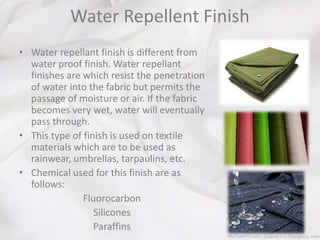

The document discusses various chemical finishes used in technical textiles. It defines technical textiles as textile materials manufactured primarily for their technical performance rather than aesthetic characteristics. The document then classifies textile finishing and describes several common chemical finishes - waterproof, water repellent, flame repellent, resin, antimicrobial, antistatic, antimoth, and antirott finishes. For each finish, it provides examples of end uses and lists specific chemicals used to impart the desired properties. In conclusion, the document states that fabric finishes play a major role in garments by improving appearance, performance, and protecting against microbes, insects and bacteria.