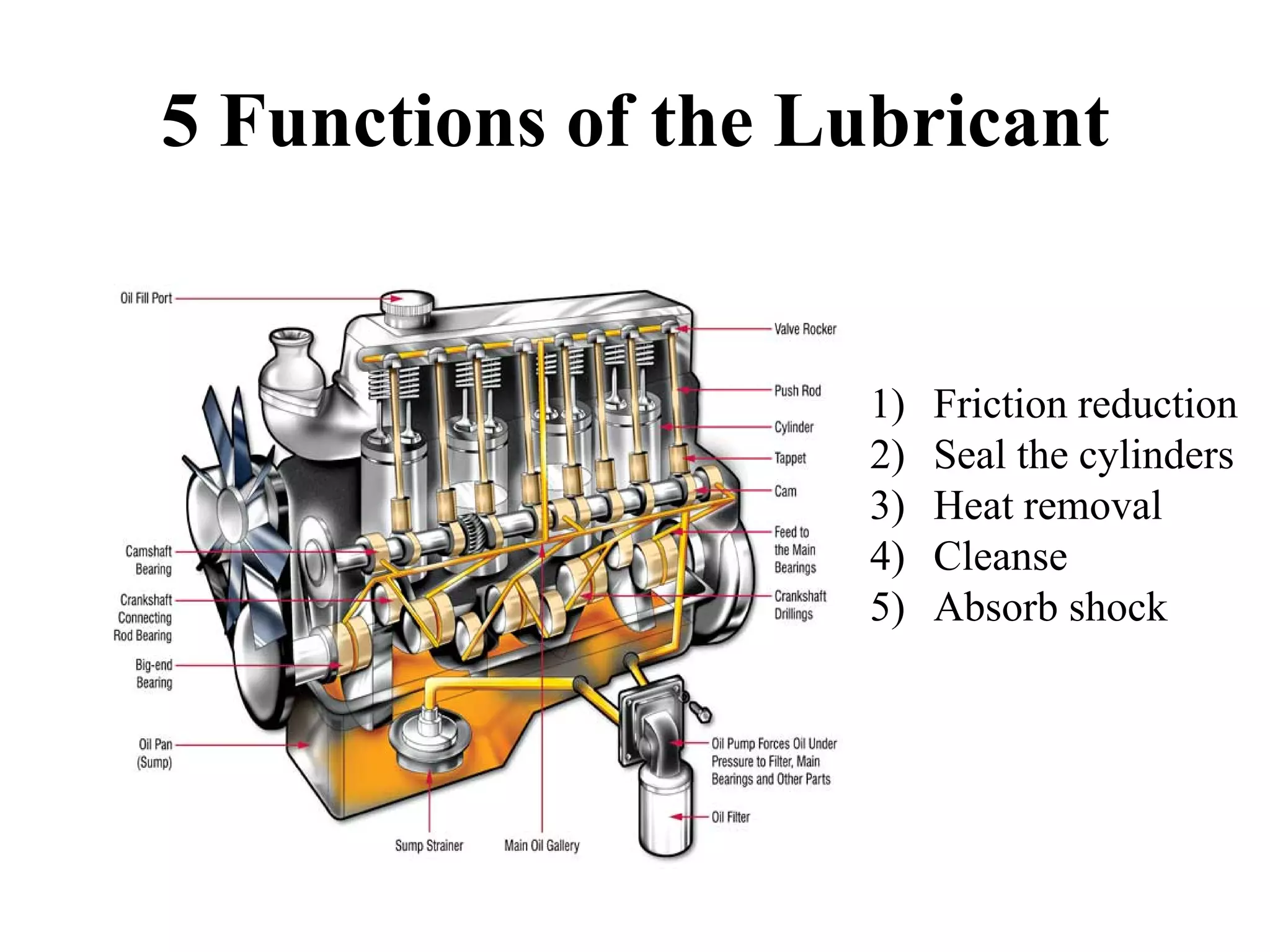

3) Engine oil serves several critical functions including reducing friction, sealing cylinders, removing heat, cleansing the engine, and absorbing shocks. Proper lubrication helps engines run smoothly and prolongs their lifespan.