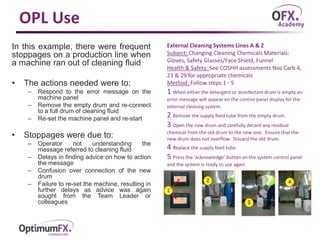

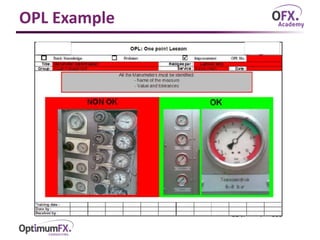

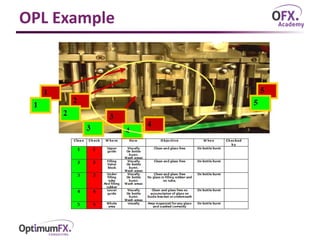

One Point Lessons (OPLs) are short, visual presentations on a single task that can be explained in about 10 minutes. They are detailed on one or two pages using diagrams, photographs or drawings. OPLs are used to provide vital instructions for tasks at the workplace and are generated and used at the point of need. An example is provided of an OPL created to address frequent stoppages on a production line caused by operators not understanding how to change an empty cleaning fluid drum. The OPL clearly outlines the steps to acknowledge the error message and replace the empty drum. OPLs help improve performance, efficiency and quality by ensuring key work instructions are available when needed.