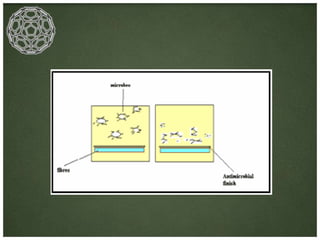

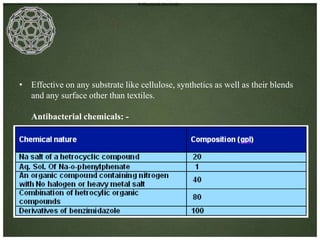

This document discusses various specialty finishes for fabrics including bio-polishing, denim bleaching, insect repellent, antibacterial, cool, thermocat, and UV protective finishes. Bio-polishing uses genetically modified enzymes to achieve tailored results with less negative effects. Denim bleaching uses laccase enzymes to create contrast while reducing dye redeposition and process time. Insect repellent and antibacterial finishes inhibit microbial growth to maintain hygiene, freshness, and prevent disease transmission. Cool finishes enhance sweat evaporation for a cooling effect. Thermocat finishes impart heat retention. And UV protective finishes shield fabrics and skin from UV radiation up to UPF 40 or higher.