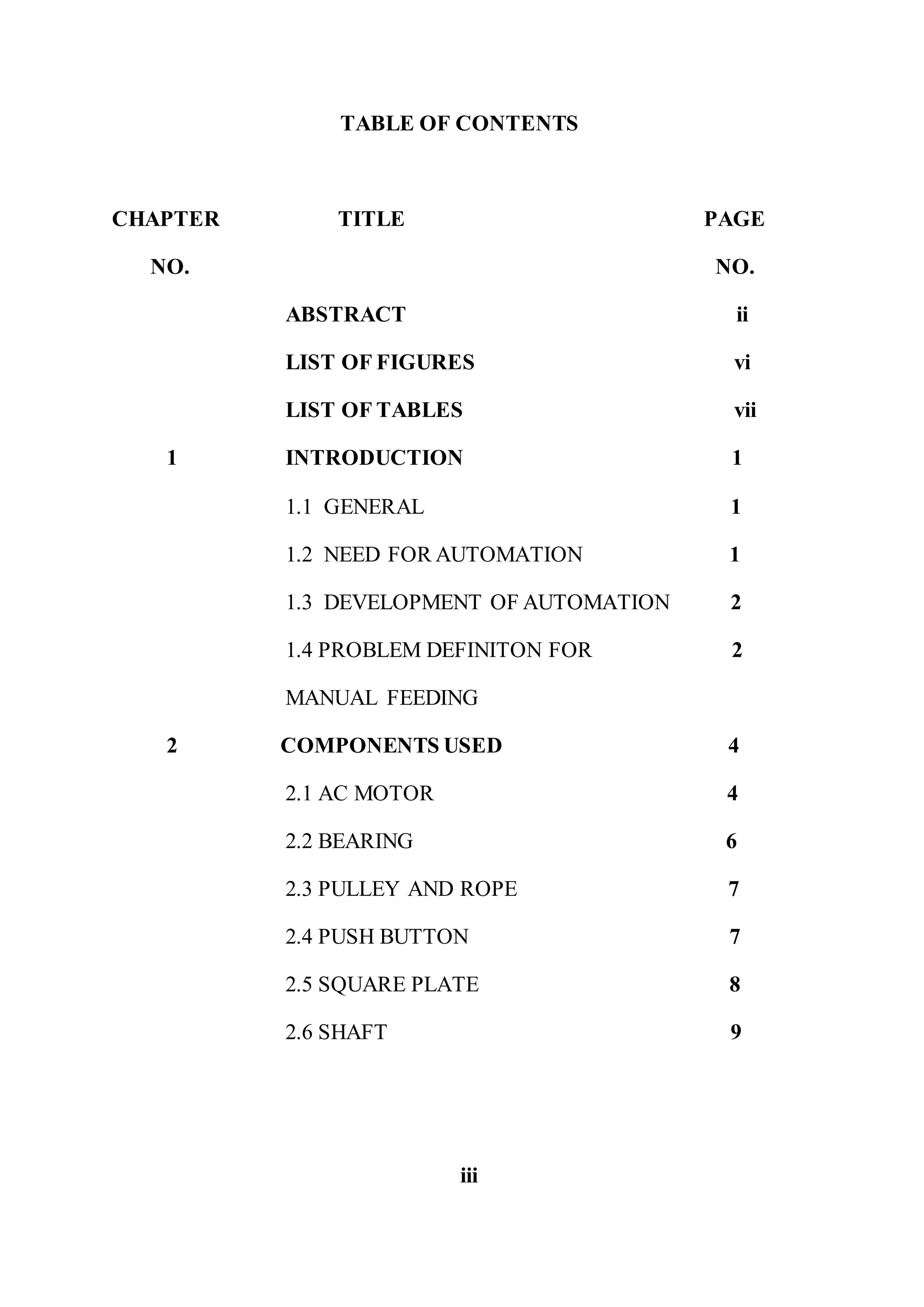

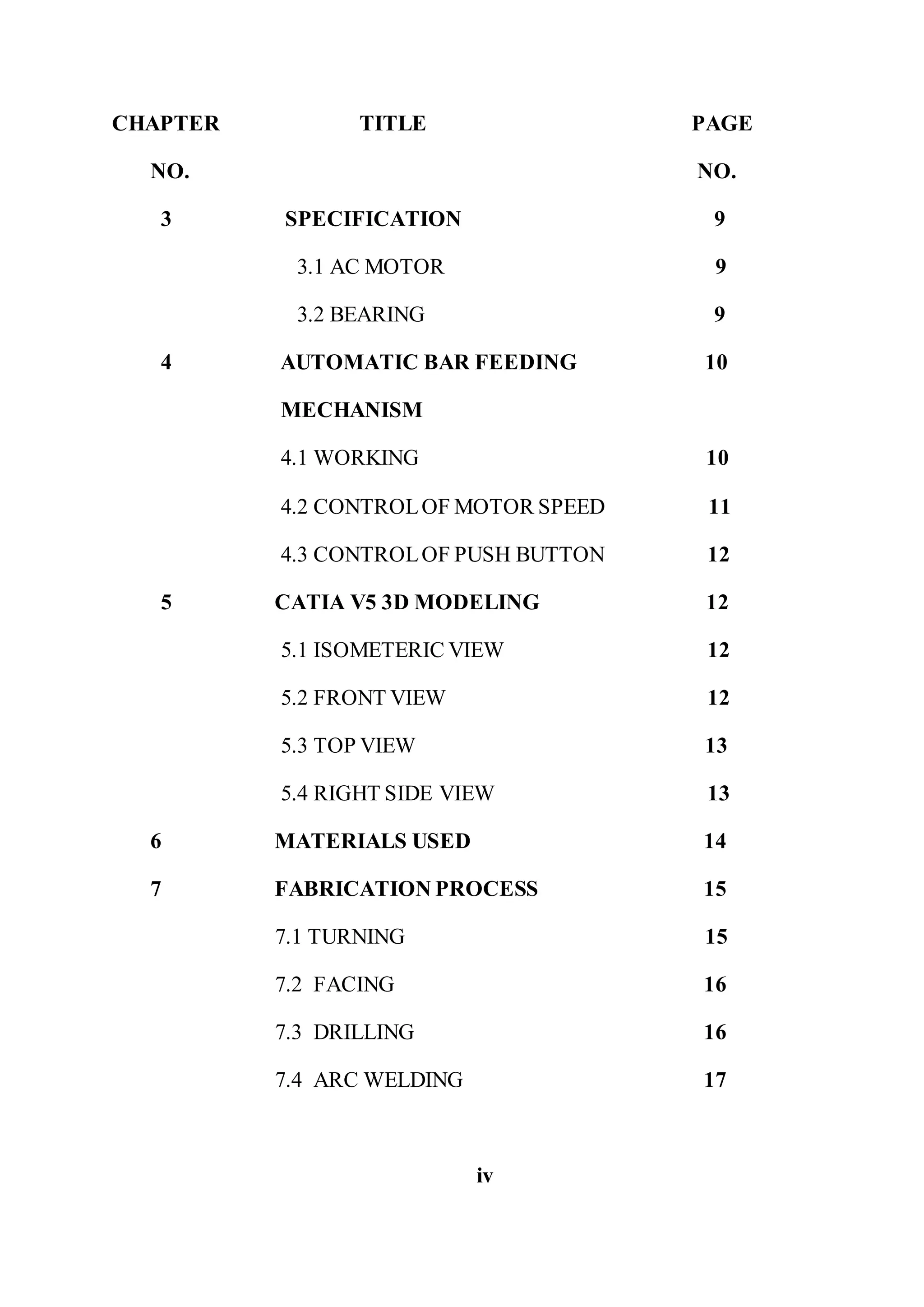

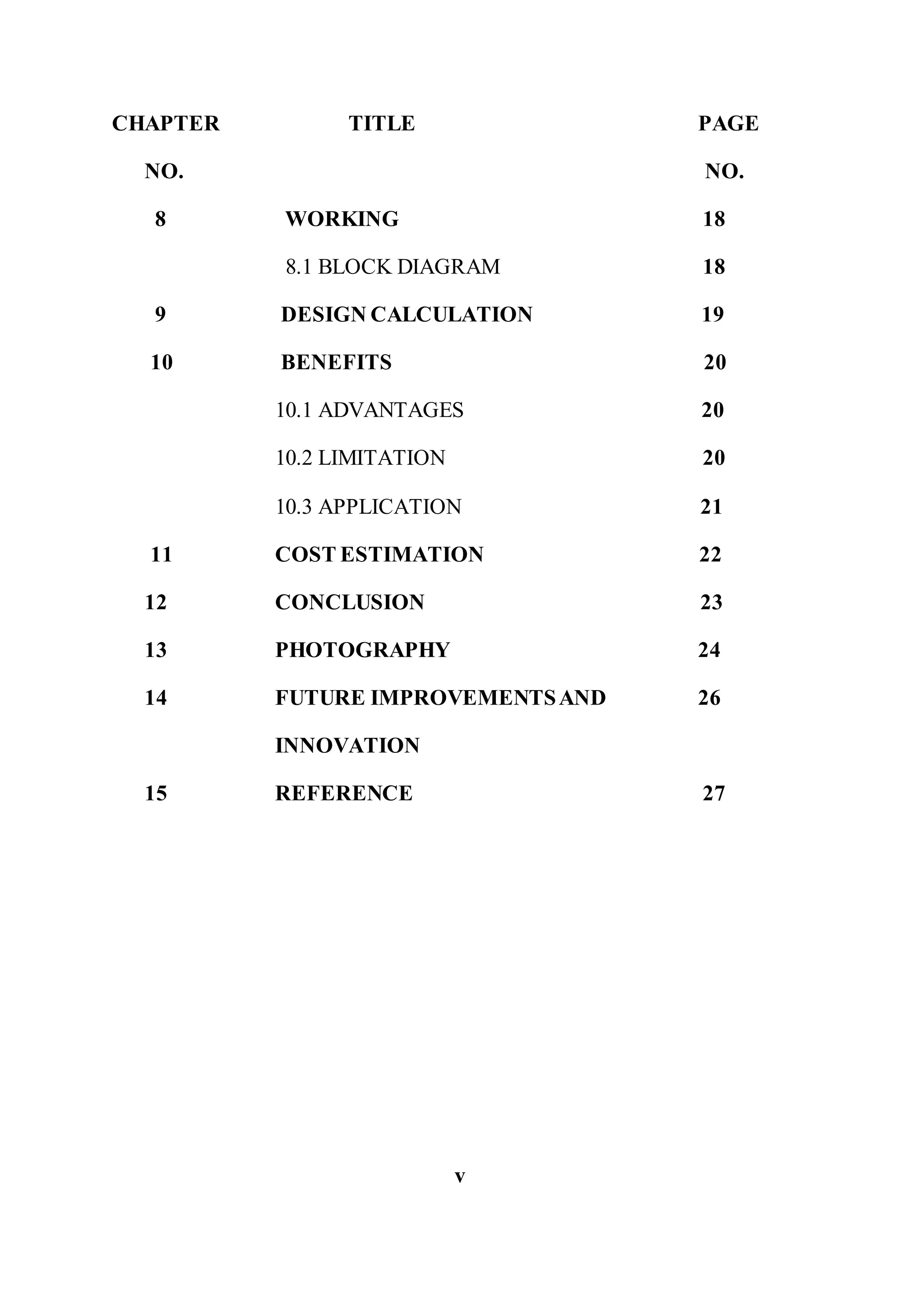

