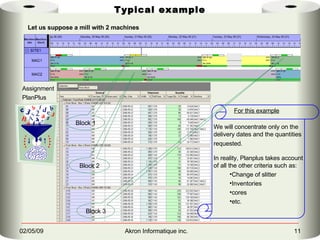

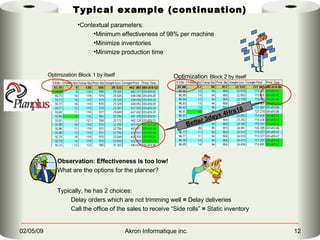

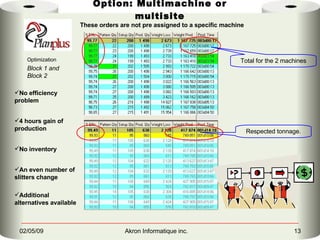

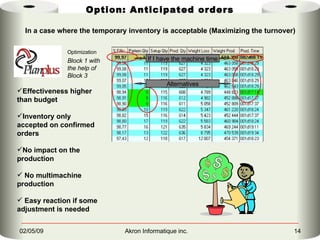

The document discusses production planning and optimization software. It highlights the software's ability to improve performance and functionality by considering all production constraints. It provides examples of how the software can optimize multiple machines and sites to increase efficiency, productivity and profitability compared to manual planning methods. The software aims to find solutions that meet all parameters and constraints to provide a solution without surprises.

![The planner Receives different instructions from many sources I want a minimum effectiveness of… It is necessary to minimize production time I do not want under-production and/or overproduction Not too much change of slitter, not too many small setups Not too many different orders on the same pattern Such customer must be made in priority […] If there is conflicts, he will apply the criteria on which he will be evaluated. Overproduction or effectiveness Late shipping or facilitated production Which order could be late , preceded , overproduced , under-produced, etc.](https://image.slidesharecdn.com/planplus-en-090502225638-phpapp01/85/PlanPlus-Trimplus-6-320.jpg)

![Contact us 1-819-758-8453 [email_address]](https://image.slidesharecdn.com/planplus-en-090502225638-phpapp01/85/PlanPlus-Trimplus-21-320.jpg)