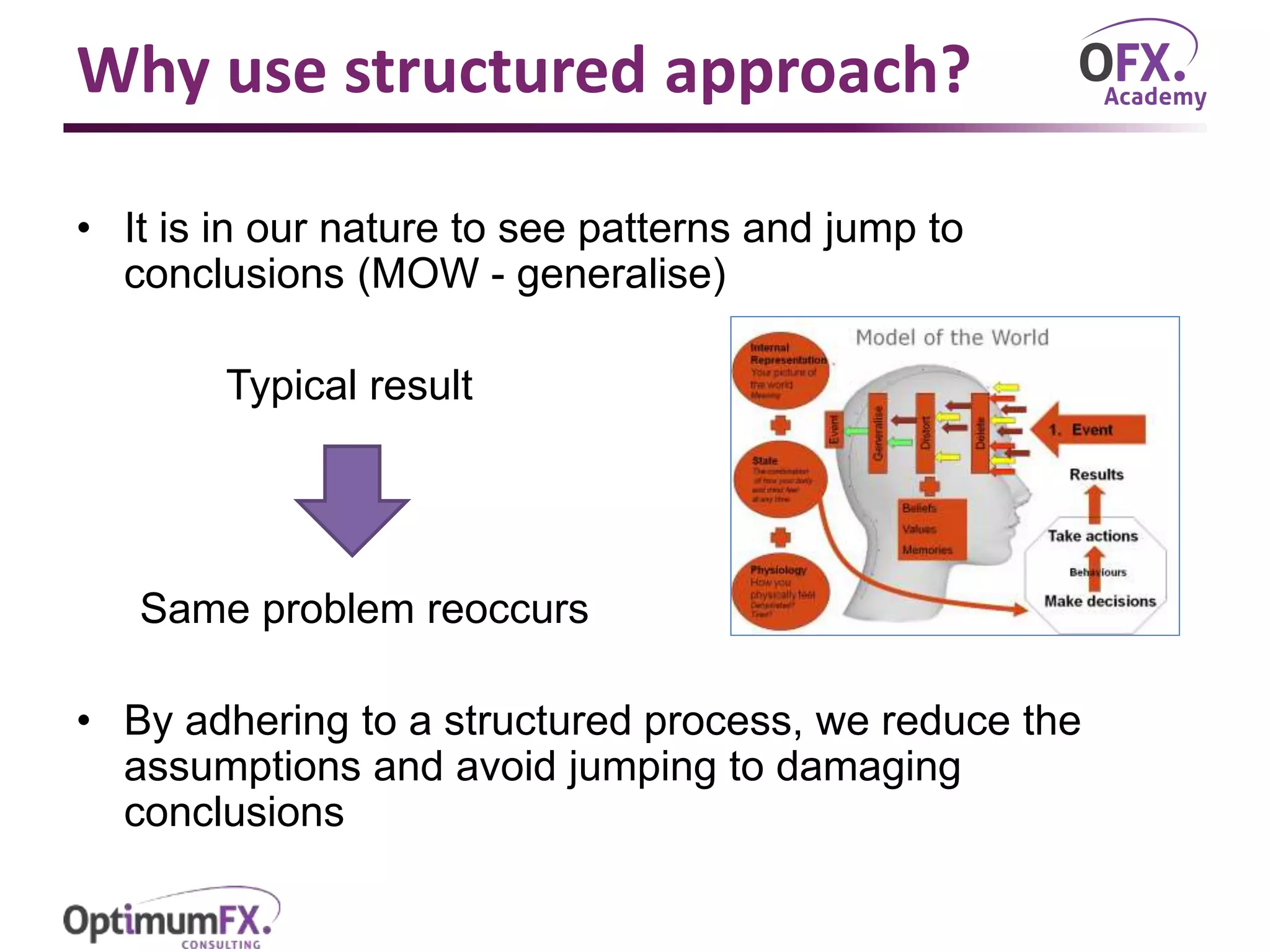

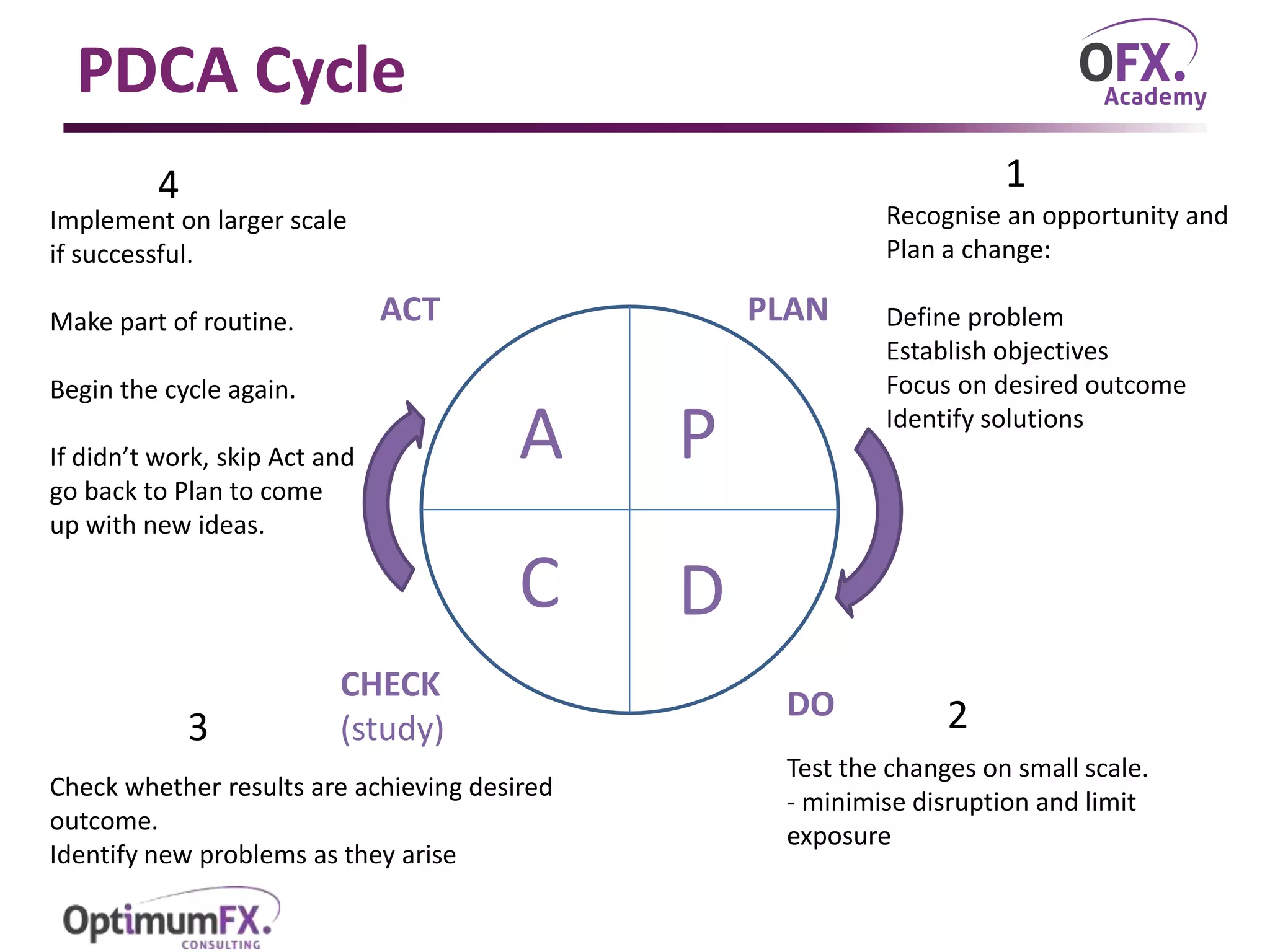

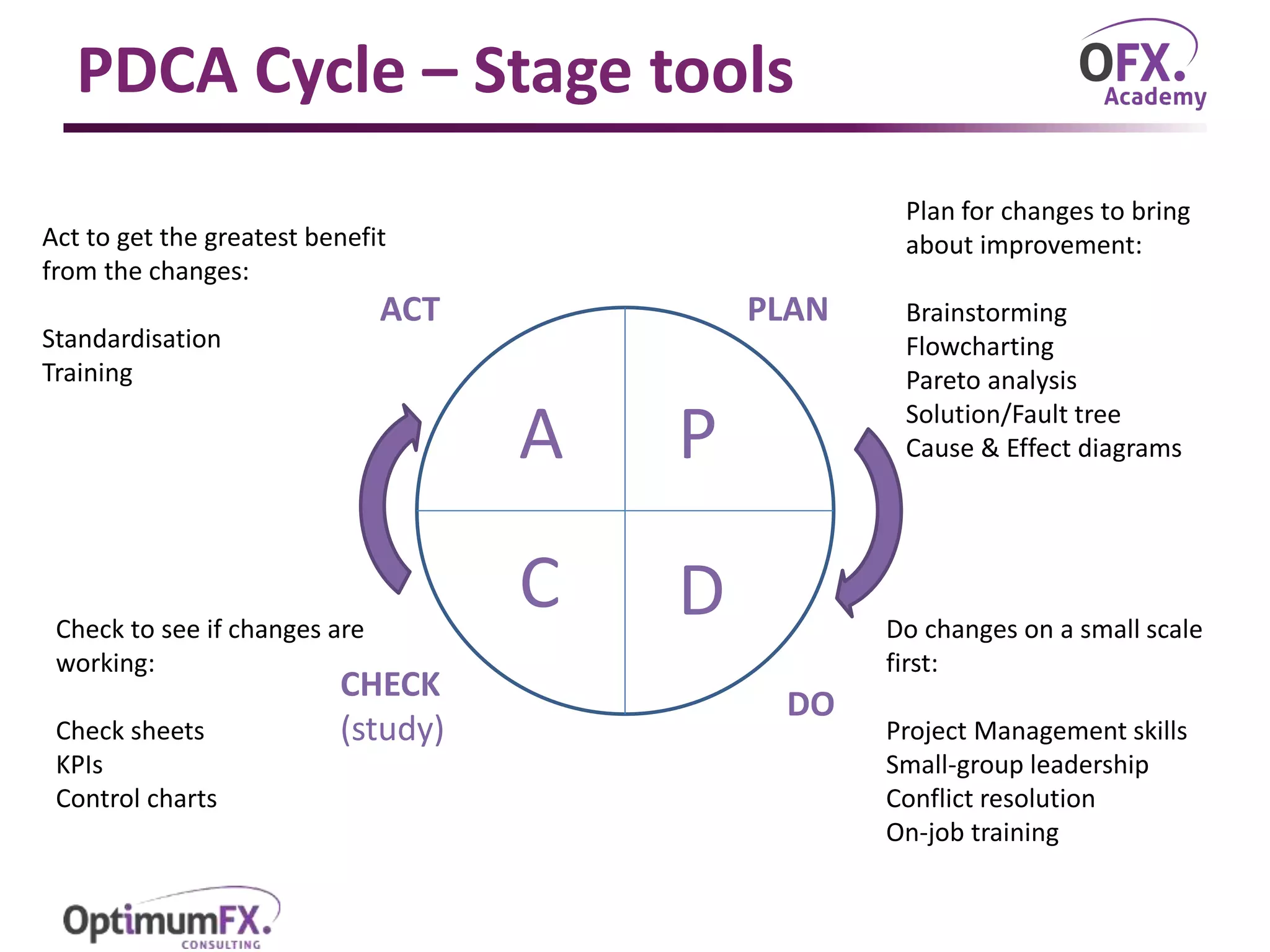