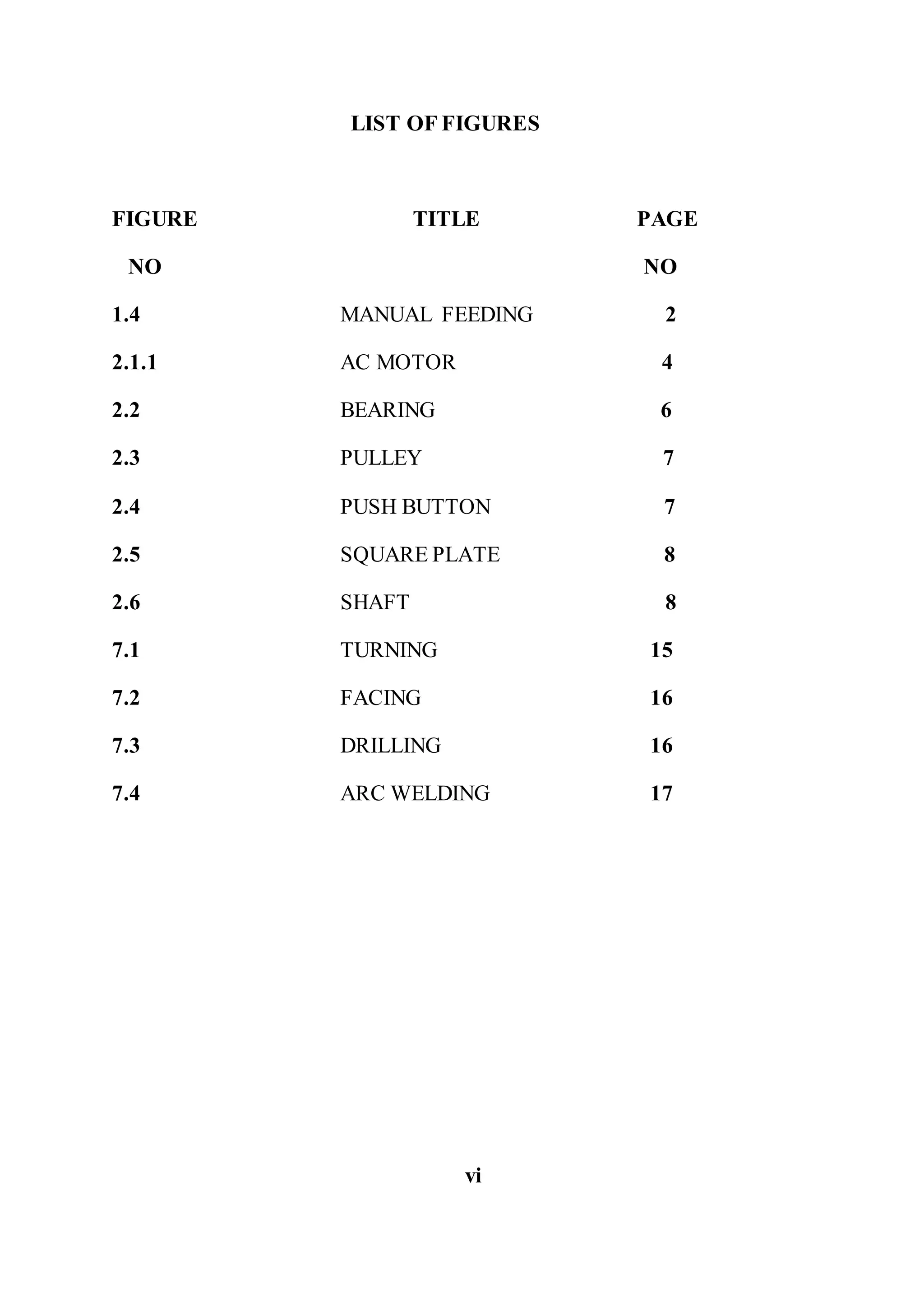

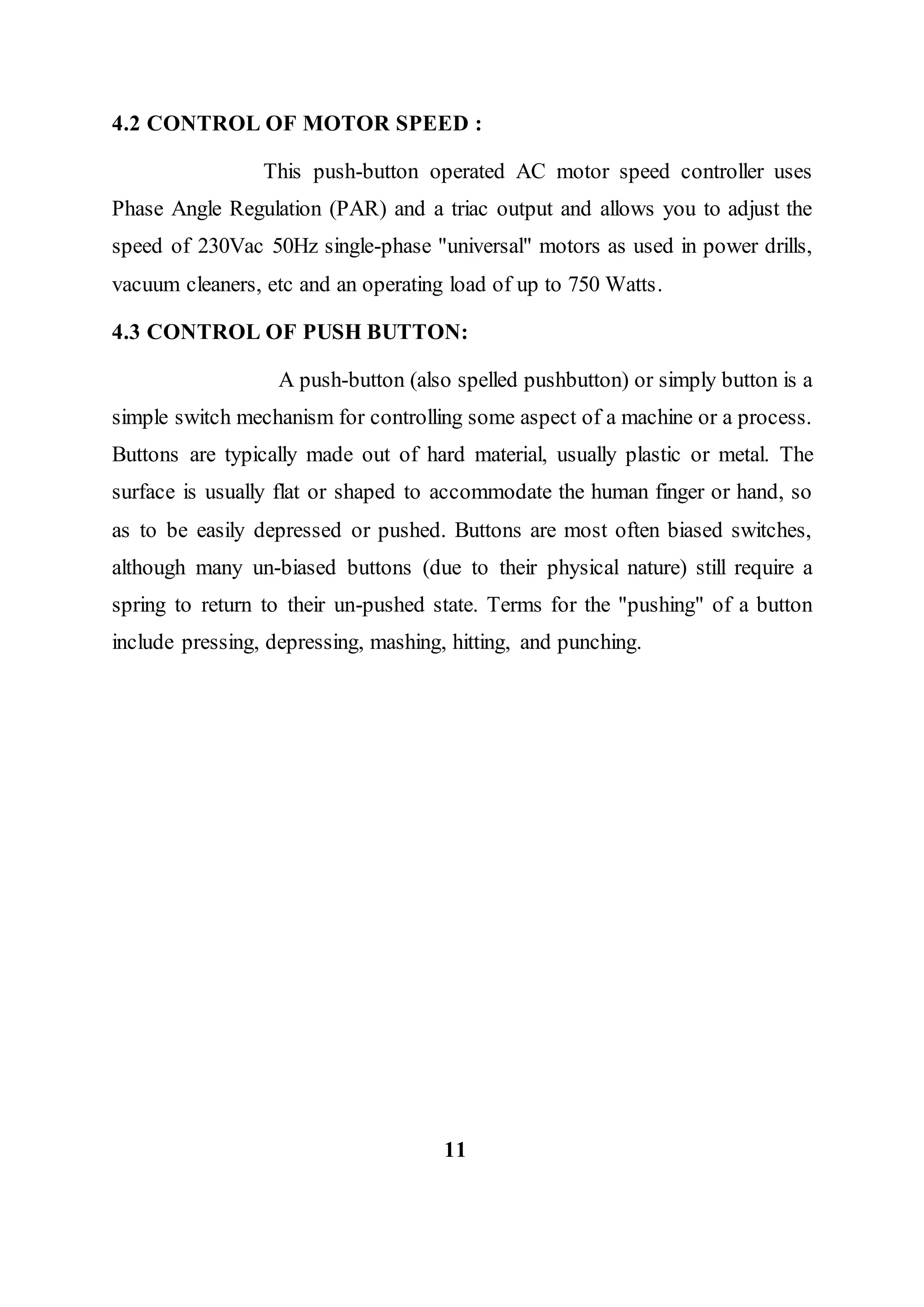

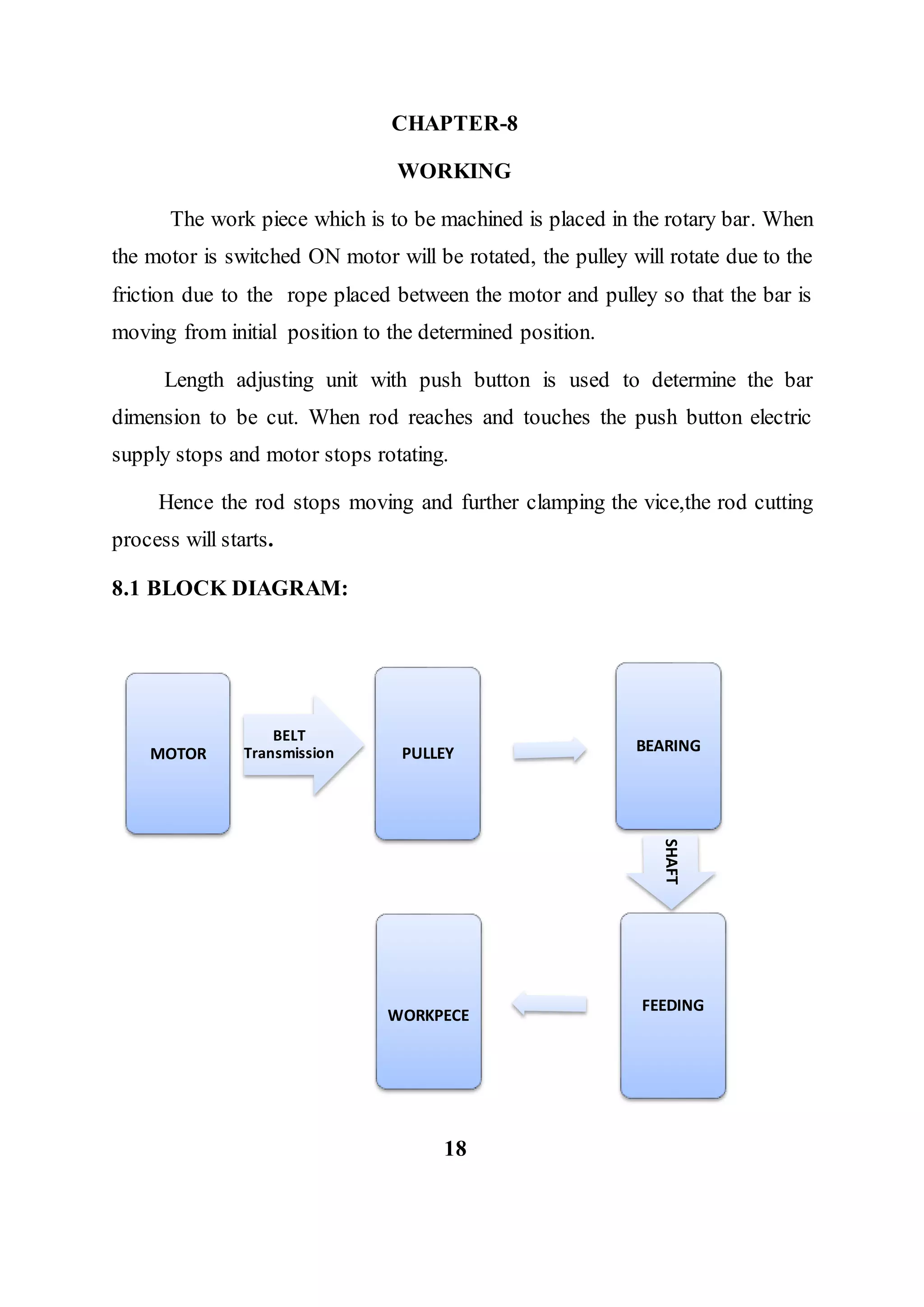

