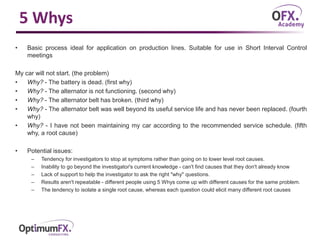

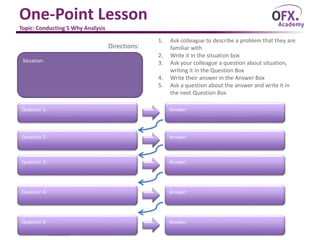

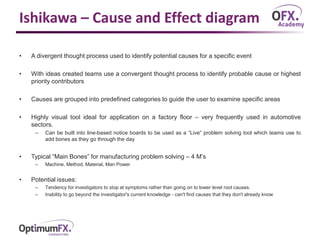

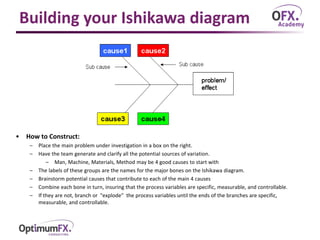

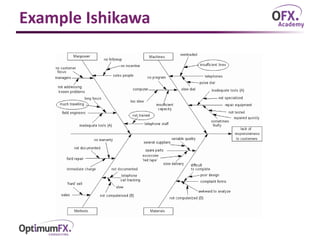

The document presents quick problem-solving tools for production teams, particularly focusing on the '5 Whys' technique to identify root causes of issues and the Ishikawa cause and effect diagram for visual problem-solving. It outlines the processes for conducting each method while highlighting potential pitfalls, such as stopping at symptoms rather than exploring deeper causes. The document also emphasizes the need for collaborative effort and clear communication when using these tools on the production floor.