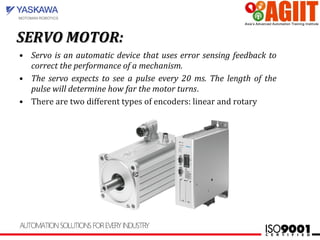

This document provides information about Axis Global Automation and its industrial automation training services. It offers training in various automation tools like PLC, SCADA, DCS, VFD, PAC, HMI, robotics, and field instruments. It has branches in India and UAE and provides both industrial and college-based training programs. It also discusses concepts in automation including the history and applications of tools like PLCs, SCADAs, VFDs, PACs, servo motors, industrial robotics, and the benefits of automation.