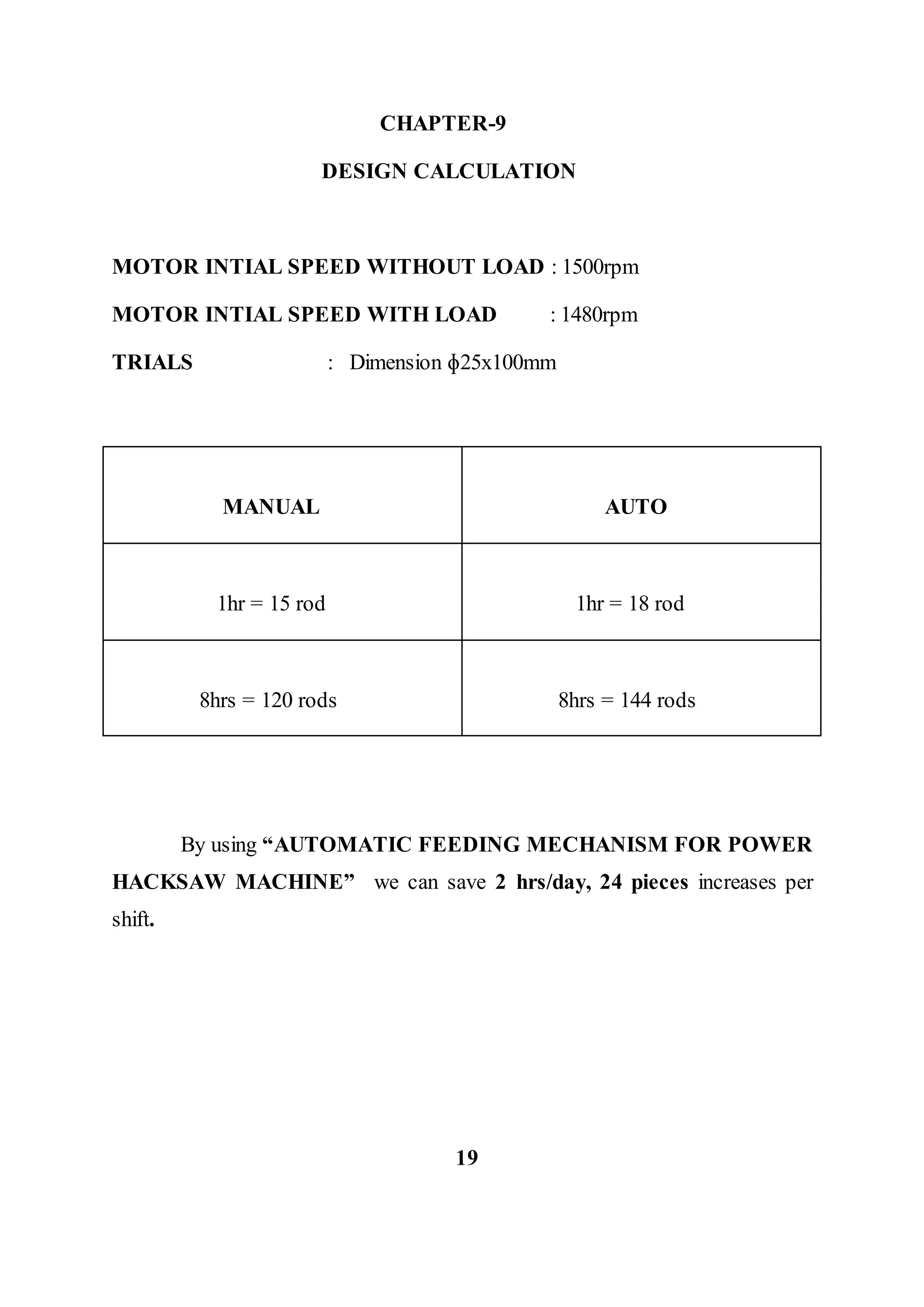

The document describes the design and fabrication of an automatic feeding mechanism for a power hacksaw machine. It was created by 4 students as their mini project to fulfill their Bachelor of Engineering degree requirements. The mechanism uses an AC motor, bearings, pulleys, a push button, square plate and shaft to automatically feed a bar into the power hacksaw machine at regular time intervals for improved accuracy and efficiency over manual feeding. The students modeled the mechanism in CATIA V5 and described the fabrication process and components in detail.