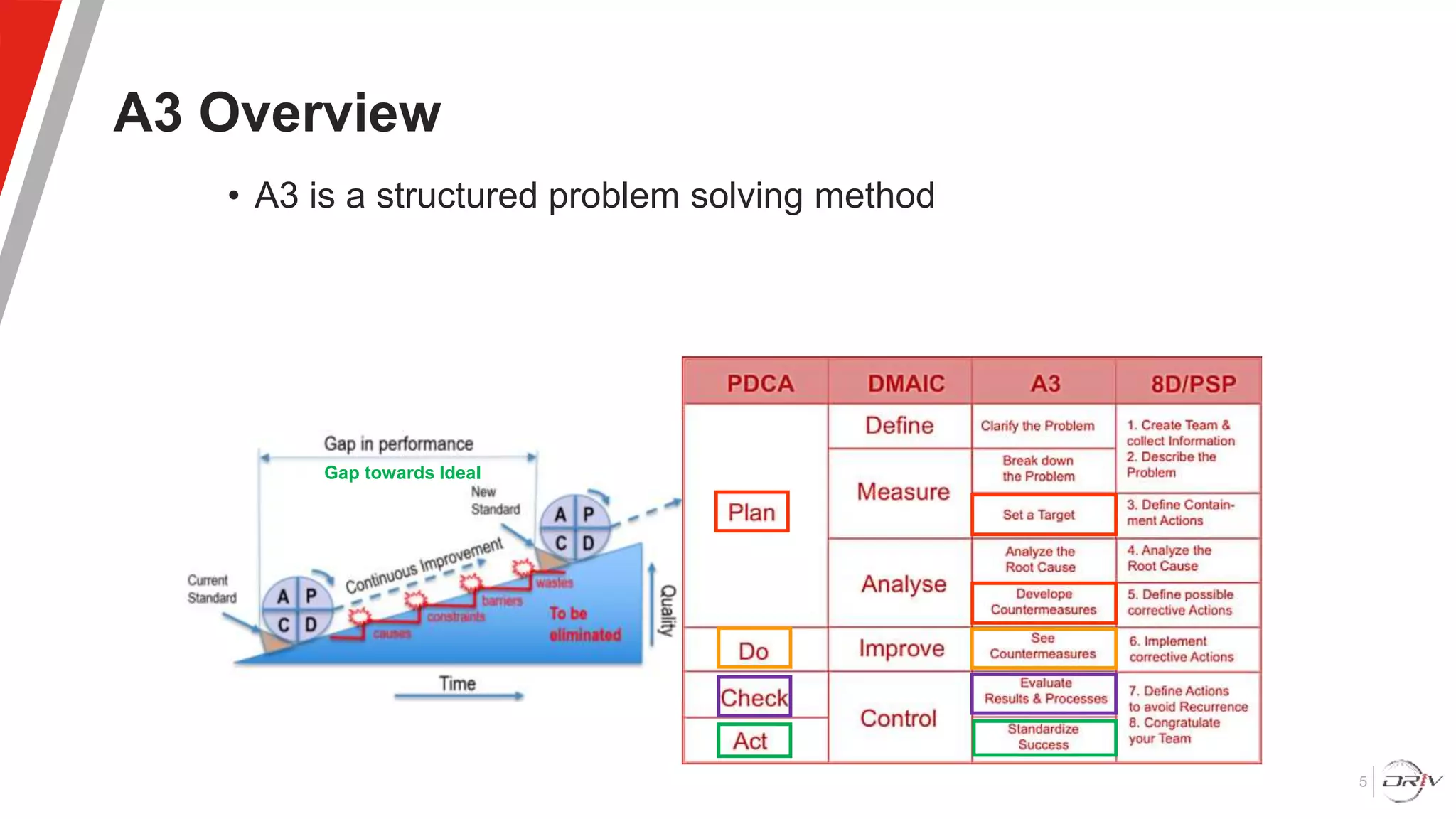

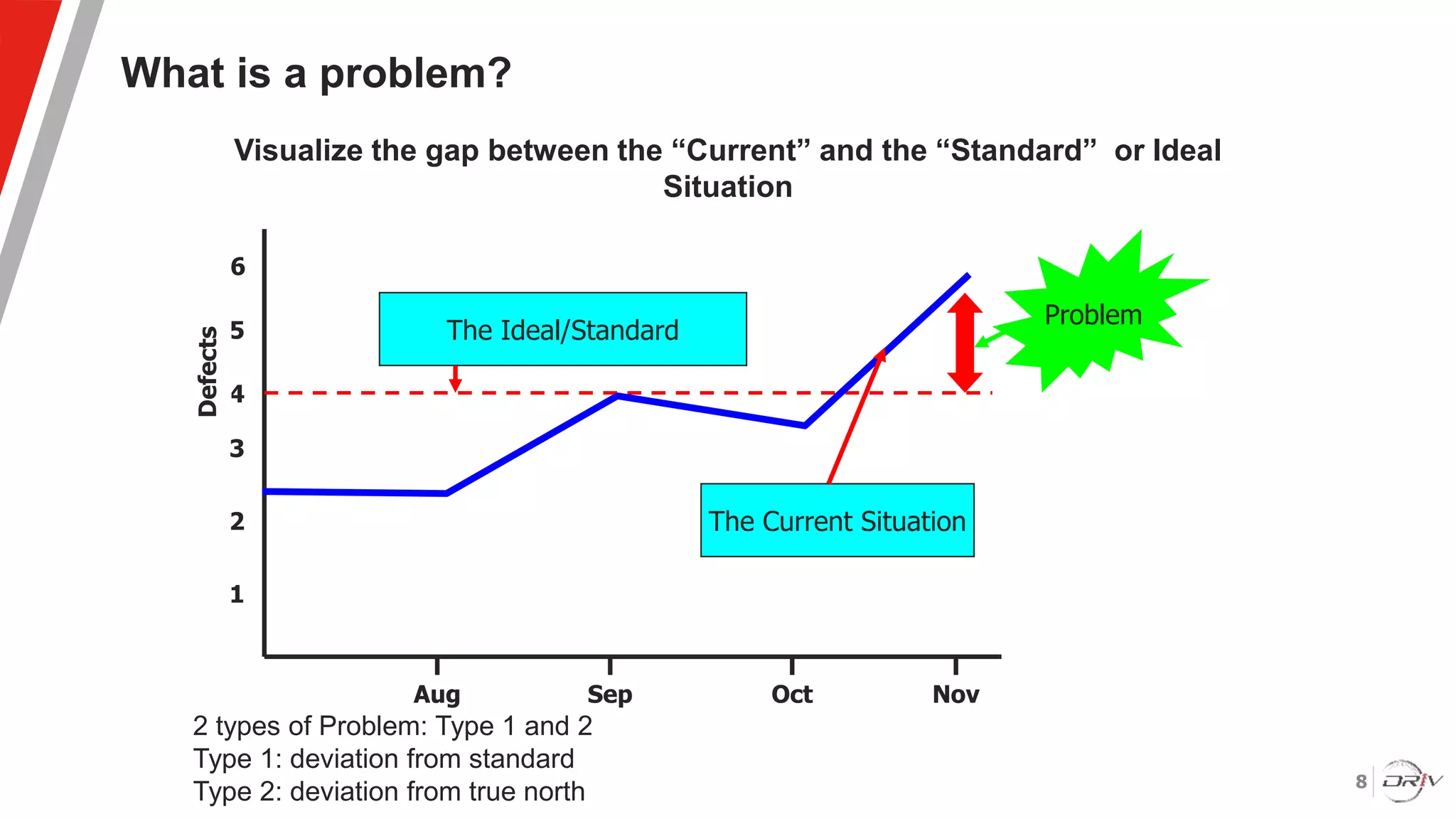

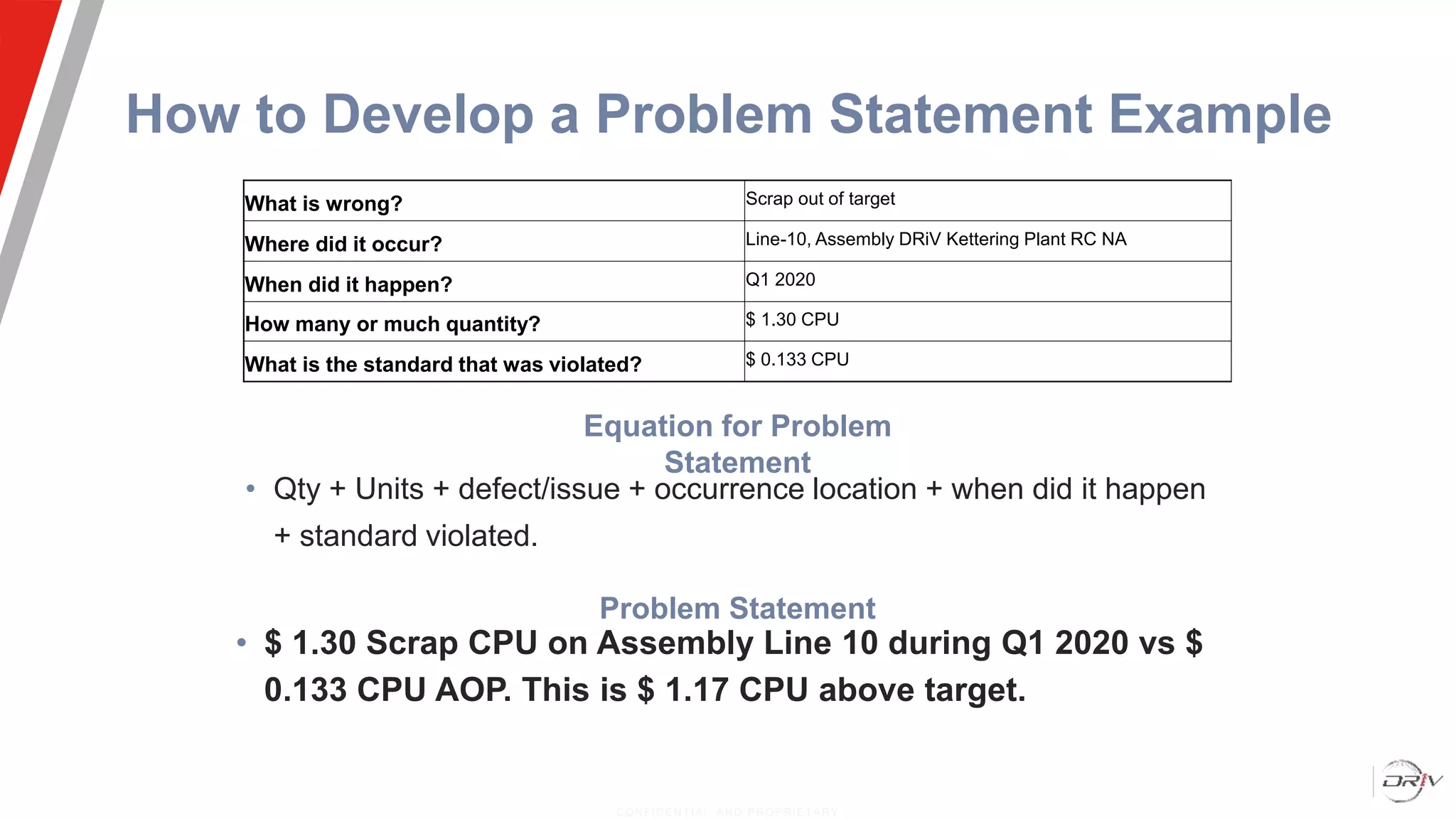

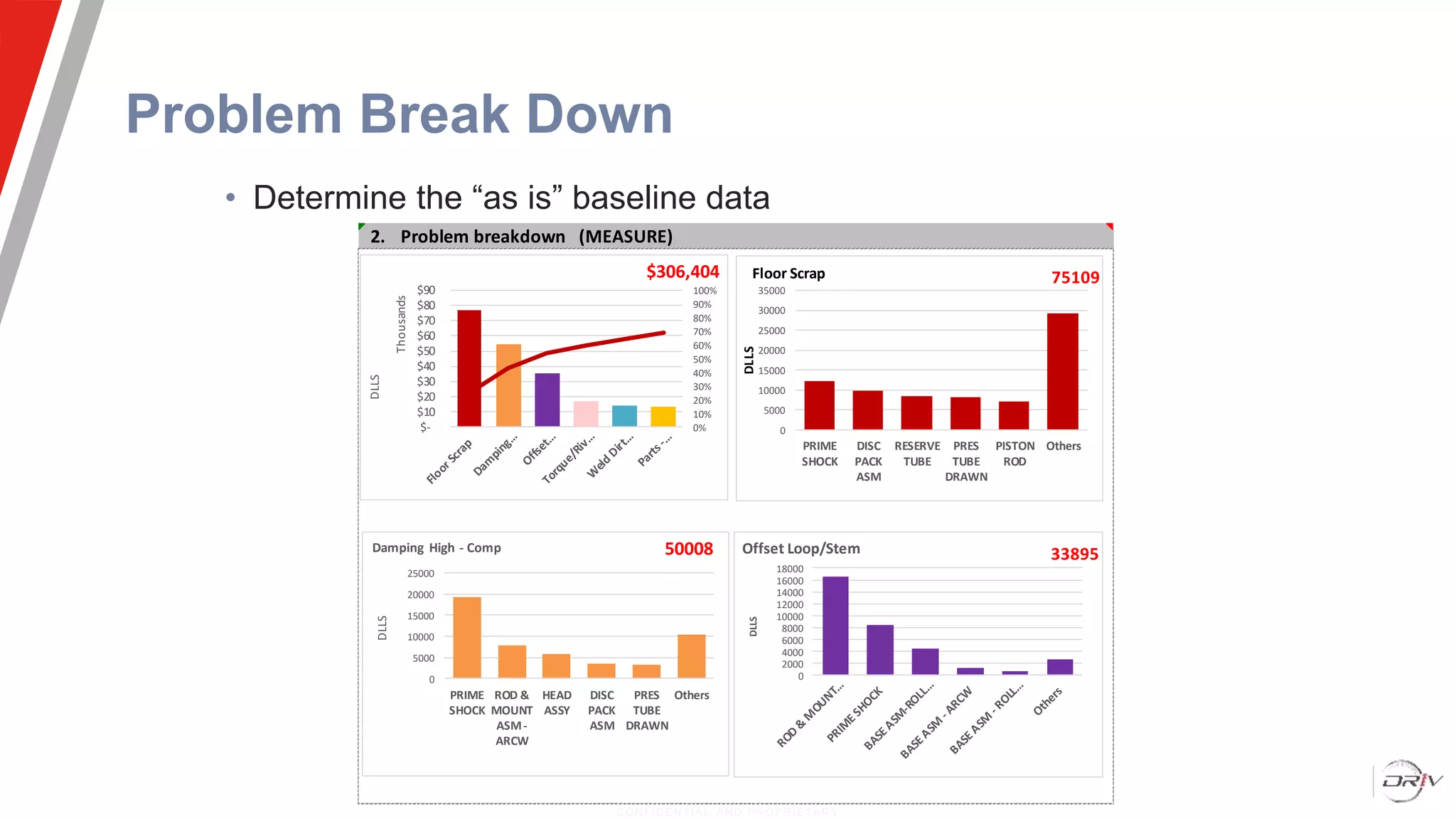

