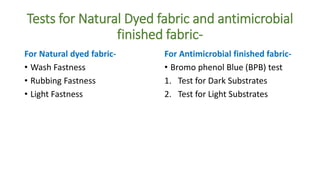

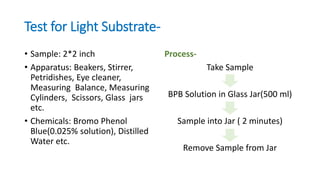

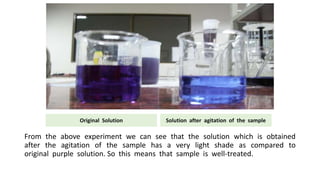

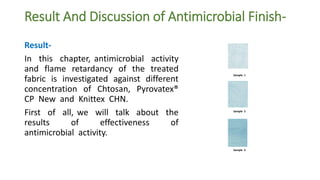

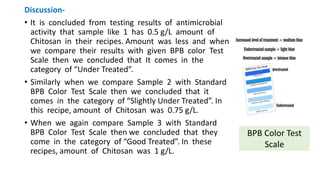

Turmeric and chitosan were used to naturally dye and antimicrobially finish cotton fabric in an environmentally friendly manner. Testing showed the natural dye provided good wash, light and rubbing fastness. The antimicrobial finish was also effective as indicated by the bromophenol blue test. Using natural dyes and finishes protects the environment from harmful chemicals compared to synthetic methods. Further research could expand the application of these ecofriendly materials to other textile fields such as medical and sportswear.

![Mordant:

Mettalic substance that creates a chemical affinity

between the substrate and the dyestuffs and fix the

coloring matter on the materials permanently. We

use Alum [KAl(SO4)2.12H2O] as a mordant.

Purpose of Mordant-

• Better absorption of dyes

• Improved color fastness properties

• Inhanced color shades.

Fig: ALUM](https://image.slidesharecdn.com/thesisrecovered-170409070141/85/Thesis-9-320.jpg)

![Chemicals-

Dyeing

Washing

Finishing

Alum [KAl(SO4)2.12H2O]

• Knittex CHN

• Pyrovatex CP

• Invadine PBN

• Turpex

• Phosphoric Acid

• Acetic Acid

Acetic Acid [CH3COOH]

ALUM

Acetic Acid

Phosphoric Acid](https://image.slidesharecdn.com/thesisrecovered-170409070141/85/Thesis-26-320.jpg)