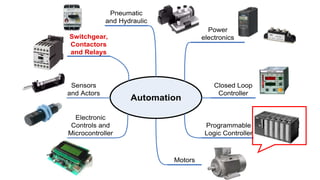

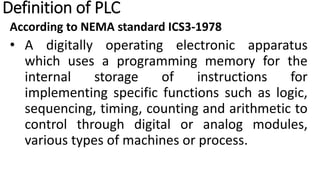

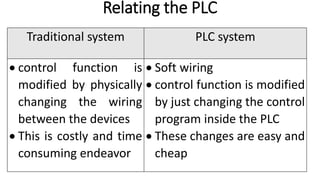

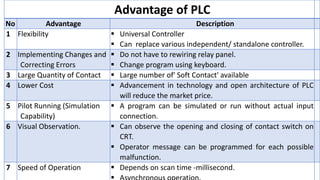

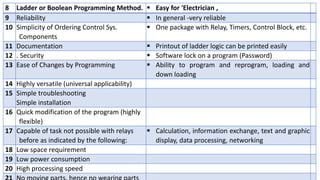

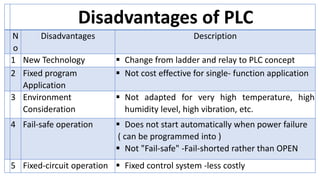

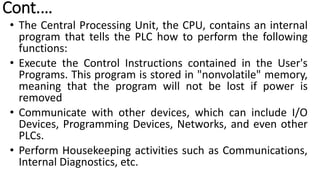

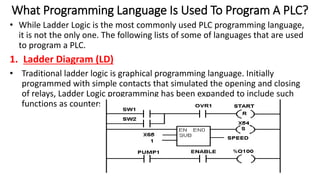

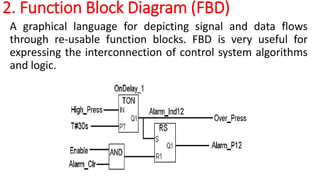

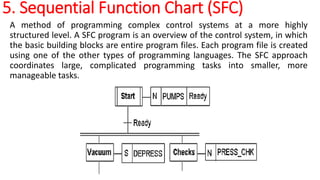

The document provides a comprehensive overview of programmable logic controllers (PLCs), including their components, programming languages, advantages, and disadvantages. It explains the essential functions of PLCs in various industrial applications and illustrates their superiority over traditional control systems in terms of flexibility and reliability. Additionally, it highlights the hardware and software design considerations that make PLCs suitable for harsh environments.