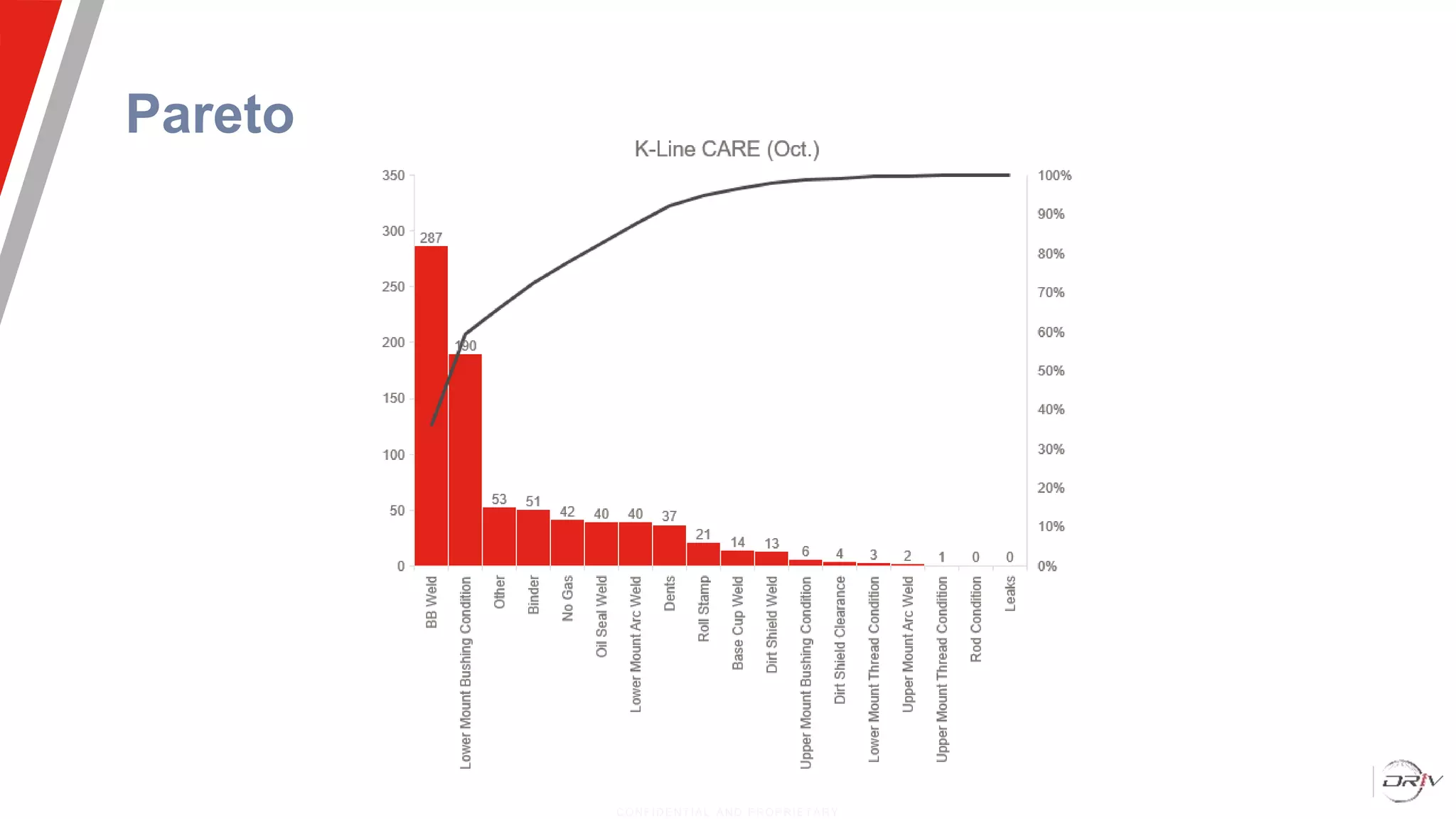

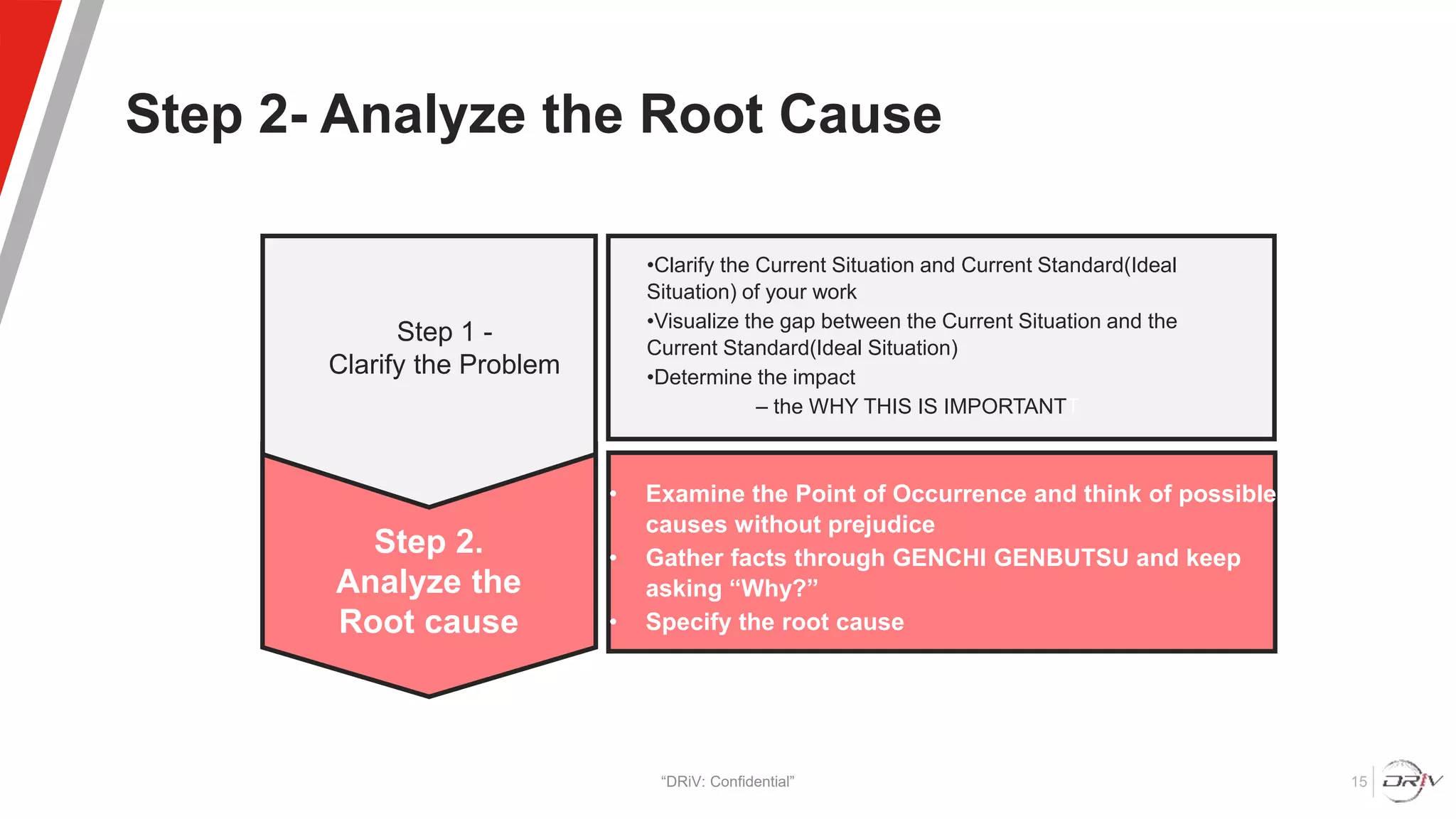

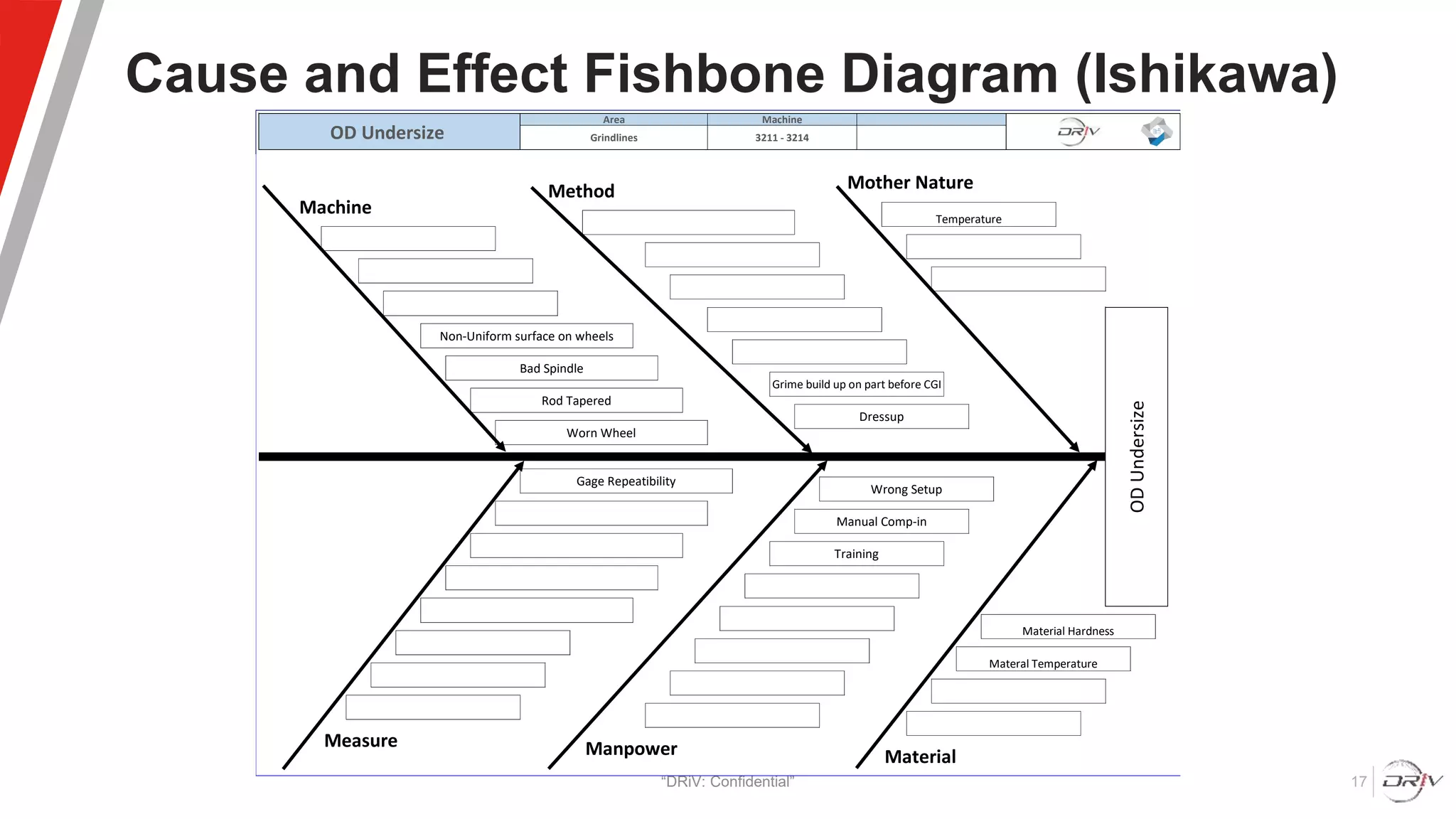

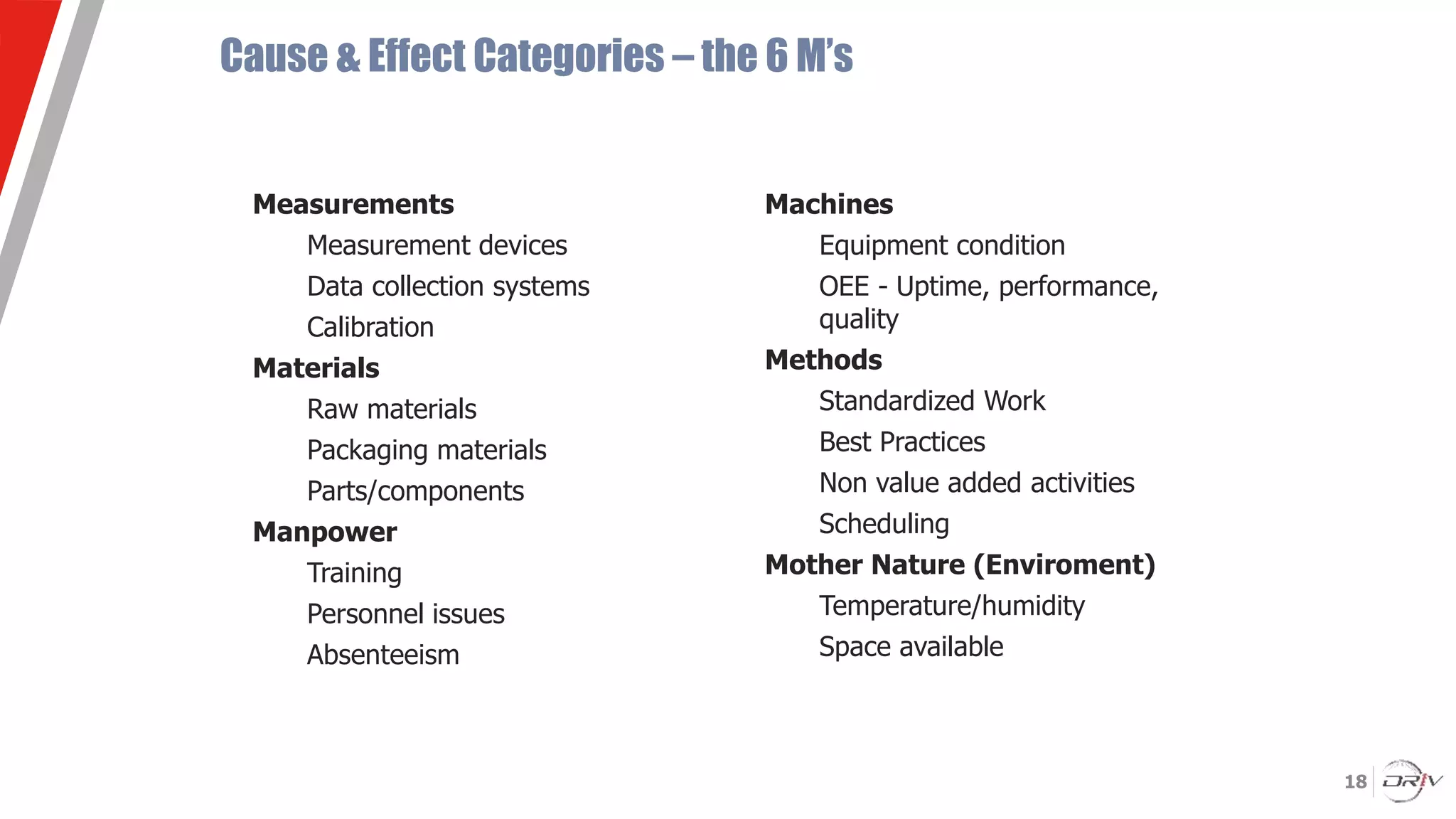

