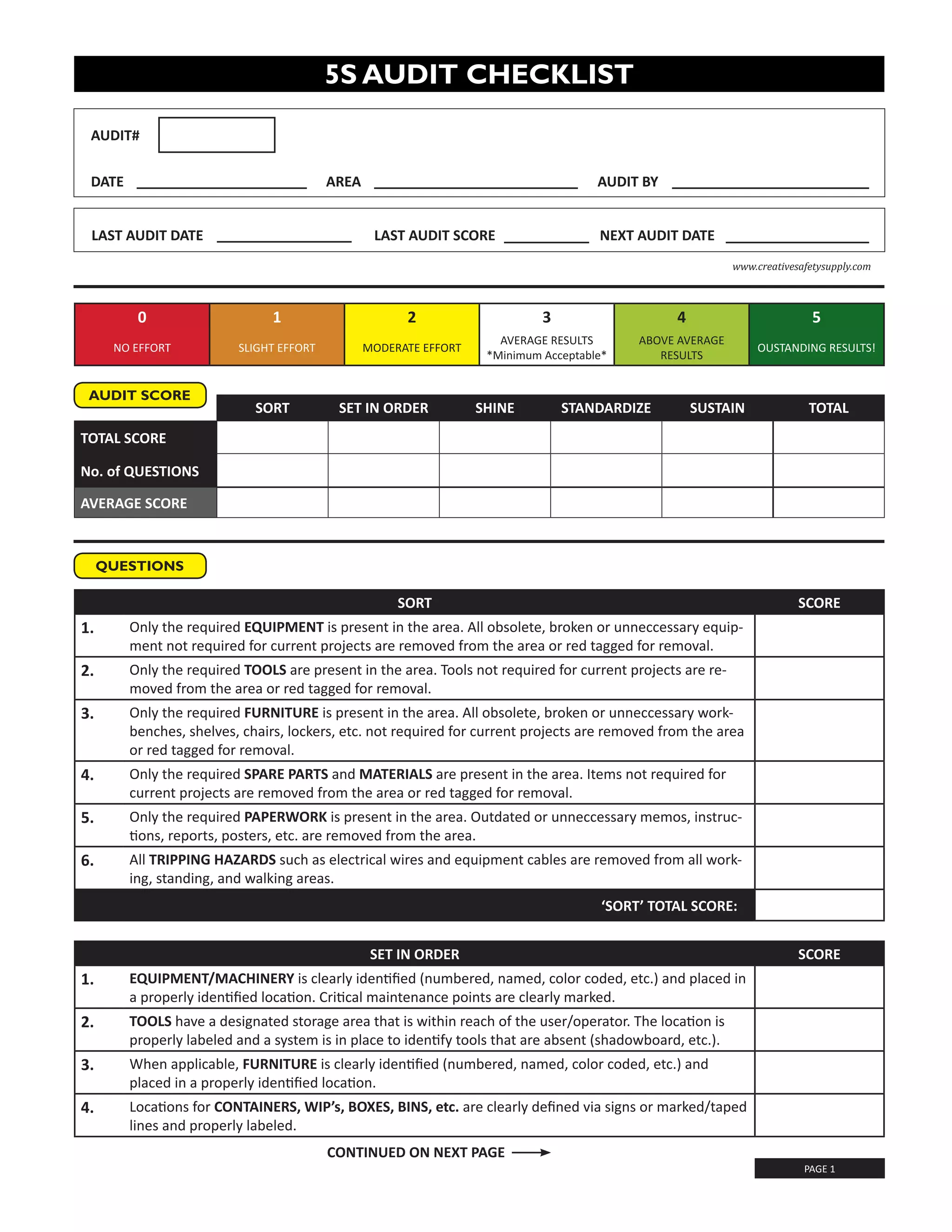

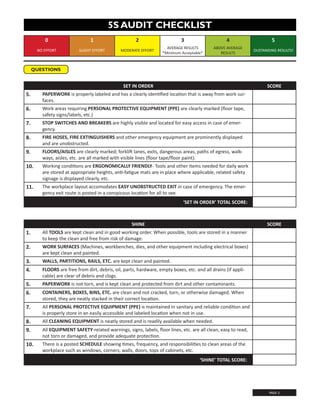

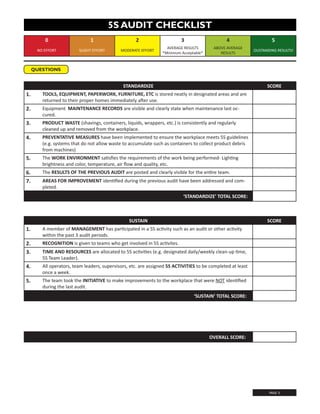

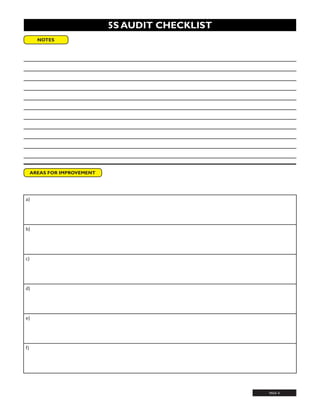

This document contains an audit checklist for evaluating 5S (Sort, Set in Order, Shine, Standardize, Sustain) practices in a workplace. The checklist contains over 50 questions organized under each of the 5S categories. Areas are scored on a scale from no effort to outstanding results. The overall goal is to remove non-essential items, clearly label and organize all necessary items, keep the workspace clean and standardized, and sustain 5S practices over time with management support and dedicated roles.