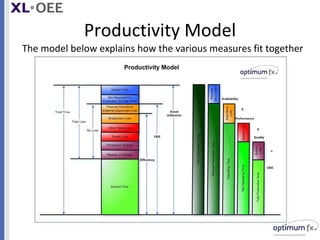

Overall Equipment Effectiveness (OEE) measures actual production output against theoretical maximum output over a given time period. Losses are categorized into availability, performance, and quality, known as the "Six Big Losses": planned downtime, breakdowns, minor stops, speed losses, production rejects, and start-up rejects. Measuring these losses provides data to target improvement areas and increase equipment effectiveness.