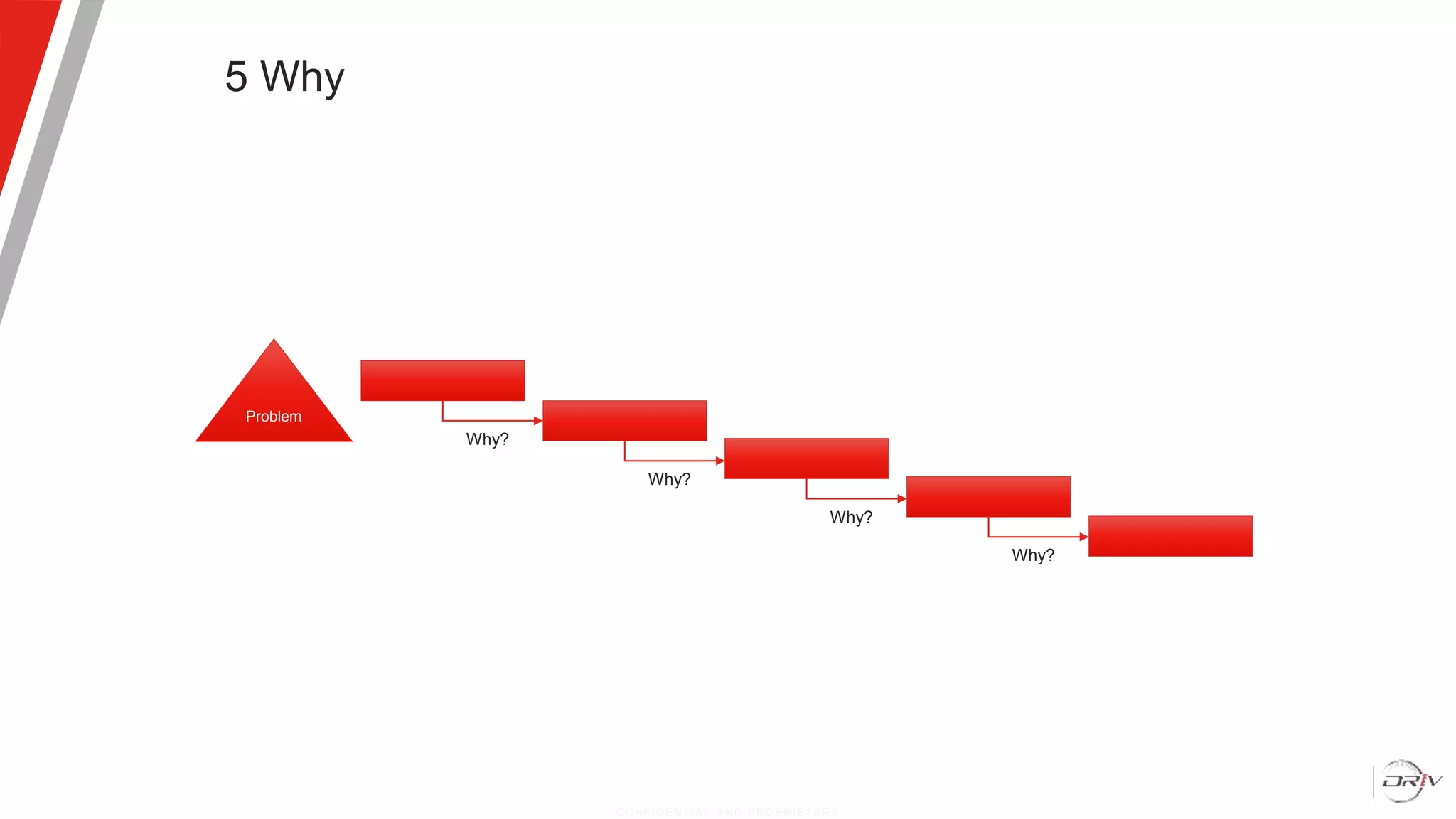

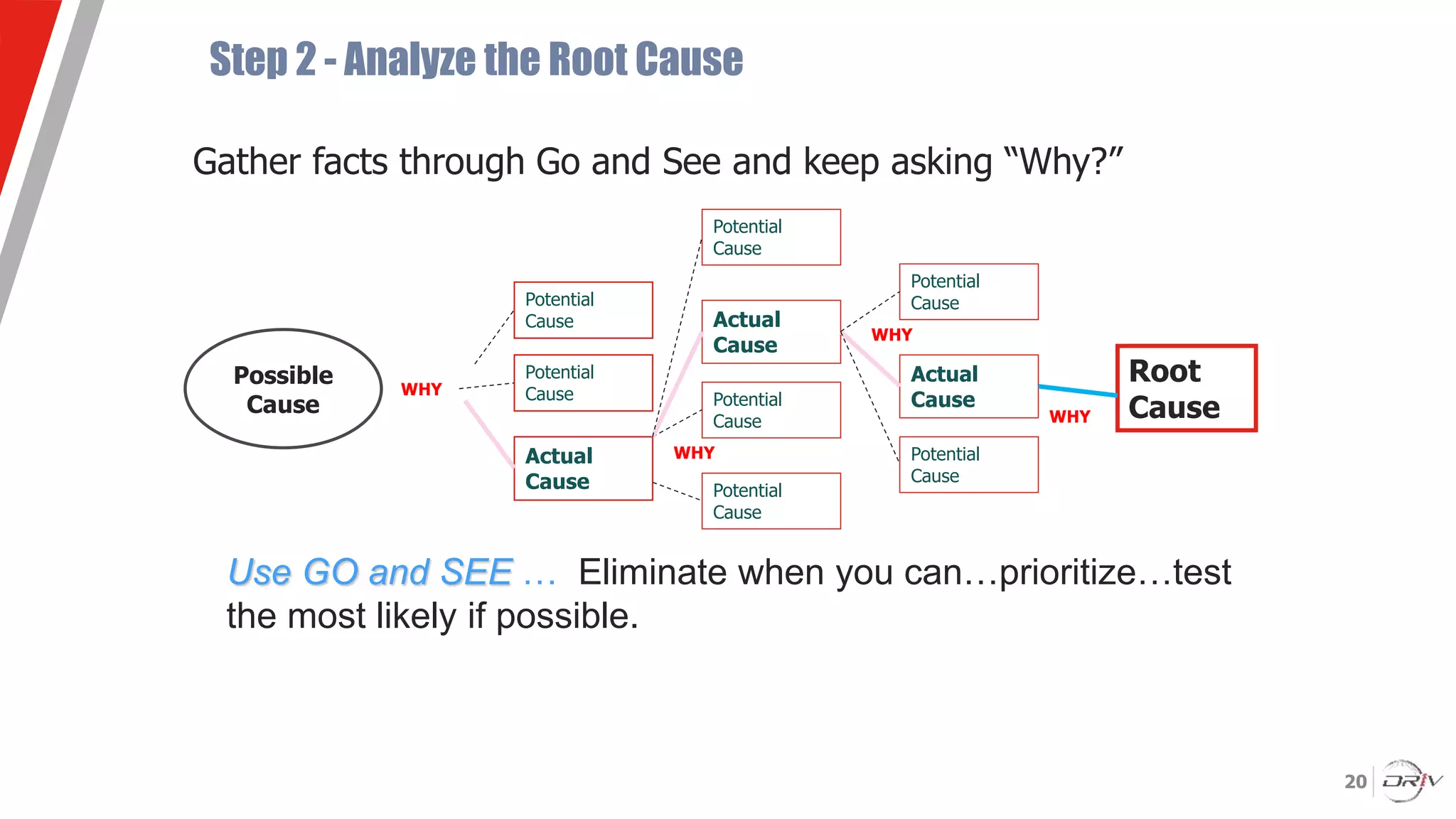

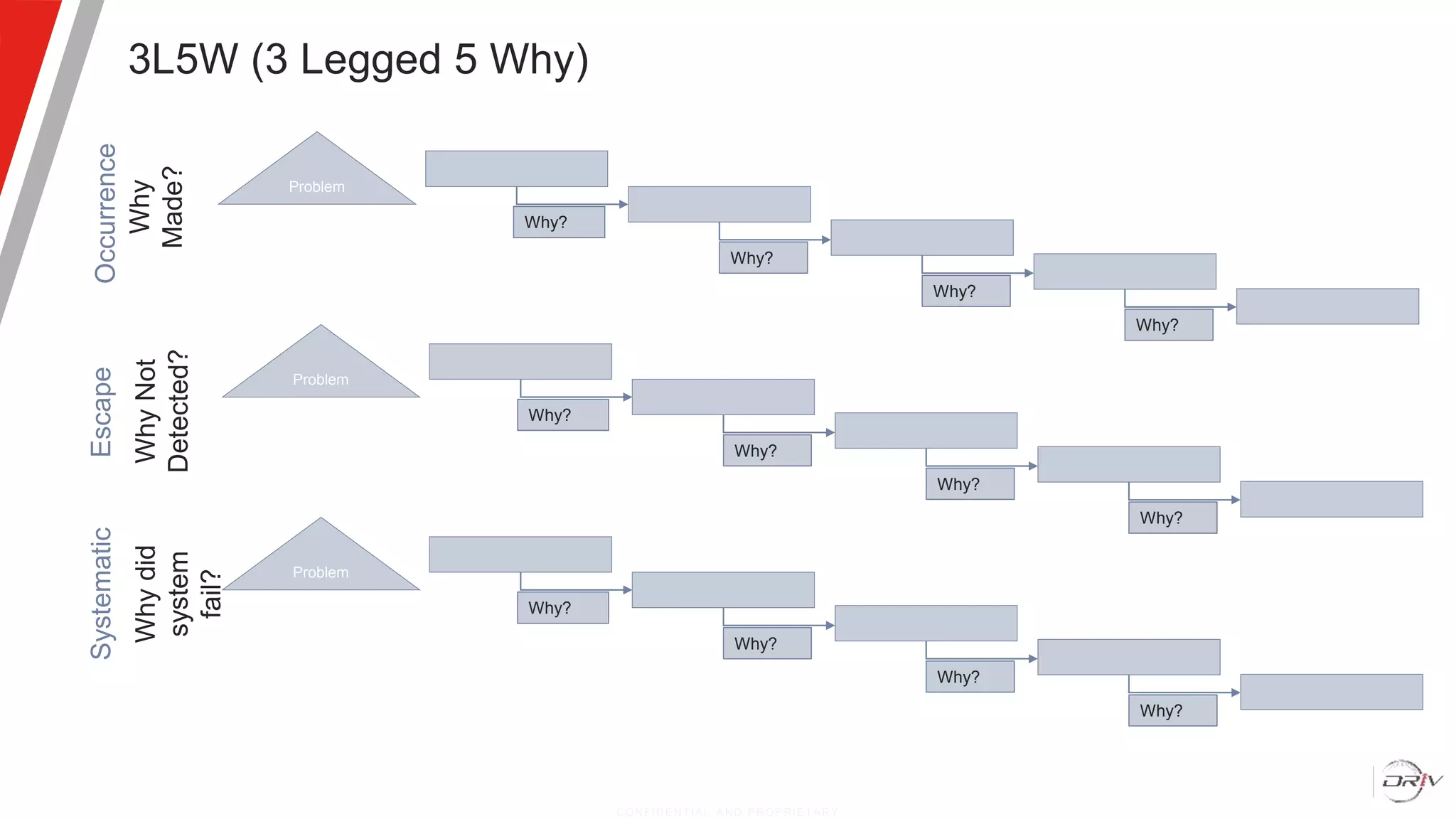

