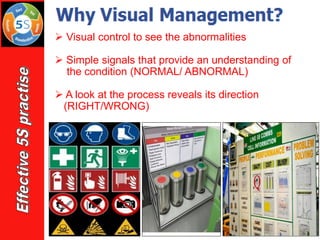

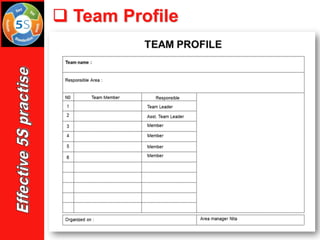

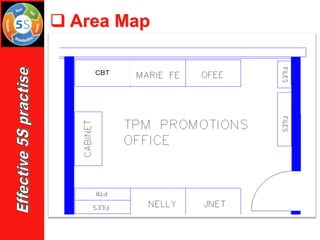

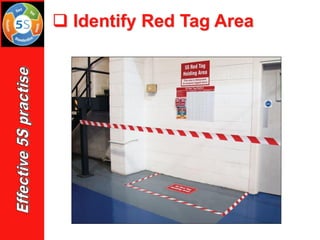

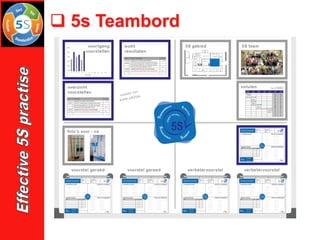

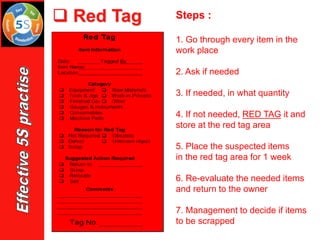

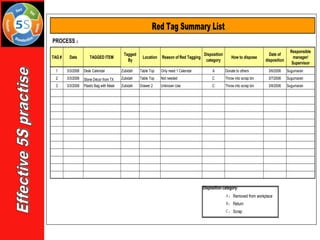

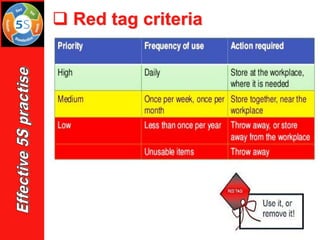

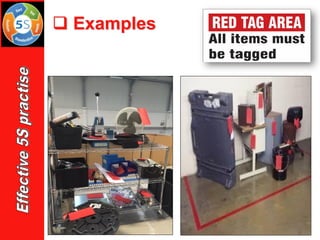

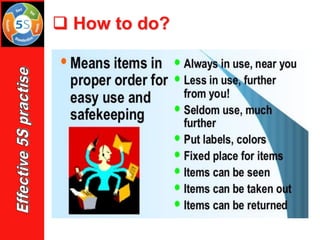

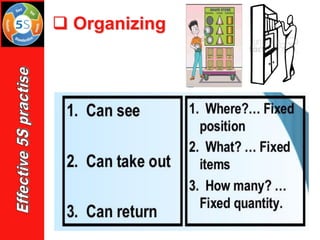

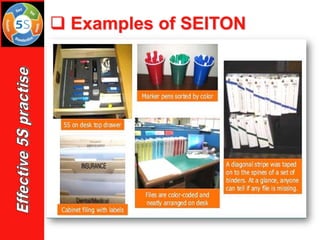

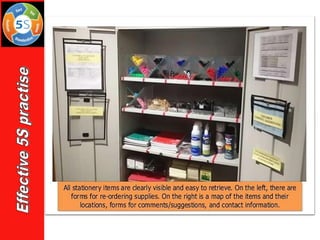

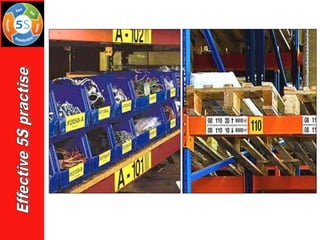

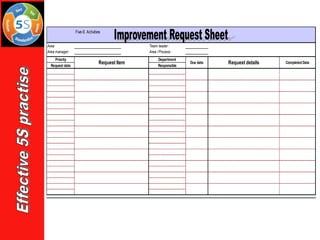

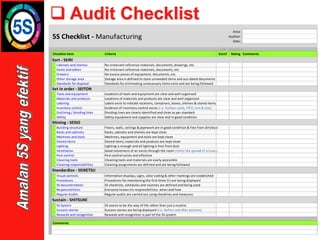

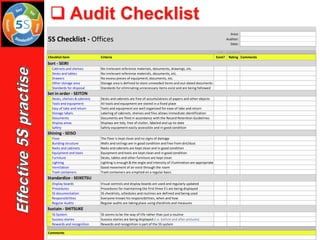

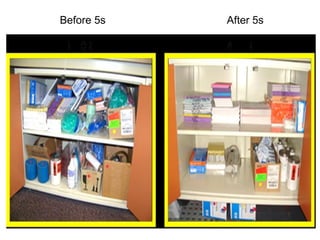

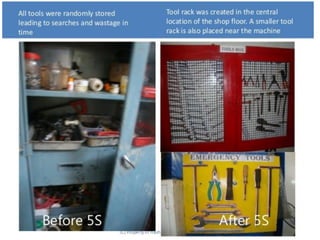