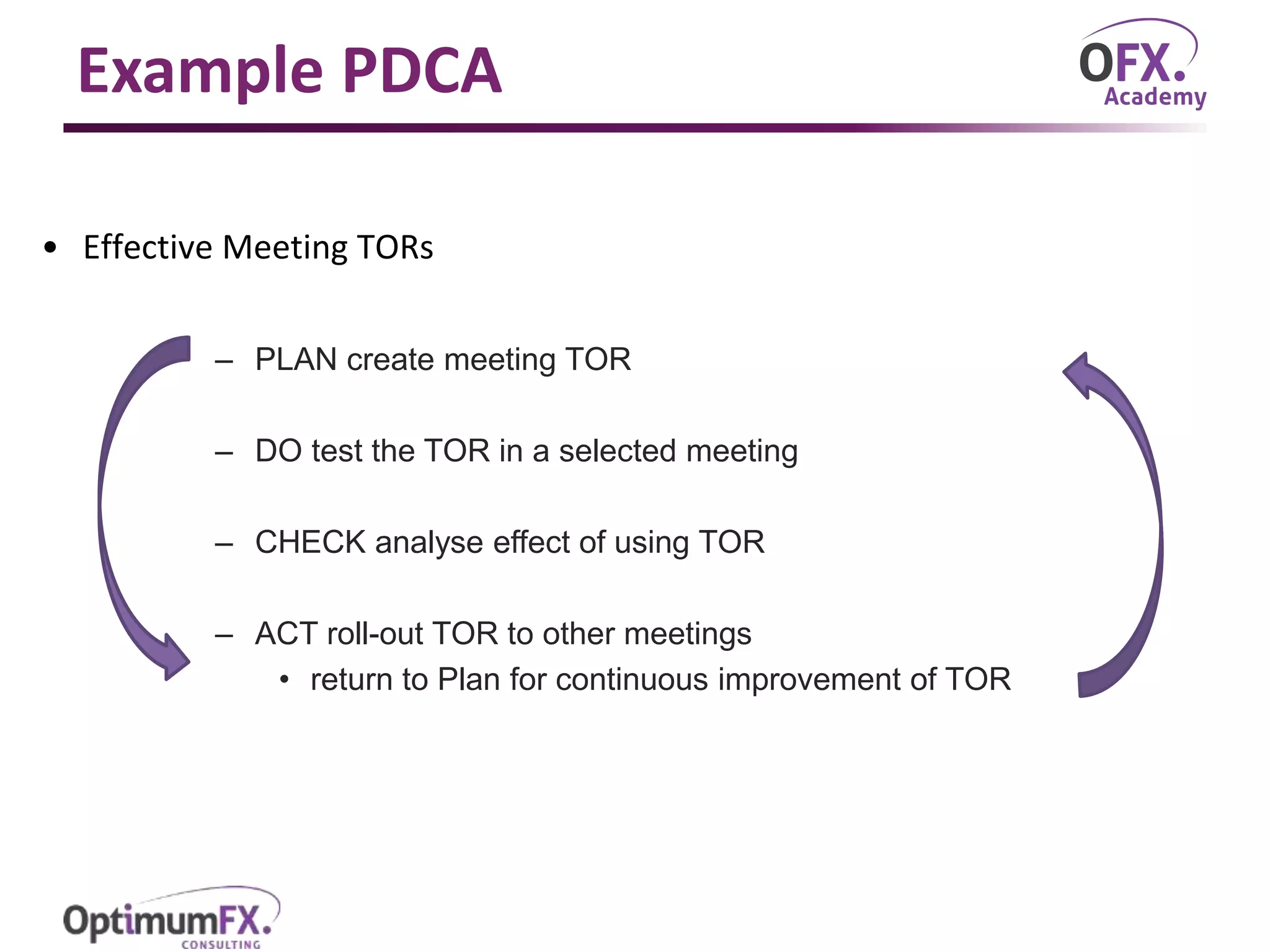

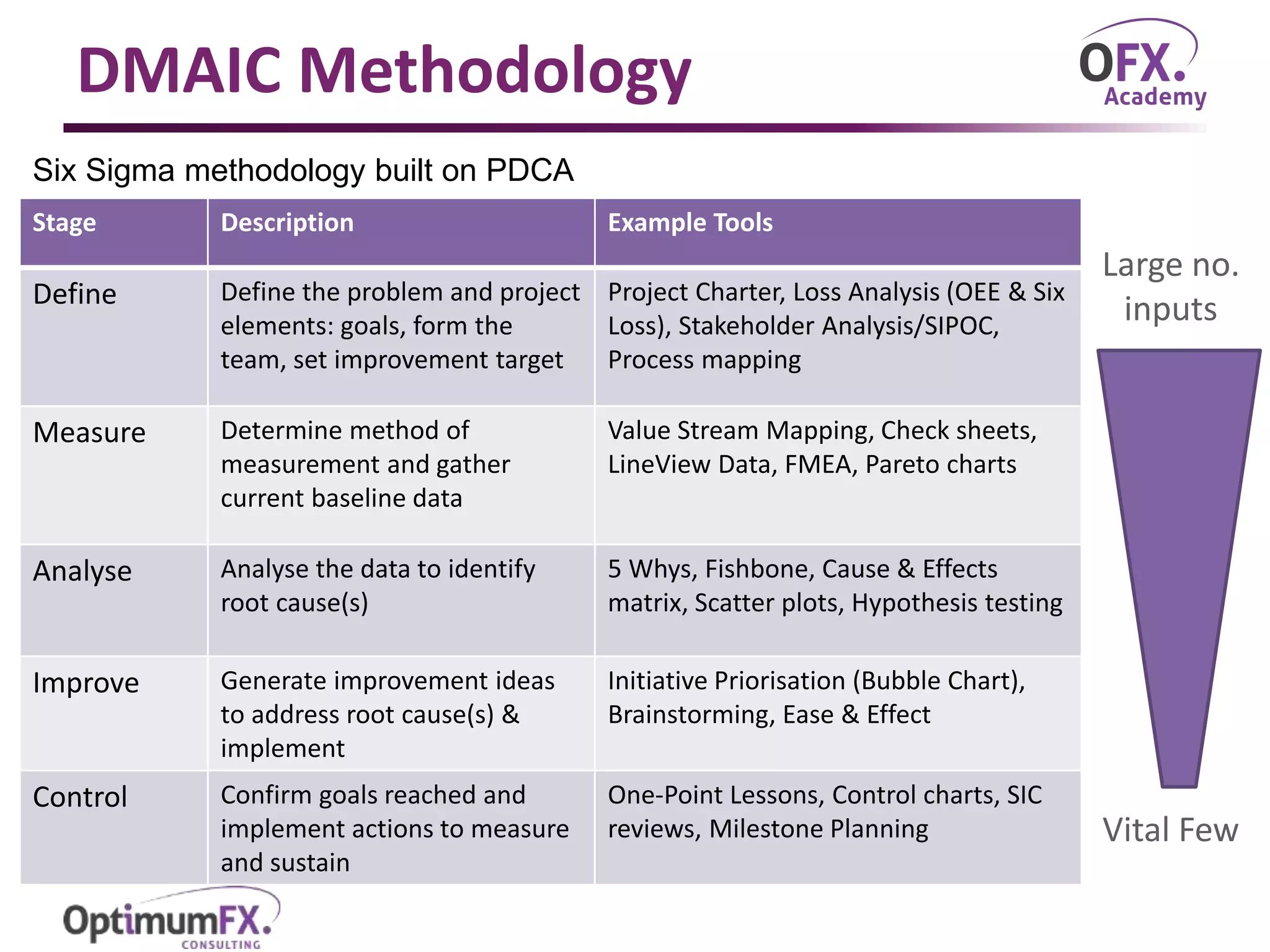

The document introduces two structured methodologies for problem-solving: PDCA (Plan-Do-Check-Act) and DMAIC (Define-Measure-Analyze-Improve-Control), demonstrating their phases and associated tools. It emphasizes the importance of a systematic approach to reduce assumptions and recurring issues. By employing these methodologies, organizations can achieve continuous improvement in processes, products, or services through careful planning, testing, and sustaining changes.