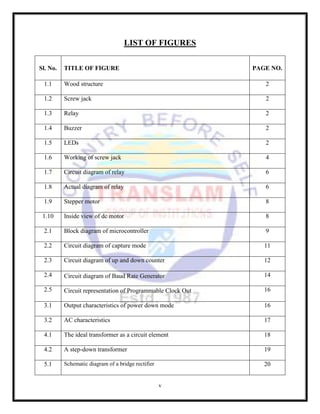

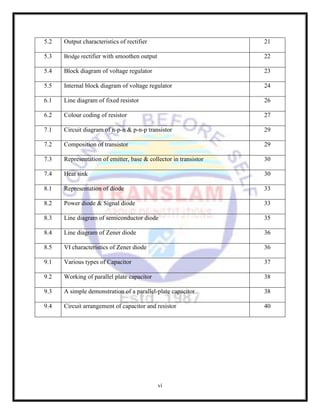

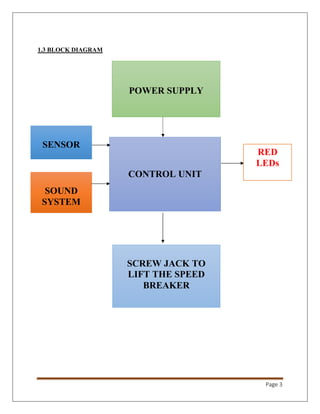

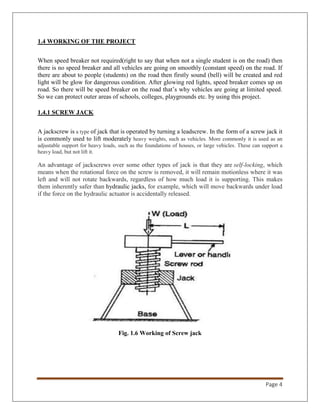

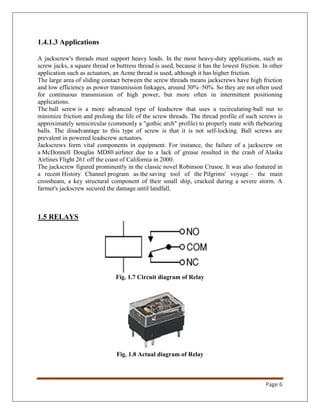

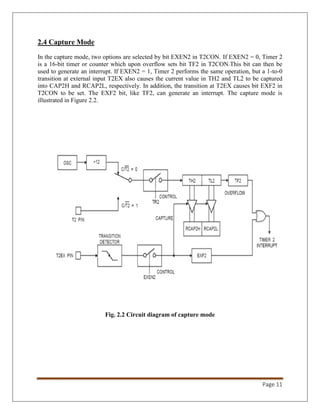

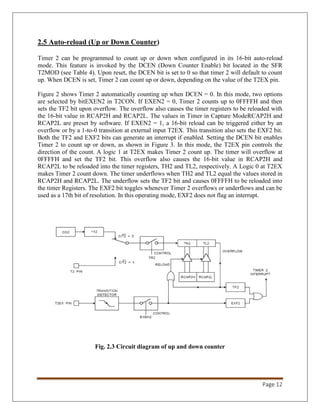

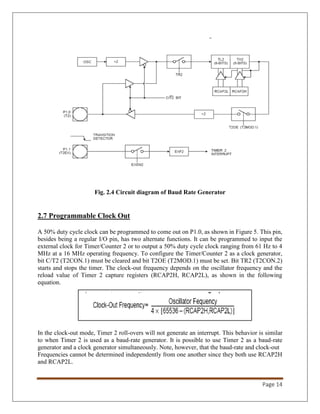

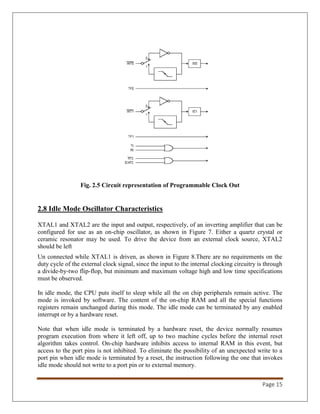

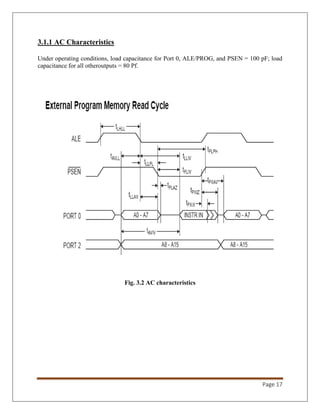

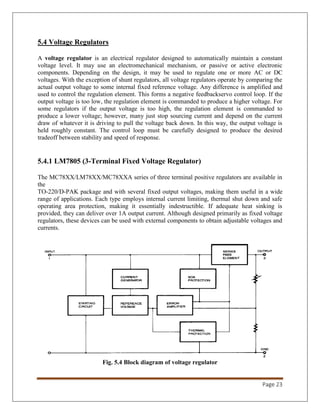

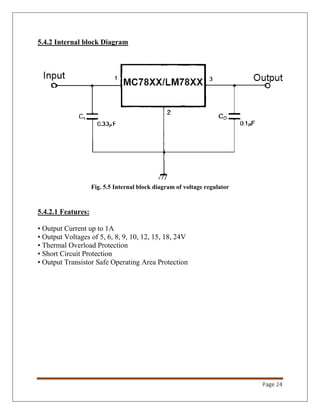

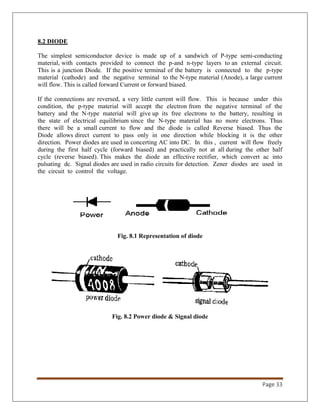

The document is a project report on an 'advanced speed breaker' produced by students from the Translam Institute of Technology and Management as part of their mechanical engineering degree. It details the design and functionality of an automatic speed breaker system aimed at improving road safety, particularly near schools and colleges, using sensors, sound alarms, and visual signals. The report includes project acknowledgments, figures, hardware requirements, and an outline of the project's working mechanism.