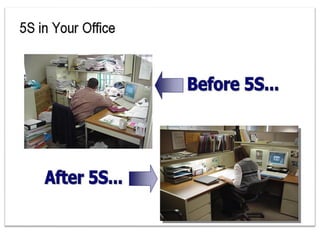

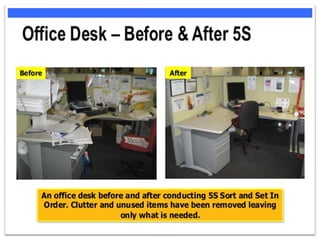

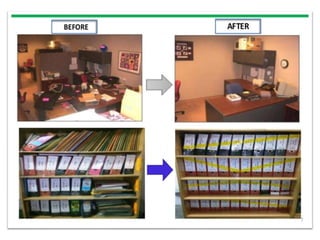

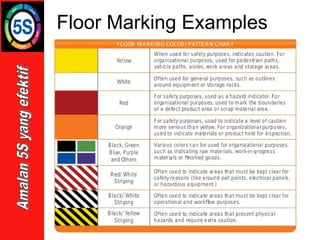

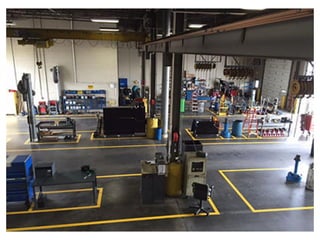

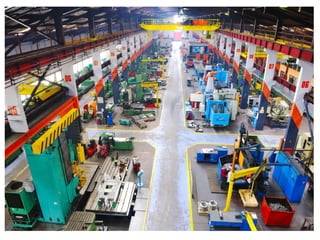

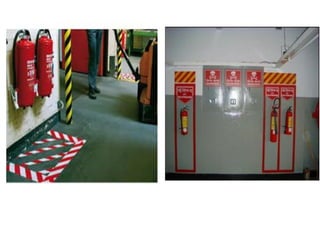

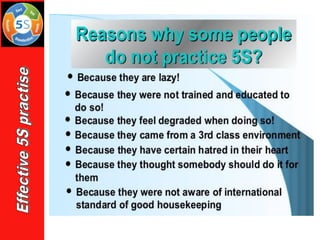

The document discusses the 5S methodology, which originated in Japan as a system for organizing and standardizing the workplace. It describes the five steps of 5S - Sort, Set in Order, Shine, Standardize, and Sustain. Implementing 5S helps create a cleaner, more organized work environment that improves safety, productivity and morale. Checklists are provided to audit compliance with 5S standards. Examples of 5S implementation show the transformation of work areas from cluttered to well-organized.