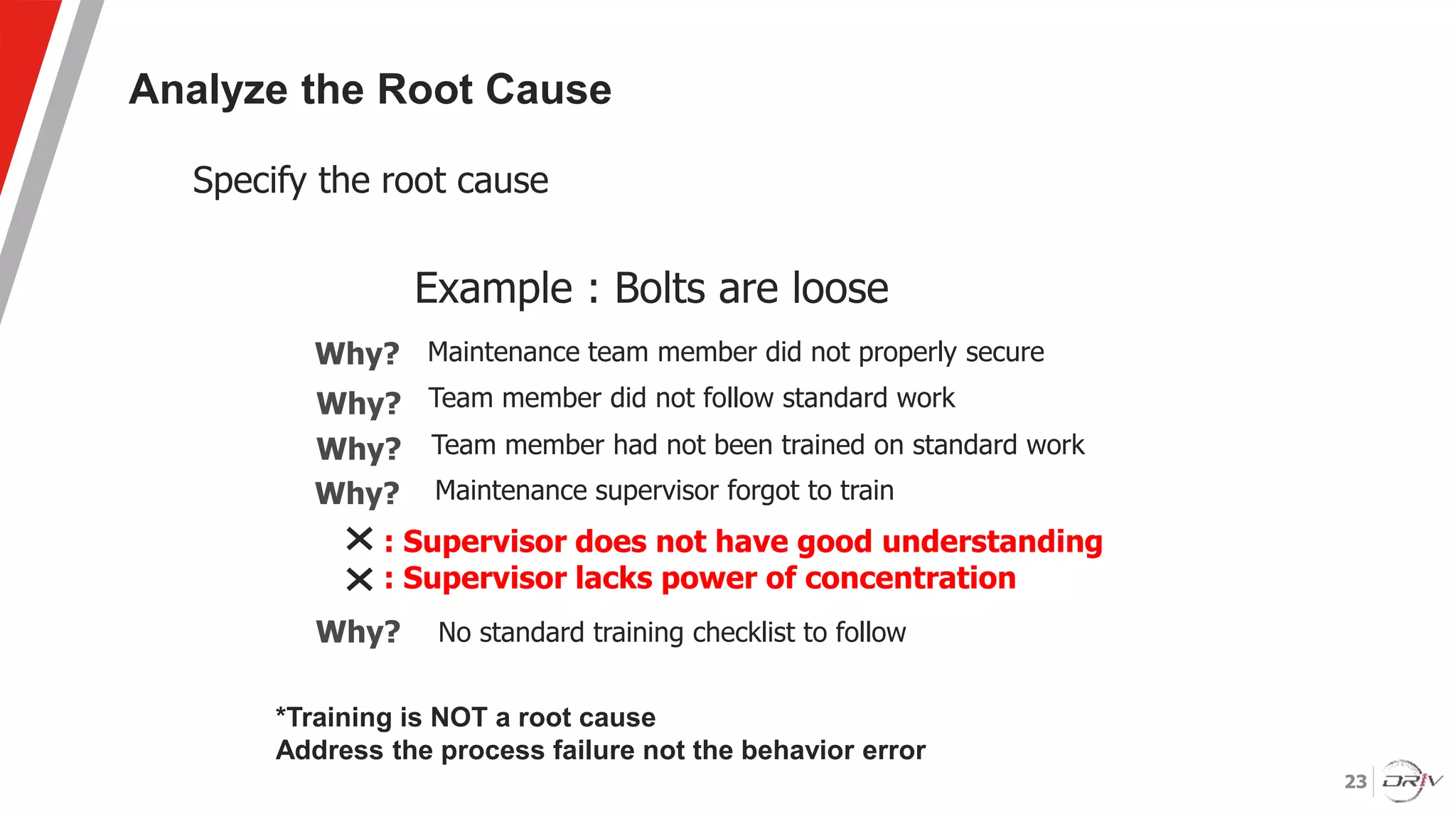

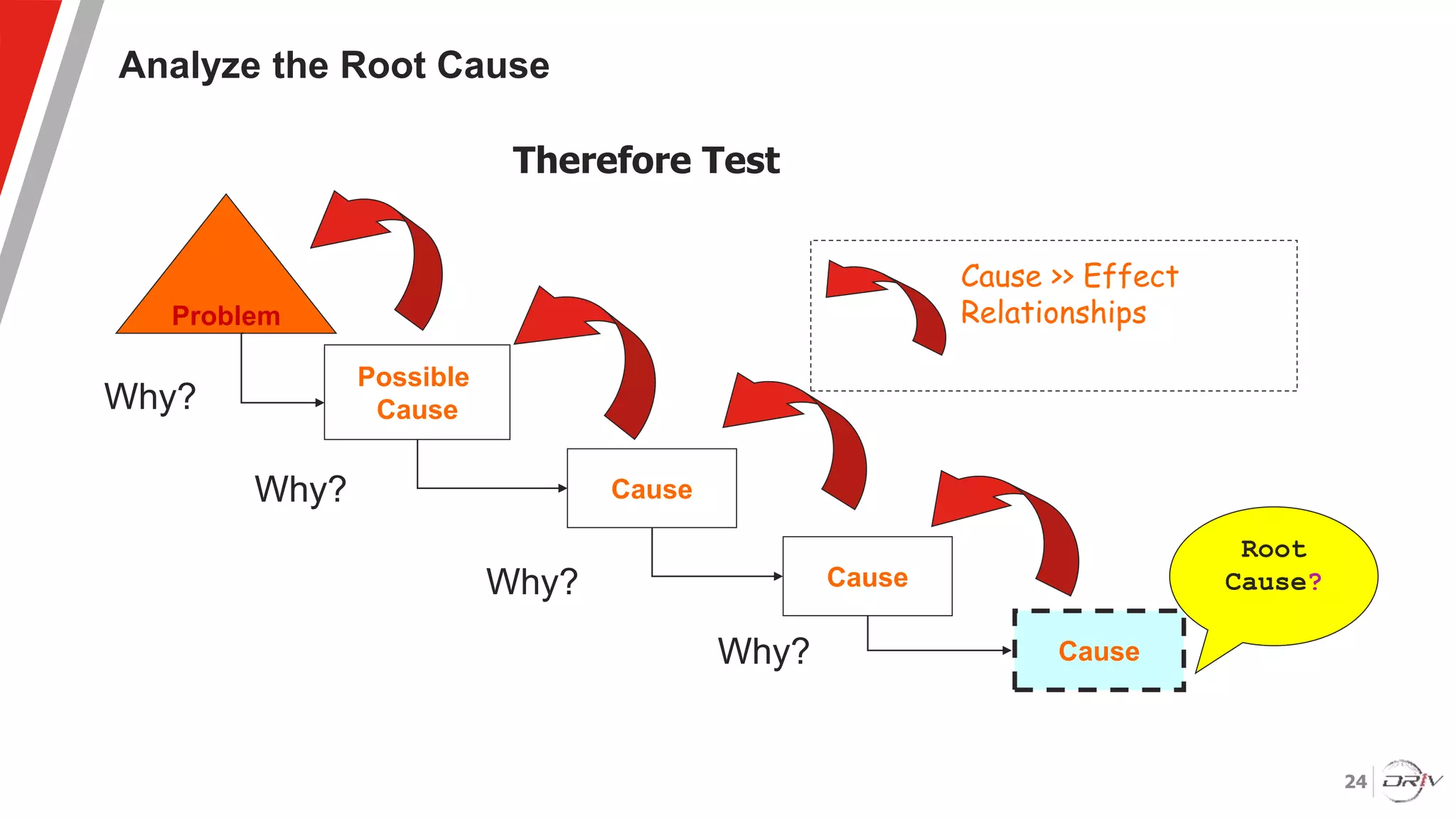

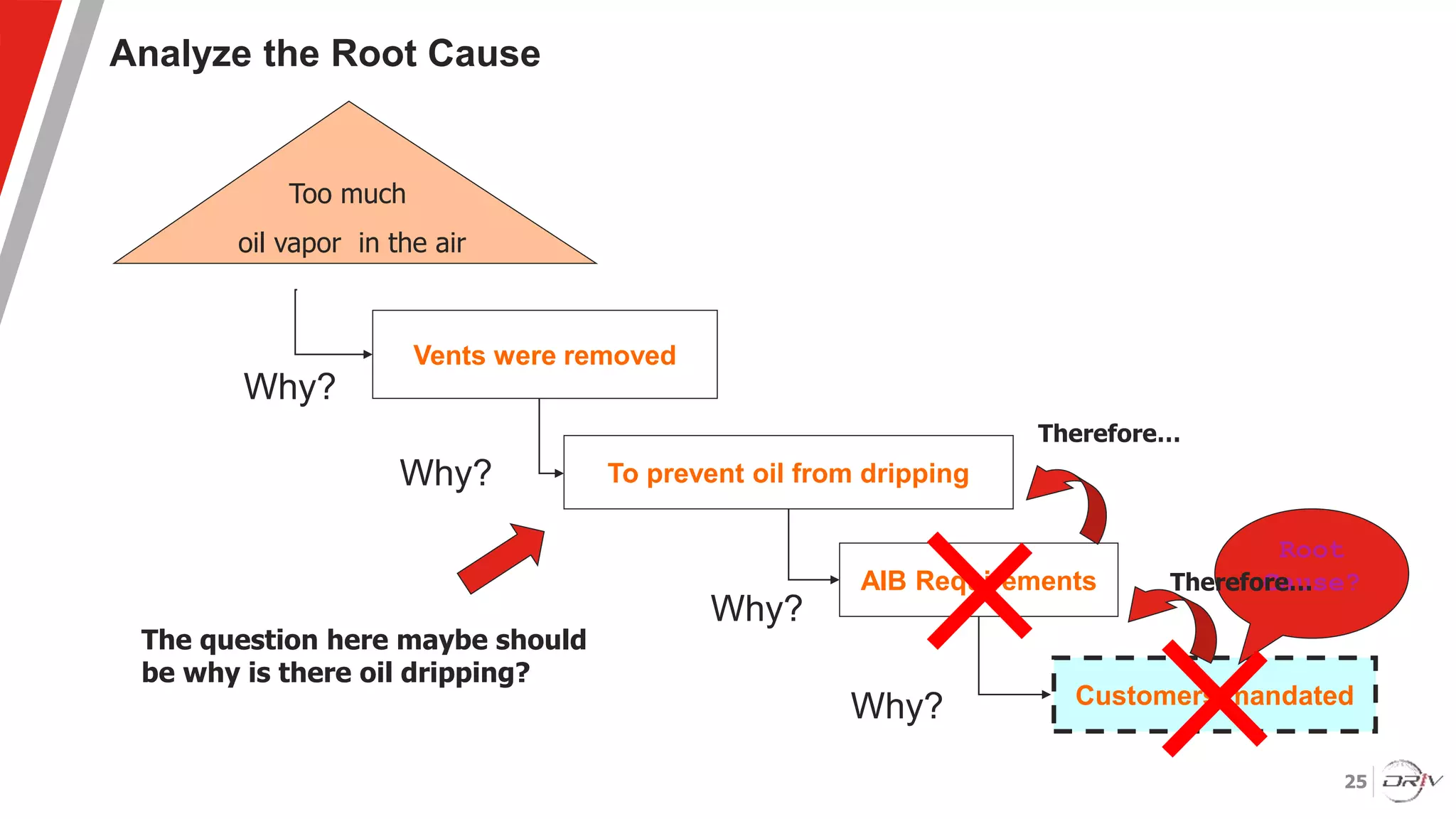

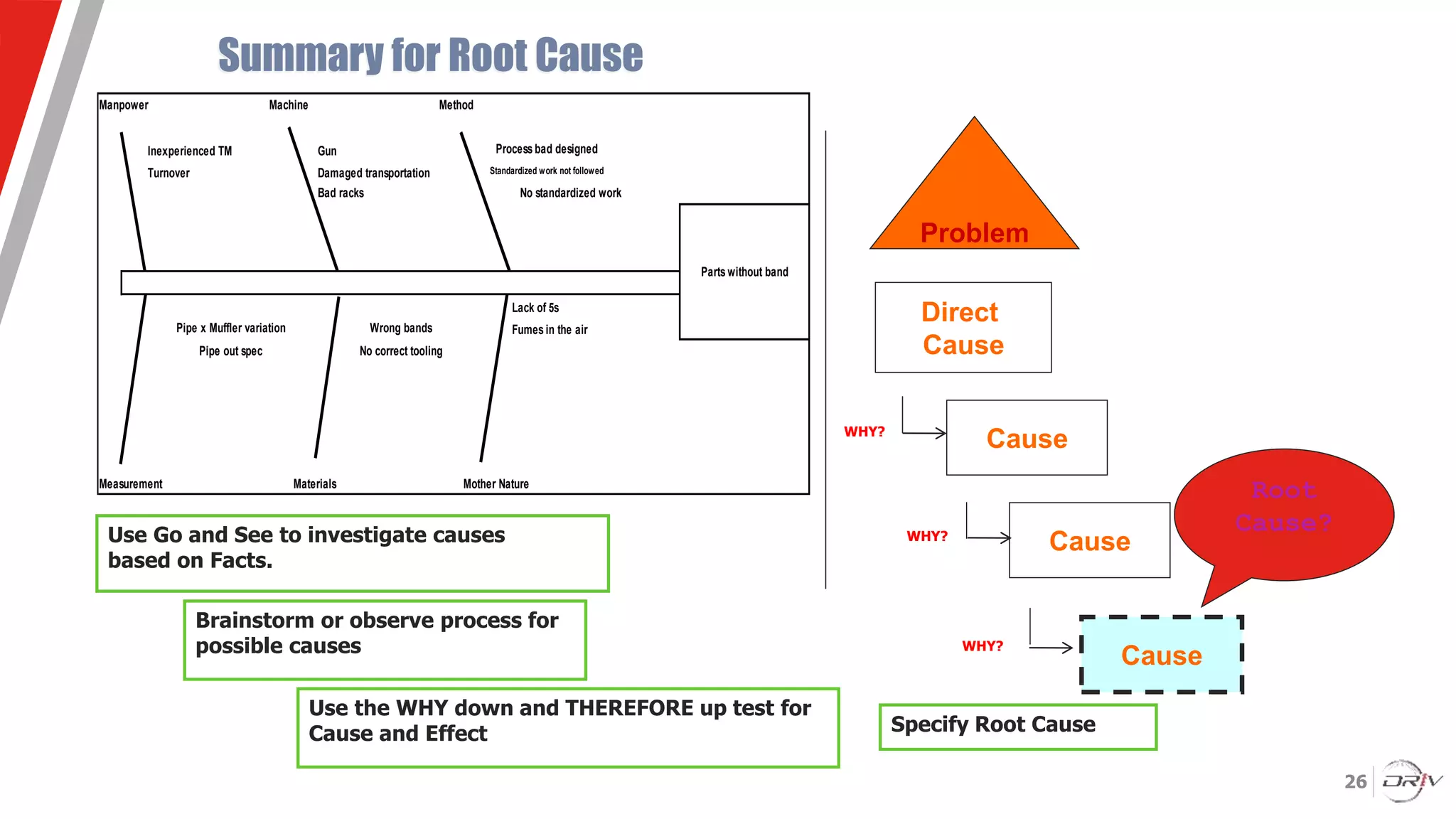

