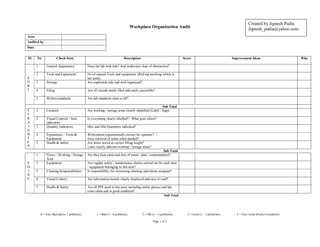

QC 5S audit

- 1. Workplace Organization Audit Area Audited by Date 0 = Very Bad (above 7 problems), 1 = Bad (5 – 6 problems), 2 = OK (3 – 4 problems), 3 = Good (1 – 2 problems), 4 = Very Good (Perfect Condition) Page 1 of 2 5S No Check Item Description Score Improvement Ideas Who S O R T 1 General Appearance Does the lab look tidy? And walkways clear of obstruction? 2 Tools and Equipment No of unused Tools and equipment. (Red tag anything which is not used) 3 Storage Are cupboards tidy and well organized? 4 Filing Are all records neatly filed and easily accessible? 5 Written standards Are lab standards clear to all? Sub Total S T R A I G H T E N 1 Location Are working / storage areas clearly identified (Label / Sign) 2 Visual Controls / Item indicators Is everything clearly labelled? / What goes where? 3 Quantity Indicators Max and Min Quantities indicated? 4 Ergonomics / Tools & Equipment Workstation ergonomically correct for operator? / Easy retrieval of items when needed? 5 Health & Safety Are items stored at correct lifting height? Lines clearly indicate working / storage areas? Sub Total S H I N E 1 Floors / Working / Storage Area Are they kept clean and free of waste / dust / contamination? 2 Equipment Are regular safety / maintenance checks carried out for each item / equipment belonging to this area? 3 Cleaning Responsibilities Is responsibility for overseeing cleaning operations assigned? 4 Visual Control Are information boards clearly displayed and easy to read? 5 Health & Safety Are all PPE used in this area, including safety glasses and lab coats clean and in good condition? Sub Total Created by Jignesh Padia Jignesh_padia@yahoo.com

- 2. Workplace Organization Audit 0 = Very Bad (above 7 problems), 1 = Bad (5 – 6 problems), 2 = OK (3 – 4 problems), 3 = Good (1 – 2 problems), 4 = Very Good (Perfect Condition) Page 2 of 2 5S No Check Item Description Score Improvement Ideas Who S T A N D A R D S 1 Work Area Are working / storage areas cleared at the end of each day? 2 Improvement Actions Improvements are being actioned 3 Key Operating Instructions Are key operating instructions written clearly and actively used? 4 Document Retrieval Can documents be retrieved in 30 seconds? (including electronic file)? 5 Health & Safety Waste disposal standards exist and are displayed? Sub Total S U S T A I N 1 Training Is everyone trained in work organization standards / practices? 2 Visual Control Are information boards up to date and regularly reviewed? 3 5S Audits Are 5S audits regularly carried out? And Are audit sheets displayed in general areas? 4 Stock Controls Are Stock controls adhered to? (Min / Max) 5 Improvement Issues Have issues from previous audit been actioned? Sub Total 0 5 10 15 20 25 Sort Straighten ShineStandards Sustain Category Score Sort Straighten Shine Standards Sustain Summary