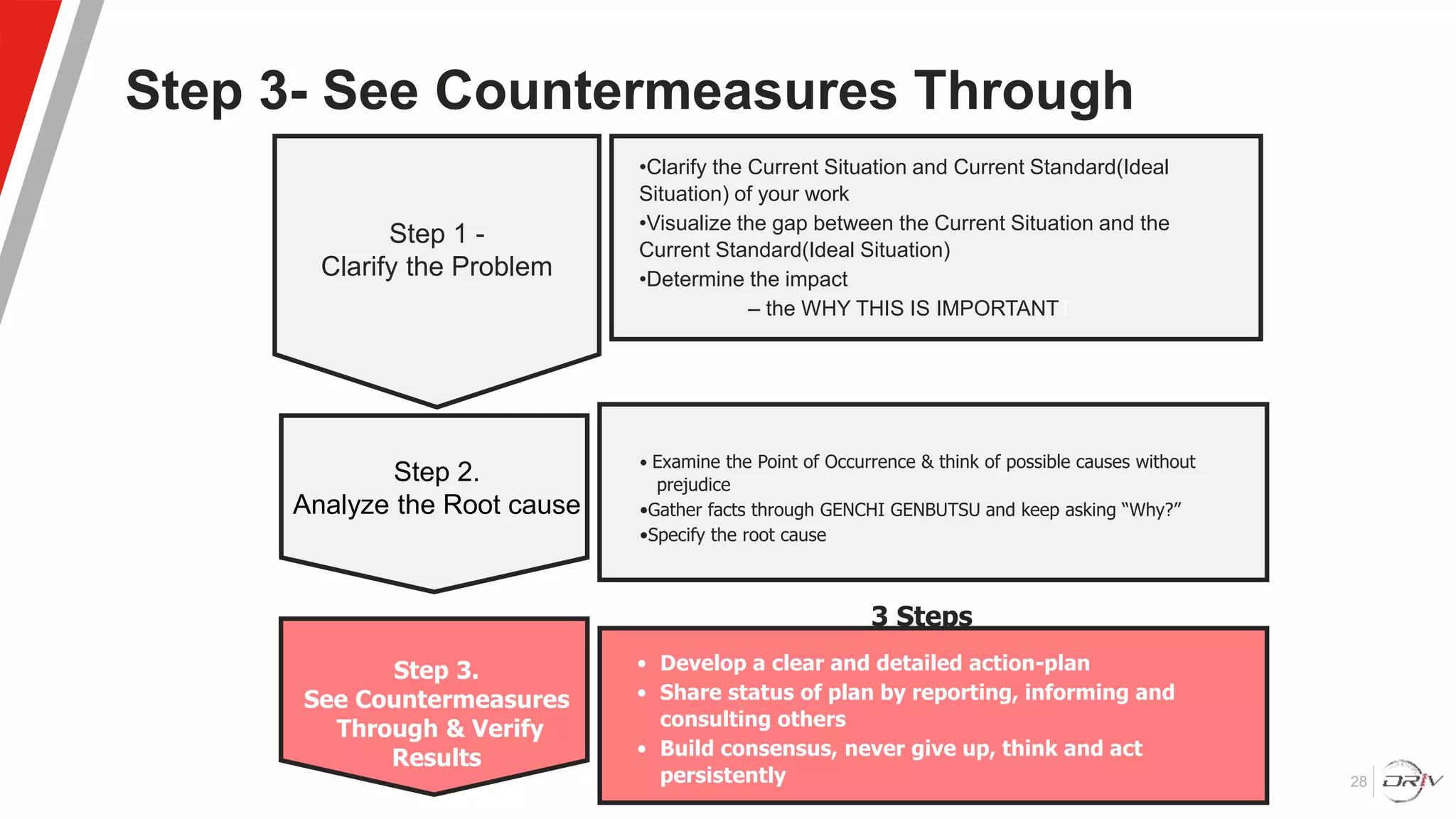

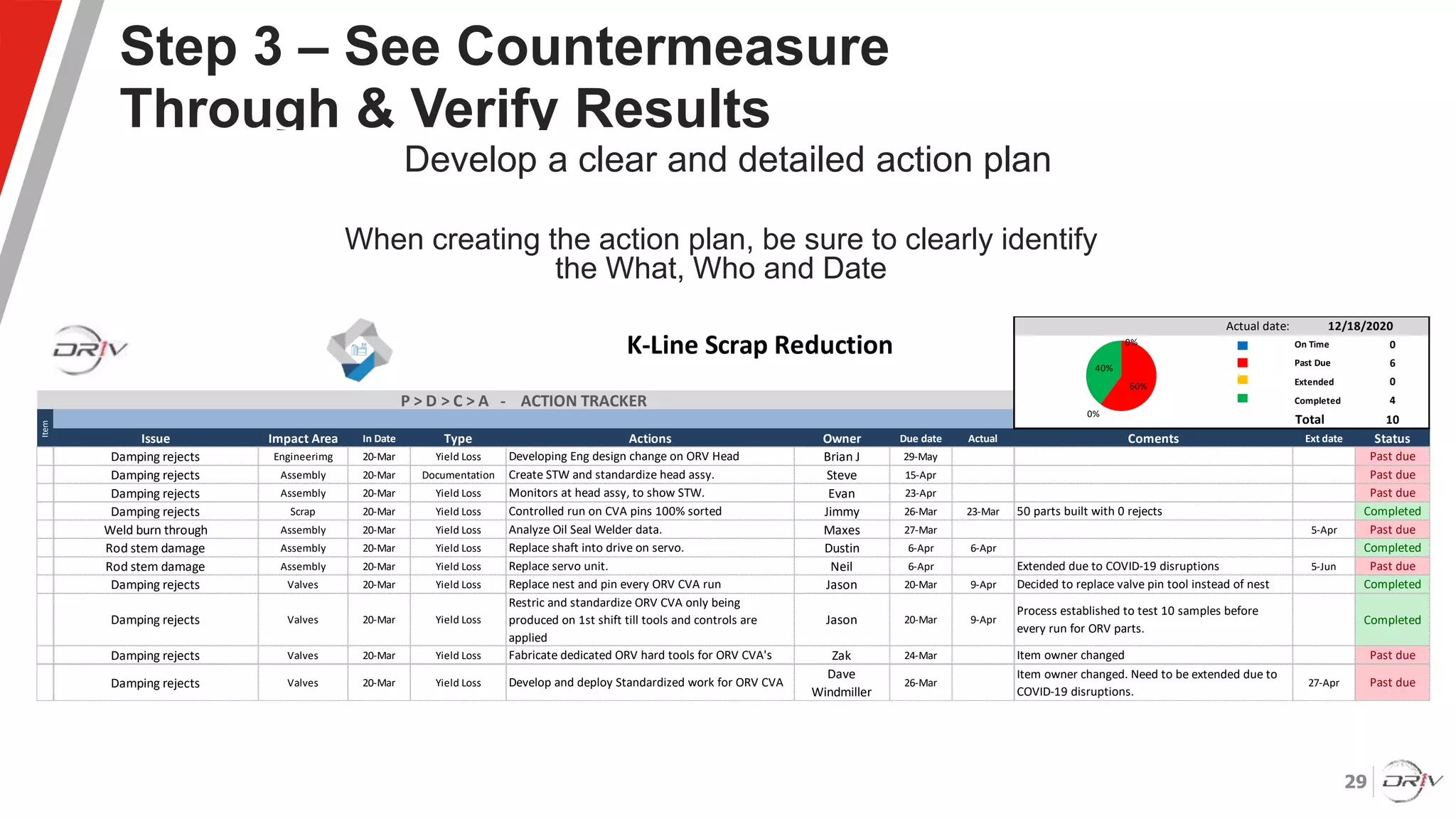

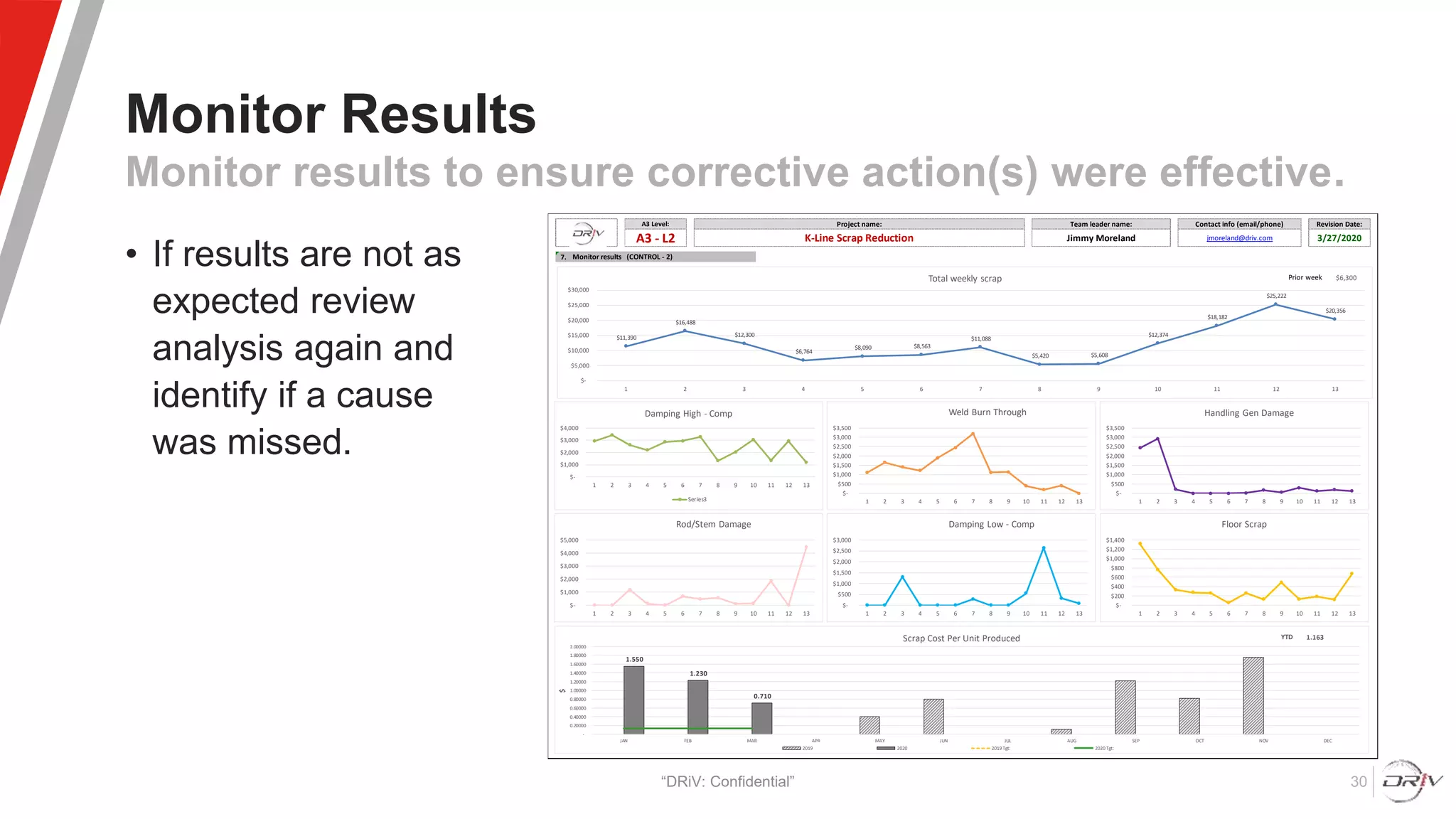

This document outlines a 3-step problem solving method: 1) clarify the problem by defining it and visualizing gaps, 2) analyze the problem to determine the root cause using tools like cause-and-effect diagrams and 5 whys, 3) see countermeasures through by developing an action plan, implementing it, and monitoring results. It discusses key aspects like defining problems, using Pareto analysis, determining the root cause, creating cause-and-effect diagrams, and implementing and tracking countermeasures to solve issues.